Surface treatment solution for bicycle common carbon steel and preparation method of surface treatment solution

A surface treatment liquid and carbon steel technology, applied in the coating process of metal materials, etc., can solve the problems of easy hydrogen embrittlement or over-corrosion of the workpiece, low cleaning efficiency, and acid mist formation, so as to achieve no oil deposition and descaling Good effect and strong cleaning power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

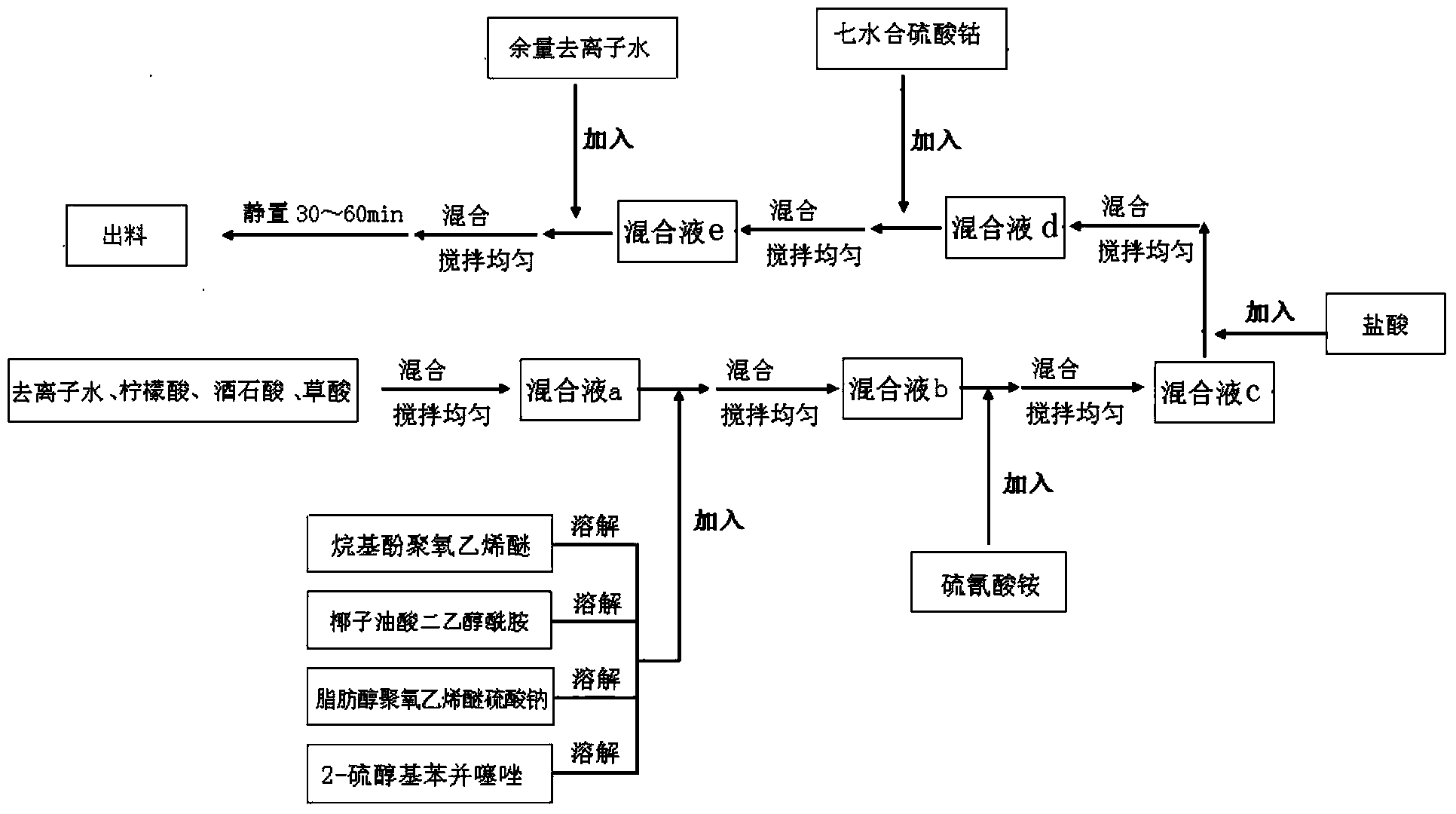

Method used

Image

Examples

Embodiment 1

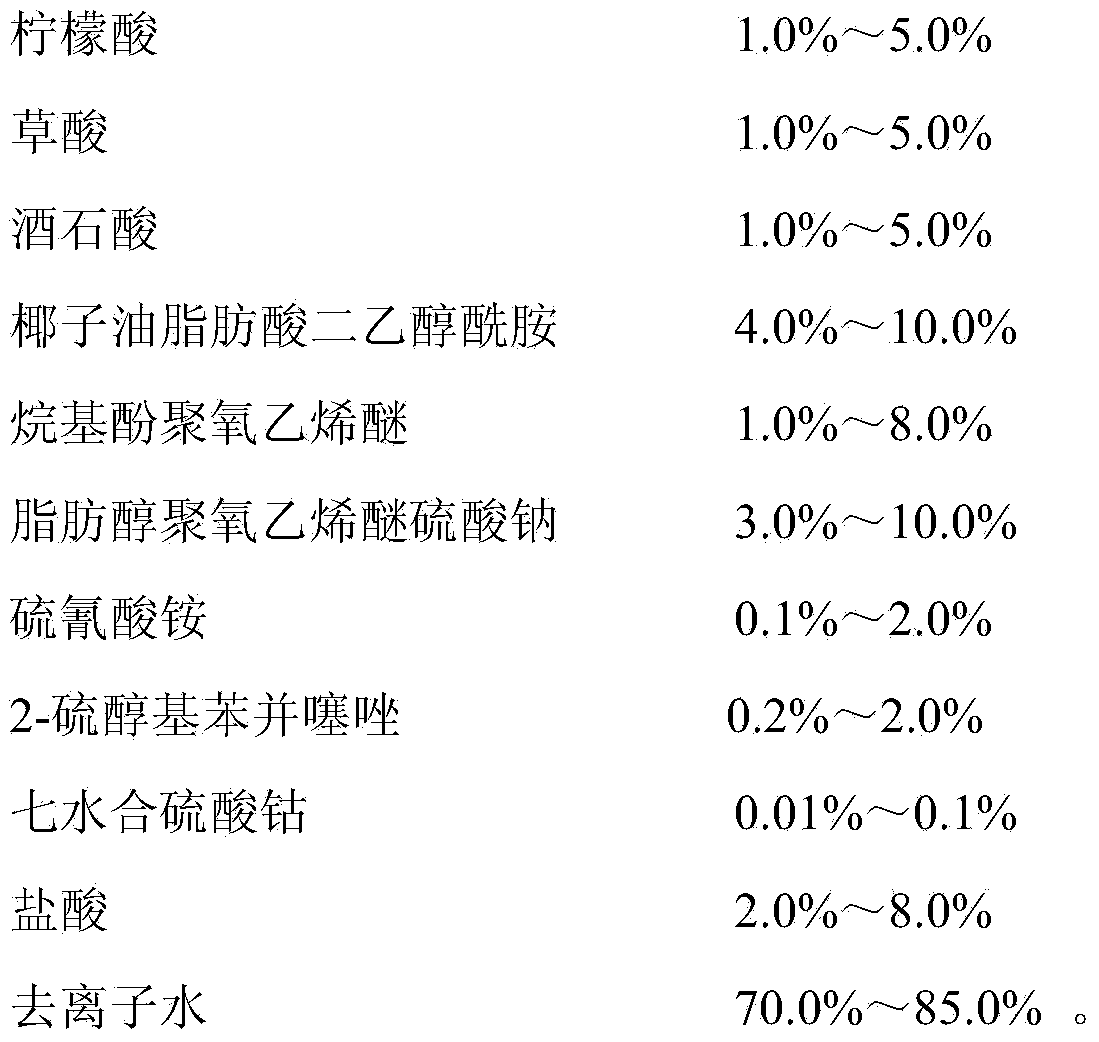

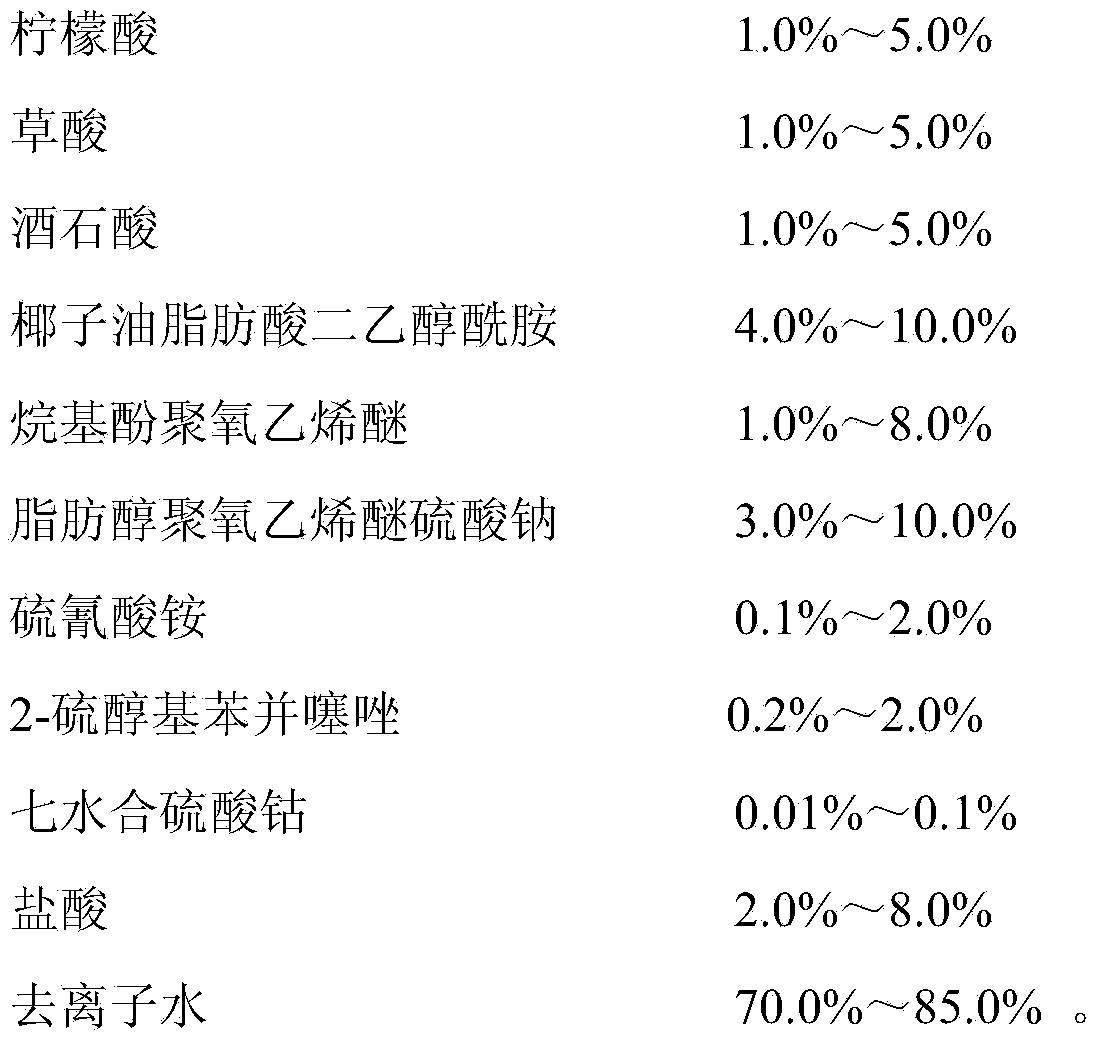

[0052] (1) Add 297.12kg of deionized water, 40kg of citric acid, 20kg of oxalic acid and 30kg of tartaric acid into the reaction kettle, stir at a speed of 60rpm for 15min, and obtain a mixture a;

