Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124 results about "2-hydroxy-4-methoxybenzophenone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-Hydroxy-4-methoxybenzophenone 98% Synonym: Oxybenzone CAS Number 131-57-7. Linear Formula HOC 6 H 3 (OCH 3)COC 6 H 5. Molecular Weight 228.24 . Beilstein Registry Number 1913145 . EC Number 205-031-5. MDL number MFCD00008387. PubChem Substance ID 24895582

Sunscreen Cosmetic

InactiveUS20120156149A1Reduce stainsIncrease the mixing ratioCosmetic preparationsToilet preparations1,3,5-TriazineMedicine

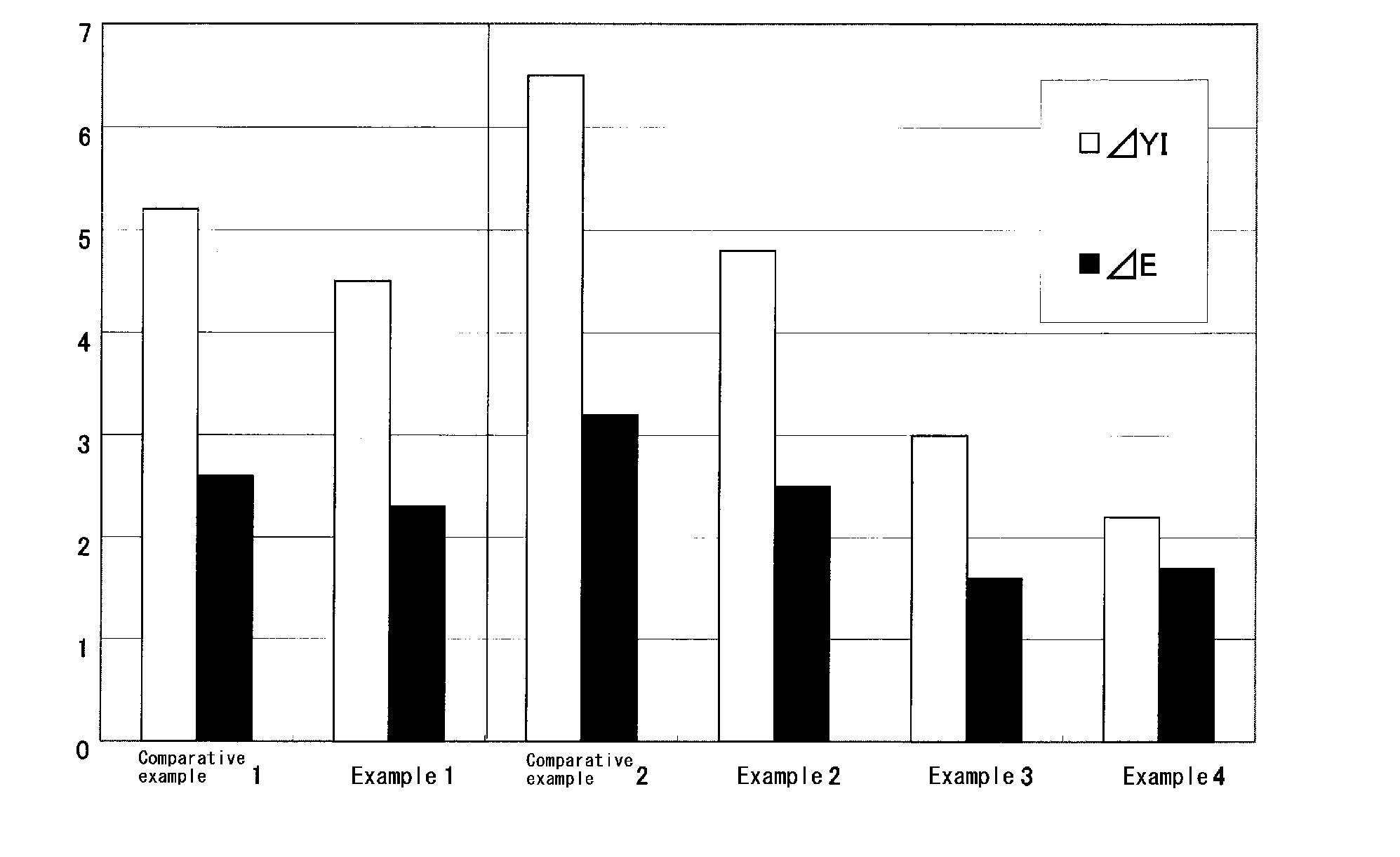

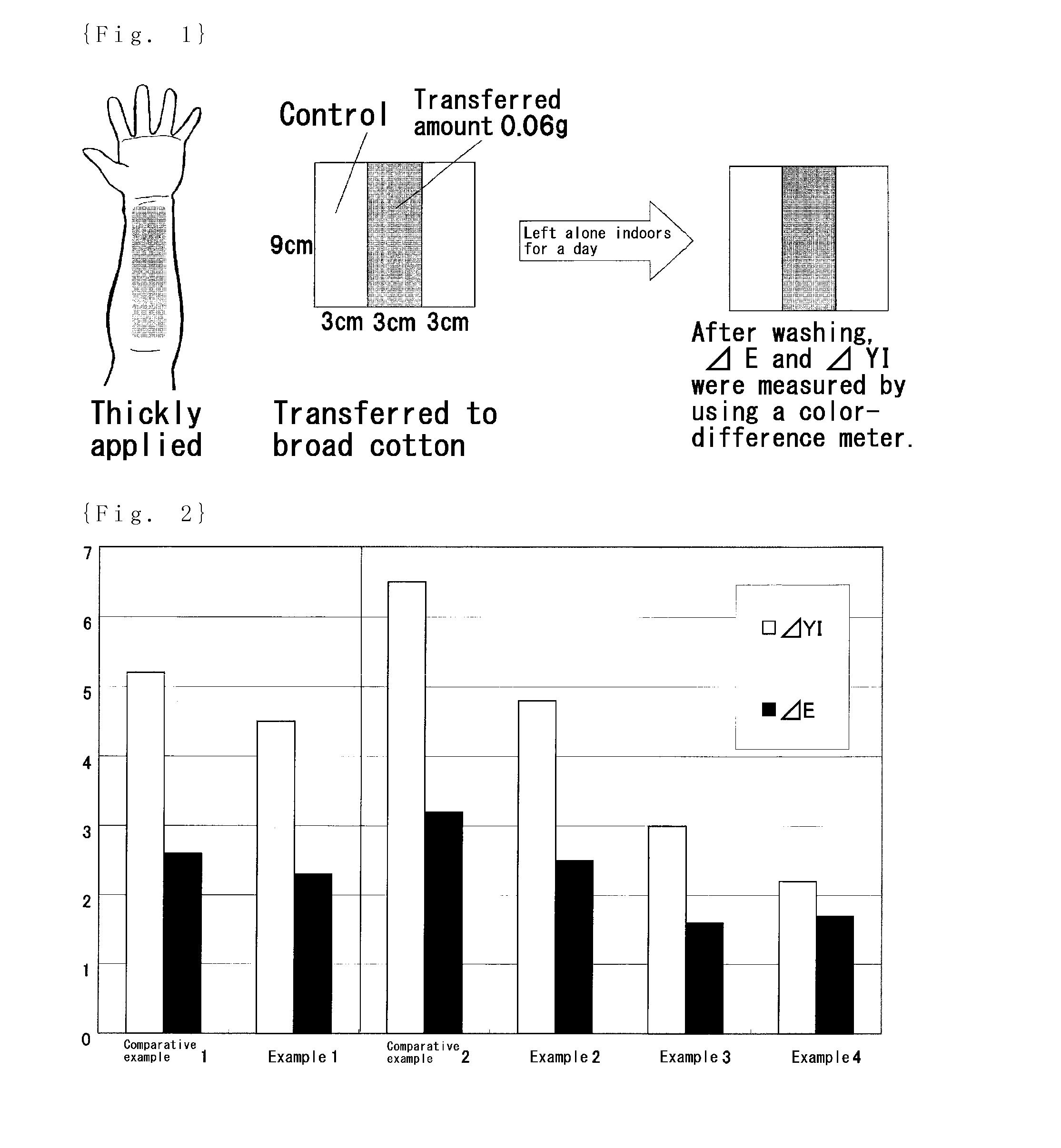

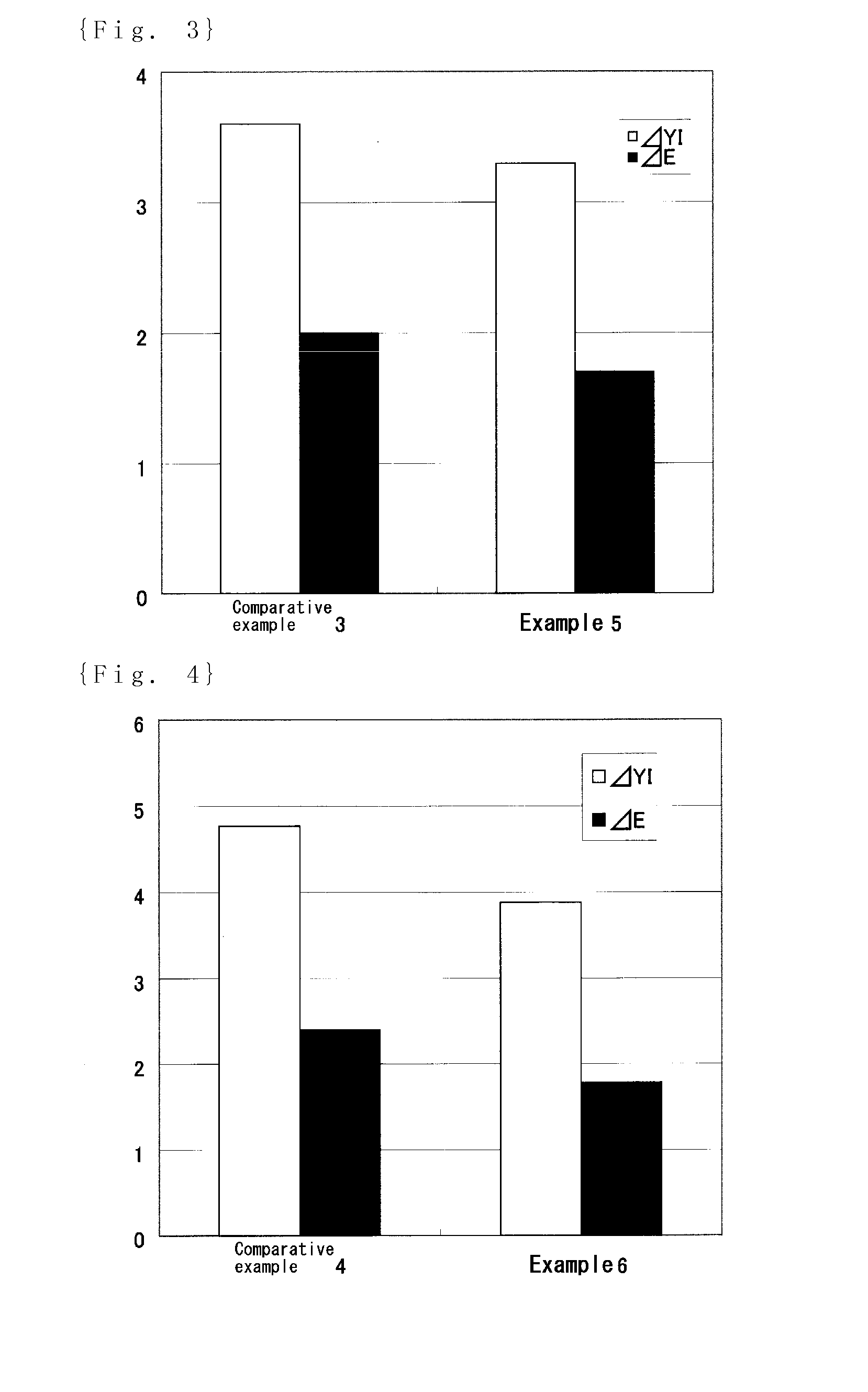

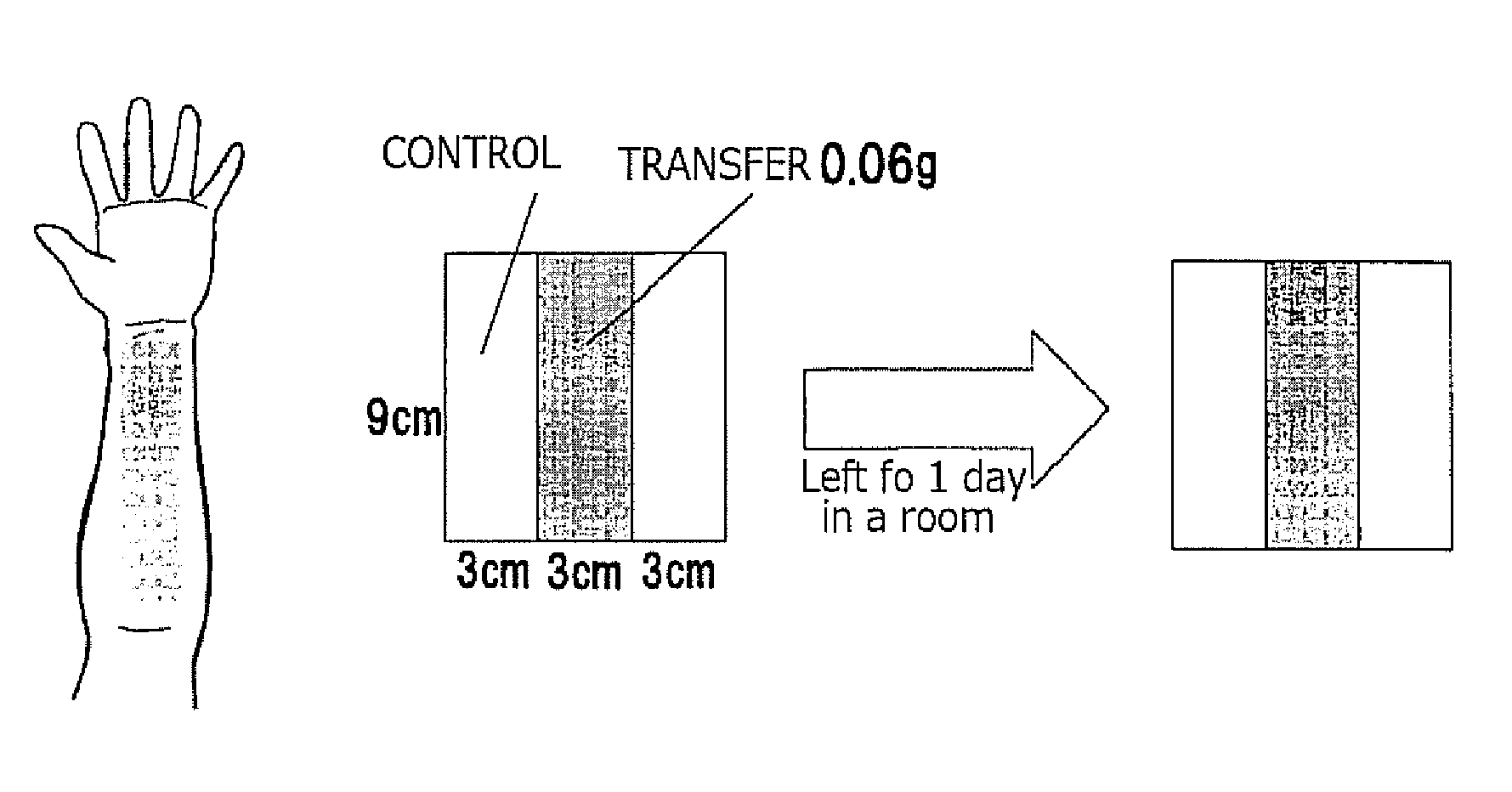

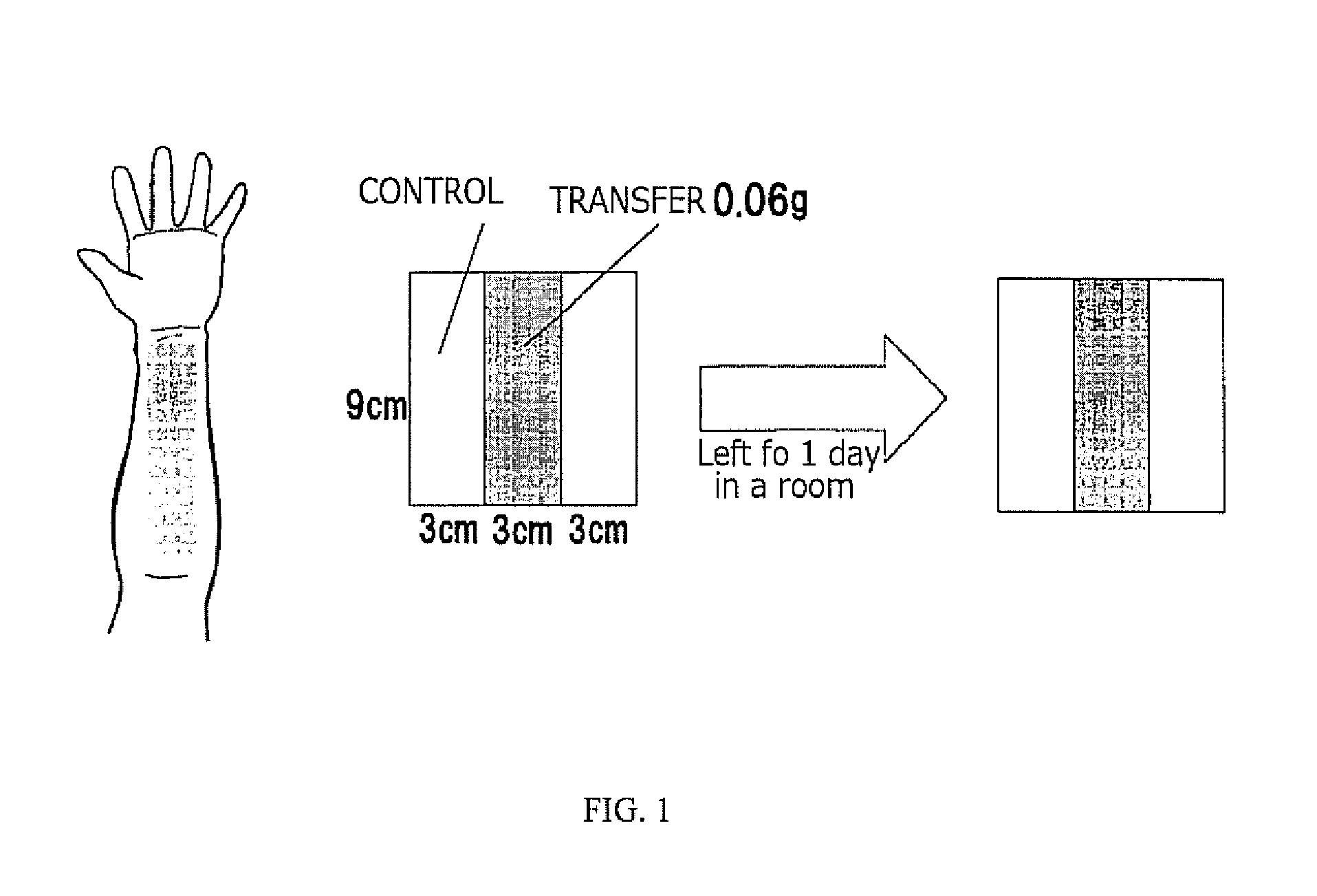

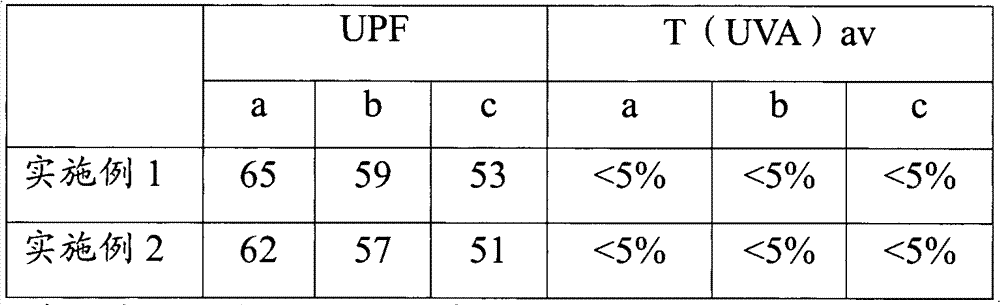

The present invention provides a sunscreen cosmetic comprising: (1) an UVA absorbent selected from one, two or more from hexyl diethylaminohydroxybenzoylbenzoate, 2,4-bis{[4-(2-ethylhexyloxy)-2-hydroxy]-phenyl}-6-(4-methoxyphenyl)-1,3,5-triazine, 