Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62 results about "Butylbenzyl phthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Benzyl butyl phthalate (BBP) is a phthalate, an ester of phthalic acid, benzyl alcohol, and n-butanol. BBP is a clear liquid with the chemical formula C19H20O4.

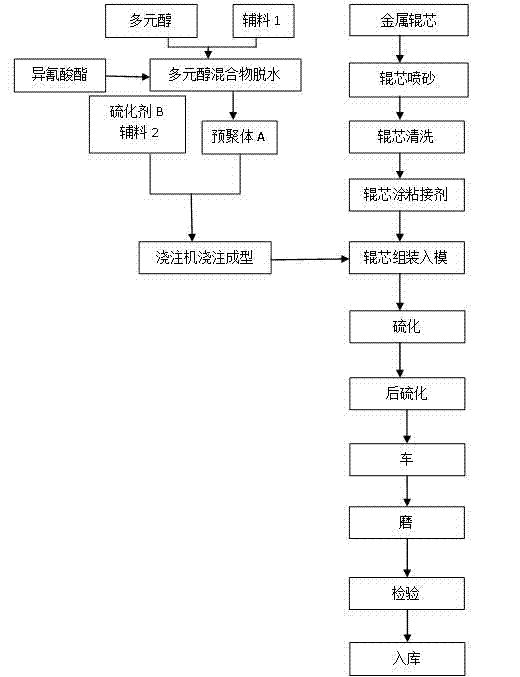

Low-hardness pouring polyurethane rubber roller and production method thereof

The invention discloses a low-hardness pouring polyurethane rubber roller and a production method thereof, and belongs to the field of production processes of polyurethane rubber rollers. The polyurethane rubber roller comprises a material A and a material B which is 16 to 26 percent of the weight of the material A, wherein the material A comprises a reaction product of polyalcohol and isocyanate toluene diisocynate (TDI) and calcium carbonate; the material B comprises diaminodiphenyl-methane (MOCA) serving as a vulcanizing agent and butyl benzyl phthalate (BBP) serving as a plasticizer; according to the material A, a mass ratio of the polyalcohol to the calcium carbonate to the isocyanate TDI is 100:4:(8-22); and according to the material B, a mass ratio of the vulcanizing agent MOCA to the BBP is (1-3):2. By the production method, the accurate proportioning of the material A and the material B in the pouring process can be realized, and the produced low-hardness pouring polyurethane rubber roller is stable in quality and high in yield.

Owner:MAANSHAN TIANXIN ROLL IND

Flame-retardant anti-corrosion paint

ActiveCN103382336AStrong adhesionImprove flame retardant performanceFireproof paintsAnti-corrosive paintsAcrylic resinPolyethylene glycol

The invention discloses a flame-retardant anti-corrosion paint comprising following ingredients, by weight: 60 to 80 portions of acrylic resin, 30 to 40 portions of melamine resin, 5 to 10 portions of benzyl butyl phthalate, 1 to 4 portions of zinc borate, 3 to 10 portions of antimonony oxide, 1 to 5 portions of N, N-dihydroxyethyldodecyl amide, 1 to 5 portions of zinc sulfate, 20 to 30 portions of mica powder, 22 to 28 portions of heavy calcium carbonate, 1 to 5 portions of polyethylene glycol 200, 0.2 to 0.6 portion of polydimethylsiloxane, 0.2 to 0.6 portion of silicon dioxide, and 70 to 80 portions of water. The flame-retardant anti-corrosion paint possesses excellent flame retardant effent and anti-corrosion effect, and relatively high adhesive force on metal products because of the combination of zinc borate, antimonony oxide, N, N-dihydroxyethyldodecyl amide and zinc sulfate, and the combined effect of the composite antifoaming agent composed of polydimethylsiloxane and silicon dioxide, and the other auxiliary agents.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

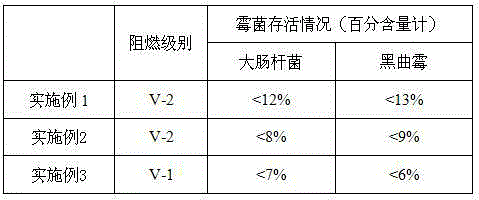

Antibacterial flame retardant coating and preparation method thereof

InactiveCN104927491AImprove surface antimicrobial propertiesSimple processFireproof paintsAntifouling/underwater paintsFiberMeth-

The invention relates to an antibacterial flame retardant coating. The antibacterial flame retardant coating comprises the following components in parts by weight: 6-10 parts of zinc pyrithione, 15-30 parts of chitosan biguanidine hydrochloride, 8-16 parts of methylphenyl silicone resins, 10-25 parts of nanometer silver powder, 8-10 parts of a phosphate flame retardant, 4-10 parts of dihexadecyl peroxodicarbonate, 12-20 parts of benzyl butyl phthalate, 0.5-1 part of superfine acrylate rubber powder, 0.1-0.5 part of dimethyl methylphosphate, 5-15 parts of aluminium silicate fibers, and 1-3 parts of zinc oxide. The antibacterial flame retardant coating disclosed by the invention is prepared under normal temperature and normal pressure, and extra equipment is not needed; the technology is simple, and the production cost is low. After the antibacterial flame retardant coating disclosed by the invention is used, the antibacterial performance of surfaces of materials can be effectively improved, and the materials have good flame retardance; the antibacterial flame retardant coating integrally has favorable antibacterial flame retardance, and can be used according to needs.

Owner:龚灿锋

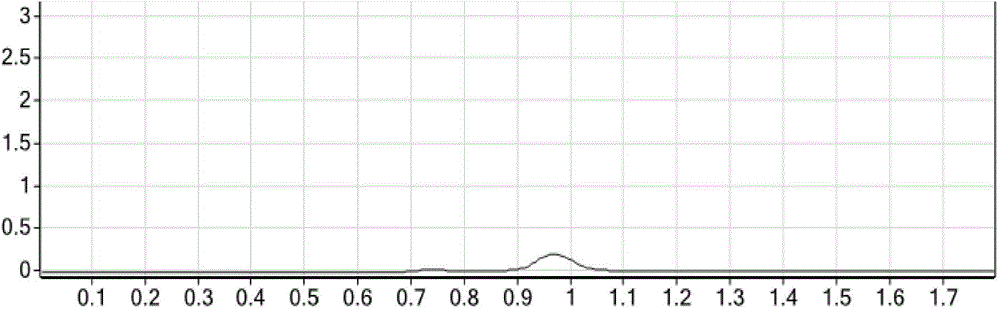

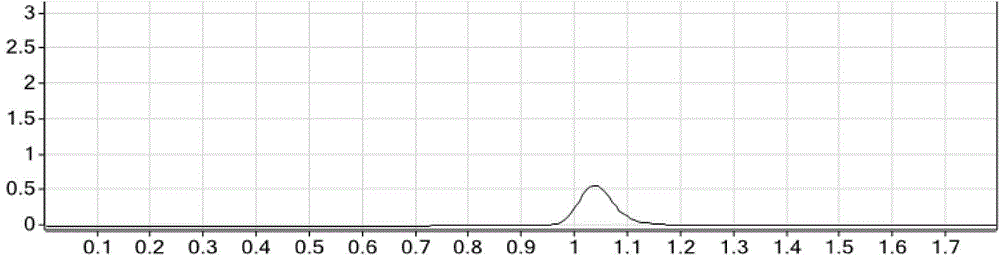

Method for detecting six phthalates in drinking water through liquid chromatography-mass spectrometry

InactiveCN104820030AEasy to operateFew samplesComponent separationButylbenzyl phthalateDi-n-octyl phthalate

The invention discloses a method for detecting six phthalates in drinking water through liquid chromatography-mass spectrometry, and belongs to the technical field of drinking water detection. The method comprises the following steps: (1) additionally arranging a protection column; (2) measuring conditions and a mode; (3) establishing a standard working curve; (4) detecting to-be-detected drinking water. According to the detection method, a sample is not required to be pretreated and can be directly fed, so that the six phthalates (DMP (Dimethyl Phthalate), DEP (Diethyl Phthalate), DBP (Dibutyl Phthalate), BBP (Benzyl Butyl Phthalate), DEHP (Di 2-Ethyl Hexyl Phthalate) and DNOP (Di N Octyl Phthalate)) in the drinking water are qualitatively and quantitatively analyzed at high speed; the method has the advantages of easiness and convenience in operation, less sampling quantity, low cost, good reproducibility, high stability and the like, is not only suitable for daily environment monitoring and is also suitable for quick screening of pollutants in emergency accidents.

