Production method of uvioresistant fiber

A technology of anti-ultraviolet and production methods, which is applied in the field of anti-ultraviolet fiber production, can solve the problems of anti-ultraviolet finishing agent toxicity, etc., and achieve the effect of excellent anti-ultraviolet effect and strong durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

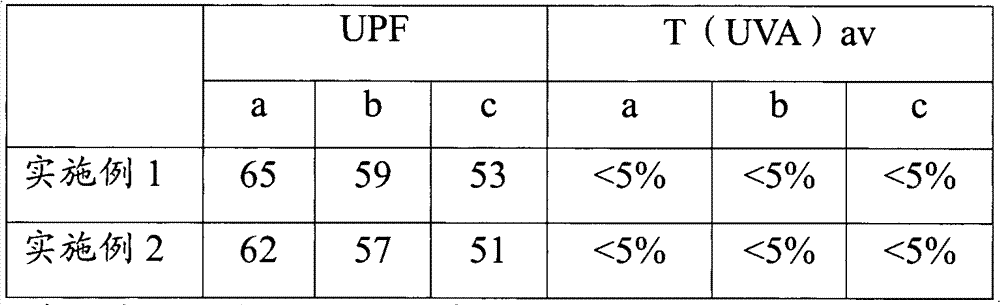

Examples

Embodiment 1

[0027] Preparation of anti-ultraviolet compound auxiliary agent:

[0028] 40 parts of titanium dioxide,

[0029] 20 parts of aluminum oxide,

[0030] Zeolite 3 parts,

[0031] 15 parts of 2-hydroxy-4-methoxybenzophenone,

[0032] 10 parts of 4-tert-butylphenyl salicylate,

[0033] Sodium polyacrylate dispersant 1 part,

[0034] Mix 2-hydroxy-4-methoxybenzophenone, 4-tert-butylphenyl salicylate and zeolite, then slowly add titanium dioxide, aluminum oxide and sodium polyacrylate dispersant simultaneously for 2 hours After the internal feeding is completed, continue mixing for 30 minutes.

[0035] Preparation of anti-ultraviolet masterbatch:

[0036] The above-mentioned anti-ultraviolet composite auxiliary agent is blended with a carrier resin, dried, melted, blended and extruded in a screw extruder, and granulated to obtain an anti-ultraviolet masterbatch. The anti-ultraviolet composite auxiliary agent in the anti-ultraviolet masterbatch accounts for 10 wt%.

[0037] Pro...

Embodiment 2

[0040] Preparation of anti-ultraviolet compound auxiliary agent:

[0041] 30 parts of titanium dioxide,

[0042] 25 parts of aluminum oxide,

[0043] Zeolite 5 parts,

[0044] 20 parts of 2-hydroxy-4-methoxybenzophenone,

[0045] 15 parts of 4-tert-butylphenyl salicylate,

[0046] Sodium polyacrylate dispersant 5 parts,

[0047] Mix 2-hydroxy-4-methoxybenzophenone, 4-tert-butylphenyl salicylate and zeolite, then slowly add titanium dioxide, aluminum oxide and sodium polyacrylate dispersant simultaneously for 1 hour After the internal feeding is completed, continue mixing for 20 minutes.

[0048] Anti-ultraviolet masterbatch preparation:

[0049] Blending and drying the above-mentioned anti-ultraviolet compound auxiliary agent with the carrier resin, entering into a screw extruder for melt blending and extruding, and granulating to obtain an anti-ultraviolet masterbatch, in which the anti-ultraviolet compound auxiliary agent accounts for 20wt%;

[0050] UV resistant fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com