4-tert-butyl-4-methoxydibenzoylmethane, and 2-hydroxy-4-methoxybenzophenone, and (2) resin spherical powder containing inside 35% or more of hydrophobicized ultra fine particles of titanium oxide.The object of the present invention is to provide a sunscreen cosmetic containing an UVA absorbent and ultrafine particles of titanium oxide wherein staining of clothing due to secondary adhesion is prevented.

Owner:SHISEIDO CO LTD

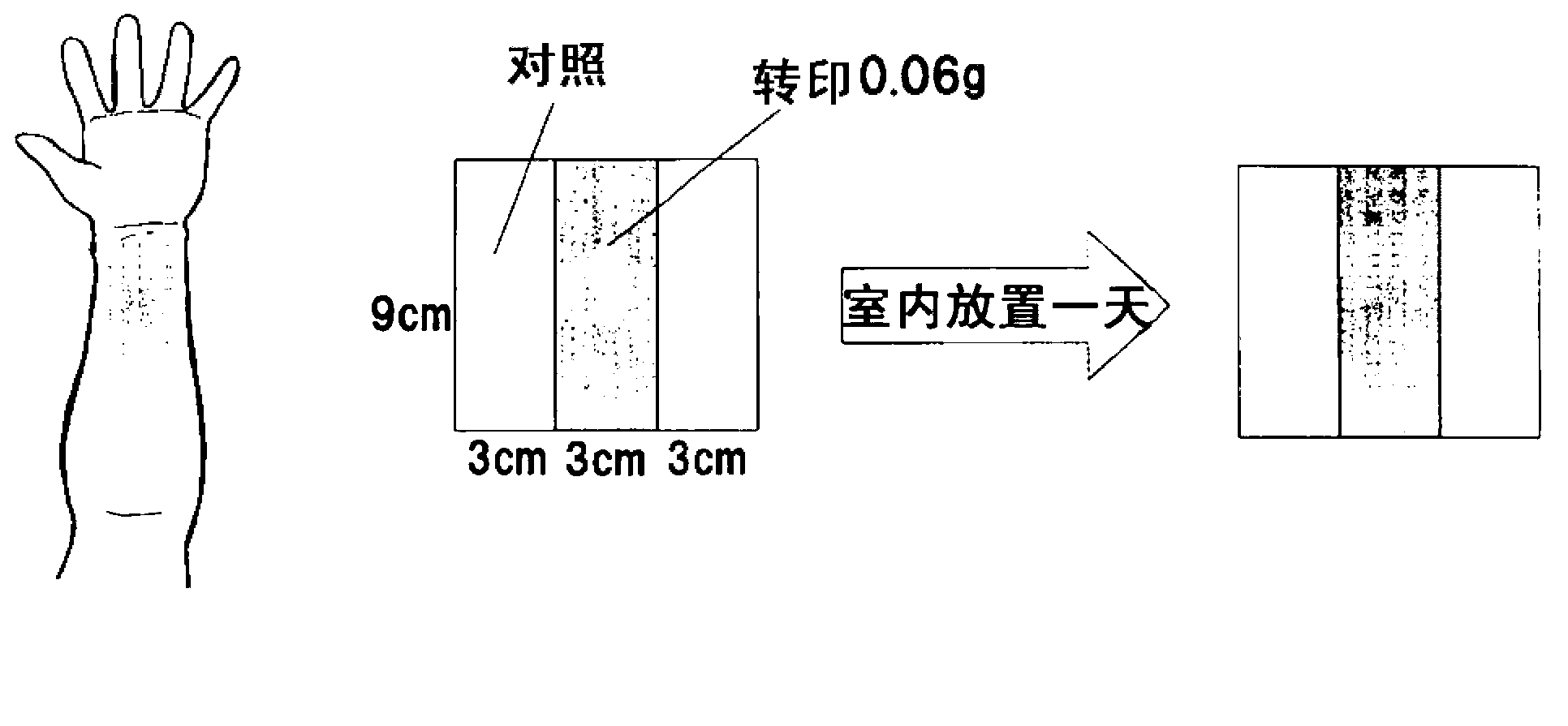

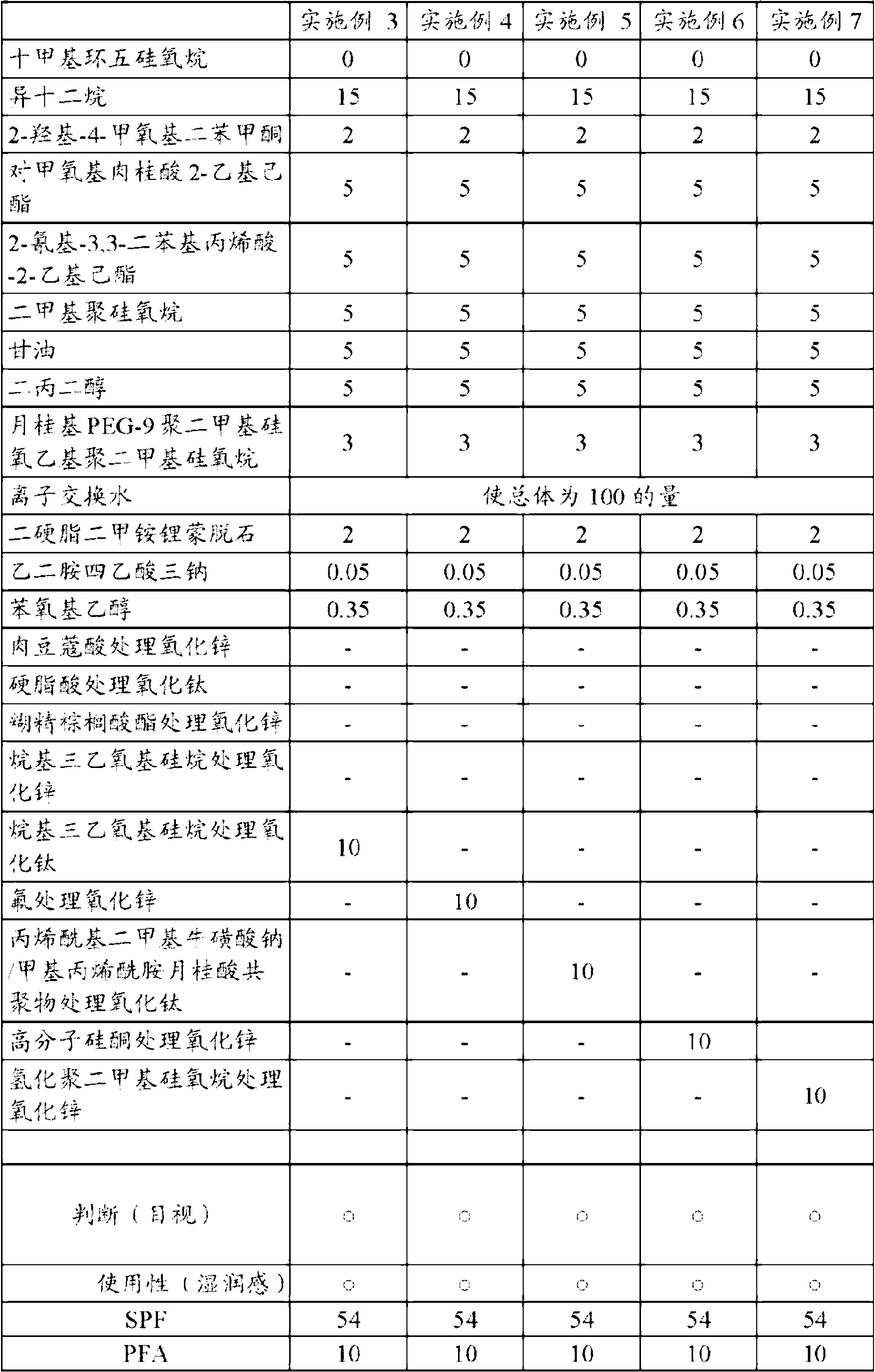

Sunscreen cosmetic

The present invention aims to provide a sunscreen cosmetic that does not contain diethylamino hydroxybenzoyl hexyl benzoate, can absorb a wide range of wavelengths of UV rays across the UVA and UVB regions, and prevent staining (dyeing) due to secondary adhesion to clothing. The present invention relates to a sunscreen cosmetic containing 2-hydroxy-4-methoxybenzophenone, 2-ethylhexyl p-methoxycinnamate, and octocrylene, a volatile hydrocarbon oil, and zinc oxide and / or titanium oxide hydrophobized with an agent other than fatty acids.