Owner:桂林市环境监测中心站

Anti-ultraviolet composite fireproof glass

The invention discloses a fireproof composite structure glass that can effectively block ultraviolet rays. The glass includes two glass substrates, between which a fireproof layer is stuffed. The fireproof layer comprises, by weight: 50% of methyl methacrylate, 15% of dibutyl ester, 20% of sodium sulfite, 1.3% of zinc oxide (ZNO), 3% of magnesium hydroxide, 0.2% of benzyl butyl phthalate, 10% of acrylamide, 0.1% of ethanol, and 0.4% of 2-hydroxy-4-methoxybenzophenone. By adopting the fireproof layer with the formula, ultraviolet rays can be effectively blocked, good fire resistance can be achieved, and the fireproof layer is unlikely to undergo foaming under a long-term use state, therefore, the light transmission performance is good.

Owner:杭州福隆鼎门窗幕墙有限公司

Stable isotope labeled benzyl butyl phthalate and synthesis method thereof

InactiveCN104860817AAtom utilization is highSimple methodOrganic compound preparationCarboxylic acid esters preparationStable Isotope LabelingButylbenzyl phthalate

The invention relates to a stable isotope labeled benzyl butyl phthalate and a synthesis method thereof. According to the invention, an organic synthesis method is adopted; stable isotope labeled phthalic anhydride is adopted as a raw material, and is subjected to a reaction with benzyl alcohol, such that stable isotope labeled monobenzyl phthalate is produced; the stable isotope labeled monobenzyl phthalate is subjected to a reaction with butanol, such that stable isotope labeled benzyl butyl phthalate is obtained. Compared with the prior art, when the stable isotope labeled benzyl butyl phthalate is separated and purified, a chemical purity can be higher than 99%, and an isotope abundance is higher than 99%, such that the demand of the detection of the illegal additive benzyl butyl phthalate in the field of food safety can be fully satisfied.

Owner:SHANGHAI RES INST OF CHEM IND +1

Manufacture method of self-cleaning fabric

ActiveCN105568426AImprove stabilityGood repeatabilityWeft knittingFilament/thread formingMolten stateEpoxy

The invention relates to a manufacture method of a self-cleaning fabric. The manufacture method comprises the following steps: uniformly mixing polyvinyl chloride, polyoxyethylene-polyoxypropylene block copolymer, epoxy resin, nanometer titania, towel gourd juice, nanometer mica powder and polystyrolsulfon acid, heating to a molten state, adding benzyl butyl phthalate, cellulose ester, nanometer chitin and residual components, uniformly mixing to obtain a modified spinning melt, performing spinning and postprocessing to obtain ultrafine denier fibers, and spinning the spinning fibers to obtain the self-cleaning fabric. By virtue of blending spinning of the combined materials, a hierarchical structure combining a micron structure with a nanometer structure is formed on the surface of the fabric, so that the surface roughness of the fabric is enhanced, and the self-cleaning property and the water and oil repellent performance of the fabric are improved greatly.

Owner:东台市天地经纬织品有限公司

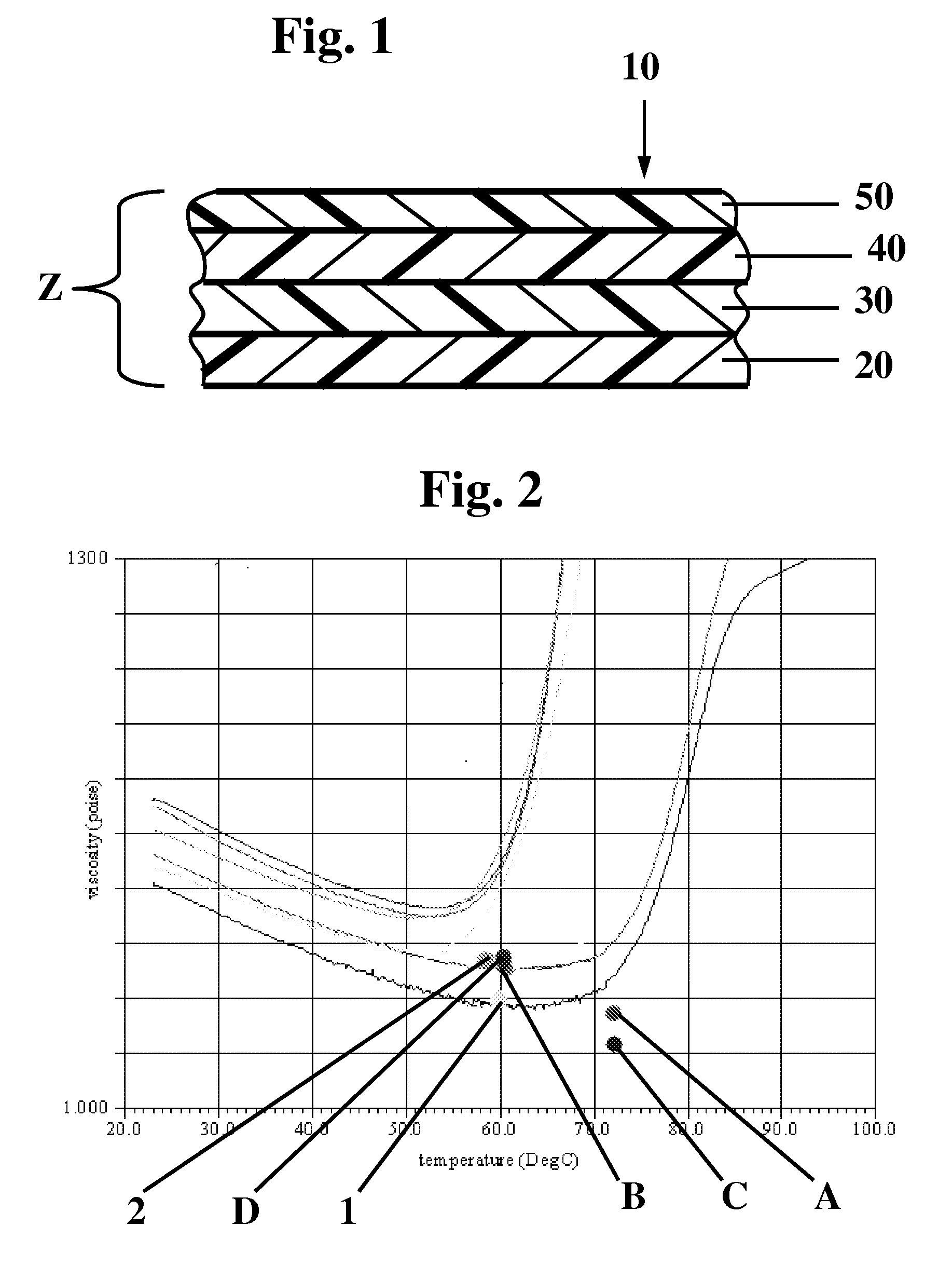

Automobile windshield

InactiveCN106183243ALight in massReduce quality problemsWindowsWindscreensButylbenzyl phthalate2-hydroxy-4-methoxybenzophenone

The invention belongs to the technical field of automobile parts and discloses an automobile windshield. The automobile windshield comprises a hydrophobic layer, a buffer layer, a heat insulating layer, first tempered glass, vacuum glass, a transparent damping film, second tempered glass, a safety layer and a water absorption layer. The hydrophobic layer and the buffer layer are bound, and the buffer layer and the heat insulating layer are bound. The buffer layer is arranged, the anti-seismic property of the windshield can be good, mass is small, the mass of an automobile can be reduced, the economical property of the automobile can be improved, and use is safe and convenient; the transparent damping film is arranged, a particle structure is arranged in the transparent damping film, and therefore a heat insulating effect can be achieved; the vacuum glass is arranged, and therefore a sound insulating effect can be achieved; the heat insulating layer prepared from 2-hydroxy-4-methoxybenzophenone, benzyl butyl phthalate and zinc oxide is arranged, therefore, the heat insulating effect is achieved, ultraviolet light in light can be filtered out, and the health of the human body can be protected.

