Cobaltous sulfide/ nitrogen-doped mesoporous carbon material, preparation method and application thereof

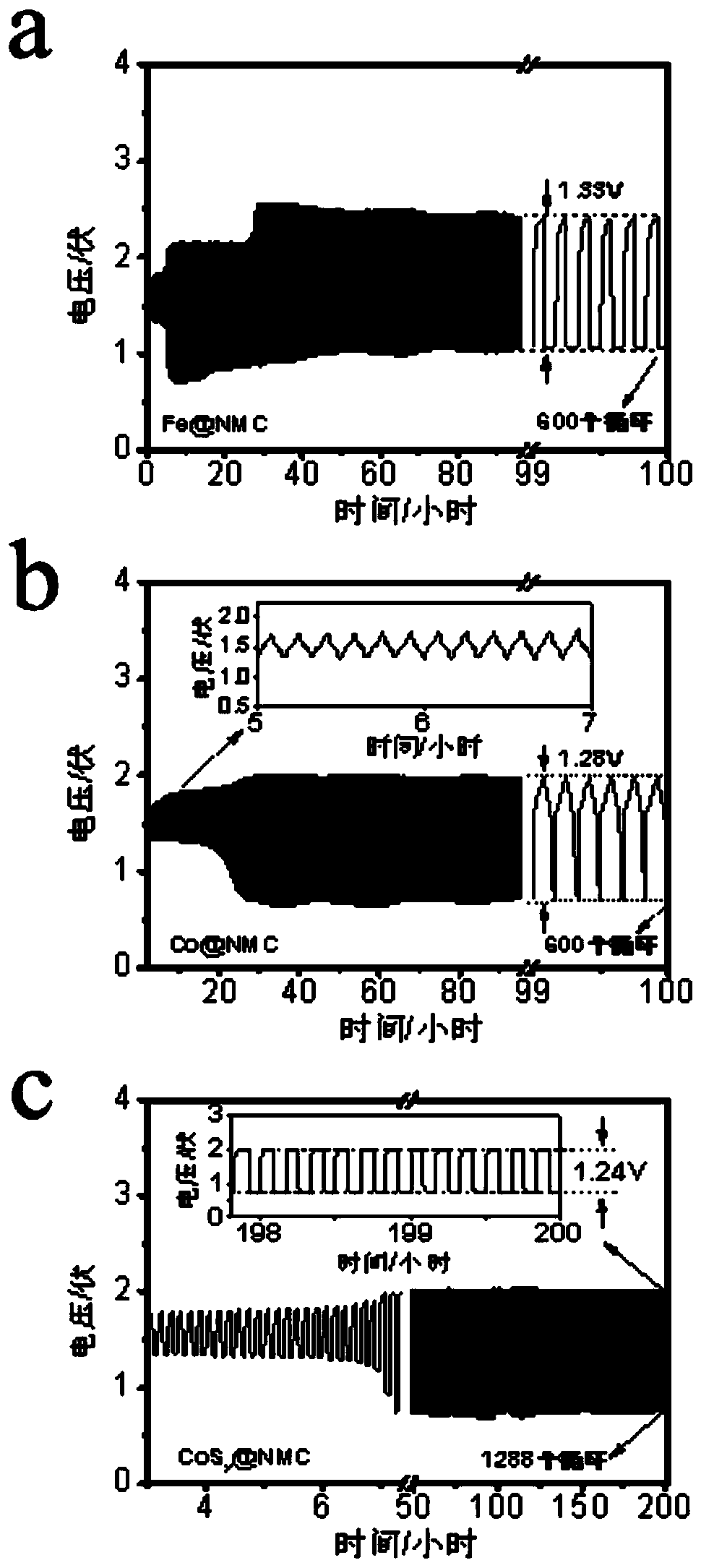

A technology of nitrogen-doped mesoporous carbon and cobalt sulfide, applied in nanotechnology for materials and surface science, fuel cell half-cells and secondary battery-type half-cells, structural parts, etc., can solve the problem of electrocatalysis Problems such as poor oxygen evolution ability, achieve high repeatability, high stability and cycle performance, and excellent dual-functional characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

