Composite modified asphalt based on multi-component biomass material, and preparation method thereof

A technology of composite modified asphalt and biomass materials, which is applied in the direction of building insulation materials, building structures, building components, etc., and can solve insufficient swelling, exhaustion of petroleum asphalt resources, reuse of waste materials, uneven mixing of low-temperature performance rubber powder, etc. problem, to achieve the effect of increasing softening point, wide range of sources, and improving anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the composite modified asphalt based on multivariate biomass material comprises the following steps:

[0035] Step 1: After heating the base asphalt to 140-160°C, add waste oil, soybean fatty acid, dried yak manure and coffee grounds one by one, keep stirring for 5-10 minutes, then add waste rubber powder, and keep stirring for 5-10 minutes;

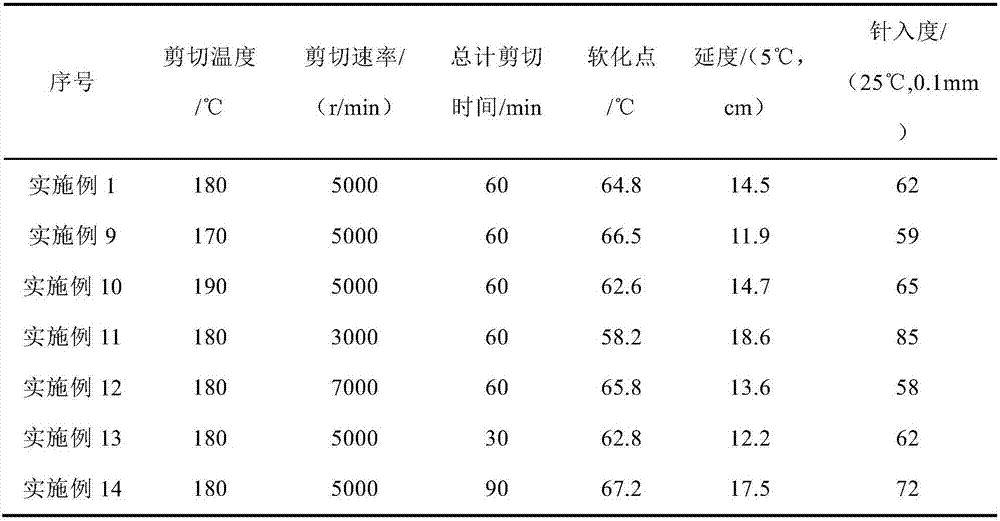

[0036] Step 2: Cut at a shear rate of 3000-7000r / min for 25-35min at 170-190°C, add boron nitride, cut for 10-15min, and then add 2-hydroxy-4-methoxydiphenyl Methanone and stabilizer, continue to shear for 15 to 20 minutes, and the total shearing time is 60 minutes;

[0037] Step 3: develop at 140-160°C for 60 minutes, and stir once every 15 minutes to obtain composite modified asphalt.

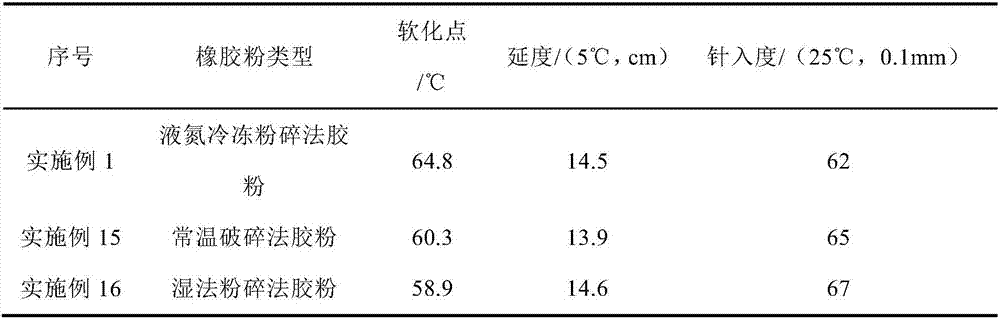

[0038] The base asphalt is straight-run 70# asphalt for road use. The waste rubber powder is 80-mesh granular rubber powder made by using liquid nitrogen freezing and crushing method for waste rubber tires.

[0039] T...

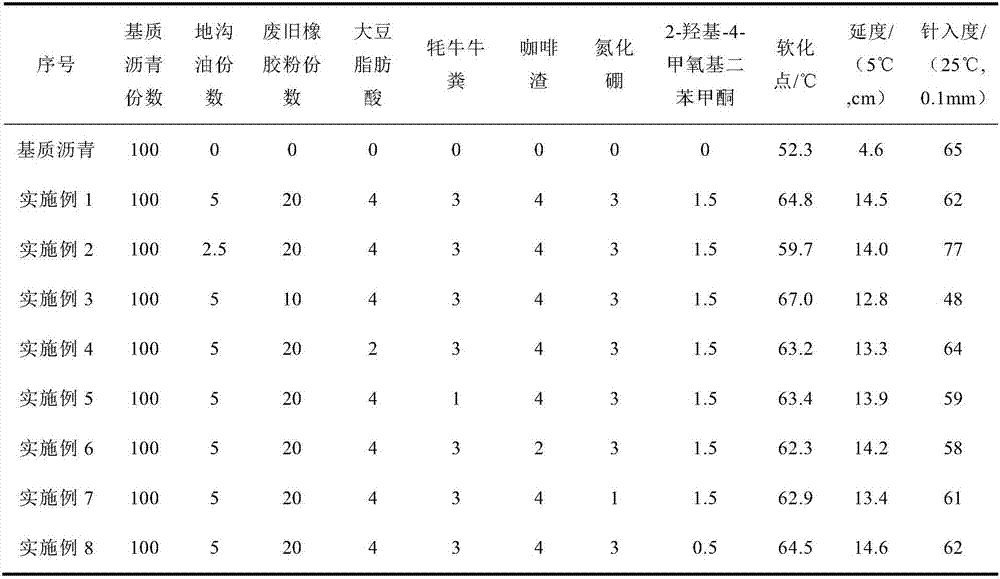

Embodiment 1

[0049] This example provides a composite modified asphalt based on multiple biomass materials, which is prepared from the following raw materials in parts by mass: base asphalt: 100 parts, waste oil: 5 parts, waste rubber powder: 20 parts, soybean fatty acid : 4 parts, yak dung: 3 parts, coffee grounds: 4 parts, boron nitride: 3 parts, 2-hydroxy-4-methoxybenzophenone: 1.5 parts, stabilizer: 0.1 parts.

[0050] Straight-run 70# base asphalt for roads was used as the base asphalt, and the waste oil was from frying waste oil after processing deep-fried dough sticks in a restaurant; waste rubber powder was 80-mesh particles obtained from waste rubber tires by liquid nitrogen freezing and crushing method; soybean fatty acid Value (mgKOH / g, ≥) 200, moisture (%): 0.5~0.6; yak dung is the yak dung collected in that year; coffee grounds are the residue left after coffee beans are ground and brewed; boron nitride is a conventional industrial Use hexagonal boron nitride; 2-hydroxy-4-meth...

Embodiment 2

[0055] This example provides a composite modified asphalt based on biomass materials, which is prepared from the following raw materials in parts by mass: base asphalt: 100 parts, waste oil: 2.5 parts, waste rubber powder: 20 parts, soybean fatty acid: 4 parts, yak dung: 3 parts, coffee grounds: 4 parts, boron nitride: 3 parts, 2-hydroxy-4-methoxybenzophenone: 1.5 parts, stabilizer: 0.1 parts.

[0056] The preparation method of the composite modified asphalt of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com