Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

199 results about "Abrasion (mechanical)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Abrasion is the process of scuffing, scratching, wearing down, marring, or rubbing away. It can be intentionally imposed in a controlled process using an abrasive. Abrasion can be an undesirable effect of exposure to normal use or exposure to the elements.

Steel plate with great heat and abrasion resistance and manufacturing method thereof

ActiveCN103205650AExcellent mechanical properties and wear resistanceImprove hardness and wear resistanceQuenchingSteel plates

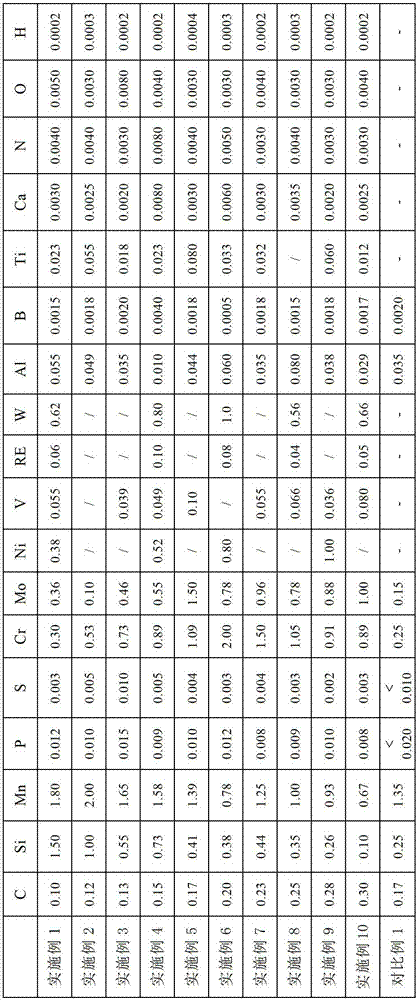

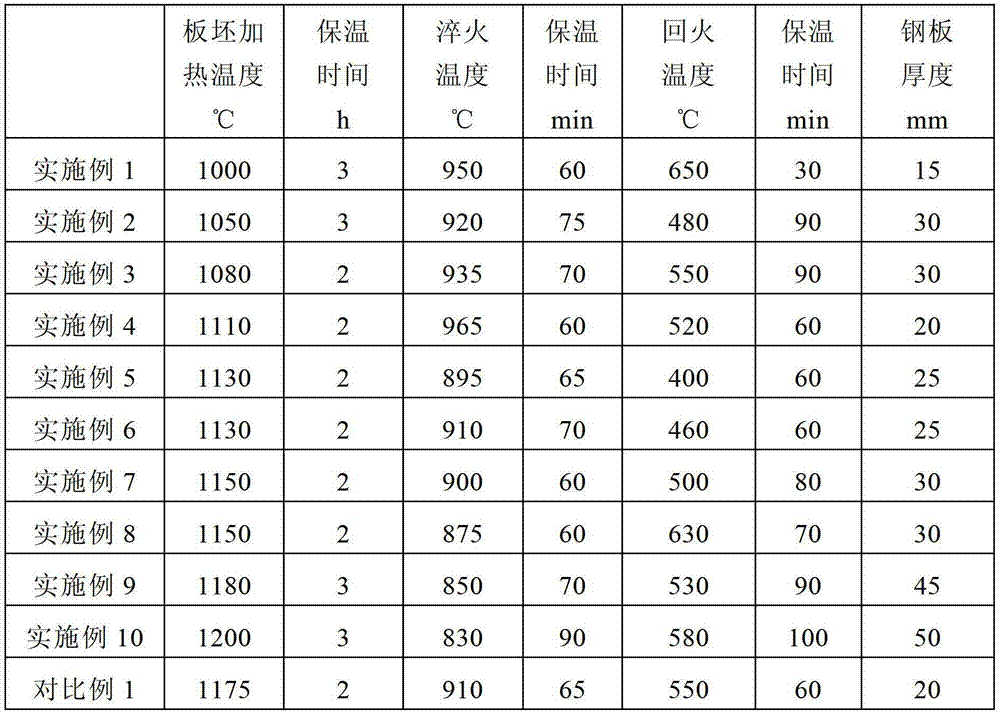

The present invention provides a steel plate with great heat and abrasion resistance and a manufacturing method thereof. The steel plate comprises the following chemical composites, in percentage by weight: 0.10-0.30% of C, 0.10-1.50% of Si, 0.50-2.00% of Mn, 0-0.015% of P, 0-0.010% of S, 0.2-2.00% of Cr, 0.10-1.50% of Mo, 0-1.00% of Ni, 0-0.10% of V, 0-0.10% of RE, 0-1.00% of W, 0.010-0.080% of Al, 0.0005 -0.0040% of B, 0-0.080% of Ti, 0.0010-0.0080% of Ca, 0-0.0080% of N, 0-0.0080% of O, 0-0004% of H and the balance being Fe and inevitable impurities. The mechanical properties of the steel plate are that the Brinell hardness is greater than 360HB, and the 500 DEG C tensile strength is more than 1000MPa. The steel plate obtained by the various components through processes such as quenching and tempering has excellent mechanical properties and abrasion resistance, and is particularly suitable for various mechanical parts which are easy to wear while working under high temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

High-speed steel for high-toughness high-abrasion resistance hobbing cutter and preparation method thereof

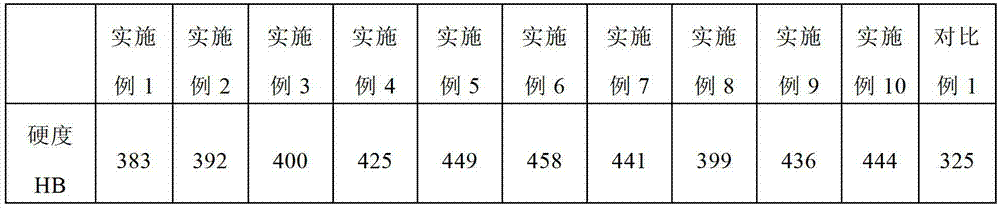

The invention discloses high-speed steel for a high-toughness high-abrasion resistance hobbting cutter and a preparation method thereof. Compared with chemical components of traditional high-performance high-speed steel, the usage of noble metal cobalt is reduced, the content of carbon and vanadium with low prices are correspondingly added, so that the grain tissue of the high-speed steel can be refined, the hardenability can be increased, and the production cost can be reduced on the premise of guaranteeing corresponding functions of high toughness and high-abrasion resistance; and by utilizing the method for preparing the high-toughness high-abrasion resistance high-speed steel provided by the invention, the content of N is controlled to be lower than 150ppm, the formation of large-particle carbide is weakened, and the grindability is improved. The method for preparing the high-speed steel can be used for preparing hobbing cutter and gear and other rotary elements in automobile and mechanical engineering industries.