Owner:SHISEIDO CO LTD

Optical adhesive and preparation method thereof

InactiveCN104099056AMeet the viscosityFulfil requirementsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesVacuum pumpingAntioxidant

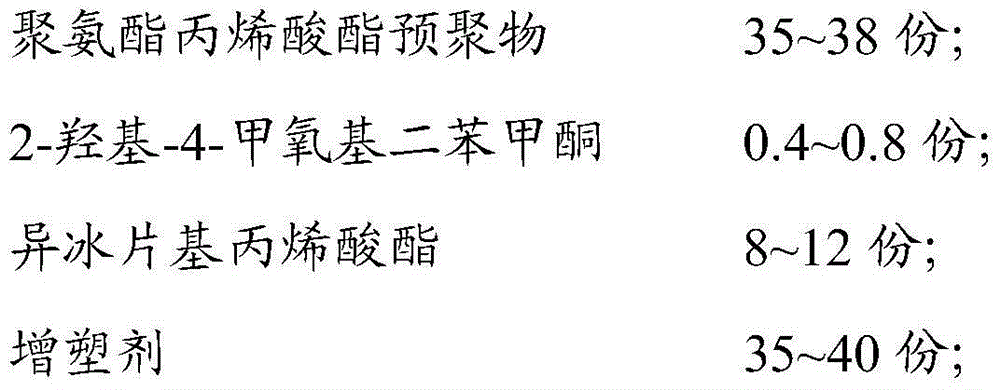

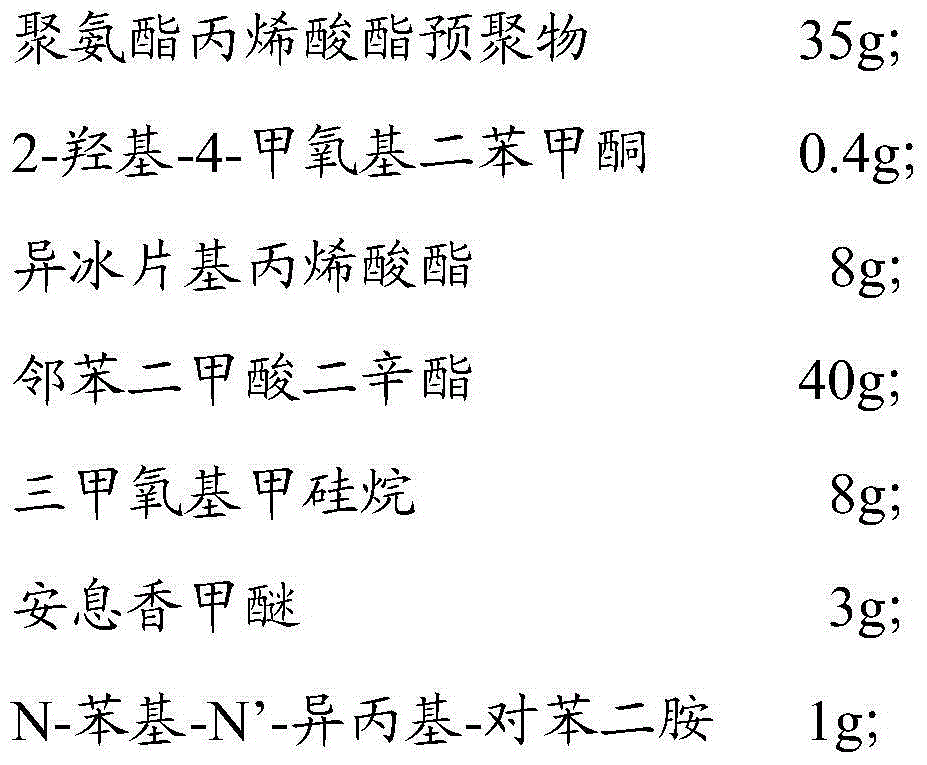

The invention discloses an optical adhesive, which is prepared from the following ingredients in parts by weight through mixing: 35-38 parts of polyurethane-acrylate prepolymer, 0.4-0.8 part of 2-hydroxy-4-methoxybenzophenone, 8-12 parts of isobornyl acrylate, 35-40 parts of a plasticizer, 6-8 parts of a coupling agent, 2-3 parts of a photoinitiator and 1-2 parts of an antioxidant. The invention further discloses a preparation method for the optical adhesive, which comprises the following steps: uniformly mixing the polyurethane-acrylate prepolymer, the 2-hydroxy-4-methoxybenzophenone, isobornyl acrylate, the plasticizer, the coupling agent, the photoinitiator and the antioxidant, heating the mixture to 50-80 DEG C, stirring for reaction for 1.5-1.8 h, performing vacuum-pumping for removing bubbles, and cooling, so that the optical adhesive is prepared. The optical adhesive provided by the invention has the advantages as follows: yellowing and ageing speed of the optical adhesive is lowered in the use process greatly, the service life of the optical adhesive is prolonged, and the refractive index of the optical adhesive is increased.

Owner:TAICANG ZHANXIN ADHESIVE MATERIAL

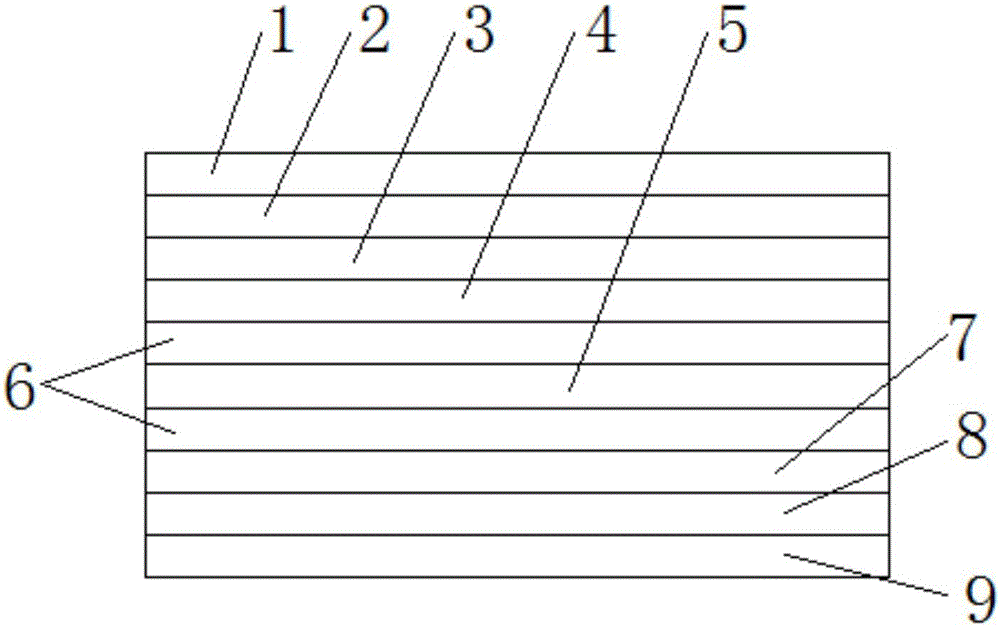

Anti-ultraviolet blue light protection film

InactiveCN106863968AEffective absorptionSimple preparation processNon-macromolecular adhesive additivesSynthetic resin layered productsTectorial membranePolyester

The invention relates to the technical field of polymer films and particularly relates to an anti-ultraviolet blue light protection film. The protection film is a composite film compounded by a polyurethane layer and a polyester layer, wherein the polyurethane layer and the polyester layer are compounded by a compound adhesive layer; the compound adhesive layer is an adhesive coating containing an ultraviolet blue light absorbent; the adhesive is a PVB adhesive; the ultraviolet blue light absorbent is a compound agent prepared from modified or unmodified melanin powder, 2-hydroxy-4-methoxybenzophenone and titanium dioxide. The preparation method of the film is simple; the film has high light transmittance, is capable of effectively absorbing ultraviolet light and blue light, and can be applied to multiple fields such as electronic industrial products and automobile adhesion films and the like according to different thicknesses of the film.

Owner:杭州科翼科技有限公司

Production method of uvioresistant fiber

InactiveCN102851773AImproves UV resistanceImprove bindingArtifical filament manufactureFiberUltraviolet

The invention discloses a production method of uvioresistant fiber. The production method includes the steps of preparing uvioresistant master-batches; mixing and drying uvioresistant compound additive and carrier resin, melting the mixture in a screw extruder for extrusion and pelletizing to obtain the uvioresistant master-batches; producing the uvioresistant fiber; and slicing and blending the uvioresistant master-batches and the fiber, and performing spinning, winding and drafting to obtain the uvioresistant fiber. The uvioresistant compound additive comprises, by weight, 30-40 parts of titanium dioxide, 20-25 parts of aluminum oxide, 3-5 parts of zeolite, 15-20 parts of 2-hydroxy-4-methoxybenzophenone, 10-15 parts of 4-t-butylphenyl salicylate, and 1-5 parts of sodium polyacrylate dispersant. The uvioresistant fiber is high in ultraviolet resistance, highly durable, nontoxic and safe.

Owner:KUNSHAN CITY ZHOUSHI FEIHUANG GARMENT FACTORY

Polymer material used for 3D printing and preparation method thereof

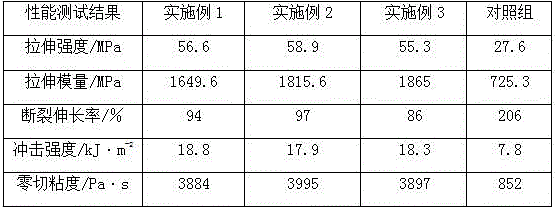

InactiveCN105732915AHigh tensile strengthHigh tensile modulusAdditive manufacturing apparatusPolymer sciencePerformance index

The invention relates to a polymer material used for 3D printing. The polymer material comprises polyurethane acrylate, epoxy resin, ethyl cellulose, polyethylene wax, wollastonite powder, hydrogenated abietinol, epoxy acrylate, 2-hydroxy-4-methoxybenzophenone, trioctyl trimellitate, dipropylene glycol diacrylate, benzidine, polyoxyethylene laurate, nano-nickel oxide, poly(butyl acrylate), trimesic acid, isodecyl acrylate, barium stearate and calcium stearate. The prepared material has higher tensile strength and tensile modulus, retains good toughness, has good performance indexes, such as elongation at break and impact strength, not only has rather high toughness but also has higher heat resistance and good usability.

Owner:王璐

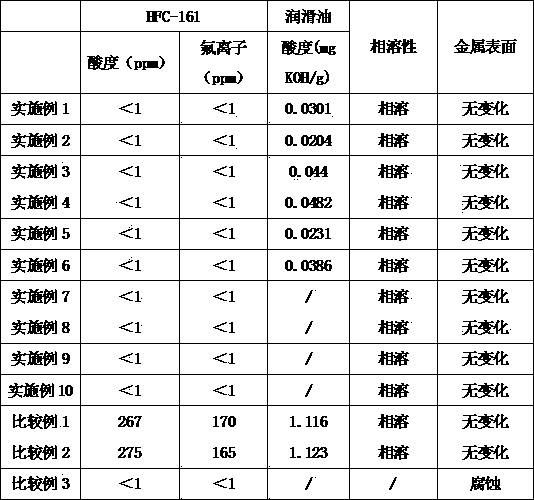

Stabilizer composition suitable for HFC-161 and HFC-161 mixed working medium

InactiveCN103627371AImprove performancePerformance impactHeat-exchange elementsAdditives4-MethoxyphenolBenzophenone

The invention discloses a stabilizer composition suitable for HFC-161 and HFC-161 mixed working medium. The stabilizer composition is composed of two ingredients; a first ingredient is a combination material comprising one, two, or more than three selected from 4-methoxyphenol, 2-hydroxy-4-methoxybenzophenone, 4-tert-butylcatechol, 2, 2-bis(4-Hydroxyphenyl)propane and benzophenone; and the second ingredient is diethylene glycol dimethyl ether and / or 2-(2-Methoxyethoxy)ethanol. The stabilizer composition is capable of ensuring that HFC-161 cycled in a refrigerating system is not decomposed at a high temperature of 175 DEG C.

