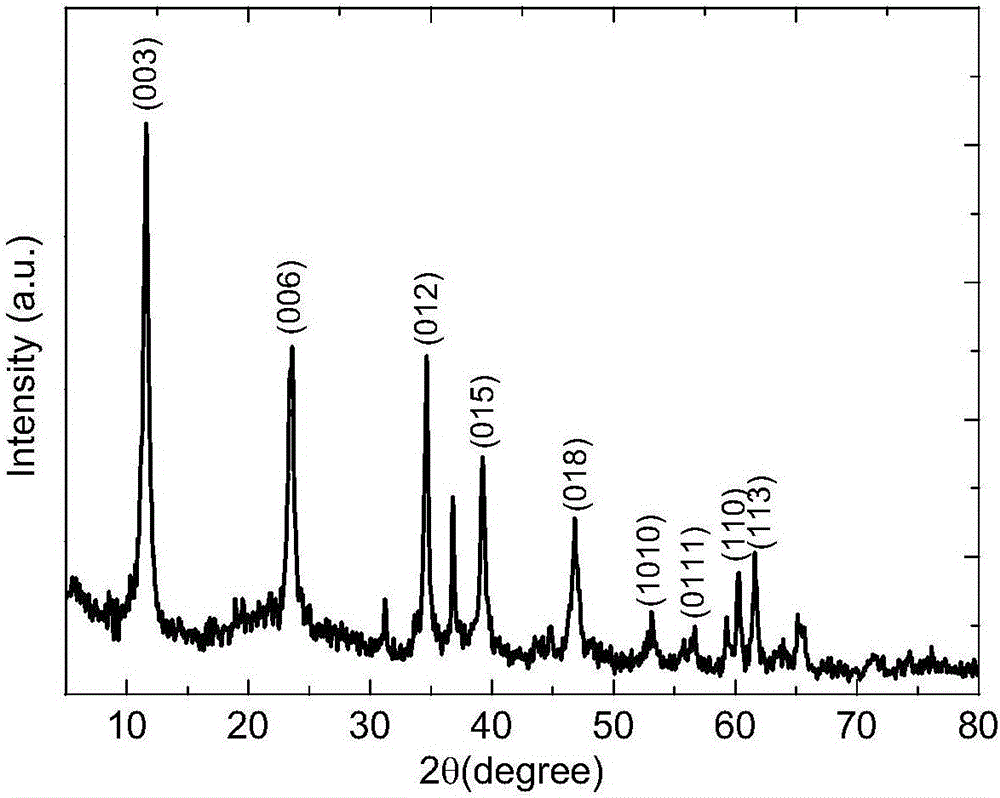

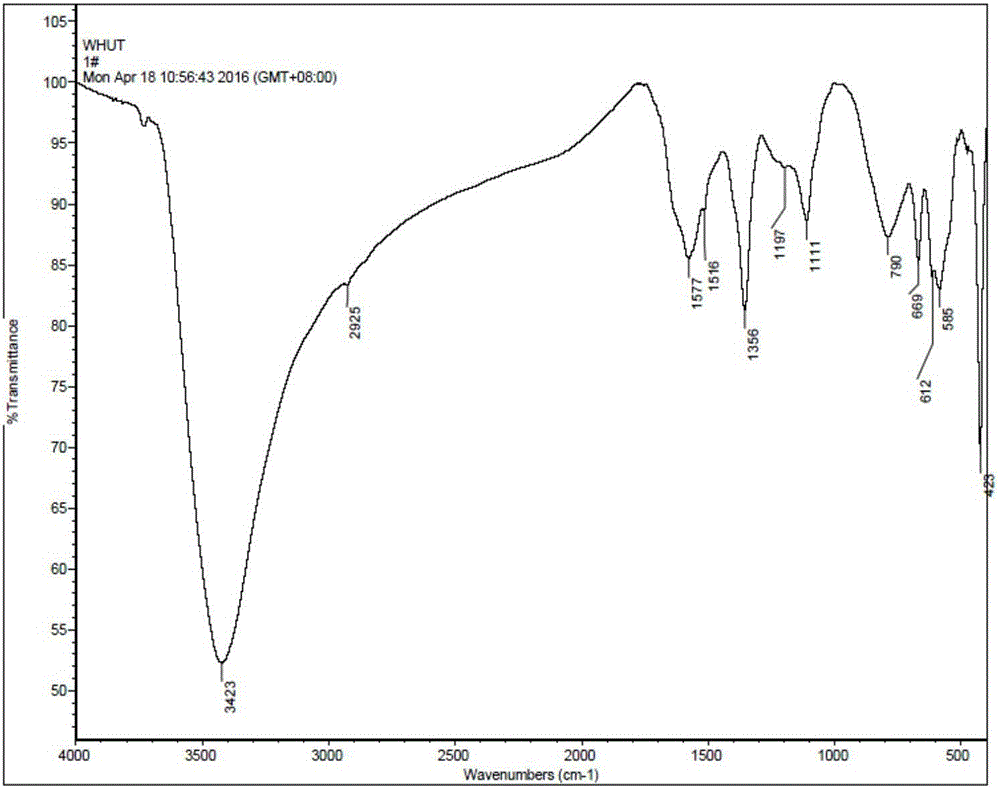

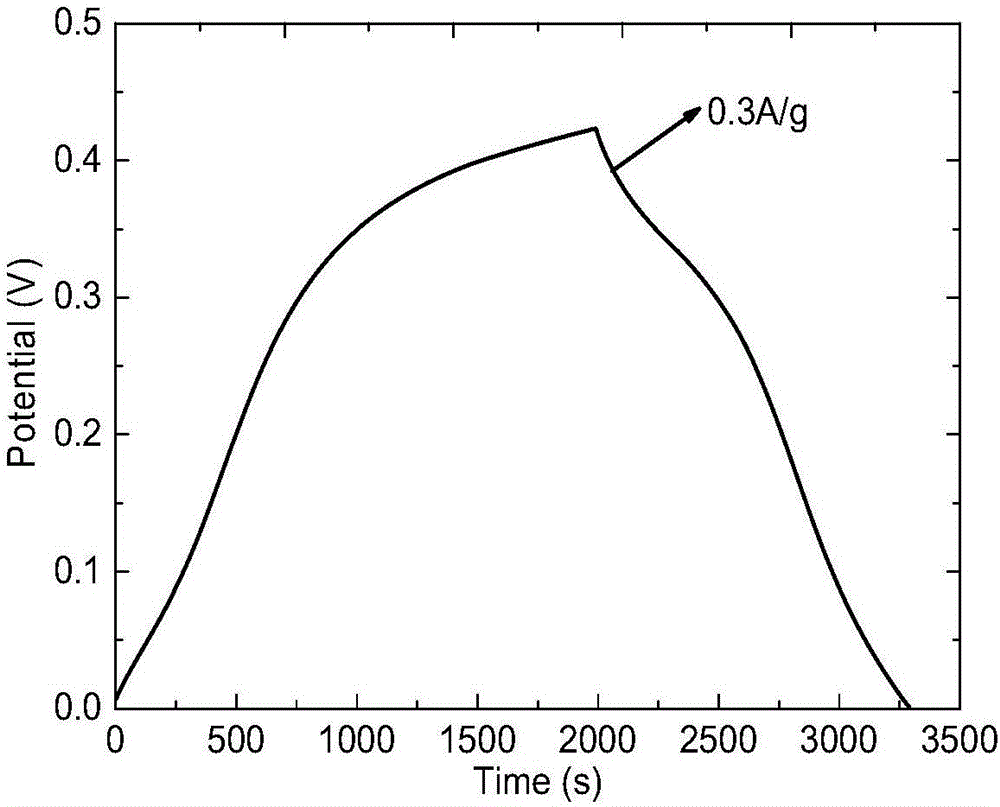

Cobalt aluminum hydrotalcite/fluorinated graphene composite material, and preparation method thereof

A technology of fluorinated graphene and composite materials, applied in cobalt compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as limited binding, reduced specific surface area, and reduced binding sites, achieving good stability and conditions Gentle, long cycle life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare cobalt aluminum hydrotalcite / fluorinated graphene composite material, the steps are as follows:

[0033] 1) adopt Hummers method to prepare graphite oxide powder;

[0034] 2) Disperse 25 mg of graphite oxide powder obtained in step 1) in 50 mL of deionized water to obtain a graphite oxide dispersion, then peel it off with an ultrasonic cell pulverizer for 6 min (pulse: 01 01, amplitude: 30%), and then use a centrifuge at 4500r Centrifuge under the condition of 25min / min, take the supernatant, and add 2mL of hydrofluoric acid solution with a mass concentration of 40% to the supernatant, stir for 2h, then transfer to an autoclave and react at a constant temperature of 150°C for 8h, then Cool to room temperature, filter and wash to neutrality to obtain fluorinated graphene;

[0035] 3) Disperse 22 mg of the fluorinated graphene obtained in step 2) in 100 mL of ethanol solution with a mass concentration of 25%, and peel it off for 10 minutes with an ultrasonic cell...

Embodiment 2

[0040] Prepare cobalt aluminum hydrotalcite / fluorinated graphene composite material, the steps are as follows:

[0041] 1) adopt Hummers method to prepare graphite oxide powder;

