Antimony cobalt sulfide-carbon composite nanorod and preparation method and application thereof

A nanorod, sulfide technology, applied in cobalt compounds, chemical instruments and methods, carbon preparation/purification, etc., can solve the problem of low electrical conductivity, high volume expansion coefficient, metal sulfide cycle performance and rate performance deterioration, etc. problem, to achieve the effect of high conductivity, increased reaction interface, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

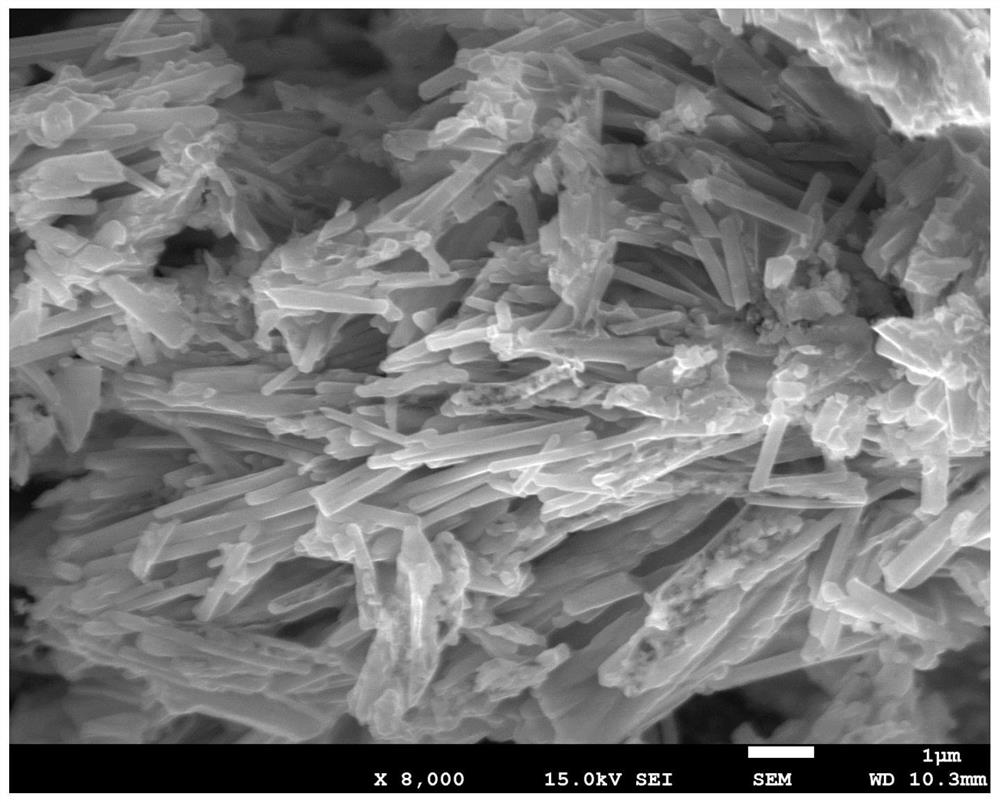

Image

Examples

preparation example Construction

[0029] A preparation method of antimony cobalt sulfide-carbon composite nanorods, comprising the steps of:

[0030] 1) Preparation of antimony sulfide nanorods: Dissolve antimony chloride, chelating agent and sulfur source in the reaction solution according to a certain ratio, stir evenly, move to the lining of the autoclave, and react at 170-210°C for 8-14h After the reaction, the product was centrifuged, washed, and dried to obtain antimony sulfide nanorods; the chelating agent was hexadecyltrimethylammonium bromide, sodium dodecylbenzenesulfonate, polyvinylpyrrolidone, At least one of sodium sulfide; the sulfur source is at least one of sodium sulfide, thiourea, and sodium thiosulfate; the carbon source is at least one of glucose, sucrose, ascorbic acid, and melamine. The reaction solution is prepared by mixing dimethyl phthalate, deionized water, and ethylene glycol in a volume ratio of 10-20:30-40:20-45. When the amount of antimony chloride is 1.37g, the total mass of th...

Embodiment 1

[0034] Weigh 1.37g of Sbcl with a balance 3 , 0.3g of SDBS, 0.3g of PVP, 1.37g of thiourea. Move it into a beaker with a volume of 100mL, then add 35mL of deionized water and 40mL of ethylene glycol, and stir magnetically for 10min at a speed of 260r / min. Then the mixture was transferred to a 100 mL reactor lining and reacted at 200 °C for 10 h. After the reaction, the reactor was left to stand, and the supernatant liquid was removed, and the centrifuge was used to wash three times with deionized water and two times with ethanol at a speed of 8000r / min, and then dried in a vacuum oven at 80°C for 10 hours.

[0035] Weigh 0.5g of Sb with a balance 2 S 3, 0.3g of cobalt nitrate hexahydrate, 0.228g of thiourea, 0.1g of glucose, 0.2g of sucrose. Move it into a beaker with a volume of 100mL, then add 30mL of deionized water and 45mL of ethylene glycol, and stir magnetically for 15min at a speed of 240r / min. Then the mixture was transferred to a 100 mL reactor lining and reacte...

Embodiment 2

[0039] Weigh 1.37g of Sbcl with a balance 3 , 0.4g of CTAB, 0.2g of SDBS, 2.16g of sodium sulfide nonahydrate, 0.685g of thiourea. Transfer it into a beaker with a volume of 100mL, then add 30mL of deionized water, 20mL of ethylene glycol, and 25mL of DMP, and stir magnetically for 15min at a speed of 230r / min. Then the mixture was transferred to a 100 mL reactor lining, and reacted at 180° C. for 13 h. After the reaction, the reactor was left to stand, and the supernatant liquid was removed, and the centrifuge was used to wash three times with deionized water and two times with ethanol at a speed of 8000r / min, and then dried in a vacuum oven at 80°C for 10 hours.

[0040] Weigh 0.5g of Sb with a balance 2 S 3 , 0.1g of cobalt nitrate hexahydrate, 0.2g of cobalt sulfate heptahydrate, 0.48g of sodium sulfide nonahydrate, 0.5g of sodium thiosulfate, 0.2g of glucose, 0.1g of ascorbic acid. Move it into a beaker with a volume of 100mL, then add 35mL of deionized water, 20mL of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com