Preparation method for cobalt-manganese-nickel oxides

A nickel oxide, cobalt manganese nickel technology, applied in the field of electronic functional powder material preparation, can solve the problems of low qualification rate, high equipment requirements, inconsistent grain and phase, and achieve uniformity and fineness improvement and uniform composition distribution. , the effect of consistent grain structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

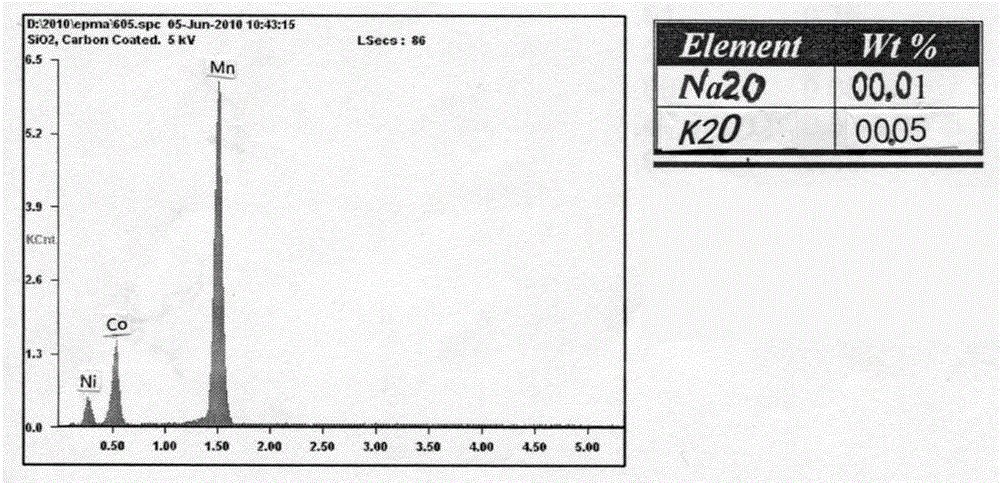

Image

Examples

Embodiment 1

[0031] The preparation method of embodiment 1 cobalt, manganese, nickel oxide

[0032] The preparation method of 2kg cobalt-manganese-nickel oxide specifically completes through the following steps:

[0033] 1) Weigh manganese sulfate monohydrate, cobalt sulfate heptahydrate, and nickel sulfate hexahydrate according to the molar ratio of Co:Mn:Ni of 16:67:17, that is, manganese sulfate monohydrate 3136g, cobalt sulfate heptahydrate 1246g, hexahydrate Nickel sulfate 1238g, dissolves with hot water respectively, puts into reaction tank, stirs;

[0034] 2) Gradually add NH in the reaction tank 4 HCO 3 Solution, the pH value is 7.5, the temperature is raised to 70°C, and the reaction is 30min;

[0035] 3) Continue to slowly add KOH solution until the pH value is 10.5, react for 30 minutes, discharge, filter, and wash with water until no SO 4 2- ionized, dried, roasted in a high-temperature furnace at 820°C for 2-3 hours, and pulverized by ball milling;

[0036] 4) Add 20 tim...

Embodiment 2

[0040] The cobalt-manganese-nickel oxide (ternary material) prepared in Example 1 was used as a raw material to prepare a polymer lithium ion battery.

[0041] Weigh a certain amount of Co-Mn-Ni oxide powder, weigh a certain amount of LiCO 3 . According to the weighing ratio Co-Mn-Ni powder: LiCO 3= 2:1 Mix well, bake at 850°C for 2 hours, cool and grind. Co-Mn-Ni-Li oxide mixture plus conductive agent and binder to make slurry, the slurry is coated on the tape to form the positive electrode, the negative electrode is layered graphite plus conductive agent and binder, coated on the copper foil base tape , the upper electrode lead, injected with polymer electrolyte, folded, aluminum-plastic soft package. The size is 120×80×4(mm), and the weight is 75g.

[0042] After testing the electrical performance: 3.8v, 13.0wh, 3500mAh.

Embodiment 3

[0044] The cobalt-manganese-nickel oxide powder obtained in Example 1 is made into an NTC thermistor element according to the resistance electronic ceramic preparation process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com