[0042] 2) Disperse 40 mg of the graphite oxide powder obtained in step 1) in 50 mL of deionized water to obtain a graphite oxide dispersion, then peel it off with an ultrasonic cell pulverizer for 9 minutes (pulse: 01 01, amplitude: 30%), and then use a centrifuge at 4000r Centrifuge under the condition of 40min / min, take the supernatant, and add 2mL hydrofluoric acid solution with a mass concentration of 40% to the supernatant, stir for 4h, then transfer to an autoclave and react at a constant temperature of 120°C for 10h, then Cool to room temperature, filter and wash to neutrality to obtain fluorinated graphene;

[0043] 3) Disperse 36 mg of the fluorinated graphene obtained in step 2) in 80 mL of ethanol solution with a mass concentration of 20%, and peel it off for 12 minutes with an ultrasonic...

Embodiment 3

[0047] Prepare cobalt aluminum hydrotalcite / fluorinated graphene composite material, the steps are as follows:

[0048] 1) adopt Hummers method to prepare graphite oxide powder;

[0049] 2) Disperse 60 mg of the graphite oxide powder obtained in step 1) in 50 mL of deionized water to obtain a graphite oxide dispersion, then peel it off with an ultrasonic cell pulverizer for 12 min (pulse: 01 01, amplitude: 40%), and then use a centrifuge at 4000r Centrifuge under the condition of 30min / min, take the supernatant, and add 6mL hydrofluoric acid solution with a mass concentration of 40% to the supernatant, stir for 6h, then transfer to an autoclave and react at a constant temperature of 140°C for 12h, then Cool to room temperature, filter and wash to neutrality to obtain fluorinated graphene;

[0050] 3) Disperse 55 mg of the fluorinated graphene obtained in step 2) in 50 mL of ethanol solution with a mass concentration of 30%, and peel it off for 15 minutes with an ultrasonic ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com