Owner:泉州市科茂利通智能科技有限公司

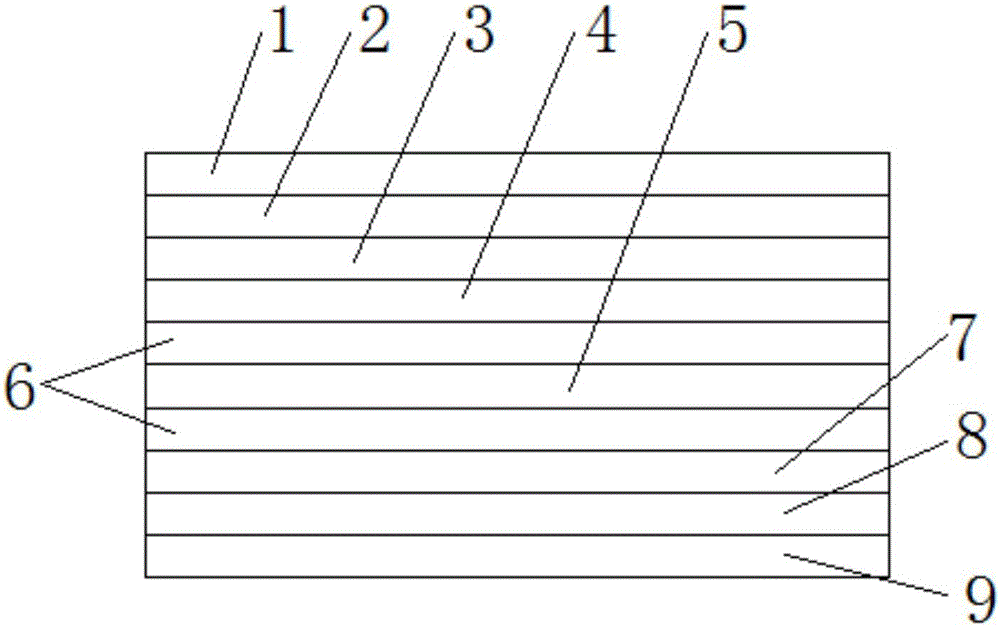

Biodegradable plastic cement material and preparation method thereof

The invention provides a biodegradable plastic cement material and a preparation method thereof. The material comprises polylactic acid, polymethyl methacrylate, polypropylene, dicapryl phthalate, butyl benzyl phthalate, castor oil, cocoanut fatty acid diethanolamide, cellulose, modified starch, butylated hydroxytoluene, butyl hydroxy anisd, polymethyl acrylate and silica. The preparation method comprises the steps of firstly, mixing, heating and stirring polylactic acid, polymethyl methacrylate, polypropylene, dicapryl phthalate, butyl benzyl phthalate, castor oil and cocoanut fatty acid diethanolamide, then adding the remaining components, conducting dispersion, then placing the mixture into a dryer for a reaction, and finally adding the mixture into a double-screw extruder for extrusion molding. The biodegradable plastic cement material can be degraded completely, is high in degradation speed and meanwhile has quite good elasticity and toughness.

Owner:SUZHOU FAST INFORMATION TECH CO LTD

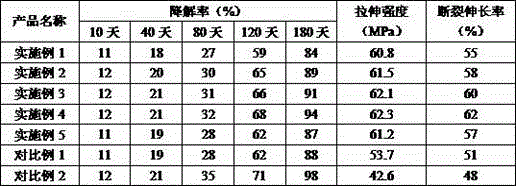

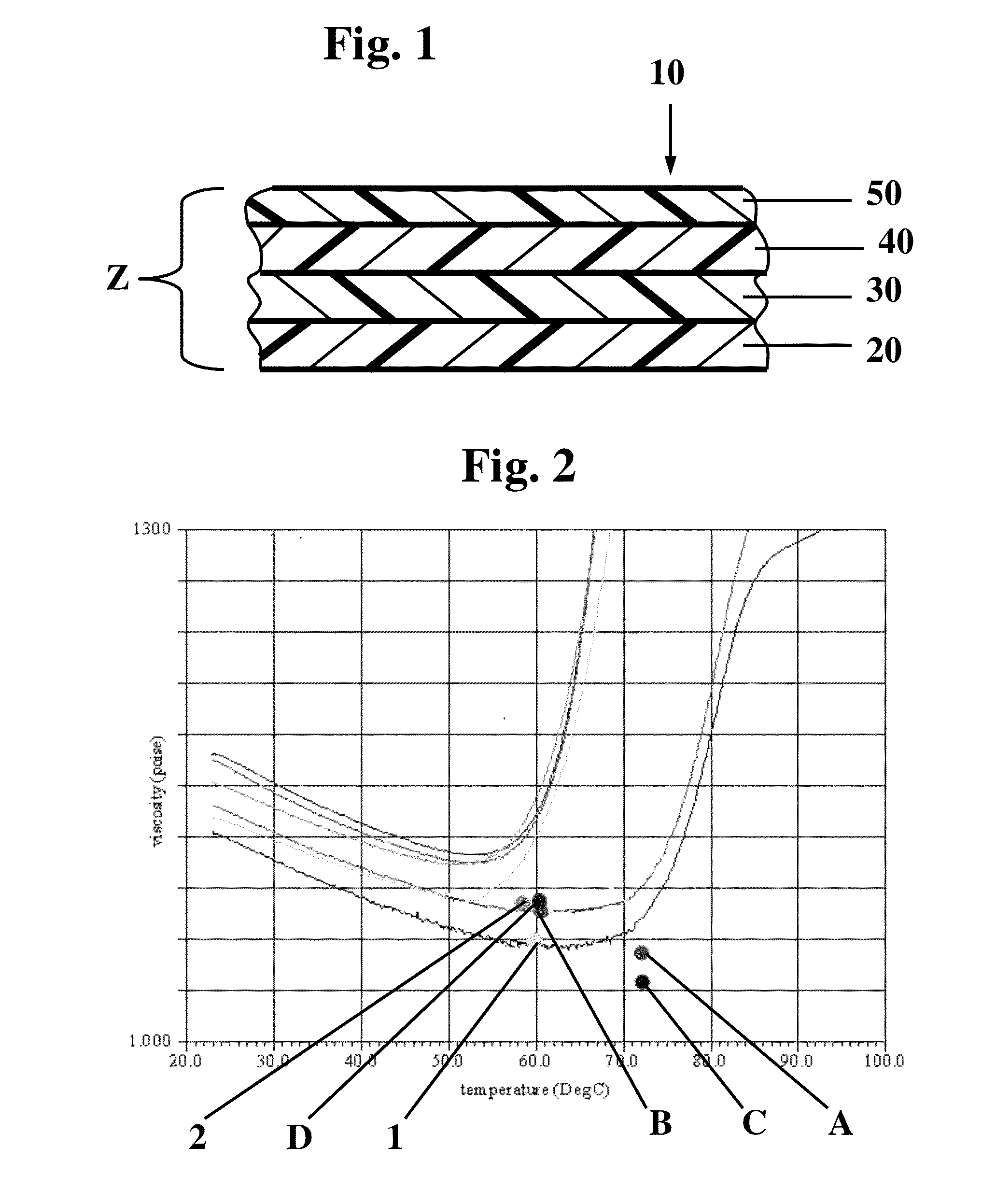

Sustainable poly(vinyl chloride) mixtures for flooring products

InactiveUS20140087081A1Improve thermal stabilityAdequate economy of scalePretreated surfacesCoatingsMETHYL SOYATEBrick

