Antibacterial flame retardant coating and preparation method thereof

A technology of flame-retardant coatings and mass fractions, applied in the field of coatings, can solve the problems of no antibacterial function, etc., achieve good antibacterial and flame-retardant effects, strong bactericidal ability, and improve the effect of antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

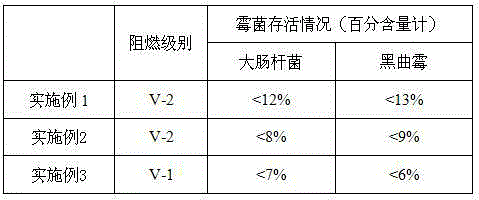

Embodiment 1

[0029] The antibacterial and flame-retardant coating in the present embodiment is made up of following mass components: 6 parts of zinc pyrithione, 15 parts of chitosan biguanide hydrochloride, 8 parts of methylphenyl silicone resin, 10 parts of nano-silver powder, phosphoric acid 8 parts of ester flame retardant, 4 parts of dihexadecyl peroxydicarbonate, 12 parts of butyl benzyl phthalate, 0.5 parts of ultrafine acrylate rubber powder, 0.1 part of dimethyl phosphate, Aluminum silicate fiber 5 parts, zinc oxide 1 part.

[0030] The preparation method of above-mentioned antibacterial flame-retardant coating comprises the following steps:

[0031] (1) Add the above mass parts of chitosan biguanide hydrochloride into water, and then add the above mass parts of zinc pyrithione, methylphenyl silicone resin, phosphate ester flame retardant, peroxydicarbonate bis Cetyl ester, butyl benzyl phthalate, dimethyl methyl phosphate, aluminum silicate fiber, zinc oxide, high-speed dispersio...

Embodiment 2

[0038] The antibacterial and flame-retardant coating in the present embodiment is made up of following mass components: 10 parts of zinc pyrithione, 30 parts of chitosan biguanide hydrochloride, 16 parts of methylphenyl silicone resin, 25 parts of nano-silver powder, phosphoric acid 10 parts of ester flame retardant, 10 parts of dihexadecyl peroxydicarbonate, 20 parts of butyl benzyl phthalate, 1 part of ultrafine acrylate rubber powder, 0.5 part of dimethyl phosphate, Aluminum silicate fiber 15 parts, zinc oxide 3 parts.

[0039] The preparation method of above-mentioned antibacterial flame-retardant coating comprises the following steps:

[0040] (1) Add the above mass parts of chitosan biguanide hydrochloride into water, and then add the above mass parts of zinc pyrithione, methylphenyl silicone resin, phosphate ester flame retardant, peroxydicarbonate bis Cetyl ester, butyl benzyl phthalate, dimethyl methyl phosphate, aluminum silicate fiber, zinc oxide, high-speed disper...

Embodiment 3

[0047] The antibacterial and flame-retardant coating in the present embodiment is made up of following mass components: 8 parts of zinc pyrithione, 18 parts of chitosan biguanide hydrochloride, 12 parts of methylphenyl silicone resin, 13 parts of nano-silver powder, phosphoric acid 9 parts of ester flame retardant, 12 parts of dihexadecyl peroxydicarbonate, 16 parts of butyl benzyl phthalate, 0.75 parts of ultrafine acrylate rubber powder, 0.3 parts of dimethyl phosphate, 10 parts of aluminum silicate fiber, 2 parts of zinc oxide.

[0048] Further, the preparation method of the above-mentioned antibacterial flame retardant coating comprises the following steps:

[0049] (1) Add the above mass parts of chitosan biguanide hydrochloride into water, and then add the above mass parts of zinc pyrithione, methylphenyl silicone resin, phosphate ester flame retardant, peroxydicarbonate bis Cetyl ester, butyl benzyl phthalate, dimethyl methyl phosphate, aluminum silicate fiber, zinc ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com