Owner:SINOCHEM LANTIAN +2

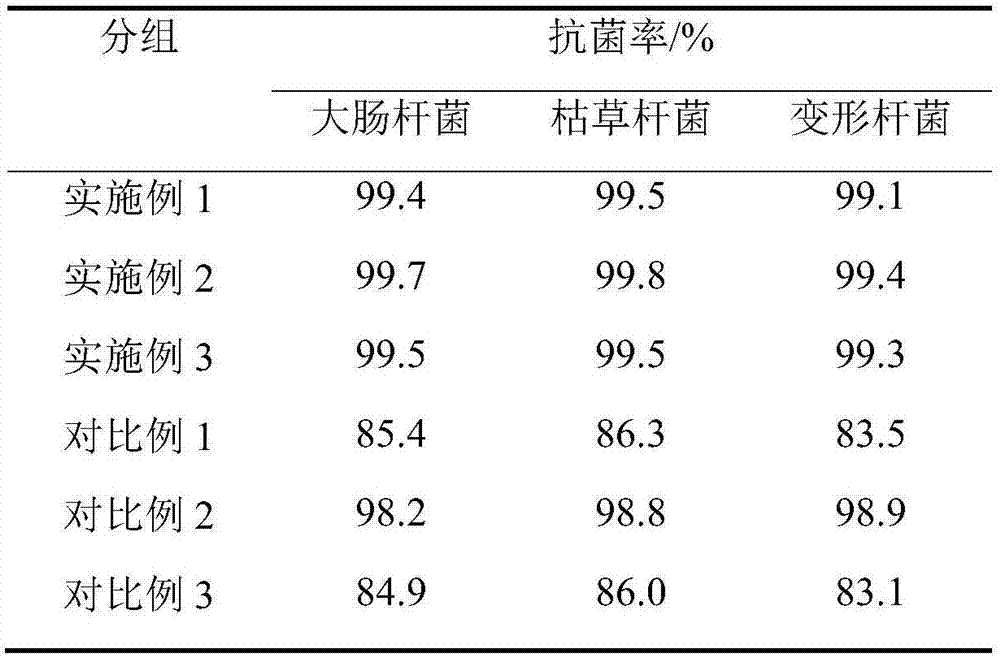

Antibacterial polyethylene pipe and preparation method thereof

ActiveCN107501695AImprove antibacterial propertiesImprove mechanical propertiesSocial benefitsAntioxidant

The invention discloses an antibacterial polyethylene pipe and a preparation method thereof. The antibacterial polyethylene pipe is prepared from, by weight, 97-99 parts of polyethylene resin, 0.1-1.0 part of crosslinking agent, 0.2-1.2 parts of antioxidant, 0.1-0.5 part of compatilizer, 0.1-0.5 part of 2-hydroxy-4-methoxybenzophenone, 0.1-0.3 part of antibacterial agent, 0.05-0.09 part of antibacterial synergist and 0.1-0.2 part of modifier. Through double action of the antibacterial agent and the antibacterial synergist, antibacterial performance of the polyethylene pipe is improved remarkably, bacteria and microorganism cells are killed, secondary pollution in the process of water delivery is reduced, and water is maintained clean and sanitary. The modifier can remarkably enhance mechanical performance of the polyethylene pipe. The preparation method is simple and easy to implement and has great application prospect and social benefit.

Owner:HONGYUE PLASTIC GROUP

Anti-ultraviolet composite fireproof glass

The invention discloses a fireproof composite structure glass that can effectively block ultraviolet rays. The glass includes two glass substrates, between which a fireproof layer is stuffed. The fireproof layer comprises, by weight: 50% of methyl methacrylate, 15% of dibutyl ester, 20% of sodium sulfite, 1.3% of zinc oxide (ZNO), 3% of magnesium hydroxide, 0.2% of benzyl butyl phthalate, 10% of acrylamide, 0.1% of ethanol, and 0.4% of 2-hydroxy-4-methoxybenzophenone. By adopting the fireproof layer with the formula, ultraviolet rays can be effectively blocked, good fire resistance can be achieved, and the fireproof layer is unlikely to undergo foaming under a long-term use state, therefore, the light transmission performance is good.

Owner:杭州福隆鼎门窗幕墙有限公司

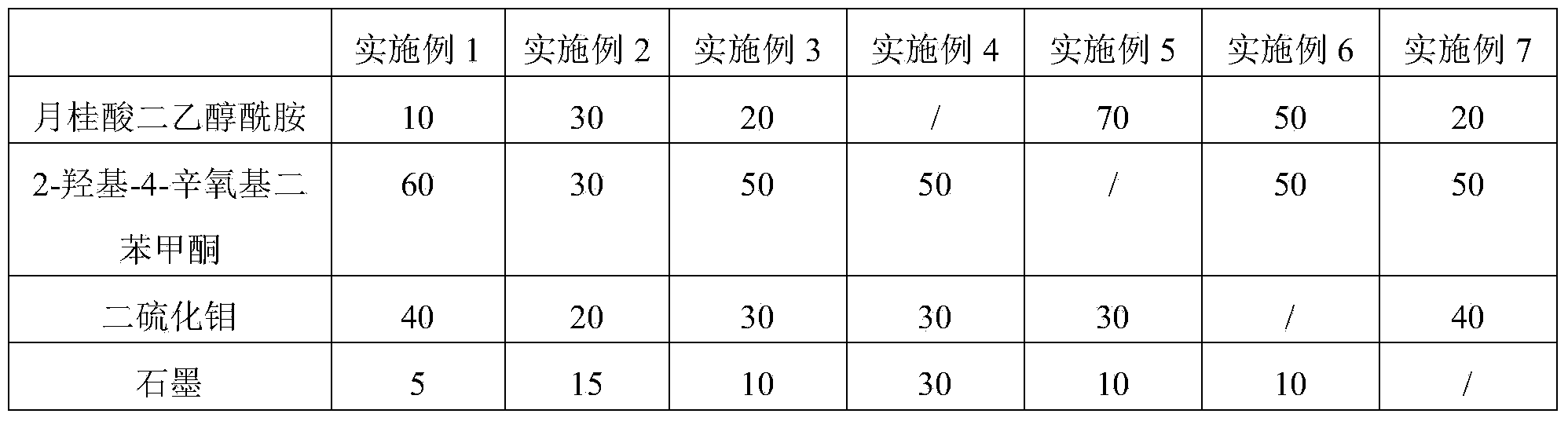

Toughened scratch-resistant PP/HDPE (Polypropylene/High Density Polyethylene) plastics for automotive interior trim parts and preparation method thereof

The invention discloses toughened scratch-resistant PP / HDPE (Polypropylene / High Density Polyethylene) plastics for automotive interior trim parts and a preparation method thereof. The toughened scratch-resistant PP / HDPE plastics for the automotive interior trim parts contain the following ingredients in parts by weight: 80 parts of PP resin, 5-15 parts of HDPE resin, 1-5 parts of coupling agent, 10-25 parts of toughening agent and 0.1-5 parts of scratch resisting agent. Preferably, the toughening agent is one or a mixture of several of peanut shell powder, walnut shell powder and cottonseed hull powder; the scratch resisting agent is one or a mixture of several of lauric diethanolamide, 2-hydroxy-4-methoxybenzophenone, molybdenum disulfide and graphite. The toughened scratch-resistant PP / HDPE plastics are low in production cost, good in processability and good in toughness and scratch resistance, can achieve waste recycling and are environment-friendly. The toughened scratch-resistant PP / HDPE plastics for the automotive interior trim parts are particularly applicable to the injection molding of various automotive interior trim parts.