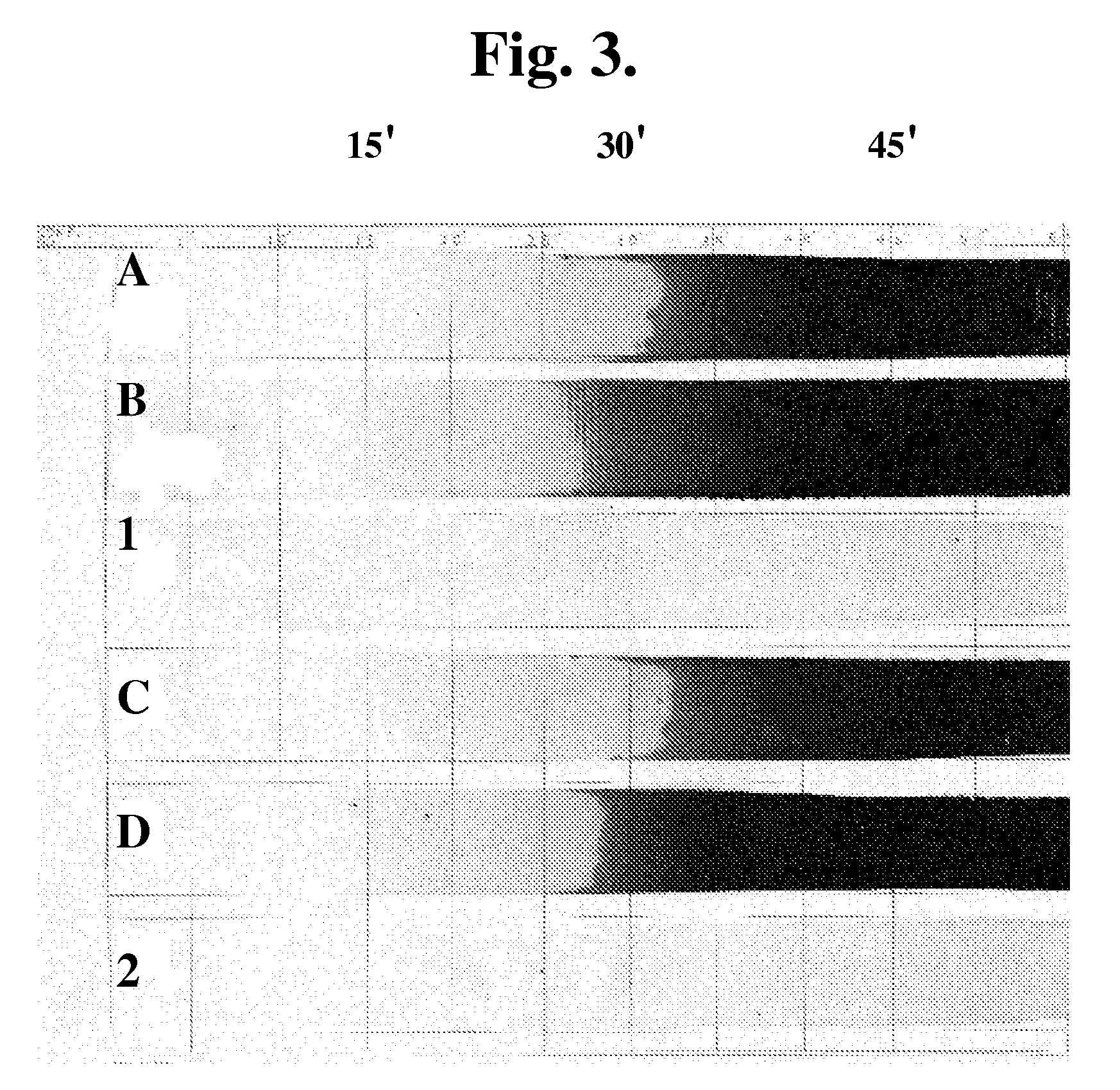

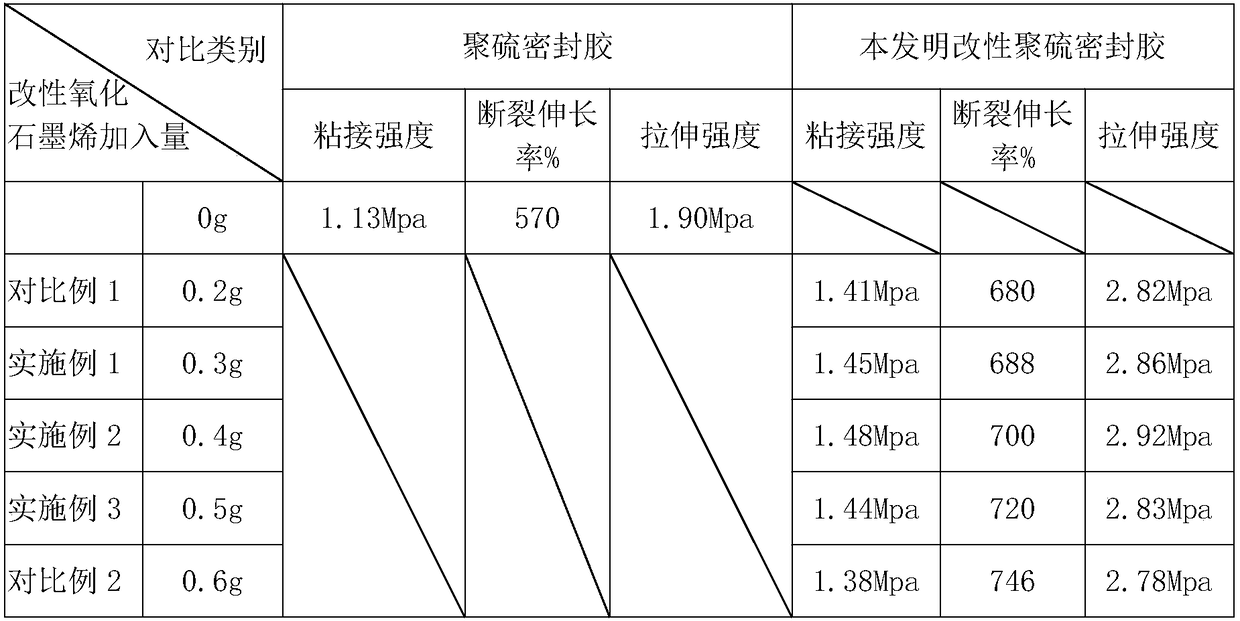

A mixture of poly(vinyl chloride) and epoxidized methyl soyate is disclosed. The epoxidized methyl soyate as a plasticizer replaces butyl benzyl phthalate which is conventionally used for the manufacture of multi-layer laminate sheet flooring or single layer tile flooring. The epoxidized methyl soyate, a bio-plasticizer, unexpectedly is a “drop-in” replacement for the butyl benzyl phthalate, both in terms of processing and performance. Also poly(vinyl chloride)-epoxidized methyl soyate mixtures have much better heat stability than poly(vinyl chloride)-butyl benzyl phthalate mixtures.