[0053](2), with 222.84kg deionized water, dissolve 60kg coconut oil fatty acid diethanolamide, 20kg alkylphenol polyoxyethylene ether, 40kg fatty alcohol polyoxyethylene ether sodium sulfate and 5kg2-mercaptobenzothiazole respectively, Mix the dissolved components with the mixed solution a, and stir for 40 minutes at a speed of 15 rpm to obtain the mixed solution b;

[0054] (3) Add 2kg of ammonium thiocyanate into the mixed solution b, and stir at a speed of 40 rpm for 10 minutes to obtain the mixed solution c;

[0055] (4) Add 40kg of hydrochloric acid into the mixed solution c, and stir at a speed of 40 rpm for 10 minutes to obtain the mixed solution d;

[0056] (5) Add 0.2 kg of cobalt sulfate heptahydrate into the mixed liquid d, and stir at a speed of 60 rpm for 20 minutes t...

Embodiment 2

[0070] (1) Add 289.56kg of deionized water, 50kg of citric acid, 30kg of oxalic acid and 15kg of tartaric acid into a reaction kettle with mechanical stirring equipment, and stir at a speed of 80rpm for 10min to obtain a mixed solution a;

[0071] (2) Take 217.17kg deionized, dissolve 40kg coconut oil fatty acid diethanolamide, 50kg alkylphenol polyoxyethylene ether, 40kg fatty alcohol polyoxyethylene ether sodium sulfate and 10kg 2-mercaptobenzothiazole respectively, and dissolve Mix the dissolved components with the mixed solution a, and stir for 30 minutes at a speed of 25 rpm to obtain the mixed solution b;

[0072] (3) Add 1 kg of ammonium thiocyanate into the mixed solution b, and stir for 5 minutes at a speed of 60 rpm to obtain the mixed solution c;

[0073] (4) Add 40kg of hydrochloric acid into the mixed solution c, and stir for 5 minutes at a speed of 60 rpm to obtain the mixed solution d;

[0074] (5) Add 0.1 kg of cobalt sulfate heptahydrate into the mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com