Owner:湖北瀚氏汽车零部件有限公司

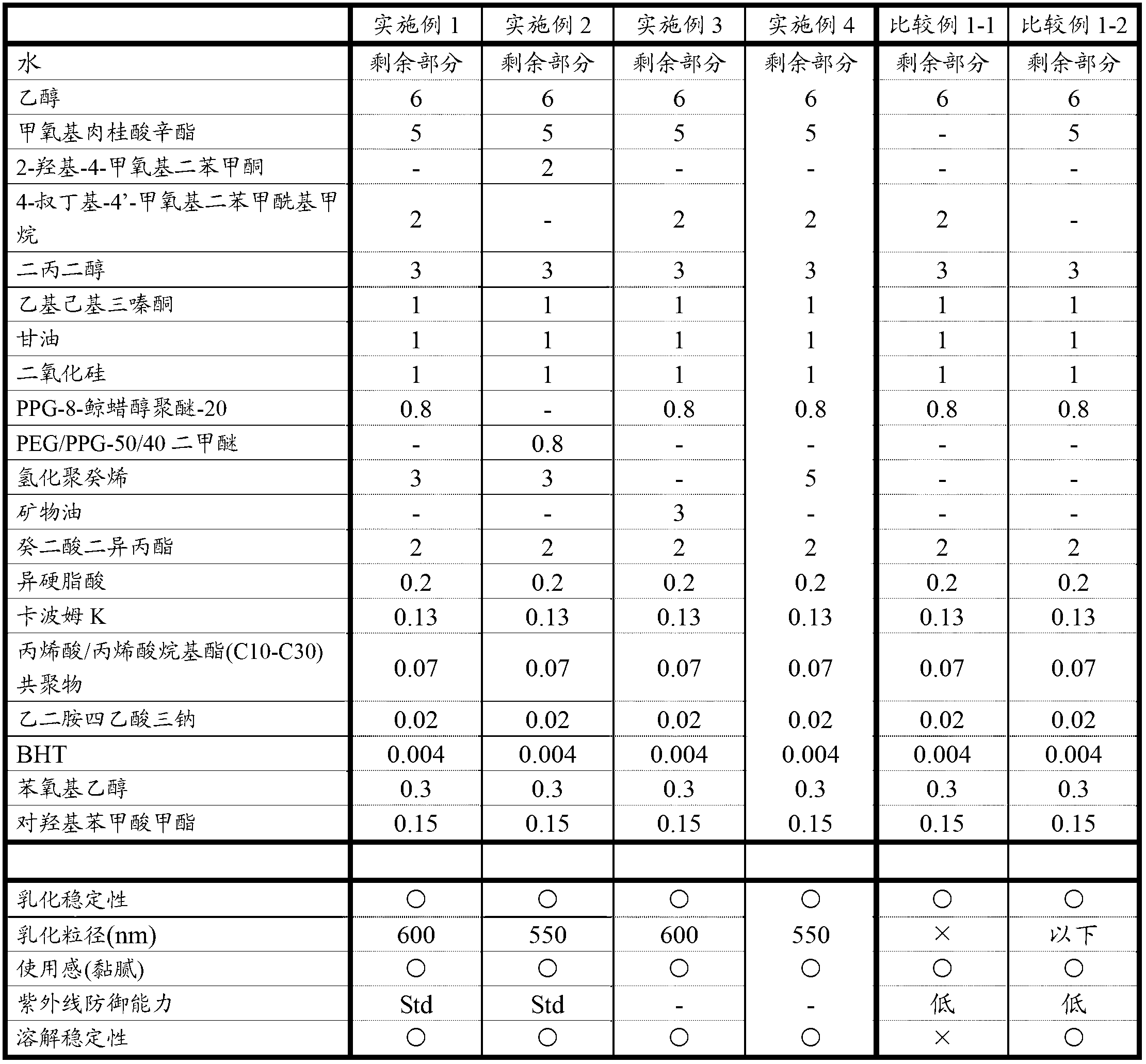

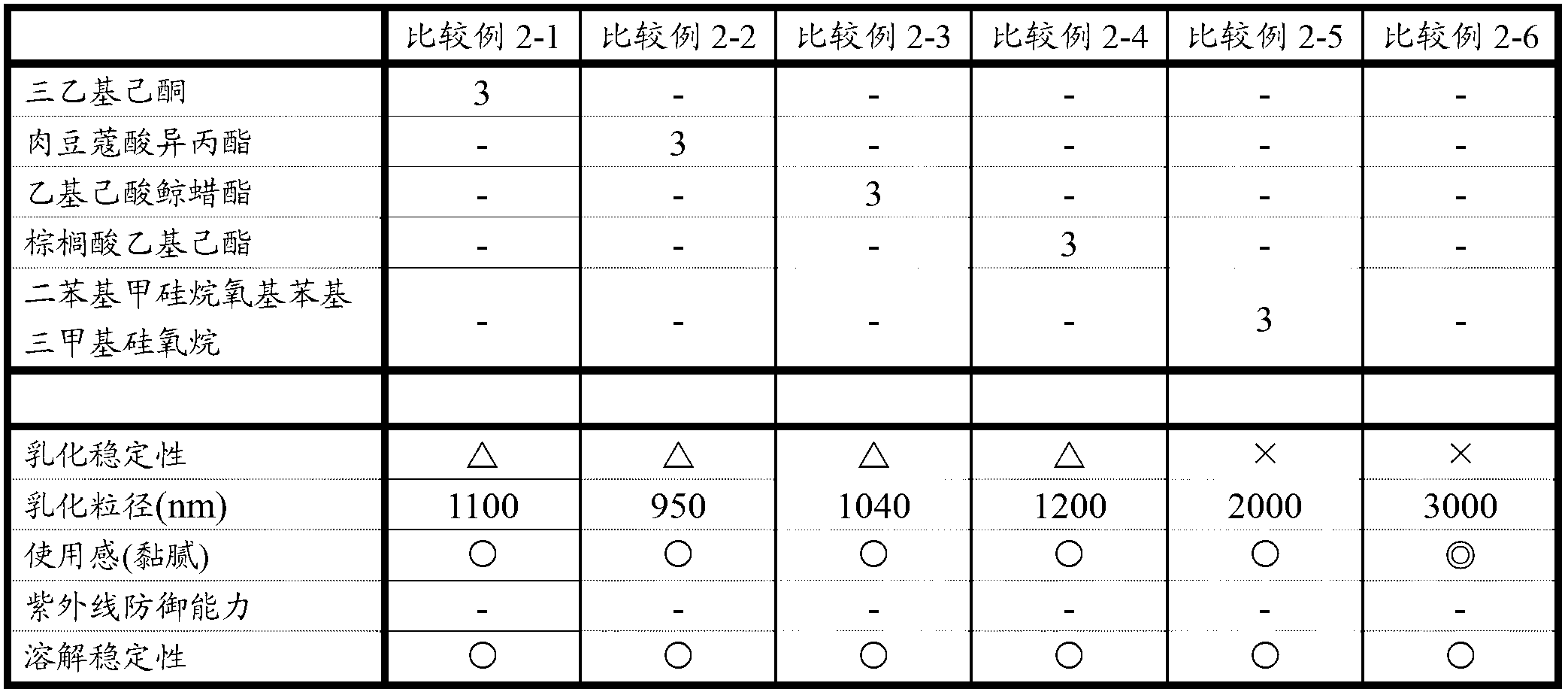

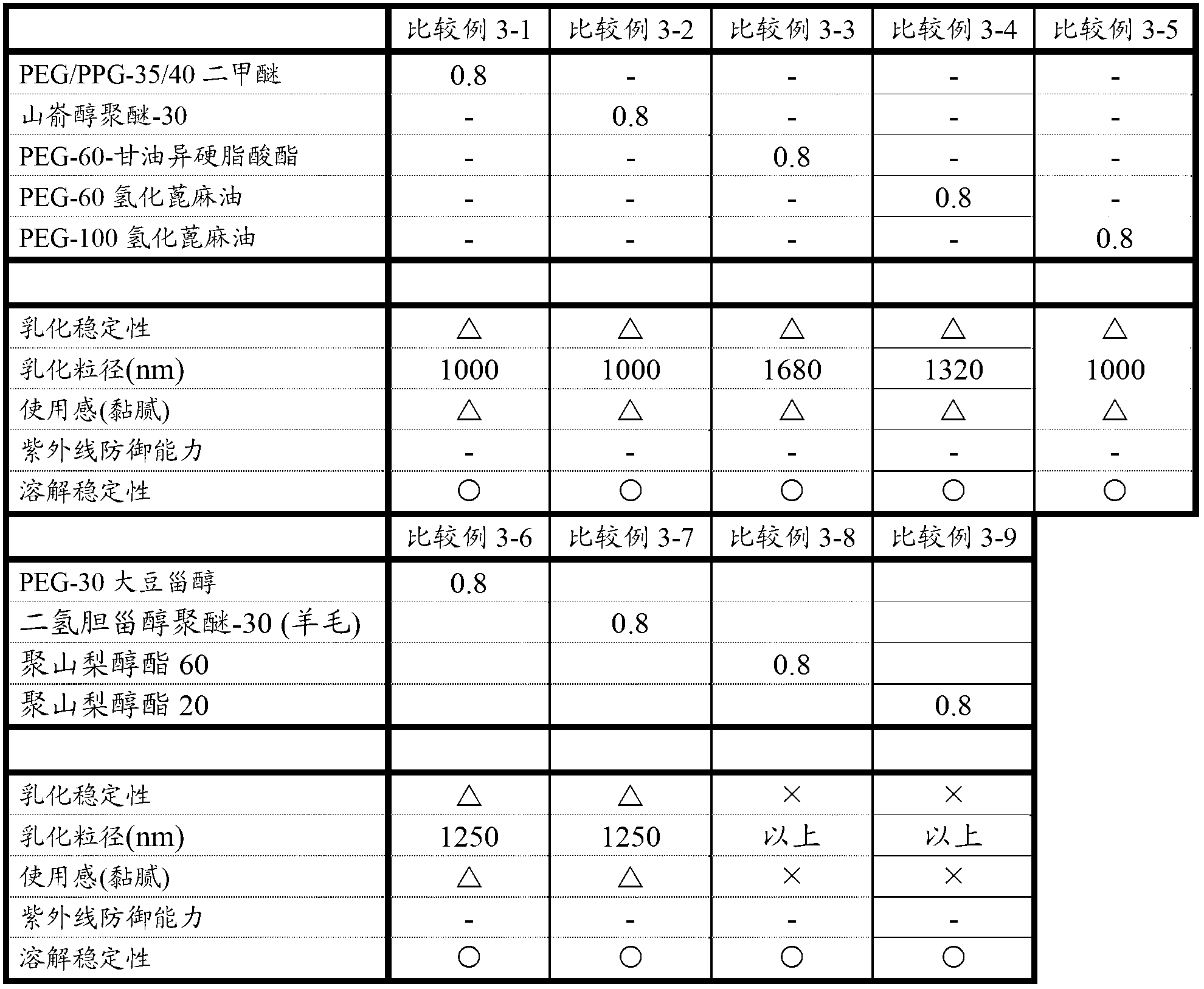

Oil-in-water emulsion sunscreen cosmetic composition

ActiveCN102740825AImprove UV protection effectEasy to useCosmetic preparationsToilet preparationsUltravioletUv absorber

Disclosed is an oil-in-water emulsion sunscreen cosmetic composition which has improved ultraviolet blocking capability by containing a large amount of an ultraviolet absorbent, while having excellent emulsion stability and good usability. Specifically disclosed is an oil-in-water emulsion sunscreen cosmetic composition which is characterized by containing (A) 1-7.5% by mass of octyl methoxycinnamate, (B) 0.5-4% by mass of t-butyl methoxybenzoyl methane and / or 2-hydroxy-4-methoxybenzophenone, (C) 0.5-3% by mass of a polyoxyethylene-polyoxyalkylene alkyl ether block polymer having a specific structure and (D) not less than 10% by mass of a nonpolar oil relative to the total amount of the oil component. The oil-in-water emulsion sunscreen cosmetic composition is also characterized by having an average emulsion particle diameter of not more than 700 nm.

Owner:SHISEIDO CO LTD

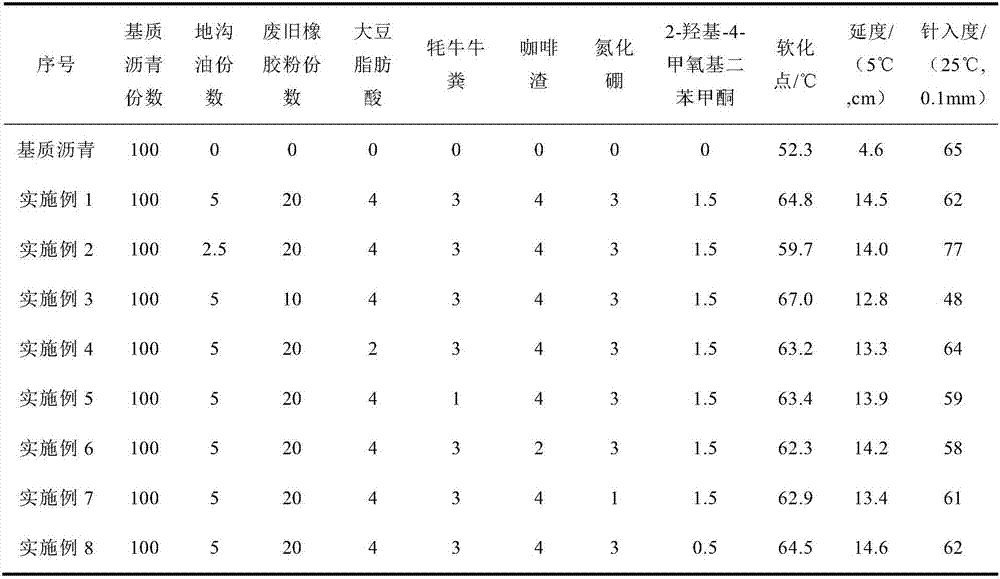

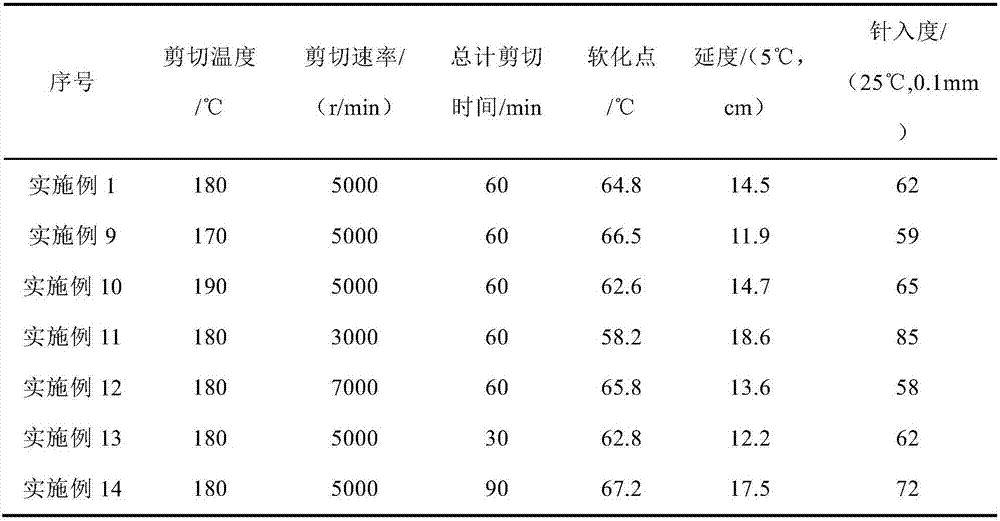

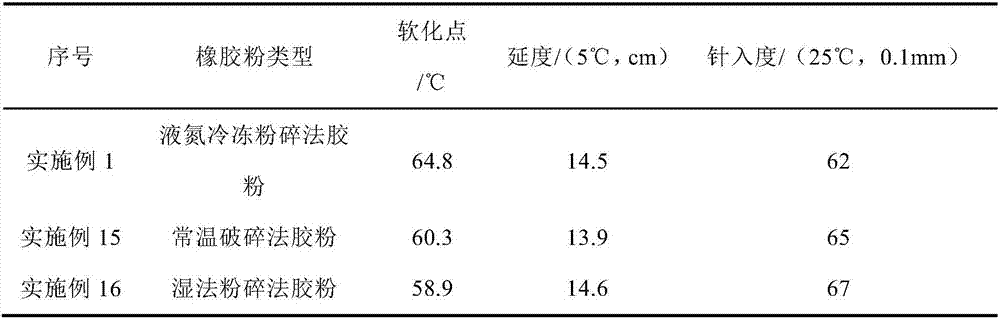

Composite modified asphalt based on multi-component biomass material, and preparation method thereof

InactiveCN106947271ALarge particle sizeLight in massBuilding insulationsRoad engineeringWaste rubber

Owner:CHANGAN UNIV

Ultraviolet light blocking agent and anti-UV treatment process of nylon skin clothing fabric using ultraviolet blocking agent

InactiveCN109295730AGood dispersionImproves UV resistanceBiochemical fibre treatmentLight resistant fibresUltraviolet lightsPolyethylene glycol

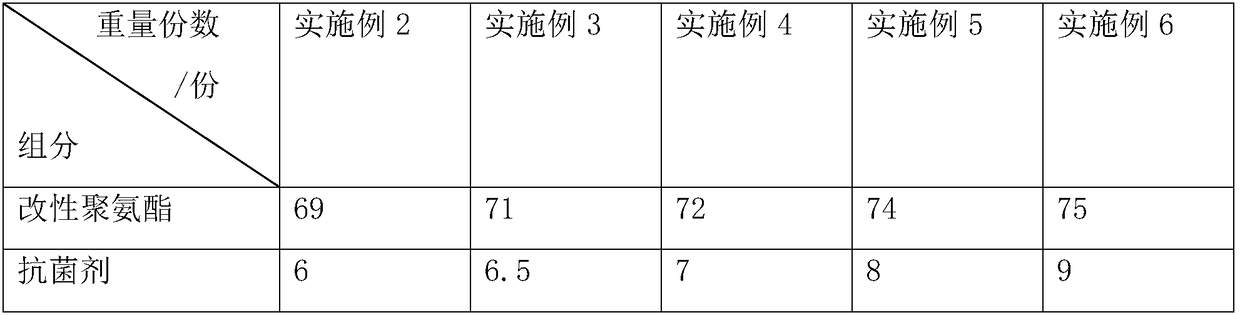

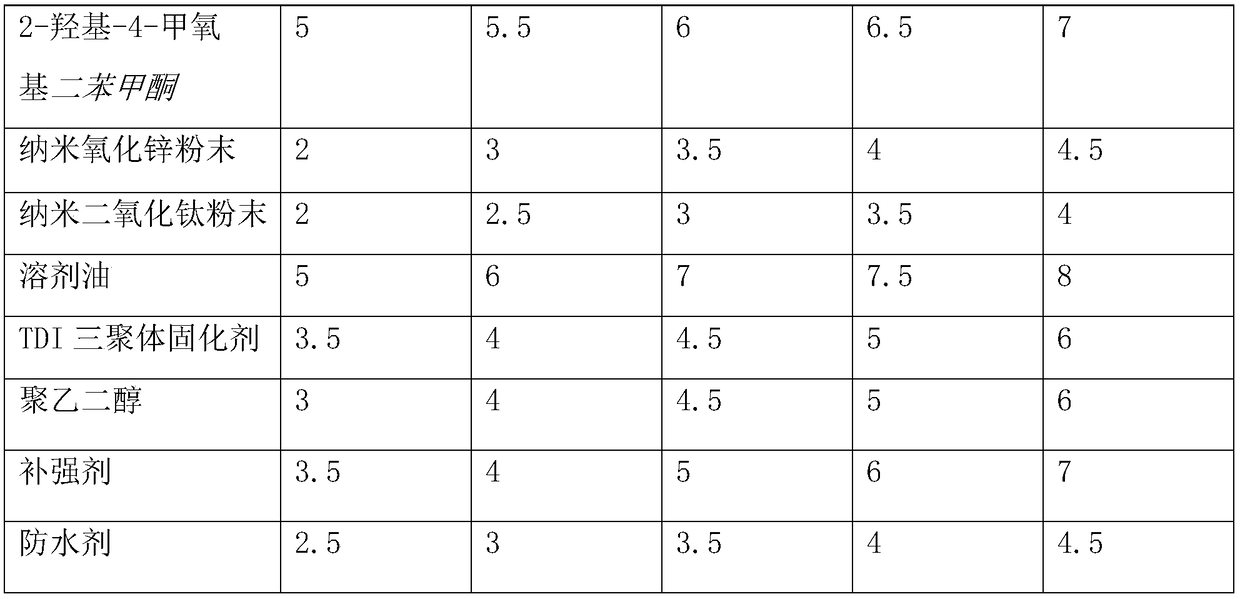

The invention discloses an ultraviolet blocking agent, and relates to the technical field of fabric after finishing, and the ultraviolet blocking agent is composed of the following components in partsby weight: 68-75 parts of modified polyurethane, 5-9 parts of an antibacterial agent, 4-7 parts of 2-hydroxy-4-methoxybenzophenone, 2-4.5 parts of nano zinc oxide powder, 2-4 parts of nano titanium dioxide powder, 5-8 parts of solvent oil, 3-6 parts of a TDI trimer curing agent and 2-6 parts of polyethylene glycol; the antibacterial agent comprises the following components by weight: 20-35 partsof silver sulfonate, 12-34 parts of Polyhexamethylene biguanidine hydrochloride, 5-15 parts of aloe vera juice and 6-12 parts of Dimethyl octadecyl ammoniumchloride. The ultraviolet blocking agent solves the problem that the nylon skin clothing fabric has poor anti-ultraviolet effect and antibacterial effect, and the ultraviolet blocking agent added with the antibacterial agent can improve the antibacterial property while improving the anti-ultraviolet effect.

