Flame-retardant antibacterial wood plastic material and preparation method thereof

A wood-plastic material and antibacterial technology, which is applied in the field of flame-retardant and antibacterial wood-plastic materials and their preparation, can solve the problems of single function and inability to provide functions, and achieve the effect of simple process, low production cost and improved antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

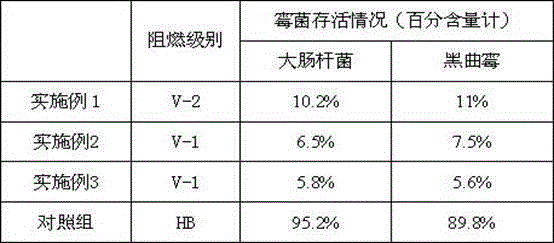

Examples

Embodiment 1

[0030] The flame-retardant and antibacterial wood-plastic material in this embodiment is composed of the following mass components: 6 parts of PVC resin, 15 parts of recycled polypropylene material, 20 parts of wood powder, 8 parts of calcium powder, 8 parts of sodium polyacrylate, poly 10 parts of tetrafluoroethylene fiber, 8 parts of methylenediethylenetriamine, 4 parts of EPDM rubber, 12 parts of nano-titanium dioxide, 0.5 part of silver carbonate, 0.1 part of artificial mica, 5 parts of montmorillonite, vinyl triethylene 1 part of oxysilane.

[0031] The preparation method of the flame-retardant and antibacterial wood-plastic material includes the following steps:

[0032] (1) Add the above-mentioned parts by mass of PVC resin, recycled polypropylene material, wood powder, calcium powder, sodium polyacrylate, polytetrafluoroethylene fiber, methylenediethylenetriamine, EPDM rubber and vinyl trifluoroethylene Ethoxysilane is added to the mixer and mixed at a speed of 400 rp...

Embodiment 2

[0037] The flame-retardant and antibacterial wood-plastic material in this embodiment is composed of the following mass components: 10 parts of PVC resin, 30 parts of recycled polypropylene material, 60 parts of wood powder, 20 parts of calcium powder, 16 parts of sodium polyacrylate, poly 25 parts of tetrafluoroethylene fiber, 10 parts of methylenediethylenetriamine, 10 parts of EPDM rubber, 20 parts of nano-titanium dioxide, 1 part of silver carbonate, 0.5 parts of artificial mica, 15 parts of montmorillonite, vinyl triethylene 3 parts of oxysilane.

[0038] The preparation method of the flame-retardant and antibacterial wood-plastic material includes the following steps:

[0039](1) Add the above-mentioned parts by mass of PVC resin, recycled polypropylene material, wood powder, calcium powder, sodium polyacrylate, polytetrafluoroethylene fiber, methylenediethylenetriamine, EPDM rubber and vinyl trifluoroethylene Ethoxysilane is added to the mixer and mixed at a speed of 5...

Embodiment 3

[0044] The flame-retardant and antibacterial wood-plastic material in this embodiment is composed of the following mass components: 8 parts of PVC resin, 18 parts of recycled polypropylene material, 30 parts of wood powder, 15 parts of calcium powder, 12 parts of sodium polyacrylate, poly 18 parts of tetrafluoroethylene fiber, 9 parts of methylenediethylenetriamine, 7 parts of EPDM rubber, 16 parts of nano-titanium dioxide, 0.75 parts of silver carbonate, 0.3 parts of artificial mica, 10 parts of montmorillonite, vinyl triethylene 2 parts of oxysilane.

[0045] The preparation method of the flame-retardant and antibacterial wood-plastic material includes the following steps:

[0046] (1) Add the above-mentioned parts by mass of PVC resin, recycled polypropylene material, wood powder, calcium powder, sodium polyacrylate, polytetrafluoroethylene fiber, methylenediethylenetriamine, EPDM rubber and vinyl trifluoroethylene Ethoxysilane is added to the mixer and mixed at a speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com