Owner:POLYONE CORP

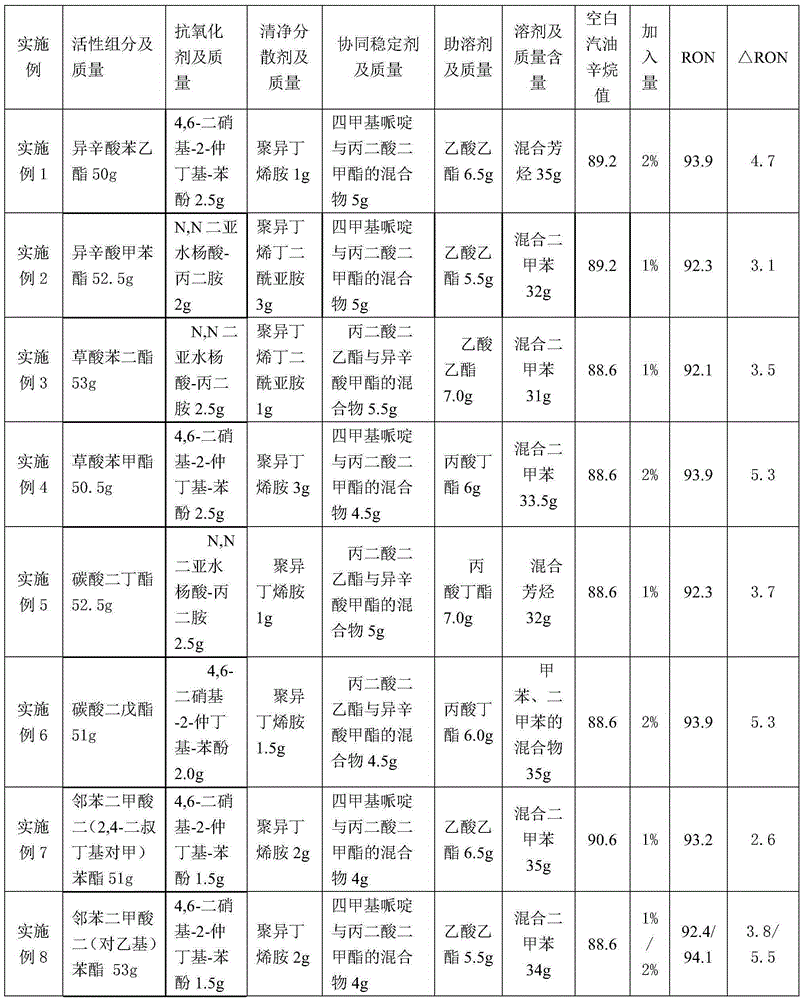

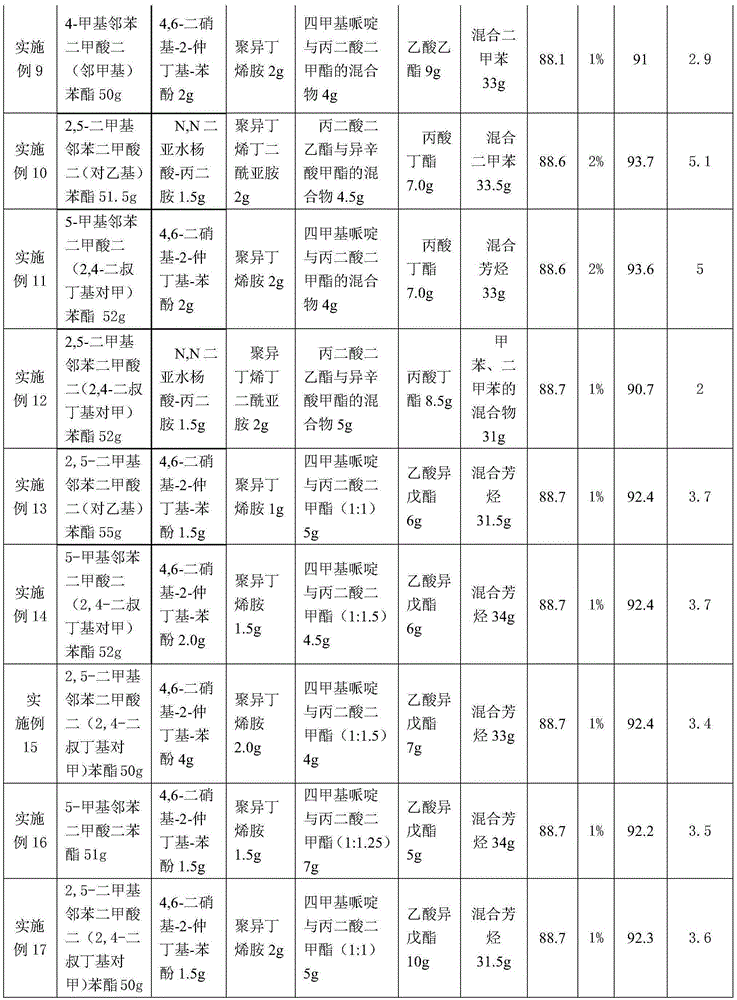

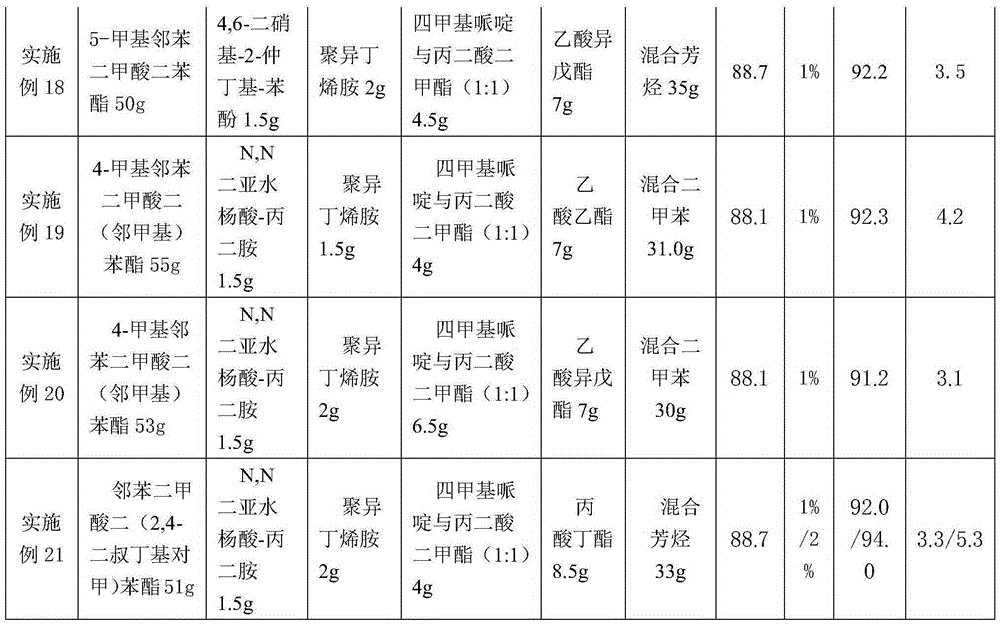

Gasoline octane value booster and preparation method thereof

InactiveCN105296027ADoes not affect evaporationBoost octaneLiquid carbonaceous fuelsAntioxidantToluene diisocyanate

The invention discloses a gasoline octane value booster which is prepared from the following raw materials in parts by mass: 50-55 parts of an active component, 1.5-4 parts of an antioxidant, 1-3 parts of a clean dispersing agent, 4-7 parts of a synergic stabilizing agent, 5-10 parts of a cosolvent and 30-35 parts of a solvent, wherein the active component is one of the following aromatic ester compounds: isocaprylic acid phenethyl ester, isocaprylic acid toluene diisocyanate, oxalic acid benzene diester, oxalic acid benzyl butyl phthalate, phthalic acid di(2,4-ditertiary butyl p-methyl) phenyl ester, phthalic acid di(p-ethyl) phenyl ester, 4-methyl phthalic acid di(o-methyl) phenyl ester, 2,5-dimethyl phthalic acid di(p-ethyl) phenyl ester, 5-methyl phthalic acid di(2,4-ditertiary butyl p-methyl) phenyl ester and 2,5-dimethyl phthalic acid di(2,4-ditertiary butyl p-methyl) phenyl ester; or the active component is fatty grease dibutyl carbonate or diamyl carbonate. The gasoline octane value booster is green and environmentally friendly and is good in compatibility with gasoline.

Owner:XIAN JIAHONG PETROCHEM TECH

Sustainable poly(vinyl chloride) mixtures for flooring products

InactiveUS20110123818A1Excellent heat stability and other physical propertyFast interactionSynthetic resin layered productsPretreated surfacesChemistryPlasticizer

A mixture of poly(vinyl chloride) and epoxidized methyl soyate is disclosed. The epoxidized methyl soyate as a plasticizer replaces butyl benzyl phthalate which is conventionally used for the manufacture of multi-layer laminate sheet flooring or single layer tile flooring. The epoxidized methyl soyate, a bio-plasticizer, unexpectedly is a “drop-in” replacement for the butyl benzyl phthalate, both in terms of processing and performance. Also poly(vinyl chloride)-epoxidized methyl soyate mixtures have much better heat stability than poly(vinyl chloride)-butyl benzyl phthalate mixtures.

Owner:POLYONE CORPORATION

A kind of preparation method of self-cleaning fabric

ActiveCN105568426BImprove stabilityGood repeatabilityWeft knittingFilament/thread formingFiberMolten state

Owner:东台市天地经纬织品有限公司

Anti-bacteria oxygen graphite fluoride-composite polymide powdery coating and preparation method thereof

InactiveCN106752891AImprove dispersionEnhanced Interfacial InteractionAntifouling/underwater paintsPaints with biocidesPropionateStearic acid

The invention discloses an anti-bacteria oxygen graphite fluoride-composite polymide powdery coating, which is prepared from the following raw materials in parts by weight: 3-4 parts of butyl benzyl phthalate, 100-110 parts of polyimide, 10-14 parts of graphite fluoride, 0.1-0.3 part of potassium persulfate, 1-2 parts of sodium nitrate, 0.1-0.4 part of potassium permanganate, 4-6 parts of sebacic acid, 0.5-1 part of phosphorus pentoxide, 0.1-0.2 part of dicyclohexylcarbodiimide, 0.1-0.2 part of 4-dimethyl aminopyridine, 1-2 parts of octyl isothiazolinone, 2-3 parts of calcium propionate, 0.4-1 parts of sodium alkyl benzene sulfonate, 0.6-1 parts of 2-bromo-4-methyl-phenol, 4-7 parts of tetrabutyl titanate, 0.8-1 parts of calcium sulfonate, 2-3 parts of polyvinyl alcohol, 0.4-1 parts of stearic acid, a proper amount of dimethyl formamide, a proper amount of sulfuric acid and a proper amount of absolute ethanol. By adding calcium propionate and the like, the anti-bacteria anti-corrosion performances of the finished product material can be effectively enhanced, and the storage stability of the finished product can be improved.

Owner:ANHUI RONGJIU OPTICAL FIBER COMM

NBR rubber for welding hoses

InactiveCN106566029AAdequate mechanical propertiesGood flexibilityButylbenzyl phthalateM-xylylenediamine

The invention discloses NBR rubber for welding hoses, which is prepared from, by weight, 150-195 parts of NBR, 10-20 parts of methyl acrylate, 50-55 parts of hydrogenated nitrile butadiene rubber, 10-20 parts of phenylene silicone rubber, 6-9 parts of phthalic dimethyl anhydride, 6-14 parts of coconut oil monoethanolamide, 3-7 parts of butylbenzyl phthalate, 12-14 parts of silicon carbide crystal whiskers, 5-10 parts of epoxy soybean oil, 4-8 parts of a filling agent, 6-9 parts of m-xylylenediamine, 4-8 parts of a silane coupling agent, 1-6 parts of an anti-coking agent, and 3-5 parts of stannous octoate. The NBR rubber for welding hoses is both rigid and flexible, not only has enough mechanical performances but also has excellent flexibility, and has good low temperature resistance and ozone tolerance.