Owner:新天地纺织印染(嘉兴)有限公司

Energy-saving material with thermal insulation function

ActiveCN104803657AImprove thermal insulationImprove thermal insulation and energy savingFiberThermal insulation

The invention discloses an energy-saving material with a thermal insulation function. The energy-saving material comprises raw materials as follows: aerogel, coal ash, isocyanate, decabromodiphenyl ethane, sulfonated acetone formaldehyde, a liquid epoxy resin dispersing agent, polyurethane, rice hulls, a coupling agent, mullite fibers, ceramic microbeads, bis(2,2,6,6-tetramethyl-4-piperidyl) sebacate, 2-hydroxy-4-methoxybenzophenone and an ultraviolet light absorber. According to the energy-saving material, the thermal insulation performance is good, the dry density of a product is 160-200 kg / m<3>, the heat conductivity coefficient is 0.02-0.03 W / (m*K), and the product has good thermal insulation and energy saving effects; the fireproof performance is good, the fire endurance is longer than 3 h and can meet the level-A fire protection standard, and accordingly, good fire resistance is achieved; the sound insulation performance is good, and noise influence can be greatly reduced; the endurance is good, and the material has the characteristics of high-temperature and low-temperature resistance, corrosion resistance, ultraviolet irradiation resistance and good weather fastness.

Owner:CHONGQING JIAOTONG UNIVERSITY

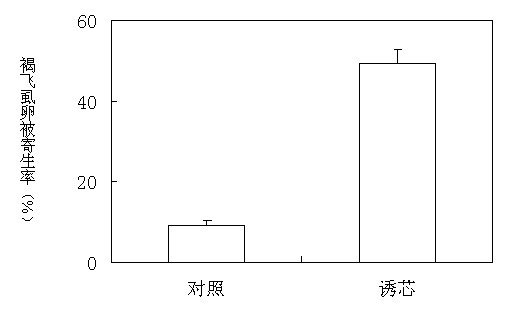

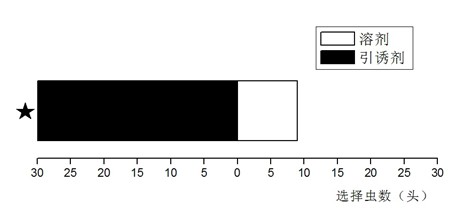

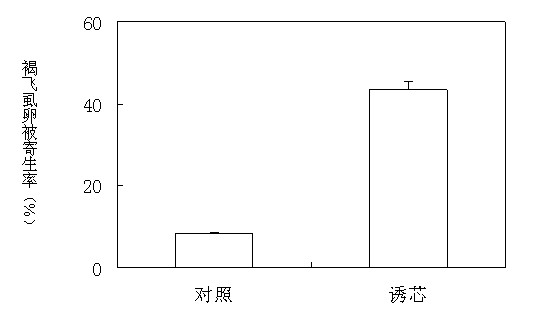

Attractant for Anagrus nilaparvatae (natural enemies of rice planthoppers) for effectively controlling quantity of rice planthopper adults

The invention discloses an attractant for Anagrus nilaparvatae (natural enemies of rice planthoppers), which comprises components including gaultherolin, cis-3-hexenal, liquid paraffin, 2, 6-di-tert-butyl-p-cresol and 2-hydroxy-4-methoxybenzophenone in a weight ratio of (0.01-0.10): (0.01-0.10):(0.2-2):(0.01-0.1):(0.01-0.1). In the invention, the attractant is made by artificially synthetic pest attracting volatile matters and can attract female adults of Anagrus nilaparvatae which are important natural enemies of rice planthoppers in ovigerm stage to reduce the quantity of rice planthopper colonies and reduce the damage of the rice planthoppers. The attractant has the characteristics of low cost, high efficiency, environmental friendliness, safety for human beings and livestock and the like.

Owner:ZHEJIANG UNIV

Preparation method for aluminum-plated paper packaging material for cigarettes

The invention discloses a preparation method for an aluminum-plated paper packaging material for cigarettes. The preparation method comprises the following steps: (1) coating a polyester thin film with stripping coating, wherein the stripping coating layer consists of the components in percentage by weight: 18-22 percent of cellulose acetate resin, 7-9 percent of bi-chloride-vinyl resin, 24-26 percent of acrylic resin, 1.5-2.5 percent of polypropylene wax, 1-2 percent of dioctyl phthalate, 0.5-1.5 percent of a titanate coupling agent, 0.2-0.4 percent of 2-hydroxy-4-methoxybenzophenone, 0.1-0.2 percent of dibutyltin dilaurate and the balance of butanone; (2) performing vacuum aluminum plating; (3) adhering composite paper; (4) performing stripping to obtain the aluminum-plated paper packaging material for the cigarettes.

Owner:WUXI HUANGSHENG PACKING PROD

Ultraviolet-resistant anti-aging paint for external walls and preparation method thereof

InactiveCN104387878AHas UV absorbing effectGood adhesionPolyurea/polyurethane coatingsRadiation-absorbing paintsDispersityWater based

The invention discloses an ultraviolet-resistant anti-aging water-based paint for external walls. The invention is characterized in that the water-based paint is prepared from the following raw materials in parts by weight: 28-30 parts of pure acrylic emulsion, 9-11 parts of water-based polyurethane resin, 3-5 parts of granite powder, 4-6 parts of precipitated barium carbonate, 0.8-1 part of 2-hydroxy-4-methoxy diphenyl ketone, 4-6 parts of silicon dioxide, 3-5 parts of paper clay, 2-3 parts of ethylene tar, 1-1.5 parts of dispersing agent NNO, 6-8 parts of modified round-grain mortar and 25-30 parts of water. By adopting the special formula and combining the sand wall paint and ultraviolet-resistant paint, the 2-hydroxy-4-methoxy diphenyl ketone has ultraviolet absorption effect; and by adding the modified round-grain mortar, the water-based paint has the advantages of favorable dispersion effect, high hardness and favorable wear resistance. The coated film has the advantages of beautiful tactile sensation, light weight, favorable dispersity, favorable adhesiveness and elegant appearance, can not increase the pressure of the building, and can satisfy different decoration demands.

Owner:HEFEI BULAOCHUANQI HEALTH CARE TECH

Making method for anti-ultraviolet all-cotton shirt

The invention discloses a making method for an anti-ultraviolet all-cotton shirt. The method comprises the steps of: 1) conducting liquid ammonia treatment on an all-cotton shirt fabric; 2) mixing 3-5 parts of coconut oil fatty acid monoethanolamide, 7-8 parts of zeolite, 7-8 parts of salicylic acid-4-tert-butyl phenyl ester, and 8-9 parts of 2-hydroxy-4-methoxy benzophenone, then slowly adding 2-3 parts of vinyl trimethoxy silane, 3-4 parts of sodium polyacrylate, 20-25 parts of titanium dioxide and 30-35 parts of aluminum oxide at the same time, controlling the charging time within 30-35min, then conducting further mixing for 1-2h, thus obtaining an anti-ultraviolet finishing agent; 3) subjecting the fabric to dip padding treatment in an impregnating solution containing 45-50% of the anti-ultraviolet finishing agent, keeping the pressure at 1-2MPa and the liquid rate at 73-75%, performing drying, then keeping the fabric at a constant temperature of 130-135DEG C for 30-35min; 4) subjecting the treated fabric to drying, cutting, and garment making; and 5) carrying out steam finishing and shaping at 160-165DEG C for 5-8min. The all-cotton shirt made by the method provided by the invention has the advantages of excellent anti-ultraviolet function, strong durability, no toxicity and safety.

Owner:常熟市赵市圣丹龙制衣厂

ABS (Acrylonitrile Butadiene Styrene) resin-polyethylene composite modified plastic

The invention discloses ABS (Acrylonitrile Butadiene Styrene) resin-polyethylene composite modified plastic. The composite modified plastic comprises ABS resin, polyethylene and additives, wherein the additives include a toughening agent, a compatilizer, a weather-resistant agent, a nucleating agent and a heat stabilizer; the toughening agent is polyvinyl butyral; the compatilizer is modified polyacrylic ester; the weather-resistant agent is 2-hydroxy-4-methoxybenzophenone; the nucleating agent is zirconium oxide; the heat stabilizer is dioctyl(maleate)tin. The prepared ABS resin-polyethylene composite modified plastic has the effects of high intermiscibility, high transparency, high mechanical strength, high weather resistance, high heat stability and the like.

Owner:苏州市涵信塑业有限公司

High weathering resistance fire retardation ABS composite material

The invention relates to a high weathering resistance fire retardation ABS composite material, which comprises the following raw materials, by mass, 70-85 parts of a ABS resin material, 5-10 parts of PEI, 0.5-1 part of polytetrafluoroethylene, 0.5-1 part of a lubricant, 0.1-0.5 part of an ultraviolet absorber, 0.4-0.6 part of an antioxidant, and 10-20 parts of a fire retardation agent, wherein the ABS resin is an acrylonitrile-butadiene-styrene copolymer, the lubricant is calcium stearate or tristearin, the ultraviolet absorbent is 2-hydroxy-4-methoxybenzophenone, 2-hydroxy-4-n-octyloxy benzophenone or 2-(2'-hydroxy-3',5'-di-tert phenyl)-5-benzotriazole chloride, and the fire retardation agent is one or two selected from triphenyl phosphate and ultrafine magnesium hydroxide. According to the present invention, PEI and ABS are compounded, and then a fire retardation agent, polytetrafluoroethylene, an ultraviolet absorber and an antioxidant are added so as to improve mechanical property, weathering resistance and fire retardation of the material.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