Owner:HEYE SPECIAL STEEL

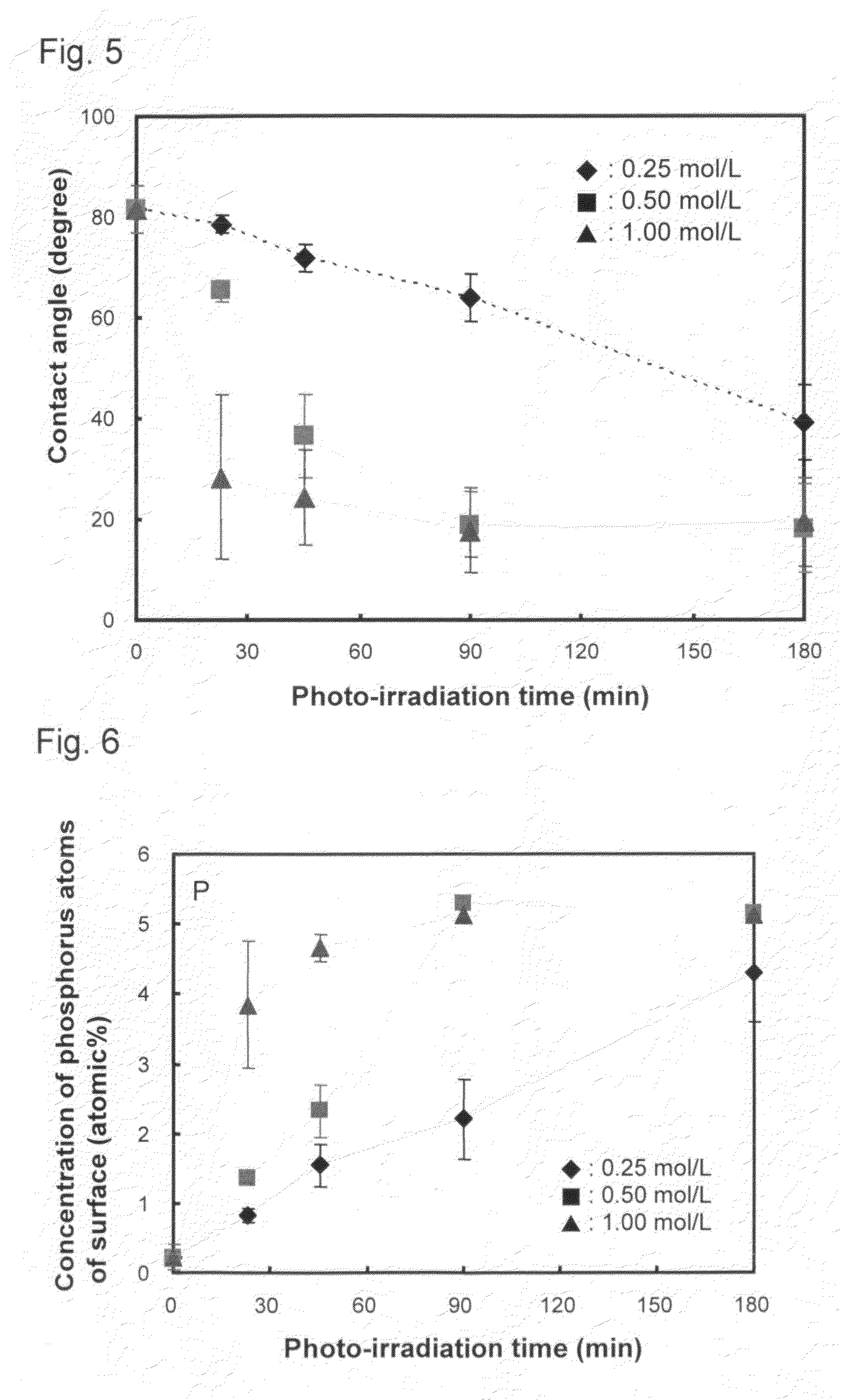

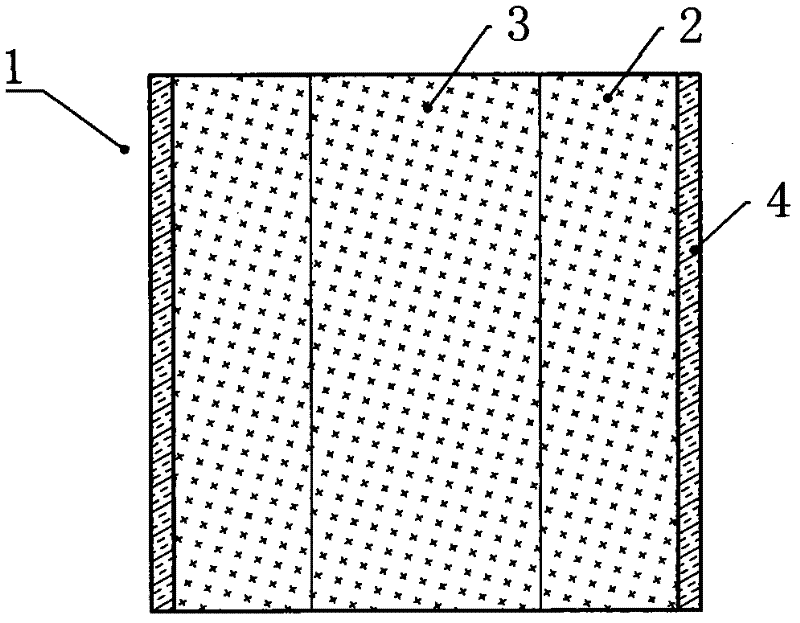

Biocompatible and low-abrasion member, and artificial joint using the same and method of producing the same

ActiveUS20120197413A1Firmly connectedSatisfactory mechanical characteristicImpression capsAnkle jointsArtificial jointsPhosphorylcholine

The object of the present invention is to provide a sliding member, a prosthesis and a method of producing the sliding member, which can suppress production of abrasive wear debris by suppressing friction of the sliding section, and also can maintain satisfactory mechanical characteristics in vivo. A sliding member comprising: a substrate 1 capable of forming hydroxyl groups; and a biocompatible material layer 4 laminated on appropriate sections of the substrate 1, wherein hydroxyl groups are formed on at least a required section of a surface of the substrate 1 by surface treating to form a surface-treated layer 2, while the biocompatible material layer 4 is formed from a polymer containing phosphorylcholine groups, and wherein the substrate 1 and the biocompatible material layer 4 are joined via a binder layer 3 formed from silica being covalently bonded with the hydroxyl groups and the biocompatible material, respectively.

Owner:KYOCERA CORP +1

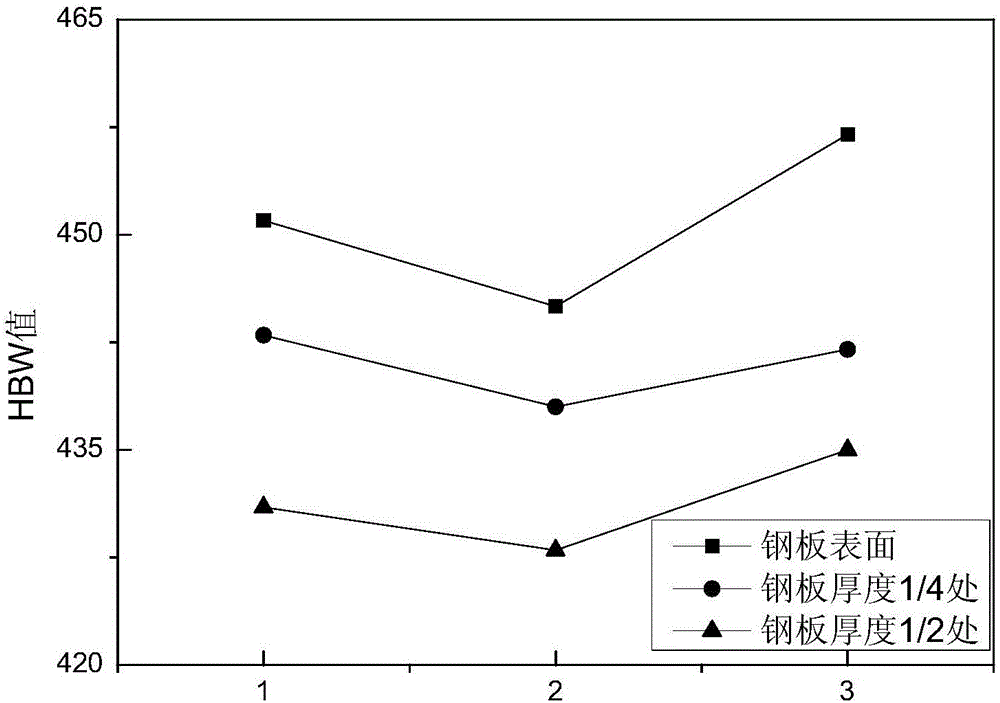

Quenching and tempering type abrasion resistant steel and heat treating method thereof

InactiveCN101451218AReasonable toughness matchingModerate hardnessHeat treatment process controlChemical compositionWear resistant

The invention relates to quenching and tempering type wear resistant steel and a heat treatment method thereof. The steel comprises the following chemical components by weight percentage: less than or equal to 0.22 percent of C, less than or equal to 0.80 percent of Si, less than or equal to 1.60 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.60 percent of Ni, less than or equal to 1.00 percent of Cr, less than or equal to 0.50 percent of Mo, 0.02 to 0.03 percent of Nb,0.04 to 0.06 percent of V, 0.020 to 0.045 percent of Al, 0.015 to 0.030 percent of Ti, less than or equal to 0.004 percent of B, and the balance being Fe and unavoidable impurities. The steel plate has reasonable obdurability matching, proper hardness, even full-thickness hardness and the mechanical properties reaching the expected design requirements. The steel plate production process has easy operation and high adaptability. The steel plates of various batches have stable and even performance and can reach the requirements for volume production. As the tempering time in a quenching machine is longer, the tempering time can be appropriately shortened in the subsequent production through tests, thereby reducing the cost.