Owner:WUXI YONGXING METAL HOSE

Coating for phosphorus determination sensor auxiliary electrode and preparation method thereof

ActiveCN104845415ASimple processSolve the problem of easy cracking and deformationAlkali metal silicate coatingsPolyvinyl alcoholButylbenzyl phthalate

The invention discloses a coating for a phosphorus determination sensor auxiliary electrode and a preparation method thereof. The coating for the phosphorus determination sensor auxiliary electrode contains, by weight, ethyl alcohol 32-40%, triethanolamine 0.5-1%, butyl benzyl phthalate 0.5-1%, water glass 4-8%, polyvinyl butyral 0.5-1%, phosphorus pentoxide powder 26-30%, calcium oxide powder 13-18% and calcium fluoride powder 13-18%. The ethyl alcohol and the triethanolamine are firstly mixed in a ball grinding mill according to the components and contents for 15-30 minutes, the phosphorus pentoxide powder, the calcium oxide powder and the calcium fluoride powder are added to perform ball grinding for 8-16 hours, then the water glass is added to perform ball grinding for 4-8 hours, and finally the polyvinyl butyral and the butyl benzyl phthalate are added to perform ball grinding for 8-16 hours so as to obtain the coating for the phosphorus determination sensor auxiliary electrode. The preparation method is simple, and the prepared coating for the phosphorus determination sensor auxiliary electrode has the advantages of being high in strength, excellent in high-temperature adhesion performance and good in using effect.

Owner:WUHAN UNIV OF SCI & TECH

Anti-ultraviolet glass

The invention discloses an anti-ultraviolet glass, which is made of the following raw materials in parts by mass: 40-45 parts of silicon dioxide, 16-18 parts of calcium silicate, 18-20 parts of methyl ester, 7-10 parts of sodium sulfite, 5-7 parts of zinc oxide, 6-9 parts of magnesium hydroxide, 4-5 parts of ethanol, 7-10 parts of diethanolamine, 6-10 parts of butyl benzyl phthalate, 3-5 parts of titanium dioxide, 4-4 parts of chromium nitrate 6 parts, 7‑10 parts of potassium permanganate, 6‑8 parts of copper sulfate pentahydrate. The invention has strong anti-ultraviolet ability, good strength and high temperature resistance, and can completely prevent and eliminate ultraviolet rays.

Owner:青岛燕园海洋生物科技有限公司

Anti-ultraviolet composite fireproof glass

Owner:杭州福隆鼎门窗幕墙有限公司

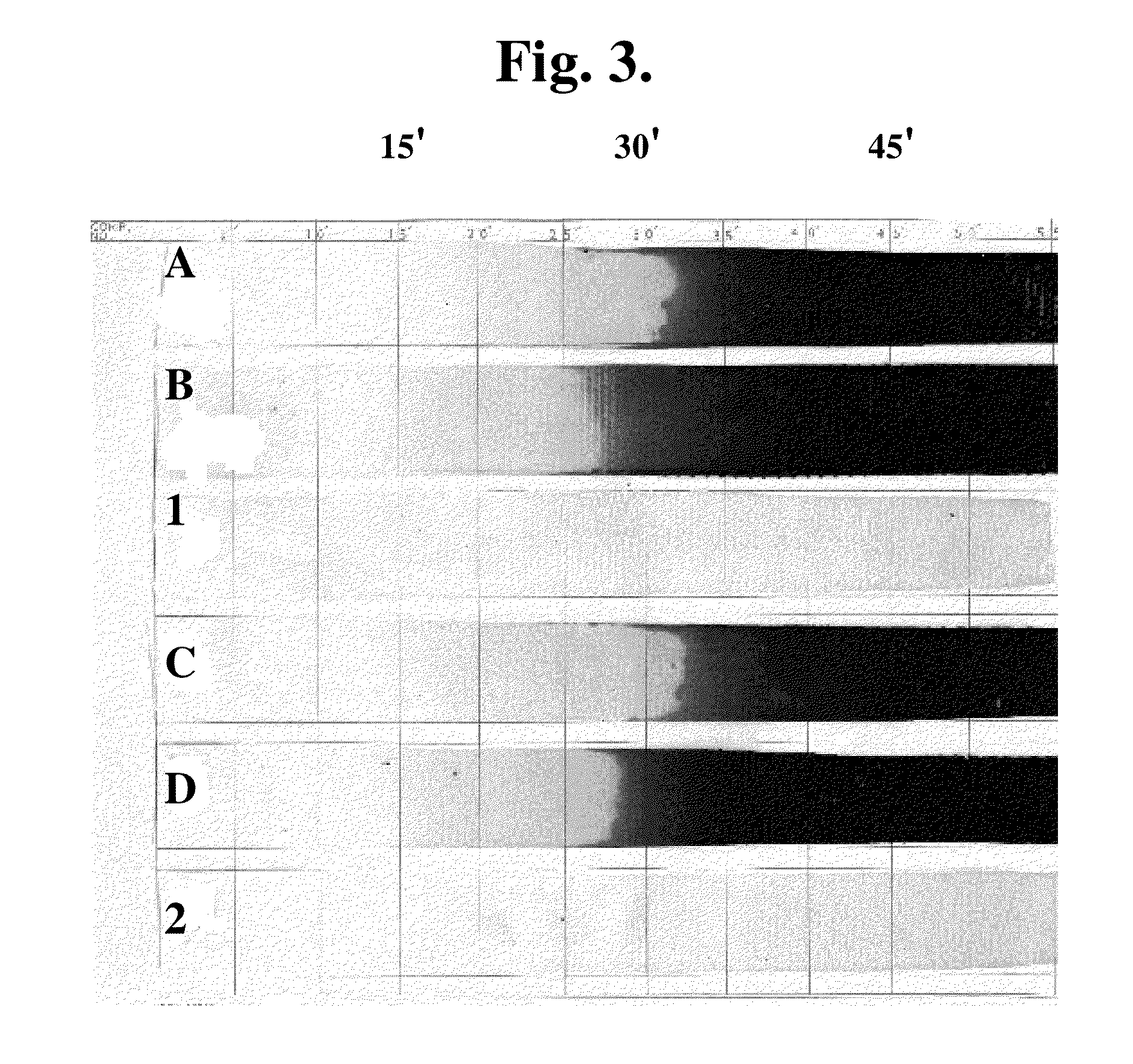

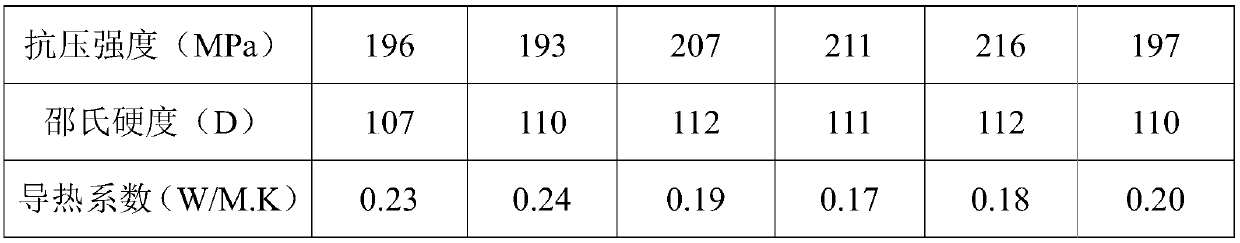

Preparation method of modified polysulfide sealant

InactiveCN108865049AHigh bonding strengthHigh elongation at breakNon-macromolecular adhesive additivesMacromolecular adhesive additivesLiquid stateButylbenzyl phthalate

The invention discloses a preparation method of modified polysulfide sealant, and relates to the technical field of sealant. The preparation method comprises the following steps: (1) preparing modified graphene oxide; (2) preparing a dispersion; (3) preparing a host agent; (4) preparing a hardening agent; (5) mixing the host agent and the hardening agent and stirring. According to the preparationmethod disclosed by the invention, the modified graphene oxide is added into a benzyl butyl phthalate solution to obtain a dispersion, and the dispersion is further applied to the synthesis and proportioning of the host agent, thus the modified graphene oxide can be better dispersed in the liquid-state polysulfide sealant; by modifying the graphene oxide with a silane coupling agent and then modifying the polysulfide sealant with the modified graphene oxide, the problems of poor adhesive property and low elongation at break of existing polysulfide sealant are solved.