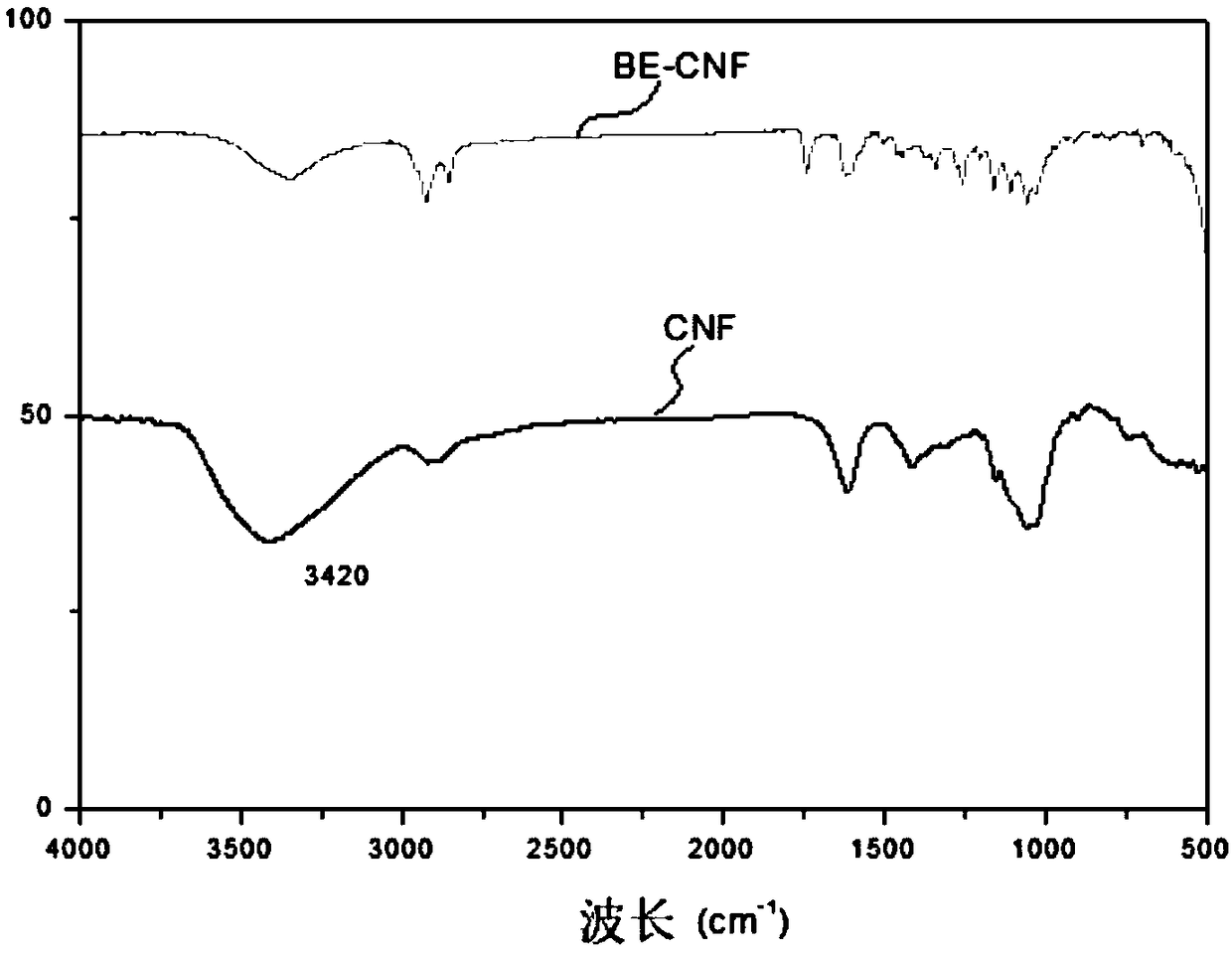

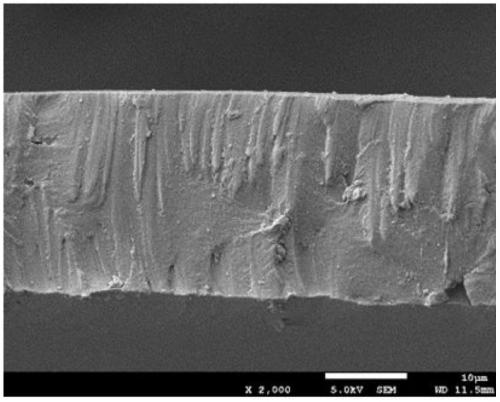

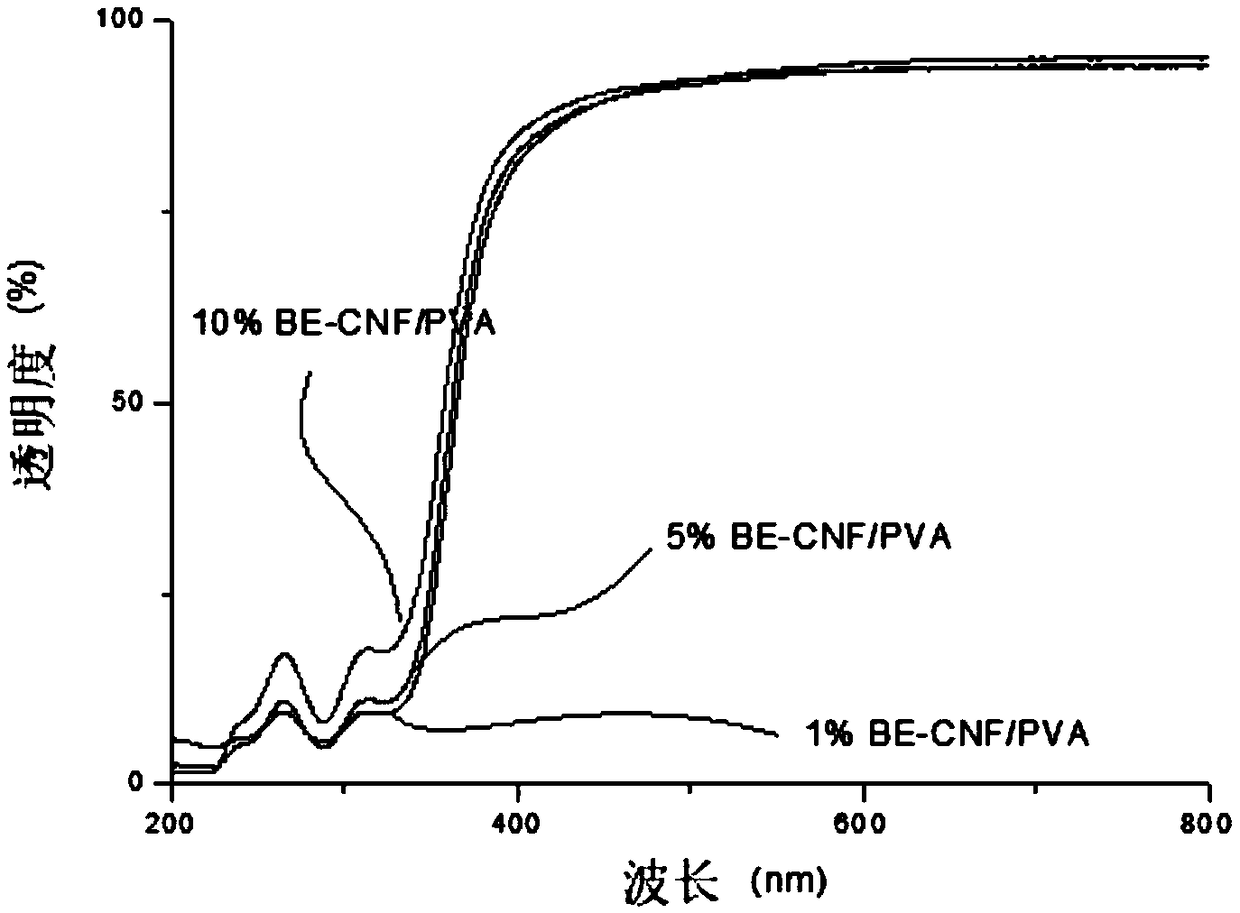

Highly-transparent anti-ultraviolet nano-cellulose composite film and production method thereof

The invention discloses a highly-transparent anti-ultraviolet nano-cellulose composite film and a production method thereof. The matrix of the composite film is polyvinyl alcohol, and a reinforcing phase is modified cellulose nano-fibers. The production method comprises the following steps: preparing cellulose nano-fibers modified with 2-hydroxy-4-methoxybenzophenone and epoxidized soybean oil; and mixing the modified cellulose nano-fibers with a polyvinyl alcohol-water solution according to a certain mass ratio, and drying the obtained mixture in an oven to obtain the uniform and transparentcomposite film. Raw materials in the invention are derived from biomass, so the composite film is biodegradable, and has good biocompatibility. The shortcoming of poor stability of a small-molecule ultraviolet absorbent is overcome, and the epoxidized soybean oil can be used as a plasticizer to increase the flexibility of the composite film. Nano-particles in the composite film are uniformly dispersed in the matrix, the composite film has a high transparency and can provide a significant anti-ultraviolet effect, and the ultraviolet protection effect can be controlled by controlling the addition amount of the nano-particles in the film.

Owner:NANJING FORESTRY UNIV

Automobile windshield

InactiveCN106183243ALight in massReduce quality problemsWindowsWindscreensButylbenzyl phthalate2-hydroxy-4-methoxybenzophenone

The invention belongs to the technical field of automobile parts and discloses an automobile windshield. The automobile windshield comprises a hydrophobic layer, a buffer layer, a heat insulating layer, first tempered glass, vacuum glass, a transparent damping film, second tempered glass, a safety layer and a water absorption layer. The hydrophobic layer and the buffer layer are bound, and the buffer layer and the heat insulating layer are bound. The buffer layer is arranged, the anti-seismic property of the windshield can be good, mass is small, the mass of an automobile can be reduced, the economical property of the automobile can be improved, and use is safe and convenient; the transparent damping film is arranged, a particle structure is arranged in the transparent damping film, and therefore a heat insulating effect can be achieved; the vacuum glass is arranged, and therefore a sound insulating effect can be achieved; the heat insulating layer prepared from 2-hydroxy-4-methoxybenzophenone, benzyl butyl phthalate and zinc oxide is arranged, therefore, the heat insulating effect is achieved, ultraviolet light in light can be filtered out, and the health of the human body can be protected.

Owner:泉州市科茂利通智能科技有限公司

Nano multifunctional paint additive

InactiveCN103555044AAnti-mildewAnti-mildew effectAntifouling/underwater paintsPaints with biocidesEmulsionUltraviolet

The invention relates to preparation method of a nano multifunctional paint additive. The nano multifunctional paint additive is characterized in that a composition consists of nano zinc dioxide, 2-hydroxy-4-methoxy diphenyl ketone, silver-loaded nano zirconium phosphate, dimethyl benzyl dodecyl ammonium bromide, auxiliary materials and water. The composition contains nano zinc dioxide as well as 2-hydroxy-4-methoxy diphenyl ketone, so that ultraviolet rays can be absorbed to achieve antioxidation and preventing paint resin from being quickly pulverized; the siliver-loaded nano zirconium phosphate can achieve antibacterial action; the dimethyl benzyl dodecyl ammonium bromide can achieve mildew-proof action. and therefore, the nano multifunctional paint additive has effects of preventing mildew, preventing corrosion, sterilizing, preventing oxidization, absorbing ultraviolet rays, and the like, and can be applied to developing emulsion paint, water-borne pigment and water-borne interior and exterior wall paint. Dosage of the nano multifunctional paint additive disclosed by the invention is 0.1%-0.3% of the paint, paint mildew-proof efficiency reaches 99.1% and the sterilizing efficiency reaches 99.6%.

Owner:SKSHU PAINT

Sunscreen cosmetic

InactiveCN102869337APromote absorptionNo secondary adhesion (contamination) problemCosmetic preparationsToilet preparationsUltravioletDiethylamino hydroxybenzoyl hexyl benzoate

Disclosed is a sunscreen cosmetic that does not contain diethylamino hydroxybenzoyl hexyl benzoate, absorbs a wide range of wavelengths of ultraviolet rays across the UVA and UVB regions, and also does not cause staining (dyeing) through secondary adhesion to clothing. The sunscreen cosmetic is characterized by containing: 2-hydrdoxy-4-methoxybenzophenone, 2-ethylhexyl p-methoxycinnamate, octocrylene, a volatile hydrocarbon oil, and zinc oxide and / or titanium oxide that has undergone hydrophobizing treatment other than with a fatty acid.

Owner:SHISEIDO CO LTD

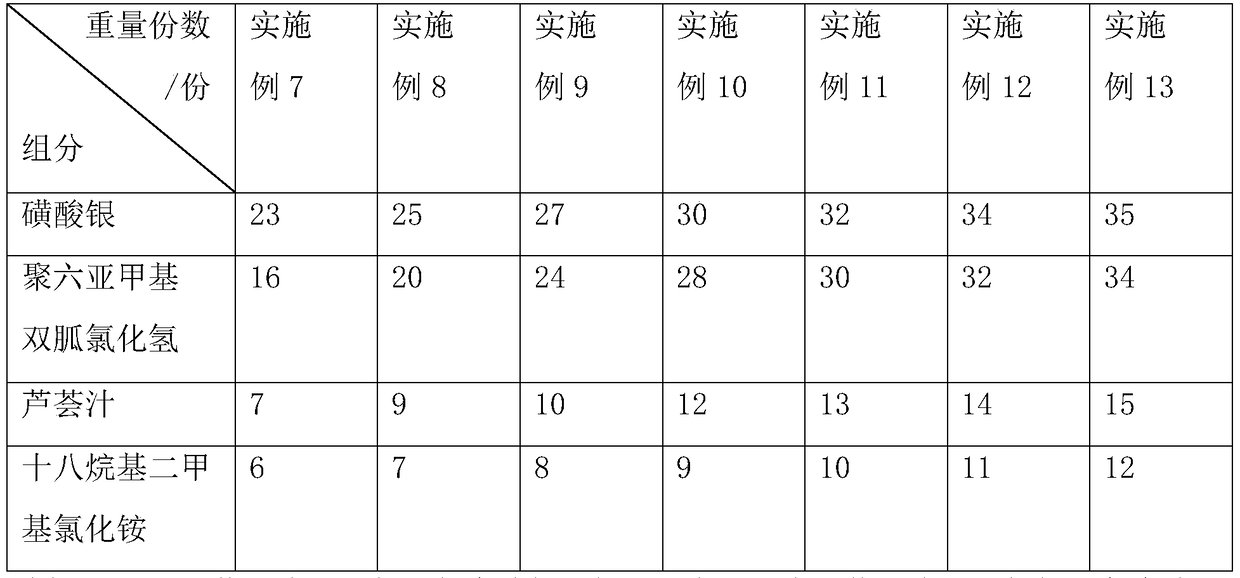

Attractant for Anagrus nilaparvatae which are natural enemies of rice planthoppers

The invention discloses an attractant for Anagrus nilaparvatae which are natural enemies of rice planthoppers, which comprises components including linalool, liquid paraffin, 2, 6-di-tert-butyl-p-cresol and 2-hydroxy-4-methoxybenzophenone in a weight ratio of (0.01-0.10):(0.2-2):(0.01-0.1):(0.01-0.1). The attractant can attract female adults of Anagrus nilaparvatae which are important natural enemies of rice planthoppers in ovigerm stage, so as to reduce the quantity of rice planthopper colonies and reduce the damage of the rice planthoppers to rice plants. The attractant has the characteristics of low cost, high efficiency, environmental friendliness, safety for human beings and livestock, and the like. The attractant for Anagrus nilaparvatae which are the natural enemies of the rice planthoppers have a bright industrialization prospect; and as the preparation method is simple, the attractant is particularly suitable to be used in pollution-free production of rice and can create great economic, social and ecological benefit.