Owner:WUYANG IRON & STEEL

Track steel having high strength, high abrasion resistance and long fatigue life, and production process for same

The invention discloses a track steel having high strength, high abrasion resistance and long fatigue life, and a production process for the same. The track steel is composed of the following elements in mass percent: 0.28-0.32% of C, 0.20-0.35% of Si, 1.45-1.60% of Mn, 0.35-0.45% of Cr, 0-0.1% of Mo, 0-0.1% of V, 0.015-0.030% of Al, 0-0.025% of P, 0.015-0.030% of S, 0.0010-0.0025% of B, 0.015-0.030% of Ti, 0-0.0015% of O, 0-0.0002% of H, 0.0040-0.0080% of N, and the balance of Fe. As can be seen from the above composition, only some conventional alloy element (0.35-0.45% of Cr) is added to the chemical components of the track steel set forth in the present application to improve the overall mechanical properties of a track, such that the production cost of an enterprise can be greatly reduced while the mechanical properties are guaranteed.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

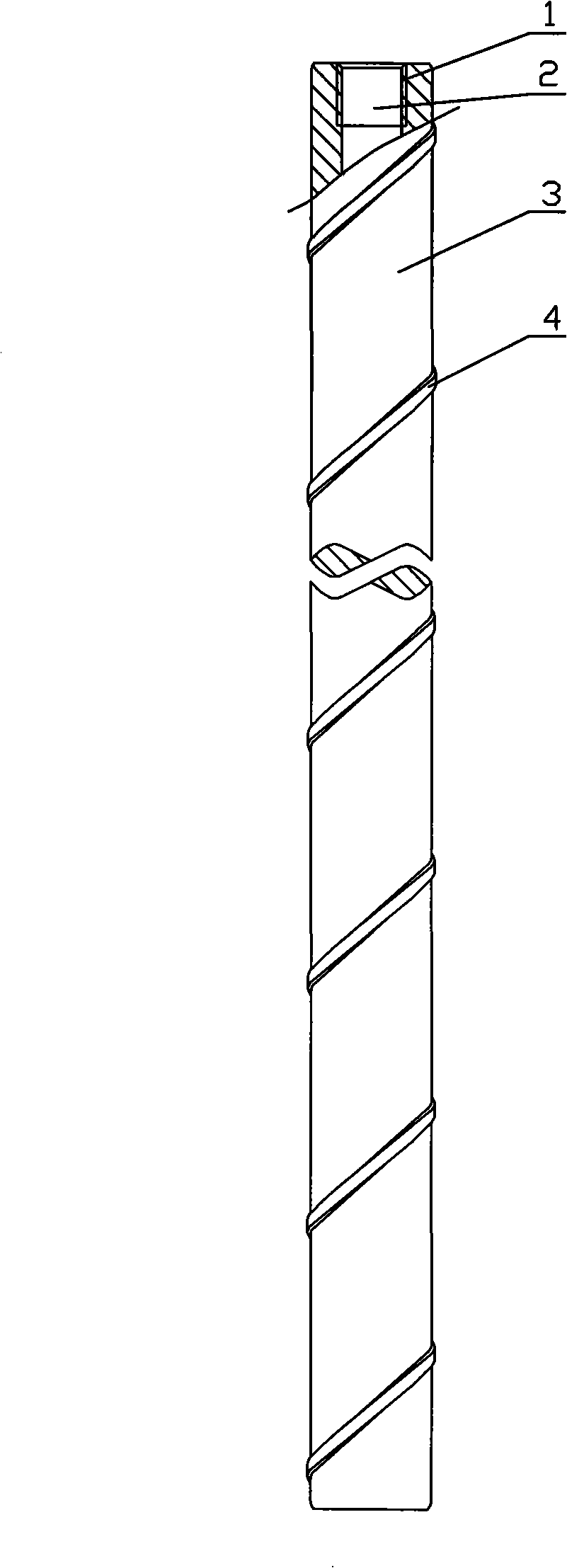

Low helical abrasion-proof drill rod for mash gas pumping drilling construction and machining process thereof

InactiveCN101280667AExtended service lifeDrilling rodsMetallic material coating processesWear resistantLiquid slag

The invention discloses a low spiral wear resistant drill rod applied to drilling construction in gas extraction and a processing technique thereof. The drill rod is a mill finish round drill rod, the center of the drill bar is provided with an inner bore, the two ends are provided with connecting threads and the outer surface of the mill finish drill rod is provided with a spiral alloy coating. The processing technique of the drill rod has the following steps: first, a normal round drill rod is made according to normal methods; second, the surface of the round drill rod is coated with spiral alloy convex reinforcements; third, heating treatment is carried out to relieve stress and the drill rod is aligned. On one hand, the low spiral wear resistant drill rod applied to drilling construction in gas extraction improves the wear resistant performance of the drill rod and prolongs the service life of the drill rod; on the other hand, the center of the drill rod is provided with the inner bore, which endows the drill rod with the function of liquid slag discharge, and the outer surface of the mill finish drill rod is provided with the spiral alloy coating, which endows the drill rod with the function of mechanical slag discharge. The drill rod is applicable to the drilling construction on weak coal seams, outburst coal seams and rocks in gas extraction.