Owner:芜湖青悠静谧环保科技有限公司

Antimicrobial aluminum electrode anti-corrosive paint and preparation method thereof

InactiveCN105860603AImprove corrosion resistanceEasy to operateAntifouling/underwater paintsPaints with biocidesDiacetone alcoholSodium diacetate

The invention discloses an antibacterial aluminum electrode anticorrosion coating, which is composed of the following raw materials in parts by weight: sodium diacetate 1-2, triethanolamine 0.1-0.13, lauroamphodiacetate disodium 0.1-0.2, hexadecane Trimethyl ammonium bromide 0.7‑1, magnesium sulfate 0.05‑0.06, benzotriazole 0.06‑0.07, octylphenol polyoxyethylene ether 1.7‑2, dodecylamine 0.3‑0.5, ethyl orthosilicate 46 ‑50, n-dodecyl trichlorosilane 0.3‑0.4, zirconium n-propoxide 13‑20, ethyl acetoacetate 7‑10, isopropanol 57‑60, silane coupling agent kh56010‑13, calcium stearate 0.4‑1, diacetone alcohol 2‑3, octylisothiazolinone 1‑2, calcium propionate 0.8‑1, lithium naphthenate 0.01‑0.02, butyl benzyl phthalate 0.2‑0.4. The invention effectively improves the antibacterial performance of the paint.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Flame-retardant compression-resistant composite for glass fiber reinforced plastic septic tank and preparation method of flame-retardant compression-resistant composite

The invention discloses a flame-retardant compression-resistant composite for a glass fiber reinforced plastic septic tank and a preparation method of the flame-retardant compression-resistant composite and relates to the technical field of glass fiber reinforced plastics. The flame-retardant compression-resistant composite comprises the raw materials in parts by weight: 100 parts of unsaturated polyester resin, 3-7 parts of acrylonitrile-butadiene-styrene copolymer, 80-110 parts of glass fibers, 3-7 parts of silica powder, 20-30 parts of bentonite, 6-12 parts of epoxypropane butyl ether, 3-7parts of curing agent, 2-5 parts of accelerant, 2-5 parts of flame retardant, 0.5-2 parts of benzotriazole, 0.5-2 parts of butylbenzyl phthalate and 1-3 parts of coupling agent. The glass fiber reinforced plastic composite disclosed by the invention is relatively high in strength and toughness, compression-resistant, corrosion-resistant, good in flame retardance and weather resistance and capableof meeting the requirement for high strength of the glass fiber reinforced plastic septic tank.

Owner:安徽汇创新材料有限公司

Plant fibre polymerized wood

The invention discloses plant fibre polymerized wood which is prepared from the following raw materials (by weight): plant fibre powder, plastic resin, methacryloxy propyl trimethoxy silane, vinyltriethoxysilane, diisononyl phthalate, butyl benzyl phthalate, a foaming agent and a lubricant. The invention has the following beneficial effects: the plant fibre polymerized wood has high strength, is used to save timber, is low-cost, has long service life, can be recycled and is beneficial to environmental protection; and the technology is simple, scientific and reasonable.

Owner:SHIFANG MIDEE WOOD IND

Modified plastic particles with stable mechanical properties and preparation process

The invention discloses modified plastic particles with stable mechanical properties. The plastic particles are prepared from the following substances: epoxy resin, butyl benzyl phthalate, lanthanum sulfate, samarium phosphate, tributyl phosphate, stearic acid, higher alcohol fatty acid ester compound and modified filler. Components of existing plastic particles are specially improved, and finallythe prepared plastic particles have stable performance, good wear resistance, corrosion resistance and tensile resistance, excellent comprehensive quality, long service life, and good popularizationand application value and market competitiveness.

Owner:界首市鑫豪塑胶有限公司

Photocatalytic self-cleaning fabric and preparation method thereof

InactiveCN109853079ARealize self-cleaningBond stronger and more durableConjugated synthetic polymer artificial filamentsArtifical filament manufactureButylbenzyl phthalateChemistry

The invention discloses a photocatalytic self-cleaning fabric and a preparation method thereof. The fabric is mainly prepared from, by mass, 65-80 parts of polyvinyl chloride, 10-15 parts of polyethylene terephthalate, 4-10 parts of sliver-loaded nano TiO2, 2-6 parts of nano SiO2, 2-6 parts of disodium hydrogen phosphate dodecahydrate, 3-6 parts of polystyrene sulfonate, 3-5 parts of cellulose ester, 8-13 parts of benzyl butyl phthalate, 2-5 parts of nano zinc oxide, 2-5 parts of nano cuprous oxide, 0.1-0.3 part of a defoaming agent, 0.4-1.2 parts of chitosan, 0.3-1 part of an emulsified wetting agent, 2-5 parts of sodium alginate and 0.5-1.5 parts of ester gum. The photocatalytic self-cleaning fabric is simple in process, easy to industrialize and suitable for application and popularization. Self-cleaning of the fabric can be achieved under visual light; the preparation method makes the combination of a photocatalyst and the fabric stronger and more durable and is simple and easy to apply and popularize.

Owner:YANCHENG INST OF TECH

Polyvinyl chloride heat dissipation coating

The invention discloses a polyvinyl chloride heat dissipation coating. The polyvinyl chloride heat dissipation coating comprises the following raw materials in parts by weight: 83-90 parts of SG-4 type PVC (polyvinyl chloride) resin, 0.6-1 part of XC-113 trifunctional aziridine crosslinking agent, 1-2 parts of magnesium chloride, 2-3 parts of beta-hydroxyalkylamide, 10-13 parts of mica powder, 1-2 parts of propylene glycol phenyl ether, 3-5 parts of white carbon black, 1-2 parts of hydroxyethyl cellulose, 4-6 parts of triethylene glycol di-2-ethylhexoate, 2-4 parts of aluminum nitride, 4-6 parts of polyvinylidene fluoride, 2-4 parts of acetate fiber, 0.6-1 part of pyromellitic dianhydride, 3-5 parts of benzyl butyl phthalate, 2-4 parts of calcium fluoride and 10-12 parts of modification additives. The powder coating disclosed by the invention has the advantages of good stability of a coat, simplicity in formation of a film, strong weatherability, simple coating process and effect of saving using cost.

