Antibacterial polyethylene pipe and preparation method thereof

A polyethylene pipe and high-density polyethylene technology, which is applied in the field of antibacterial polyethylene pipes and their preparation, can solve problems such as negative effects on the liver, and achieve the effects of improving antibacterial properties, enhancing mechanical properties, good application prospects and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

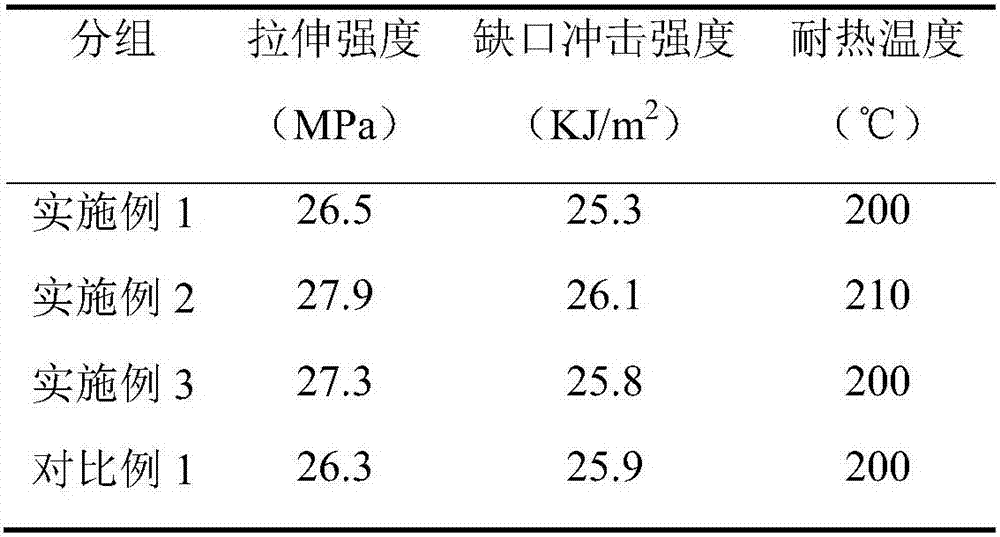

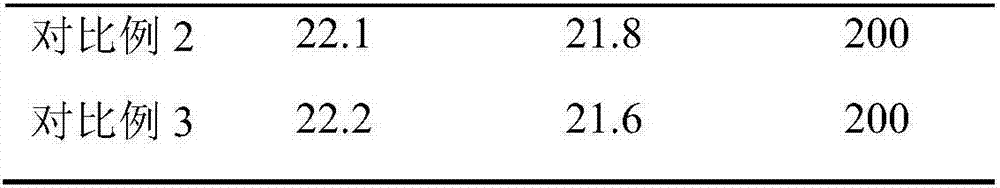

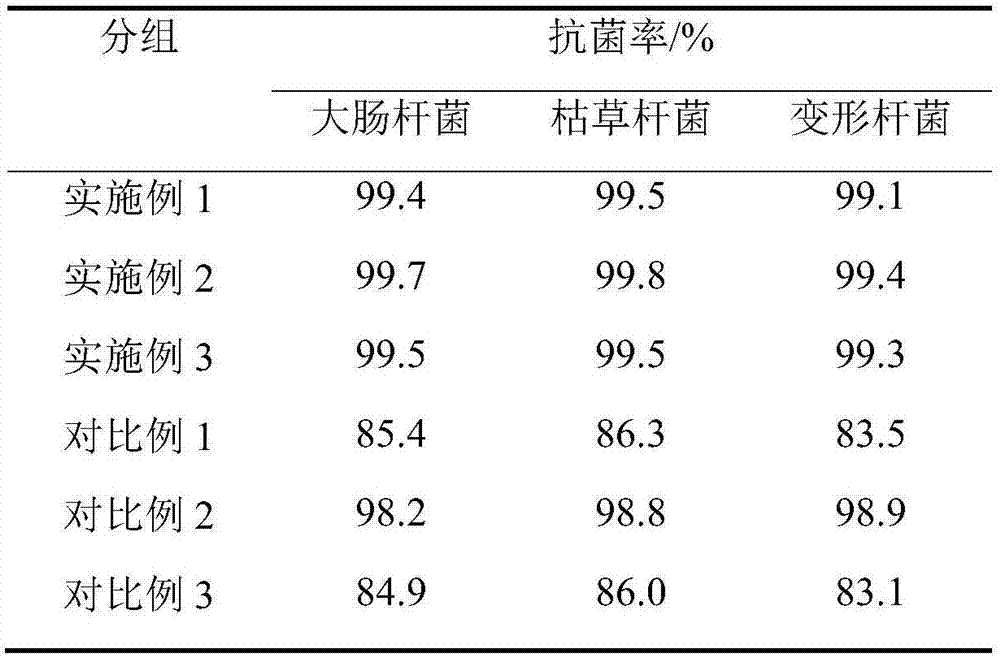

Examples

Embodiment 1

[0026] An antibacterial polyethylene pipe is prepared from the following raw materials in parts by weight: 97 parts of high-density polyethylene resin, 1 part of crosslinking agent, 0.2 part of antioxidant, 0.1 part of compatibilizer, 2-hydroxy-4 - 0.5 part of methoxybenzophenone, 0.1 part of antibacterial agent, 0.05 part of antibacterial synergist, and 0.2 part of modifier.

[0027] As mentioned, the antibacterial agent is prepared from methylisothiazolinone and titanium dioxide in a weight ratio of 0.4:1.

[0028] As mentioned, the antibacterial synergist is prepared from diethanol monoisopropanolamine maleate compound and ethylenediaminetetraacetic acid in a weight ratio of 1:0.5.

[0029] Described, diethanol monoisopropanolamine maleate compound is prepared by the following method: add diethanol monoisopropanolamine and maleic anhydride in the reactor, add catalyst, under stirring condition Reduce the pressure to 0.4MPa, heat, control the temperature at 100°C, maintain ...

Embodiment 2

[0039] An antibacterial polyethylene pipe is prepared from the following raw materials in parts by weight: 98 parts of high-density polyethylene resin, 0.5 part of crosslinking agent, 0.8 part of antioxidant, 0.3 part of compatibilizer, 2-hydroxyl-4 - 0.3 part of methoxybenzophenone, 0.2 part of antibacterial agent, 0.07 part of antibacterial synergist, and 0.15 part of modifier.