Owner:SHANXI LUAN MINING GRP +1

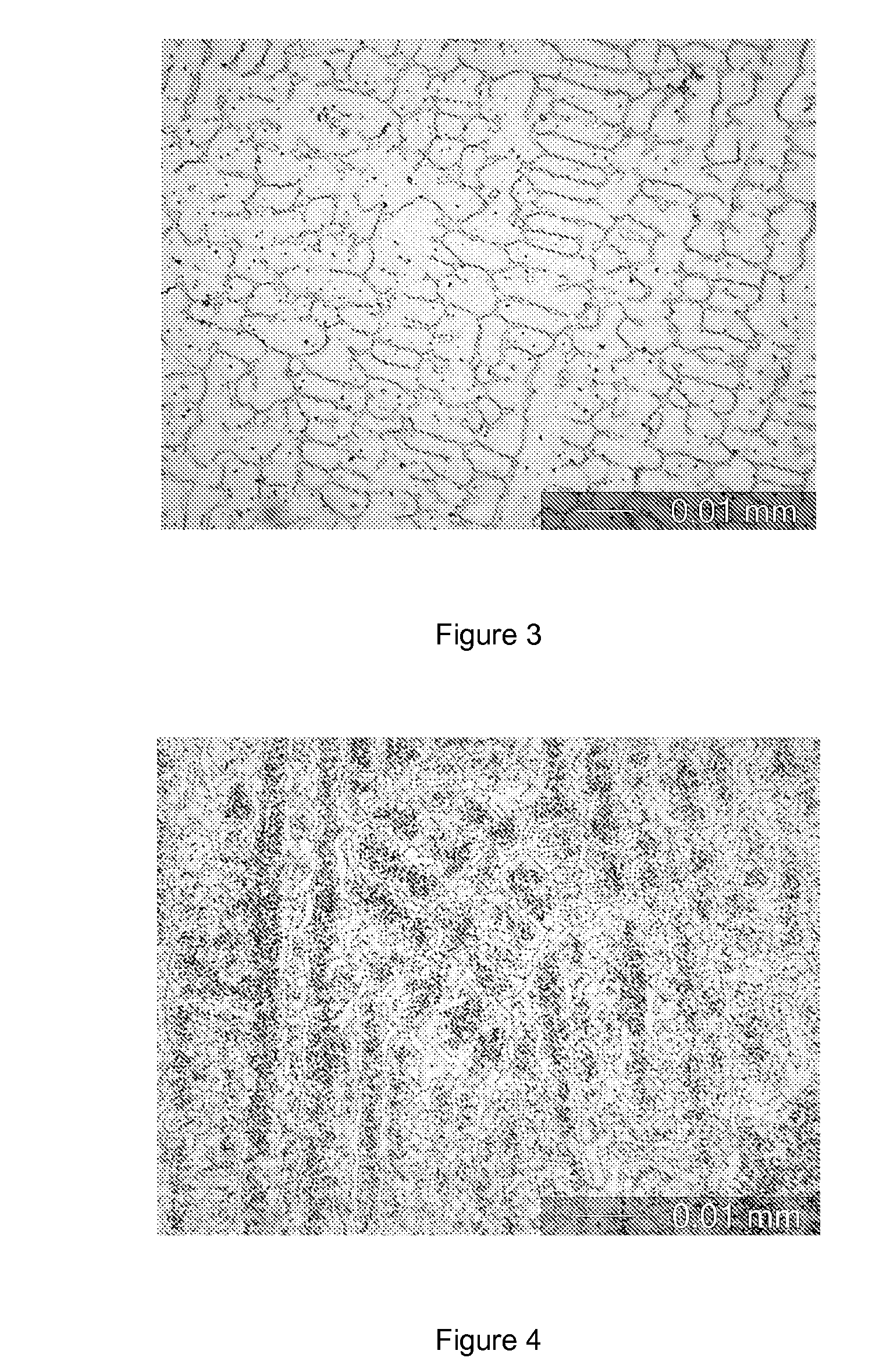

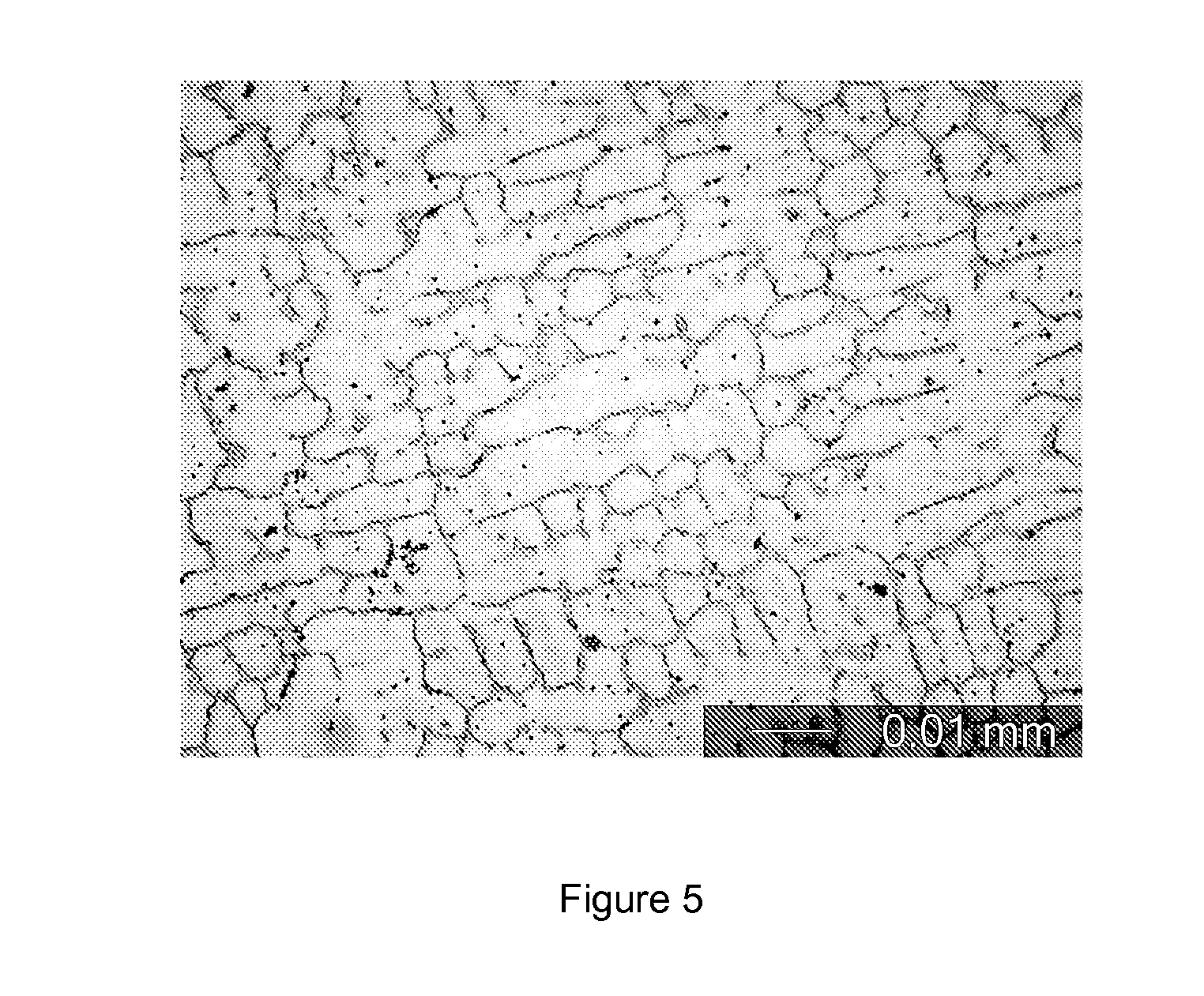

PROCESS AND METHOD TO INCREASE THE HARDNESS OF Fe-Cr-C WELD OVERLAY ALLOY

ActiveUS20080230155A1High hardnessResistance to abrasive wearFurnace typesHeat treatment furnacesSufficient timeMechanical components

A method of preparing a mechanical component with an Fe—Cr—C hardfacing weld overlay alloy for improving the resistance of the mechanical component to abrasion, erosion or erosion / corrosion for use in very abrasive, erosion or erosive / corrosive environments by significantly increasing the hardness of the weld overlay is disclosed. To improve the resistance to abrasion, erosion or corrosion, a weld overlay of a Fe—Cr—C hardfacing alloy is applied onto the surface of a metallic component, such as tubes, pipes, or vessels. Welding and cladding methods including gas-metal-arc welding (GMAW), gas-tungsten-arc welding (GTAW), and laser cladding may be utilized. Then, the component is heat-treated at elevated temperatures for a sufficient time, resulting in additional hardening and thus further increasing the weld overlay's resistance to abrasion, erosion, or erosion / corrosion.

Owner:AZZ WSI

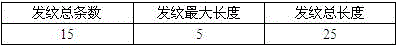

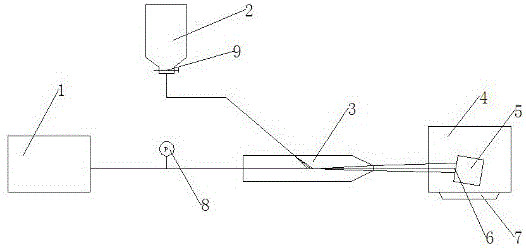

Corrosion experiment and injury evaluation methods of engineering material under wind sand environment

InactiveCN105738235AEasy to controlTotal Damage Assessment StudyInvestigating abrasion/wear resistanceMacroscopic scaleAbrasion (mechanical)

The invention relates to an experiment method and an injury evaluation method of an engineering material and particularly relates to corrosion experiment and injury evaluation methods of the engineering material under a wind sand environment. An experiment system and a method for operating the experiment system are included; the experiment system comprises a wind sand environment simulation system and an erosion room; the injury evaluation method of the engineering material based on a wind sand environment experiment system comprises a weight-loss grading method and a weight-loss rate evaluation method, wherein weight loss is the difference of masses of a test piece before and after an abrasion test, namely deltam=m1-m2; the weight-loss rate is the ratio of the difference of the masses of the test piece before and after the abrasion test to the total mass of sand used in the time period, namely alpha=(deltam / ms*t)*100%=(m1-m2 / ms*t)*100%. The experiment system provided by the invention has the advantages that an actual wind and sand corrosion environment can be really simulated, erosion mechanical parameters are easy to accurately control, a testing period is short and the research cost is low; the experiment and injury evaluation methods explore an erosion abrasion rule and an injury mechanism of the engineering material from macroscopic and microcosmic aspects.