Owner:WUHU BAOYI AMUSEMENT EQUIP

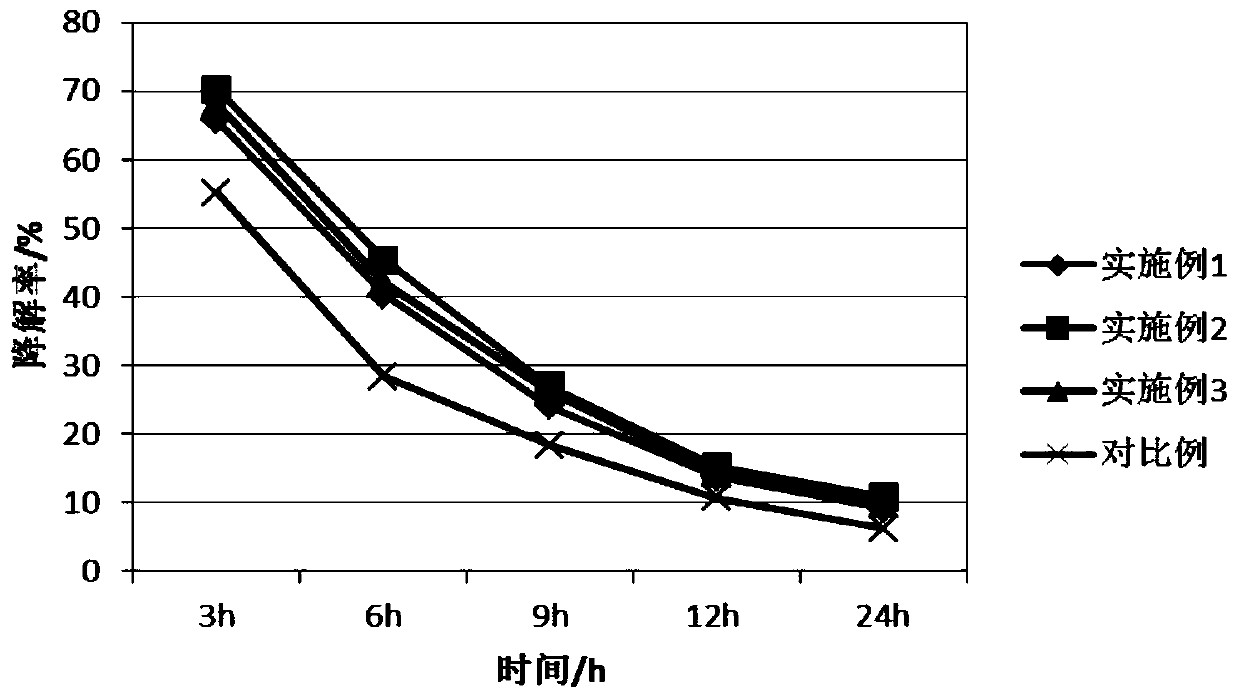

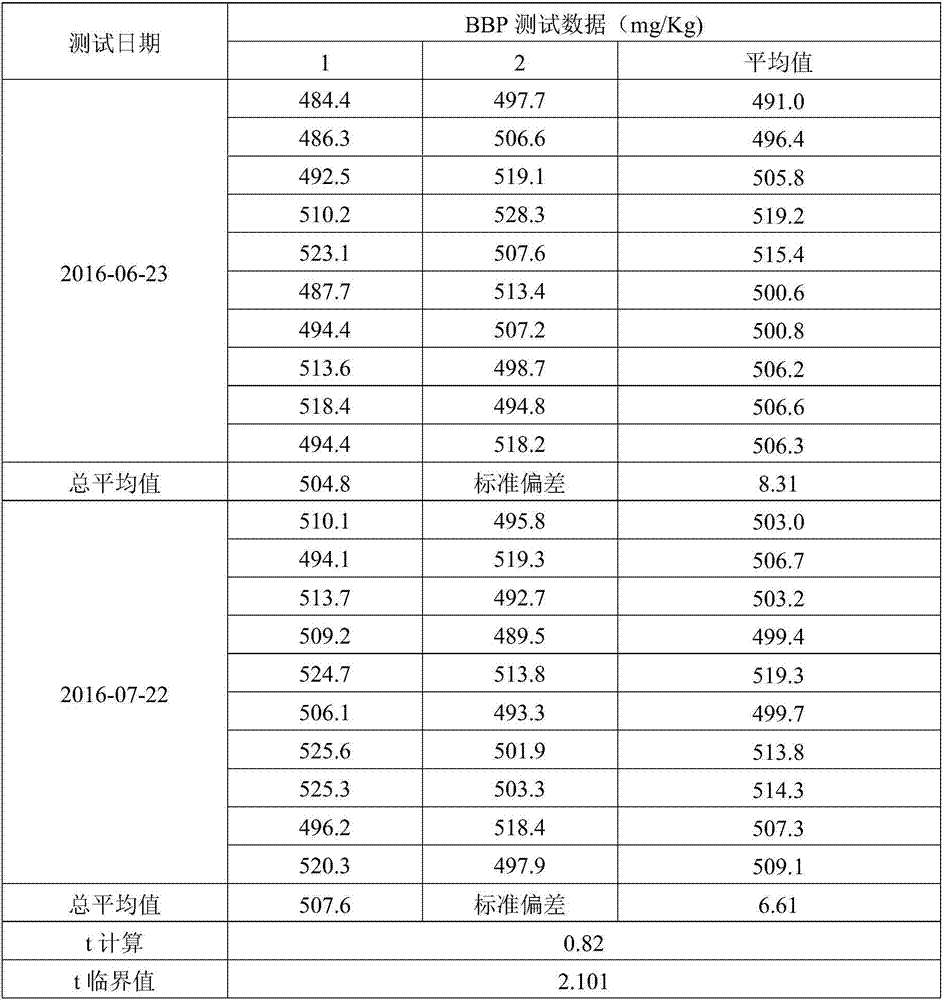

Proficiency testing samples used for determination of benzyl butyl phthalate (BBP) in textiles and preparation method thereof

InactiveCN106940369AEasy to prepareIncrease success rateTextile testingButylbenzyl phthalateProficiency testing

The invention discloses proficiency testing samples used for determination of BBP in textiles. The concentrations of BBP in the proficiency testing samples are in a range of 479.9 to 2129.1 mg / kg. The invention also discloses a preparation method for the proficiency testing samples. According to the invention, textile PVC samples with different BBP concentrations are prepared by using BBP and a simple PVC film coating process and are used for proficiency testing for determination of BBP in textiles. Meanwhile, the preparation method for the proficiency testing samples is simple in process and high in success rate; and the prepared proficiency testing samples can be stored and transported at normal temperature, and the uniformity and stability of the prepared proficiency testing samples meet requirements prescribed in the Evaluation Manuel for Uniformity and Stability of Proficiency Testing Samples CNAS-GL03.

Owner:PEOPLES REPUBLIC OF CHINA BEIJING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Composite nanometer weather-proof waterproof coating and preparing method thereof

InactiveCN104893436ASignificant weather resistanceSignificant water resistancePolyester coatingsButylbenzyl phthalateTitanium nitride

Composite nanometer weather-proof waterproof coating and a preparing method thereof are disclosed. The coating comprises nanometer titanium nitride, nanometer magnesium carbonate, alkyd resin, polyvinylidene chloride resin, chlorosulfonated polyethylene, benzyl butyl phthalate, tung oil, n-butanol and amyl acetate. The preparing method includes (1) weighing the nanometer titanium nitride and nanometer magnesium carbonate, and fully mixing in a high-speed mixer; (2) adding the tung oil, the n-butanol and the amyl acetate into a stirring tank, and stirring in a sealed manner until the mixture is fully mixed; (3) adding the alkyd resin, the polyvinylidene chloride resin, the chlorosulfonated polyethylene and the benzyl butyl phthalate into the stirring tank, and mechanically stirring; and (4) adding the powder fully mixed in the step (1) into the stirring tank, and fully stirring to obtain the coating.

Owner:SUZHOU DEXIANG DECORATION ENG

Saponified antibacterial leather coating and preparation method thereof

InactiveCN106634367AImprove water resistancePrevent penetrationAntifouling/underwater paintsPaints with biocidesMeth-Butylbenzyl phthalate

The invention provides a saponified antibacterial leather coating. The saponified antibacterial leather coating is composed of the following raw materials in parts by weight: 1 to 2 parts of butyl benzyl phthalate, 0.3 to 1 part of polyethylene benzenesulfonic acid, 1.7 to 2 parts of polyvinylpyrrolidone, 0.8 to 1 part of polyacrylamide, 1.6 to 2 parts of stannous chloride, 0.1 to 0.13 part of triethanolamine, 190 to 200 parts of methyl methacrylate, 3 to 4 parts of sodium dodecyl sulfate, 0.1 to 0.2 part of Urotropine, 0.2 to 0.3 part of ammonium persulfate, 6 to 7 parts of a formaldehyde solution with a concentration of 20 to 25%, 16 to 20 parts of zinc acetate, 4 to 7 parts of silver nitrate, 0.8 to 2 parts of polyether glycol, 1 to 2 parts of sodium myrastate, 0.1 to 0.2 part of nonylphenol, 0.8 to 1 part of ammonium zirconium carbonate, 0.1 to 0.3 part of hexamethyl cyclotrisiloxane and 1 to 2 parts of sodium hydroxide with a concentration of 3 to 5 mol / l. The saponified antibacterial leather coating provided by the invention has good antibacterial properties and excellent water vapor permeability and water resistance; and the leather coated by an emulsion has good antibacterial properties and excellent hygienic properties.

Owner:WUHU HONGKUN AUTO PARTS

Treating liquid used for bristle osier and preparing method of treating liquid

InactiveCN106182269AGood film formingGood emulsion propertiesReed/straw treatmentWood impregnation detailsBristleButylbenzyl phthalate

The invention discloses treating liquid used for bristle osier and a preparing method of the treating liquid. The treating liquid is composed of the following raw materials including, by weight, 15-18 parts of rice bran wax, 8-12 parts of dialkyl group diphenylamine, 10-15 parts of benzyl butyl phthalate, 4-6 parts of sodium sebacic acid, 8-10 parts of vinyl silicone oil, 4-7 parts of vinisol cooh, 4-6 parts of ferrocene, 3-5 parts of p-tert-butylbenzoic acid, 10-16 parts of white carbon black and 22-28 parts of a bacteriostasis additive. Compared with the prior art, the treating liquid and the preparing method of the treating liquid have the following beneficial effects that the treating liquid prepared through the method is good in film forming performance, has good emulsion performance and is high in adhesive force, treatment is conducted under the condition of ultrasonic waves with the corresponding frequency, the osier can be filled with a certain number of colloidal materials so that the toughness of the osier can be enhanced, meanwhile, insects and mould can be prevented effectively, stability is good, weather resistance is high, and the economic value of the bristle osier is improved.

Owner:阜南县宏泰工艺品有限公司

Corrosion-resistant high-mechanical-strength cable insulation material

InactiveCN106366385AHigh mechanical strengthImprove thermal stabilityRubber insulatorsPlastic/resin/waxes insulatorsFiberAntioxidant

The invention discloses a corrosion-resistant high-mechanical-strength cable insulation material which is prepared from the following raw materials in parts by weight: 20 to 30 parts of urea resin, 15 to 25 parts of ethylene octylene segmented copolymer, 20 to 40 parts of hydrogenated butadiene-acrylonitrile rubber, 1 to 2 parts of white factice, 3 to 7 parts of modified lecithin, 1.5 to 3 parts of castor oil, 0.5 to 1 part of cresyl diphenyl phosphate, 0.8 to 1.2 parts of benzyl butyl phthalate, 0.1 to 0.5 part of dioctyl phthalate, 6 to 14 parts of talcum powder, 8 to 12 parts of lignin, 6 to 12 parts of coconut fiber, 3 to 9 parts of asbestos, 6 to 10 parts of sea-foam stone powder, 1.5 to 2.5 parts of colorant, 1.5 to 3 parts of stabilizer, 1.5 to 2.5 parts of antistatic agent and 1.5 to 3 parts of 1010 antioxidant. The corrosion-resistant high-mechanical-strength cable insulation material is good in thermal stability, high in mechanical strength and excellent in corrosion resistance.

Owner:ANHUI LAND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com