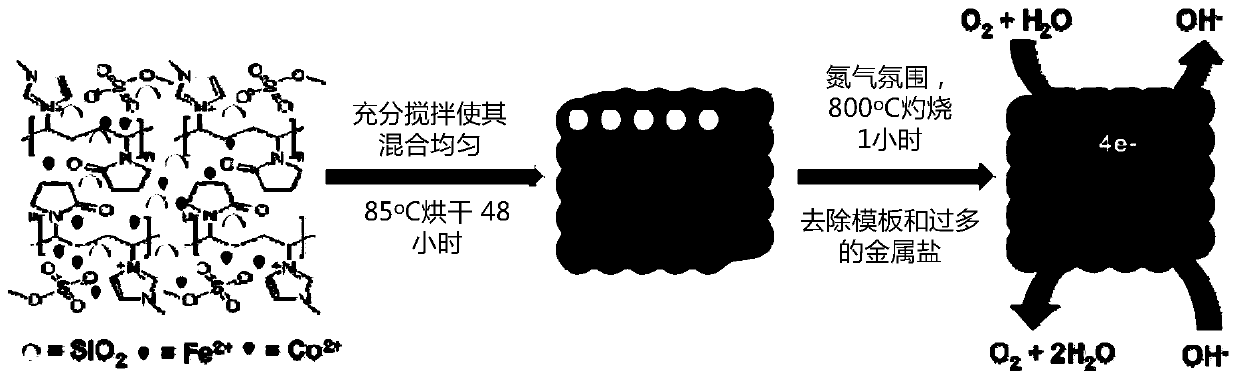

[0039] This example provides a method for preparing a cobalt sulfide / nitrogen-doped mesoporous carbon material (CoSx@NMC) with bifunctional activity, such as figure 1 As shown, the specific preparation steps are as follows:

[0040] Step 1: Put 5g of silica nano-silicon spheres (500nm) in a 100mL beaker, add 15mL of 1M HCl solution, stir to form a paste and ultrasonically vibrate to obtain a uniformly dispersed silica template;

[0041] Step 2: Put 5.625g of polyquaternium 44 in a 100mL beaker, add 15mL of HCl with a concentration of 1M and fully stir to disperse it evenly to obtain polyquaternium 44 solution;

[0042] Step 3: Under the condition of magnetic stirring, 3.75g FeSO 4 ·7H 2 O and 1.79g CoSO 4 ·7H 2 O was dissolved in 20 mL of HCl with a concentration of 1M, fully dissolved, slowly added to the polyquaternium 44 solution obtained in step 2 and stirred to disperse evenly, and then the obtained mixed solution was added to the silica template obtained in step 1 I...

Embodiment 2

[0047] This example provides a method for preparing a cobalt sulfide / nitrogen-doped mesoporous carbon material (CoSx@NMC) with bifunctional activity, such as figure 1 As shown, the specific preparation steps are as follows:

[0048] Step 1: Put 5g of silica nano-silicon spheres (500nm) in a 100mL beaker, add 15mL of 1M HCl solution, stir it into a paste with a glass rod and then ultrasonically oscillate to obtain a uniformly dispersed silica template;

[0049] Step 2: Put 5.625g of polyquaternium 44 in a 100mL beaker, add 15mL of HCl with a concentration of 1M and fully stir to disperse it evenly to obtain polyquaternium 44 solution;

[0050] Step 3: Under the condition of magnetic stirring, 5.625g FeSO 4 ·7H 2 O was dissolved in 20mL of HCl with a concentration of 1M, fully dissolved, slowly added to the polyquaternium 44 solution obtained in step 2 and stirred to disperse evenly, and then the obtained mixed solution was added to the silica obtained in step 1 Template agen...

Embodiment 3

[0055] This example provides a method for preparing a cobalt sulfide / nitrogen-doped mesoporous carbon material (CoSx@NMC) with bifunctional activity, such as figure 1 As shown, the specific preparation steps are as follows:

[0056] Step 1: Put 5g of silica nano-silicon spheres (500nm) in a 100mL beaker, add 15mL of 1M HCl solution, stir it into a paste with a glass rod and then ultrasonically oscillate to obtain a uniformly dispersed silica template;

[0057] Step 2: Put 5.625g of polyquaternium 44 in a 100mL beaker, add 15mL of HCl with a concentration of 1M and fully stir to disperse it evenly to obtain polyquaternium 44 solution;

[0058] Step 3: Under the condition of magnetic stirring, 5.36g CoSO 4 ·7H 2 O was dissolved in 20mL of HCl with a concentration of 1M, fully dissolved, slowly added to the polyquaternium 44 solution in step 2 and stirred to make it evenly dispersed, and then the obtained mixed solution was added to the silica template obtained in step 1 and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com