Owner:INNER MONGOLIA UNIV OF TECH

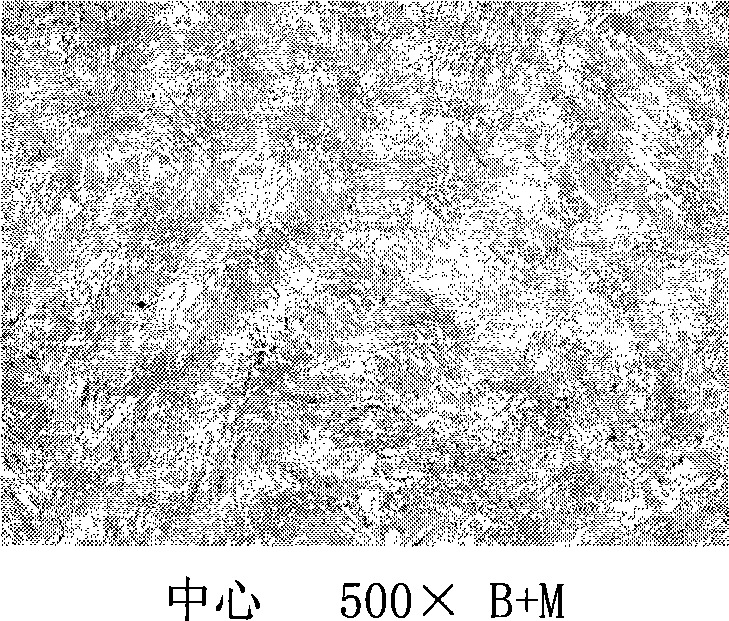

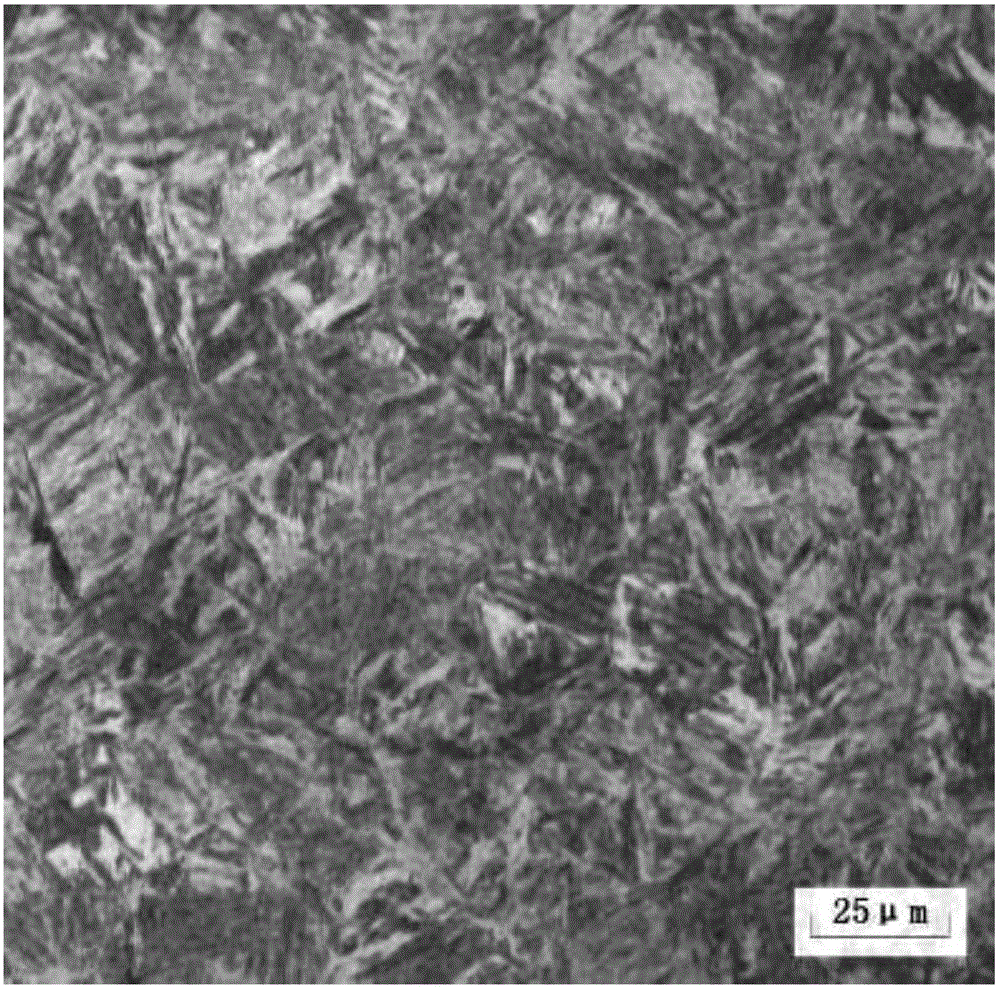

High-toughness stable-brinell-hardness extra-thick abrasion-resistant steel and preparation method thereof

The invention provides high-toughness stable-brinell-hardness extra-thick abrasion-resistant steel and a preparation method thereof, and belongs to the technical field of metal material manufacturing. The abrasion-resistant steel comprises, by weight, 0.18% to 0.22% of C, 0.10% to 0.30% of Si, 0.90% to 1.10% of Mn, 0.40% to 0.60% of Cr, 0.30% to 0.50% of Mo, 0.10% to 0.30% of Ni, 0.01% to 0.03% of Nb, 0.010% to 0.020% of Ti, 0.010% to 0.030% of Alt, 0.0015% to 0.0025% of B, smaller than or equal to 0.012% of P, smaller than or equal to 0.005% of S and the balance Fe and inevitable impurities. The preparation method includes the steps of casting blank smelting, casting blank casting, casting blank heating, steel plate rolling and heat treatment. The high-toughness stable-brinell-hardness extra-thick abrasion-resistant steel and the preparation method have the advantages that through the reasonable component design and technology improvement, a steel plate is excellent in comprehensive mechanical property, good in impact toughness and stable in abrasion resistance index-brinell hardness value, and the high-toughness stable-brinell-hardness extra-thick abrasion-resistant steel can be massively applied to coal mine machinery and engineering machinery industries and has the high application prospect.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

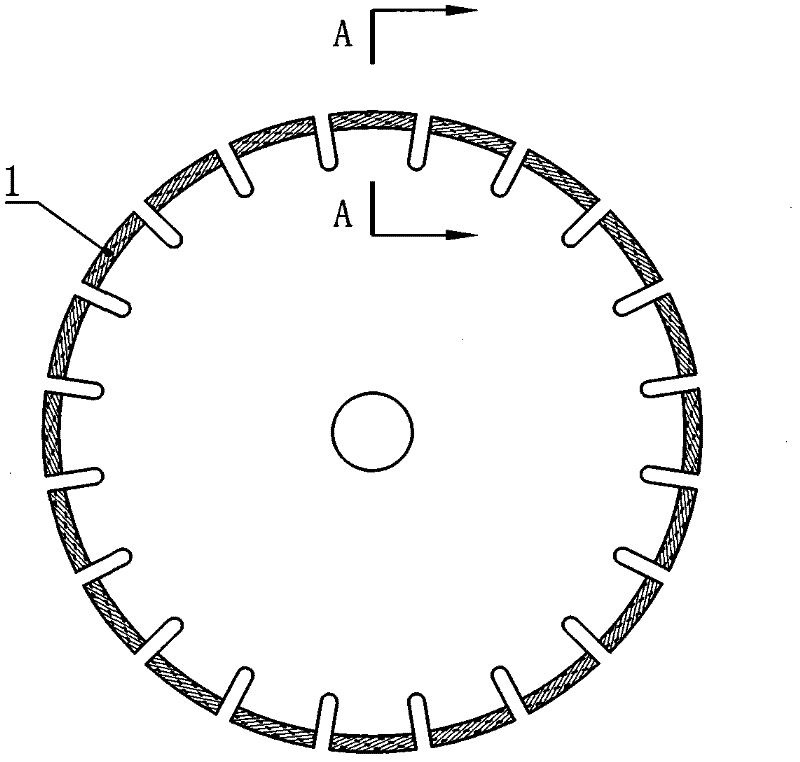

Superhard material tool bit with high surface abrasive resistance and manufacturing method thereof

InactiveCN102390087AImprove surface wear resistanceMaintain Thickness DimensionsStone-like material working toolsMachining processHigh surface

Owner:山东日能超硬材料有限公司

Claw provided with novel abrasion-resisting layer structure and manufacturing method thereof

InactiveCN106853525AFine grainImprove mechanical propertiesAdditive manufacturing apparatusNuclear energy generationNuclear powerMathematical model

The invention discloses a nuclear power station control rod drive mechanism claw provided with a novel abrasion-resisting layer structure and a manufacturing method thereof. According to the structure of the claw, the appearance of an abrasion-resisting layer of a pin hole is square, and the combining face of claw teeth and a base body is a plane. The claw adopts a laser 3D printing technology. The laser 3D printing technology comprises the following manufacturing steps that S1, a three-dimensional mathematical model of a workblank is established; S2, a laser deposition manufacturing scheme is formulated, and slicing and laser scanning path planning are conducted on the mathematical model; S3, manufacturing parameters are set and a process control program is compiled; S4, preparation work before manufacturing is completed; S5, laser deposition manufacturing is performed according to the set program; S6, the claw workblank is cut and separated from a base plate and then heat treatment is performed; S7, the claw workblank obtained after heat treatment is machined to obtain a finished claw product. The manufactured claw has the mechanical property better than that of an oxyacetylene overlaying claw, the production process is completely and automatically controlled and is not influenced by operators, and the claw is suitable for batch production and can completely replace the oxyacetylene overlaying claw.

