Anti-flaming anti-bacteria coating

A technology of antibacterial coating and furfuryl alcohol resin, which is applied in the field of coatings, can solve the problems of not having antibacterial function, achieve excellent optical stability, simple process, and improve the effect of antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

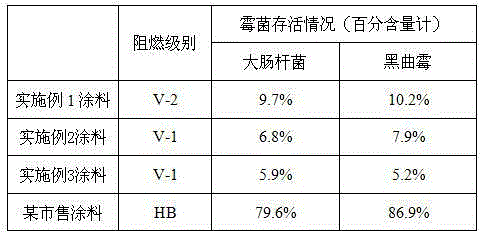

Examples

Embodiment 1

[0030] The flame retardant and antibacterial coating in the present embodiment is made up of the following mass components: 6 parts of furfuryl alcohol resin, 15 parts of butylated hydroxyanisole, 8 parts of polyhexamethylene guanidine, 10 parts of zircon powder, methyl lactate 8 parts of oxoprim, 4 parts of bismaleimide resin, 12 parts of antimony trioxide, 0.5 parts of cobalt blue, 0.1 part of chlorothalonil, 5 parts of magnesium stearate, 1 part of isophorone diisocyanate, 30 parts of deionized water.

[0031] The preparation method of above-mentioned flame retardant antibacterial coating comprises the steps:

[0032] (1) Add the butylated hydroxyanisole in the above-mentioned parts by mass to deionized water, and then add the furfuryl alcohol resin, polyhexamethyleneguanidine, trimethoprim lactate, and bismaleimide resin in sequence in the above-mentioned parts by mass , antimony trioxide, chlorothalonil, magnesium stearate, isophorone diisocyanate, high-speed dispersion;...

Embodiment 2

[0037] The flame retardant and antibacterial coating in the present embodiment is made up of the following mass components: 10 parts of furfuryl alcohol resin, 30 parts of butylated hydroxyanisole, 16 parts of polyhexamethylene guanidine, 25 parts of zircon powder, methyl lactate 10 parts of oxoprim, 10 parts of bismaleimide resin, 20 parts of antimony trioxide, 1 part of cobalt blue, 0.5 parts of chlorothalonil, 15 parts of magnesium stearate, 3 parts of isophorone diisocyanate, 100 parts of deionized water.

[0038] The preparation method of above-mentioned flame retardant antibacterial coating comprises the steps:

[0039] (1) Add the butylated hydroxyanisole in the above-mentioned parts by mass to deionized water, and then add the furfuryl alcohol resin, polyhexamethyleneguanidine, trimethoprim lactate, and bismaleimide resin in sequence in the above-mentioned parts by mass , antimony trioxide, chlorothalonil, magnesium stearate, isophorone diisocyanate, high-speed disper...

Embodiment 3

[0044] The flame retardant and antibacterial coating in the present embodiment is made up of the following mass components: 8 parts of furfuryl alcohol resin, 18 parts of butylated hydroxyanisole, 12 parts of polyhexamethylene guanidine, 13 parts of zircon powder, methyl lactate 9 parts of Oxyprimidine, 12 parts of bismaleimide resin, 16 parts of antimony trioxide, 0.75 parts of cobalt blue, 0.3 parts of chlorothalonil, 10 parts of magnesium stearate, 2 parts of isophorone diisocyanate, 65 parts of deionized water.

[0045] The preparation method of above-mentioned flame retardant antibacterial coating comprises the steps:

[0046] (1) Add the butylated hydroxyanisole in the above-mentioned parts by mass to deionized water, and then add the furfuryl alcohol resin, polyhexamethyleneguanidine, trimethoprim lactate, and bismaleimide resin in sequence in the above-mentioned parts by mass , antimony trioxide, chlorothalonil, magnesium stearate, isophorone diisocyanate, high-speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com