Toughened scratch-resistant PP/HDPE (Polypropylene/High Density Polyethylene) plastics for automotive interior trim parts and preparation method thereof

A technology for automotive interior parts and scratch resistance, which is applied in the field of modified PP/HDPE plastics and its preparation, toughened and scratch-resistant PP/HDPE plastics for automotive interior parts and its preparation, and can solve the limitation of polypropylene resin Application, poor toughness and scratch resistance of polypropylene resin, etc., to achieve the effect of low product cost, simple preparation process and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] According to the corresponding data of Example 1 in Table 1, each anti-scratch agent component was weighed, after fully mixing, the composite anti-scratch agent of Example 1 was obtained;

[0038] Take 80 kg of dried polypropylene resin, 5 kg of high-density polypropylene resin, 2 kg of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 15 kg of peanut shell powder, and 0.5 kg of ultramarine blue and 1 kg of the compound scratch resistance agent of Example 1, after fully mixing at high speed for 5 minutes, add to the feeding port of the screw extruder; control the rotating speed of the screw extruder at 300rpm, and the temperature at 200°C, and extrude through the screw extruder Machine extruded granulation, promptly obtains the toughened and scratch-resistant PP / HDPE plastics of automobile interior parts of embodiment 1.

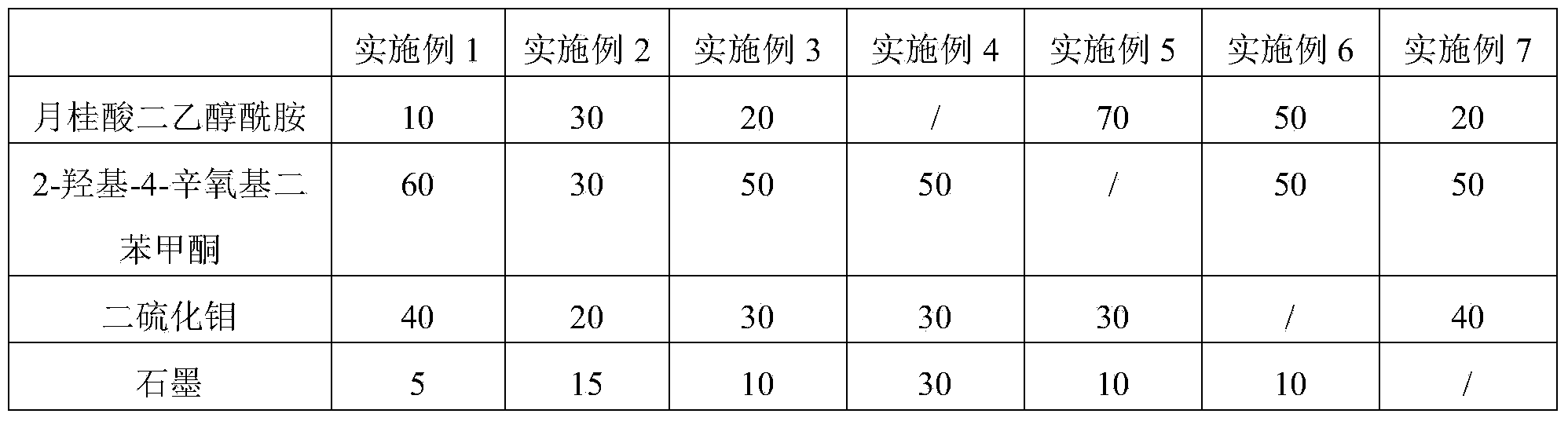

[0039] Table 1: PP / HDPE plastic anti-scratch agent formulation table of embodiment 1-7 unit: kilogram

[0040]

Embodiment 2

[0042] According to the data of Example 2 corresponding in Table 1, each anti-scratch agent component was weighed, and after fully mixing, the composite anti-scratch agent of Example 2 was obtained;

[0043] Take 80 kg of dried polypropylene resin, 5 kg of high-density polypropylene resin, 2 kg of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 15 kg of peanut shell powder, and 0.5 kg of ultramarine blue With 1 kg of the compound scratch resistance agent of Example 2, after fully mixing at high speed for 5 minutes, add to the feeding port of the screw extruder; control the rotating speed of the screw extruder at 300rpm, and the temperature at 200°C, and extrude through the screw extruder Machine extruded granulation, promptly obtains the toughened and scratch-resistant PP / HDPE plastics of automobile interior parts of embodiment 2.

Embodiment 3

[0045]According to the corresponding data of Example 3 in Table 1, each anti-scratch agent component was weighed, and after fully mixing, the composite anti-scratch agent of Example 3 was obtained;

[0046] Take 80 kg of dried polypropylene resin, 5 kg of high-density polypropylene resin, 2 kg of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 15 kg of peanut shell powder, and 0.5 kg of ultramarine blue With 1 kg of the compound scratch resistance agent of Example 3, after fully mixing at high speed for 5 minutes, add to the feeding port of the screw extruder; control the rotating speed of the screw extruder at 300rpm, and the temperature at 200°C, and extrude through the screw extruder Machine extruded granulation, promptly obtains the toughened and scratch-resistant PP / HDPE plastics of automobile interior parts of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com