Owner:TSC LASER TECH DEV BEIJING CO LTD

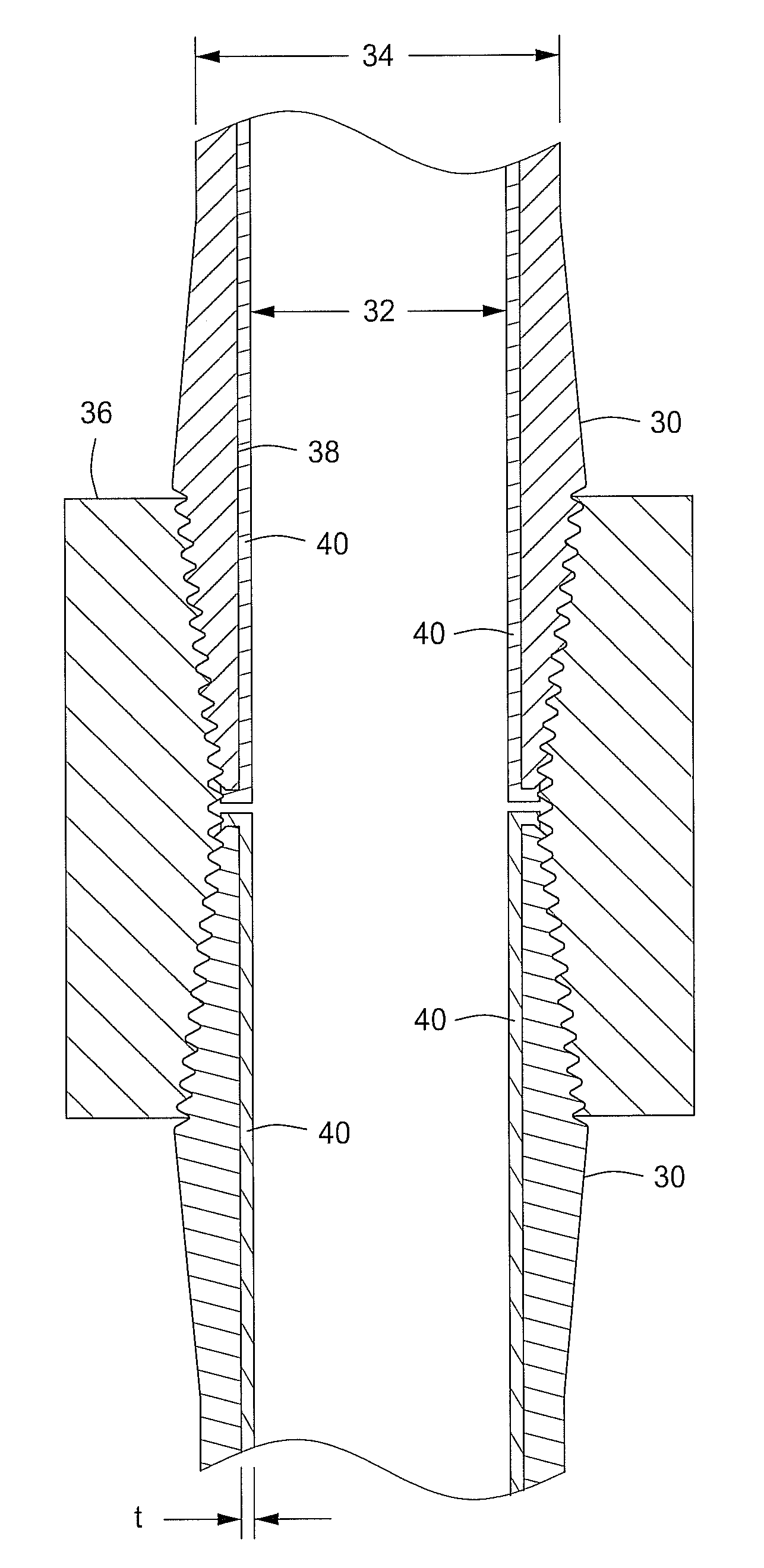

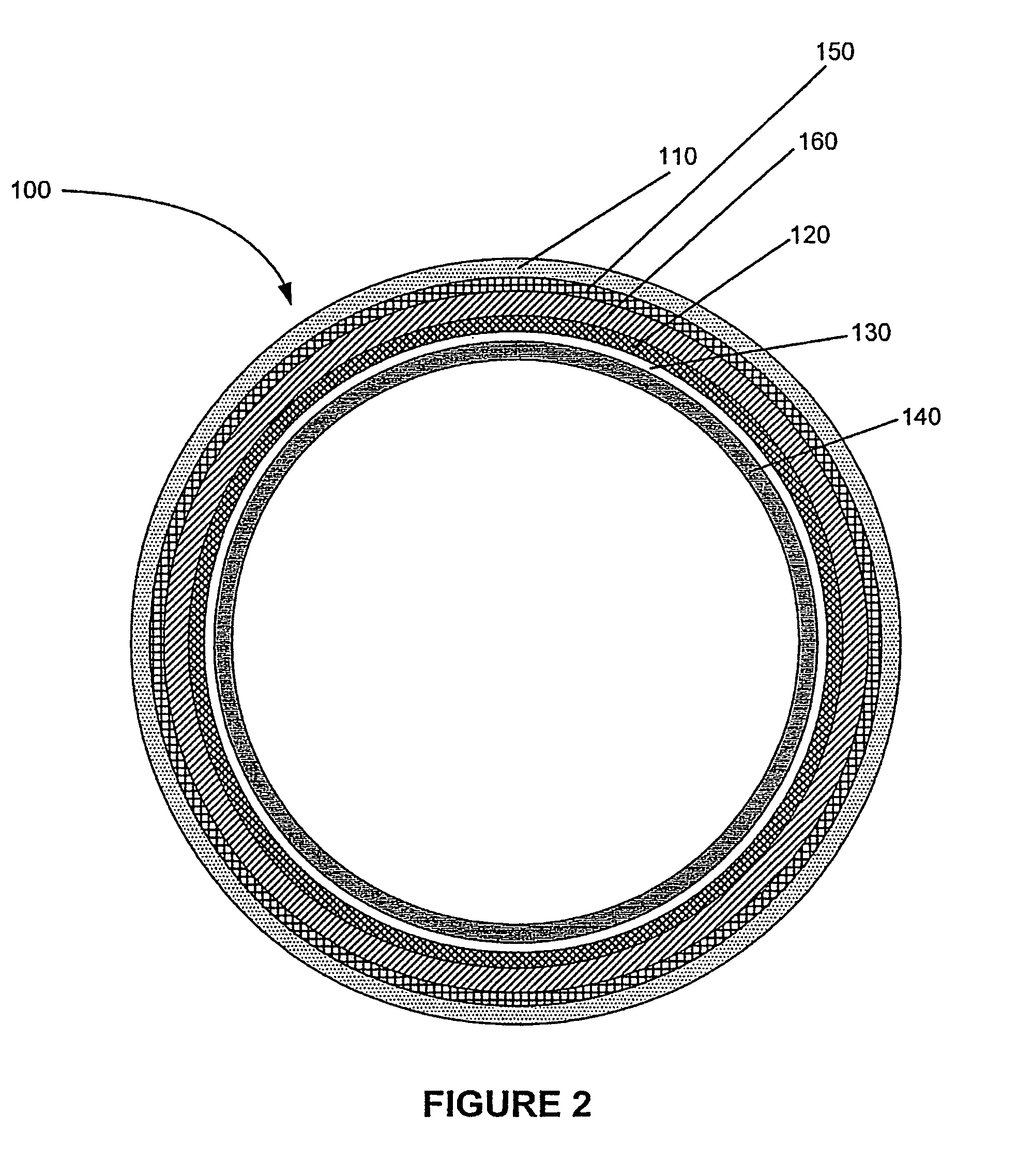

Downhole oilfield tubulars

The installation and use of abrasion and corrosion resistant polyolefin and polyolefin blend liners in the production or injection string of a well is shown. The lining is employed for the principal purpose of reducing wear or corrosion on the tubing string or wear on the associated production equipment. In a preferred embodiment of the invention, the polymer liner is characterized by polypropylene material, which is abrasion resistant and which has a coefficient of friction that is lower that the coefficient of friction of metal tubing. Also, disclosed herein are tubular goods and tubular good liners which decrease or eliminate friction and mechanical wear and decrease or eliminate chemical corrosion to the walls of the tubular good. The liners may include a diffusion barrier, an adhesive, and a friction and wear resistant layer.

Owner:WAGON TRAIL VENTURES

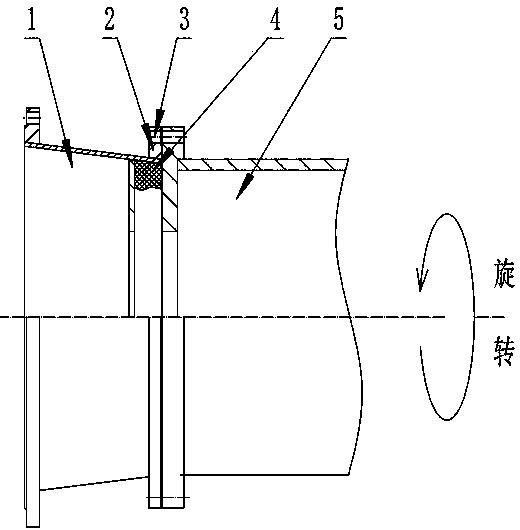

Repair method of NTC multi-wire sawing machine main roller and main roller structure after repair

ActiveCN103934626AAchieve reuseGuaranteed cutting accuracyShaft and bearingsFine working devicesEngineeringConical surface

The invention discloses a repair method of an NTC multi-wire sawing machine main roller and a main roller structure after repair. The repair method comprises the steps of shaft head removal, clamping hole machining, novel shaft head machining, mechanical fixing and the like. The reutilization of the NTC multi-wire sawing machine main roller is achieved with low investment, and the economic loss brought by conical surface abrasion is minimized. The repair method and the main roller structure have great economic value.

Owner:SUZHOU RUNDE NEW MATERIAL

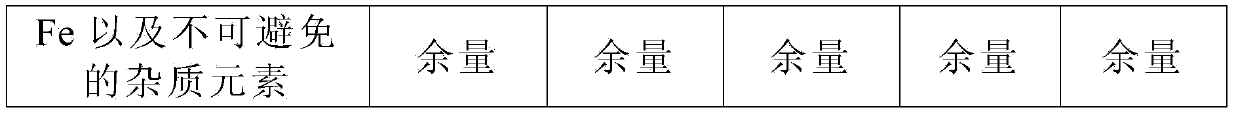

High-strength high-toughness abrasion-resistant cast steel material and preparation method thereof

The invention relates to a high-strength high-toughness abrasion-resistant cast steel material and a preparation method thereof. The novel high-strength high-toughness abrasion-resistant cast steel material is pertinently designed and developed for the severe working conditions that in the operation process, a trough side not only bears violent friction of coal, a scraper blade and a chain, but also bears operation load of a coal cutter, lateral force and longitudinal force used for pushing and pulling a hydraulic support, extrusion force and impact force generated when large sized coal and rock get stuck in a trough and the like. According to the mechanical performance indexes the cast steel material can reach, the tensile strength Rm>=900 MPa, the fracture elongation A>=16%, the impact absorbing energy Aku>=32J, and the Brinell hardness HB is 270-310. According to the abrasion resistance, weightlessness is 1.55+ / -0.03 g, and the weight loss ratio is 15.5+ / -0.3 mg / m. According to the preparation method, production is easy, the cost is low, and the performance is high. Quantity production and application can be achieved in the industries such as mines, energy, transportation, agricultural machinery and engineering machinery.