Owner:ZHEJIANG UNIV

Self-cleaning coating material for castings and preparation method thereof

InactiveCN108610861AAccelerated corrosionImprove self-cleaning abilityAntifouling/underwater paintsPaints with biocidesAntioxidantAcrylic resin

The invention provides a self-cleaning coating material for castings. The self-cleaning coating material is prepared from the following raw materials by weight: 40-60 parts of modified acrylic resin,10-18 parts of a polytetrafluoroethylene emulsion, 4-9 parts of trimethylolpropane oleate, 3-5 parts of nano titanium dioxide, 2-4 parts of nano silicon carbide, 2.5-5 parts of nano zinc oxide, 2-5 parts of nano cerium oxide, 1-3 parts of gamma-aminopropyl triethoxysilane, 1.5-4 parts of 2-hydroxy-4-methoxybenzophenone, 1-3 parts of a mixed antioxidant, 0.5-2 parts of 3-(2, 2, 6, 6-tetramethylpiperidine-4-amino)dodecyl propionate, 1-2.5 of tri(2-hydroxyethyl)isocyanurate, 0.8-2.5 parts of an antibacterial mould inhibitor, 0.3-1 part of a leveling agent EFKA-3772, and 10-20 parts of a diluent.The coating material has the advantages of high mechanical strength, good self-cleanliness and strong ageing resistance, thus having wide application prospects.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

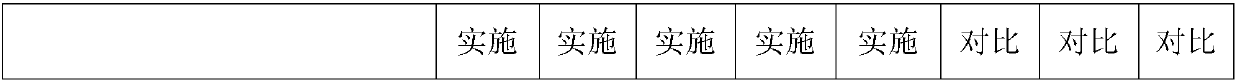

Circuit board substrate with good heat dissipation and preparation method thereof

InactiveCN109251481ANot easy to breakImprove stabilitySynthetic resin layered productsElectrical equipmentN dimethylformamideAntioxidant

The invention discloses a circuit board substrate with good heat dissipation. The circuit board substrate comprises the following raw materials in parts by weight: 60-80 parts of bisphenol A type epoxy resin, 20-30 parts of polytetramethylene adipamide, 10-20 parts of silicone resin, 10-20 parts of phenolic resin, 3-6 parts of glass fiber, 5-10 parts of calcium carbonate, 8-16 parts of silicon carbide, 3-6 parts of graphene, 5-10 parts of diamond micro-powder, 10-20 parts of polyethylene glycol, 2-6 parts of 2-hydroxy-4-methoxybenzophenone, 1-2 parts of N, N-dimethylformamide, 2-4 parts of di-2,4-dichlorobenzoyl peroxide, 1-2 parts of an antioxidant, and 3-5 parts of copper foil. The invention also discloses a preparation method of the circuit board substrate with good heat dissipation. The circuit board substrate has good heat dissipation performance under the cooperation effect of various raw materials, and ensures the service life and performance of the electronic products.

Owner:张玉锦

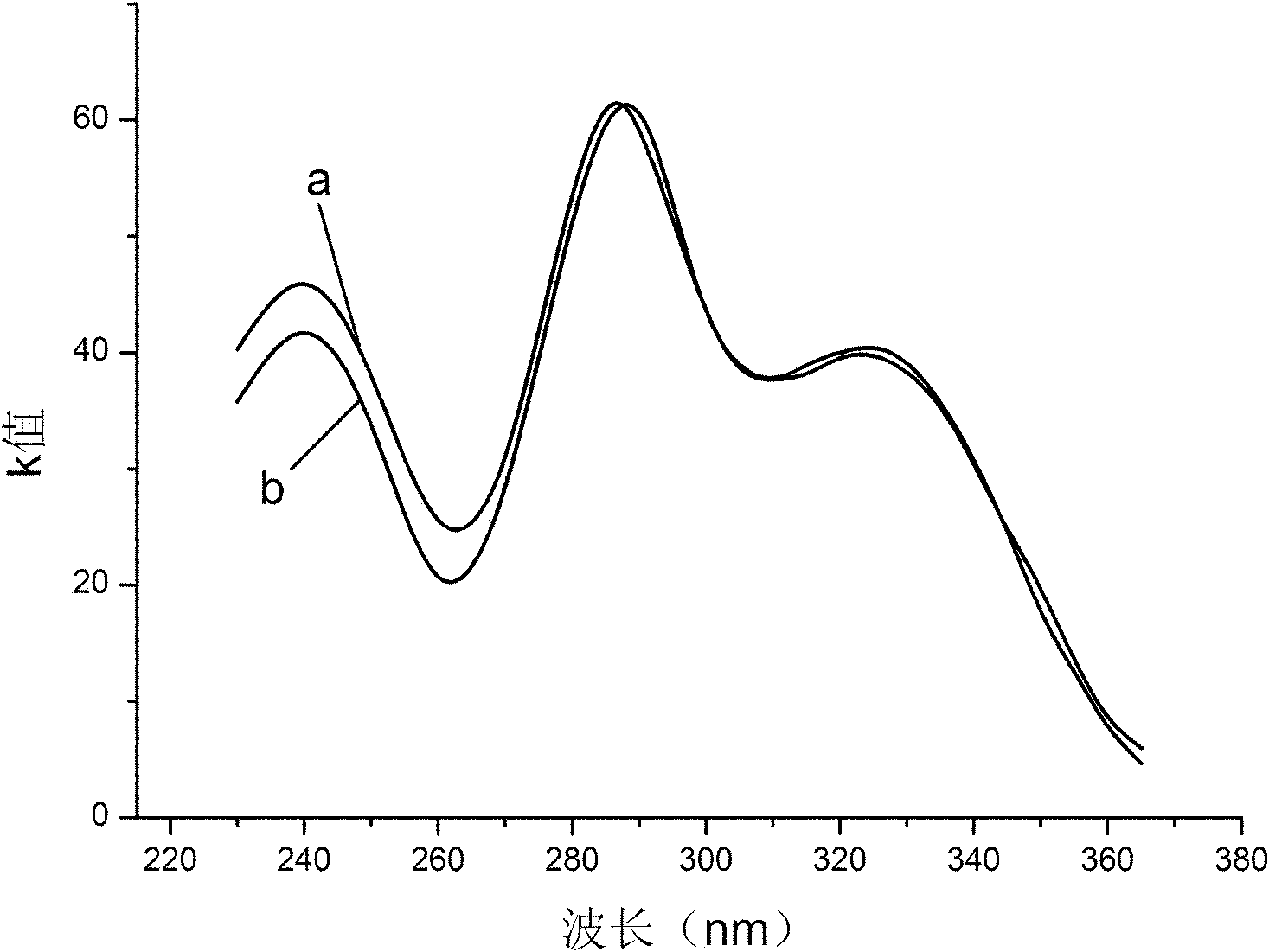

Thermal-insulation and energy-saving material and cement plate thereof

ActiveCN104829192AImprove thermal insulationImprove thermal insulation and energy savingSolid waste managementCeramicwareFiberThermal insulation

The present invention discloses a thermal-insulation and energy-saving material, wherein the raw materials comprise ordinary silicate cement, fly ash, hydrogen peroxide, bis(pentabromophenyl) ethane, a sulfonated acetone formaldehyde polycondensate, a liquid-state epoxy resin dispersant, polyurethane, a foam stabilizer, a coupling agent, mullite fibers, ceramic micro-beads, bis(2,2,6,6,-tetramethyl-4-piperidyl)sebacate, 2-hydroxy-4-methoxy benzophenone, and an ultraviolet ray absorber. The thermal-insulation and energy-saving material has the following characteristics that the thermal insulation property is good, the product dry density is 160-200 kg / m<3>, and the thermal conductivity is 0.05-0.08 W / (m*K); the fire prevention performance is good, the fire resistance limit is more than 3 h, and the material can meet the grade A fire prevention standard so as to provide good fire resistance; the sound insulation performance is good so as to substantially reduce the noise impact; and the durability is good, and characteristics of high temperature resistance, low temperature resistance, corrosion resistance, ultraviolet ray radiation resistance, and good weathering resistance are provided.

Owner:CHONGQING BANGRUI NEW MATERIAL CO LTD

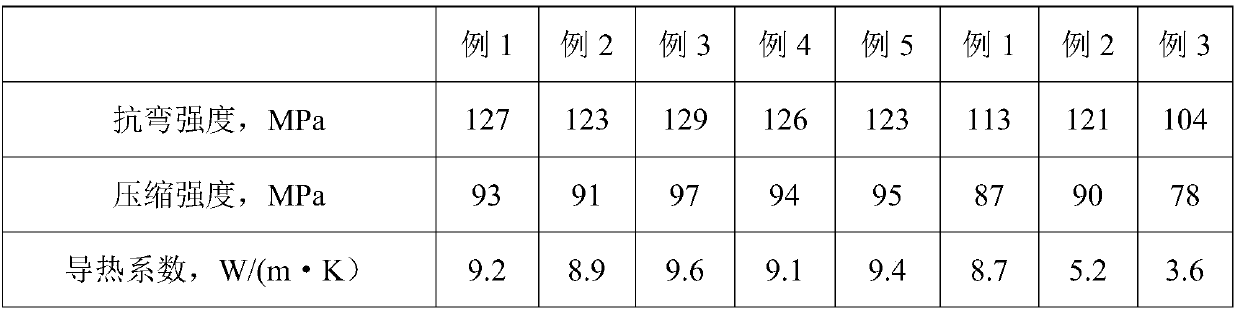

Method for preparing crude 2-hydroxy-4-methoxybenzophenone

InactiveCN102010314AMeet needsReduce manufacturing costOrganic compound preparationCarbonyl compound preparationAlkane2-hydroxy-4-methoxybenzophenone

The invention discloses a method for preparing crude 2-hydroxy-4-methoxybenzophenone. The method comprises the following steps of: adding crude 2,4-dihydroxybenzophenone and sodium carbonate into dimethyl sulfate according to a proportion; raising temperature, and preserving heat and reacting at the temperature of between 70 and 78 DEG C in a reaction vessel; after the reaction, washing a product in water until pH value is 6.5 to 8.0; and standing and layering, taking the material of the lower layer, and performing dehydration to obtain the crude 2-hydroxy-4-methoxybenzophenone. The method is simple, can be operated safely and conveniently and is environmental-friendly; the obtained product has high yield and purity, and the purity of the crude 2-hydroxy-4-methoxybenzophenone is over 98.0 percent; and the residual solvent of the final product does not contain solvents of first class, such as alkanes and the like, and the method meets the standard requirement of the United States Pharmacopeia (USP).

Owner:HUBEI MEIKAI CHEM

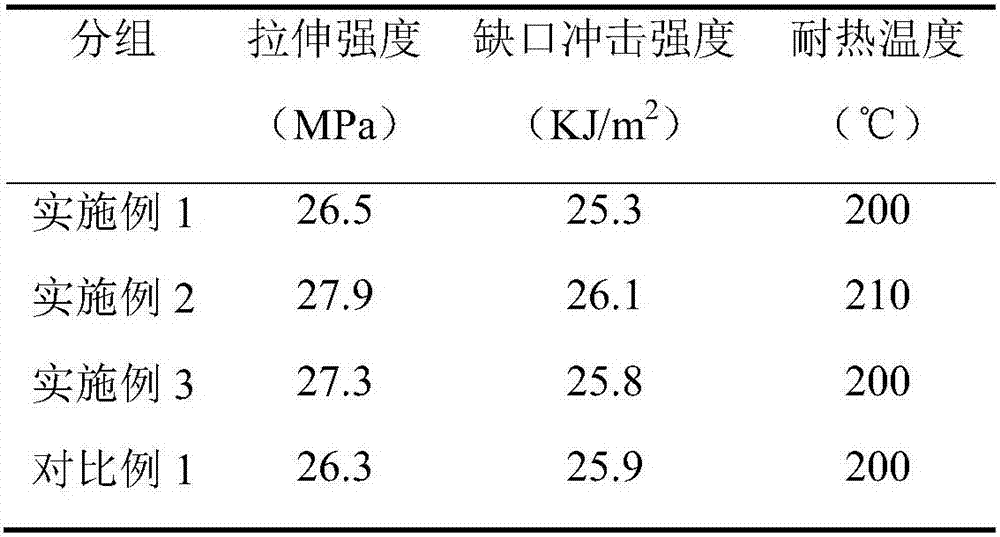

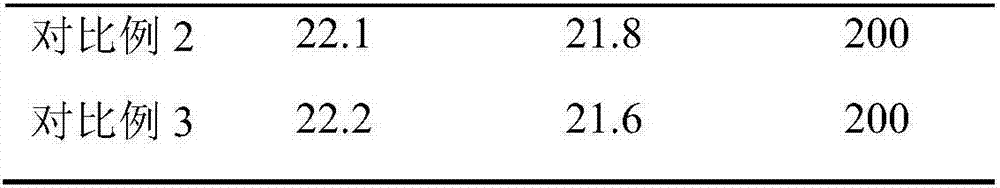

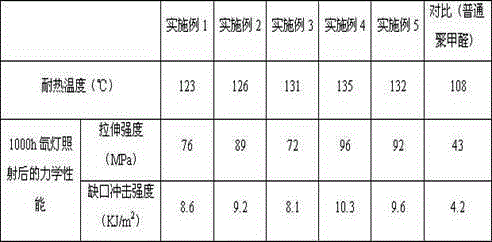

Stably modified polyformaldehyde material and preparation method thereof

InactiveCN105199307AImprove heat resistanceImprove aging resistanceAntioxidant2-hydroxy-4-methoxybenzophenone

The invention discloses a stably modified polyformaldehyde material. The stably modified polyformaldehyde material is prepared from the following raw materials in parts by weight: 62 to 85 parts of polyformaldehyde, 5 to 9 parts of carbon black, 4 to 13 parts of triethanolamine, 3 to 9 parts of dicyandiamide, 4 to 8 parts of ammonium molybdate, 2 to 10 parts of triphenyl phosphate, 3 to 8 parts of methyl stearate, 2 to 9 parts of 2-hydroxy-4-methoxybenzophenone, 3 to 10 parts of calcium hydroxide, 2 to 6 parts of magnesium carbonate, 3 to 9 parts of zinc sulfate, 2 to 7 parts of organic titanium, 3 to 8 parts of urea, 2 to 7 parts of tourmaline and 1 to 5 parts of antioxidant. The invention further discloses a preparation method of the stably modified polyformaldehyde material. According to the polyformaldehyde material prepared by using the preparation method, the range of the heat resistant temperature is 123 to 135 DEG C, the tensile strength is 76 to 96 MPa after being irradiated by a 1000h xenon lamp, the notch impact strength is 8.6 to 10.3 KJ / m<2>, and the polyformaldehyde material has the advantages of good heat resistance and aging resistance and good stability and is suitable for a larger applicable range.

Owner:SUZHOU FAST INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com