[0040] As mentioned, the antibacterial agent is prepared from methylisothiazolinone and titanium dioxide in a weight ratio of 0.3:1.

[0041] Said antibacterial synergist is prepared from diethanol monoisopropanolamine maleate compound and ethylenediaminetetraacetic acid in a weight ratio of 1:0.6.

[0042] Described, diethanol monoisopropanolamine maleate compound is prepared by the following method: add diethanol monoisopropanolamine and maleic anhydride in the reactor, add catalyst, under stirring condition Reduce the pressure to 0.4MPa, heat, control the temperature at 100°C, maintain the const...

Embodiment 3

[0052] An antibacterial polyethylene pipe is prepared from the following raw materials in parts by weight: 99 parts of high-density polyethylene resin, 0.1 part of crosslinking agent, 1.2 parts of antioxidant, 0.5 part of compatibilizer, 2-hydroxy-4 - 0.1 part of methoxybenzophenone, 0.3 part of antibacterial agent, 0.09 part of antibacterial synergist, and 0.1 part of modifier.

[0053] As mentioned, the antibacterial agent is prepared from methylisothiazolinone and titanium dioxide in a weight ratio of 0.2:1.

[0054] As mentioned, the antibacterial synergist is prepared from diethanol monoisopropanolamine maleate compound and ethylenediaminetetraacetic acid in a weight ratio of 1:0.7.

[0055] Described, diethanol monoisopropanolamine maleate compound is prepared by the following method: add diethanol monoisopropanolamine and maleic anhydride in the reactor, add catalyst, under stirring condition Reduce the pressure to 0.4MPa, heat, control the temperature at 100°C, mainta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com