Owner:SHANXI ZHONGTIAOSHAN MECHANICAL & ELECTRONICS EQUIP

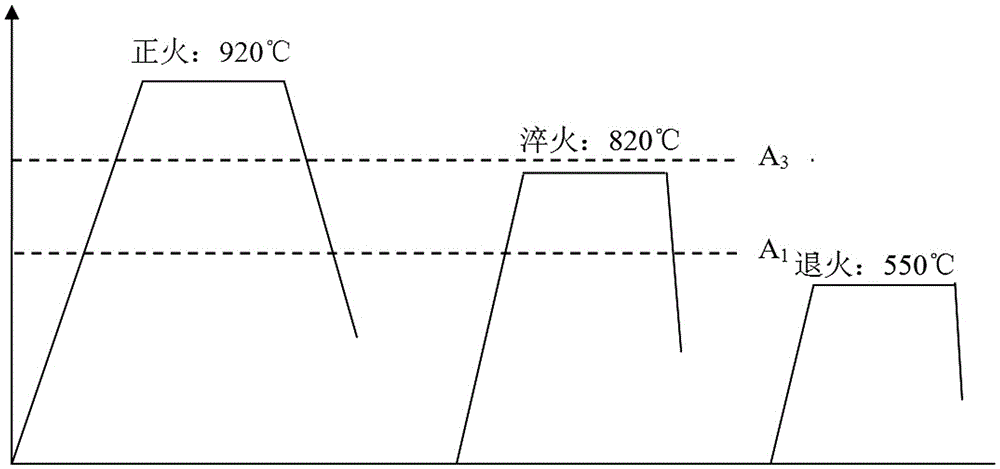

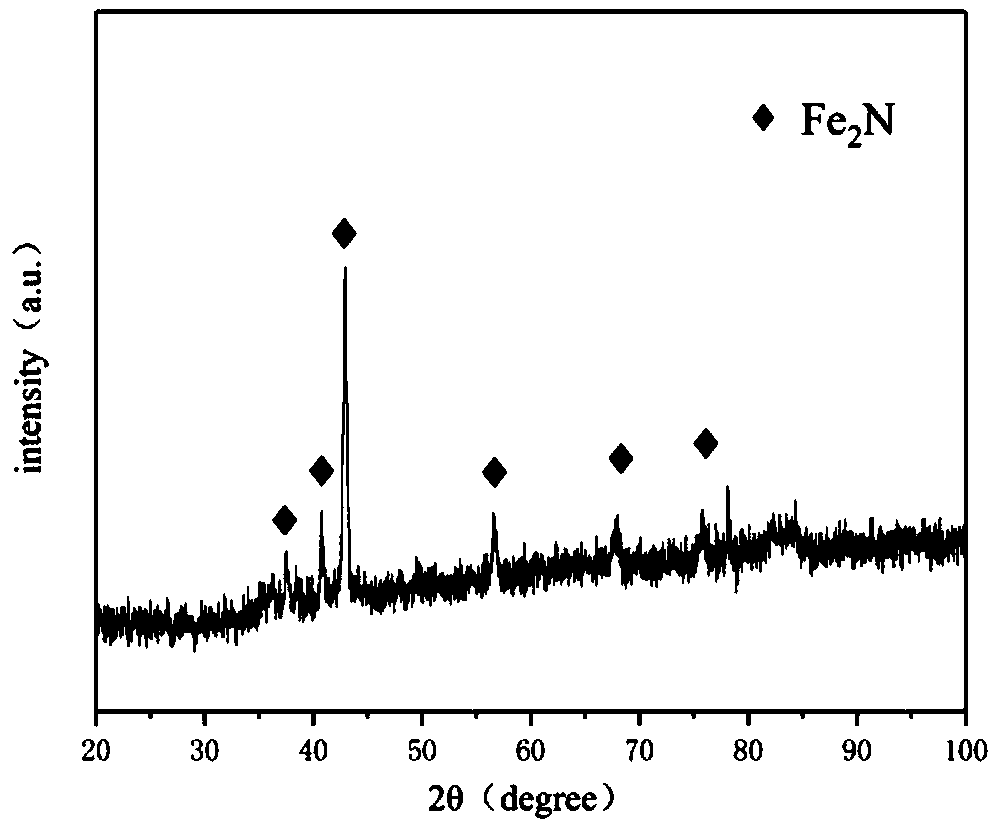

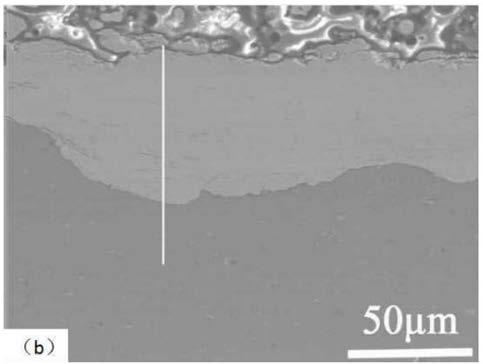

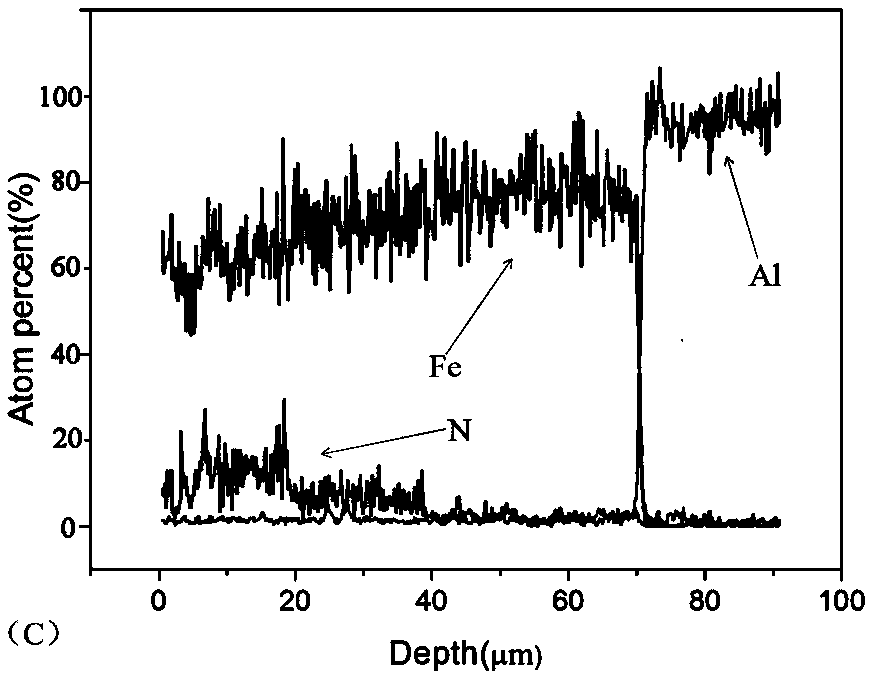

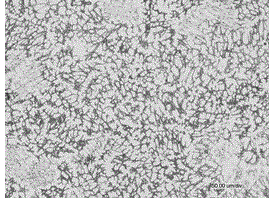

Method for preparing aluminum alloy surface composite gradient modified layer

InactiveCN109183020AImprove incompatibilityHigh hardnessSolid state diffusion coatingPressure inorganic powder coatingNano structuringBinding force

The invention discloses a method for preparing an aluminum alloy surface composite gradient modified layer. The method comprises the following steps: (1) pretreating the surface of an aluminum alloy material, namely grinding the surface with abrasive paper, sequentially washing respectively in alcohol and acetone solution to remove surface stains; (2) introducing a ferroalloy layer having a certain thickness and a nano-structure to the aluminum alloy surface by adopting a surface mechanical nano-alloying method; and (3) performing nitriding treatment at a certain temperature on the sample which is subjected to surface alloying treatment. By adopting the method, a modified layer having a gradient composite structure and excellent abrasion resistance is prepared on the surface of the aluminum alloy matrix, and has excellent compatibility and binding force with the matrix. Furthermore, the method is simple in process and low in cost, and is suitable for large-scale surface treatment of flat aluminum alloy materials.

Owner:HEFEI UNIV OF TECH

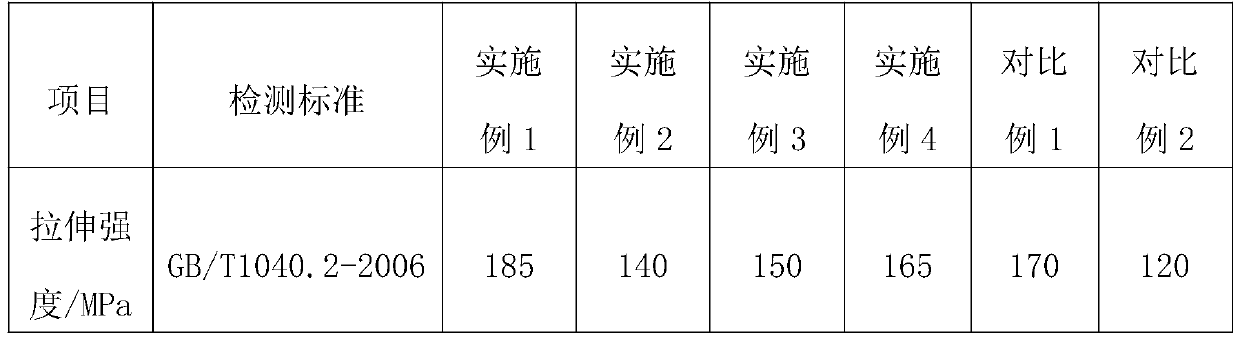

High-temperature-resistant self-lubricating wear-resistant composite material and preparation method thereof

The invention discloses a high-temperature-resistant self-lubricating wear-resistant composite material and a preparation method thereof, and belongs to the field of high polymer materials. The composite material is prepared from the following raw materials in parts by weight: 45 to 80 parts of a high-temperature thermoplastic resin, 10 to 35 parts of carbon fiber, 5-25 parts of a wear-resistant filler, 5-20 parts of a lubricant, and 0.5 to 3.0 parts of a coupling agent. The high-temperature-resistant self-lubricating wear-resistant composite material disclosed by the invention has the characteristics of excellent mechanical property, high-temperature resistance, low friction coefficient and low abrasion loss, and can be widely applied to the fields of bearings, shaft sleeves, gears, retainers and the like.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Metal material and its forming method

InactiveCN102260828AReduce machining timeImprove anti-wear performanceManufacturing cost reductionRoom temperature

The invention discloses a metallic material and a method for forming same. The invention solves the technical problem of enhancing the shock resistance and the abrasion resistance of the metallic material and lowering cost. The metallic material disclosed by the invention is made from the following materials in percentage by mass: 0.5-2.1% of C, 0.2-0.9% of Si, 0.69-3.3% of Mn, 0.015-0.05% of S, 0.015-0.05% of P, 0.8-4.6% of Cr, 0.6-3.8% of W, 0.6-6% of Ni, 0.69-1.5% of Mo, 0.05-0.8% of Co, 0.3-2.8% of Cu and the rest percent of Fe. Forming is casting; and demolding of the metallic material is realized by being put in heat-preserving medium or a heat-preserving box body for cooling to room temperature and annealing. Compared with the prior art, the metallic material is once formed by casting without quenching or nitriding, thus the shock resistance and the abrasion resistance of the metallic material are enhanced, the time for mechanically machining of metallic parts or dies is saved and the manufacturing cost is lowered.

Owner:武燕萍

Gear pair abrasion loss prediction method based on dynamic meshing force

ActiveCN109871652ATaking into account efficiencyTaking into account the accuracySpecial data processing applicationsGear wheelEngineering

The invention belongs to the technical field of mechanical dynamics, and particularly relates to a gear pair abrasion loss prediction method based on dynamic meshing force, which comprises the following steps: S1, acquiring basic parameters of a gear pair; S2, calculating the time-varying meshing stiffness and static load distribution coefficient of the worn gear pair according to the acquired basic parameters of the gear pair and a gear tooth bearing contact analysis method; S3, introducing the time-varying meshing stiffness obtained through calculation into a gear rotor system dynamic modelto calculate a dynamic meshing force and a dynamic load distribution coefficient of the gear pair; and S4, adopting an Archard wear theory, a wear coefficient empirical formula, the dynamic meshing force of the gear pair and the dynamic load distribution coefficient to calculate and obtain the tooth surface wear loss of the gear pair. According to the gear pair abrasion loss prediction method based on the dynamic meshing force, prediction efficiency and prediction precision are both considered.

Owner:NORTHEASTERN UNIV

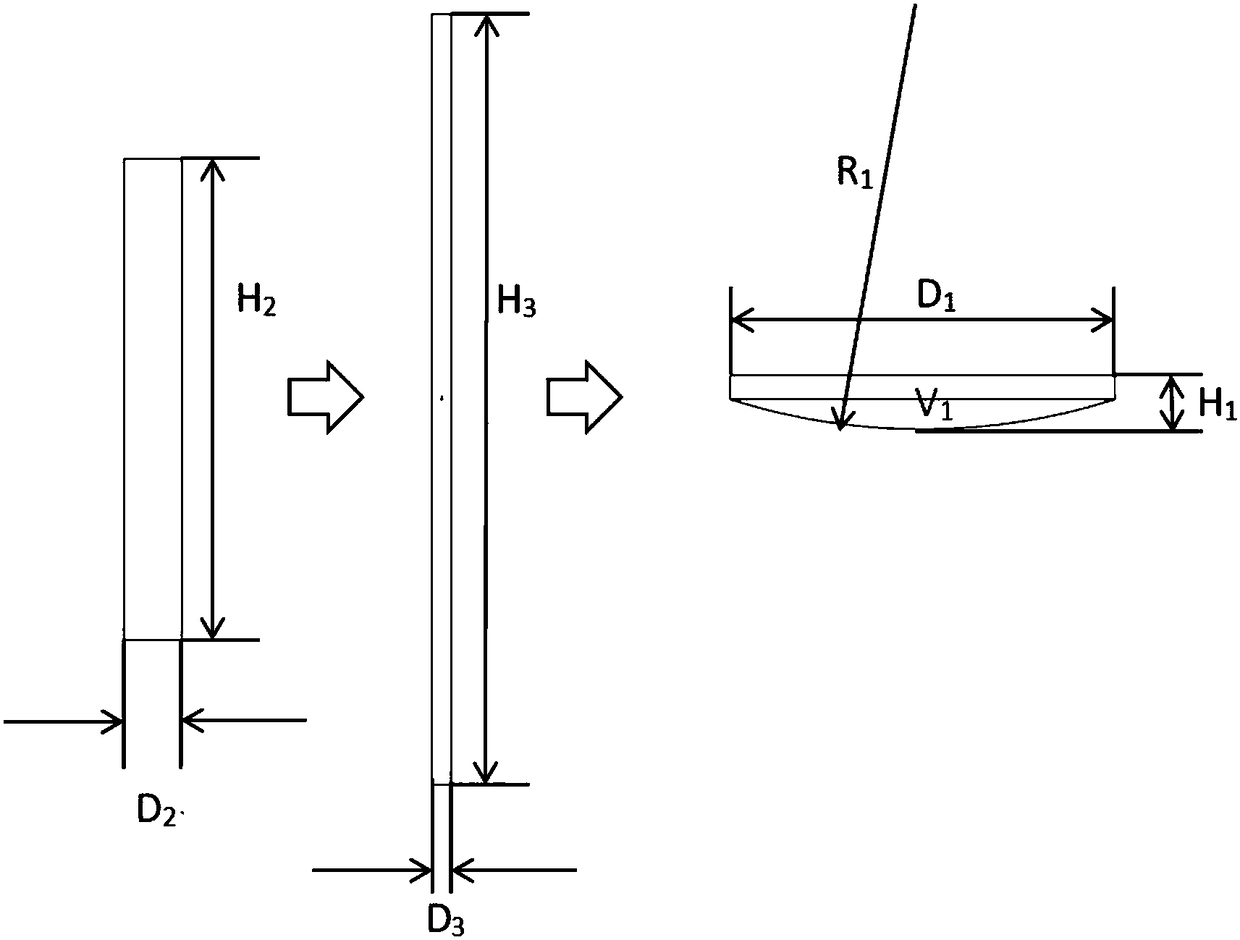

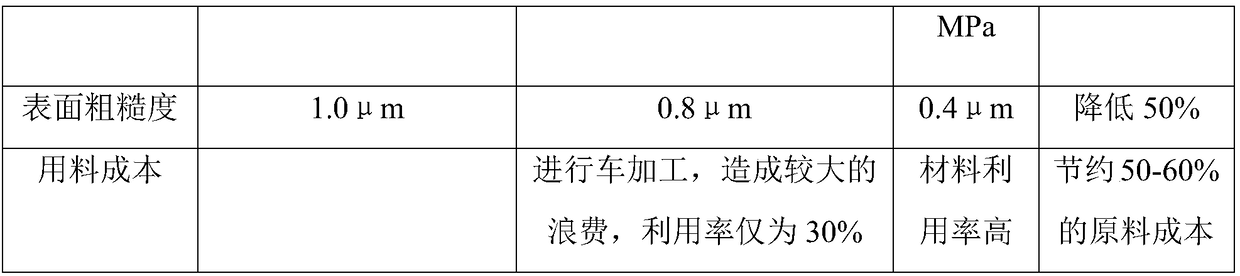

Aluminum alloy having high abrasion resistance, spherical cap made of aluminum alloy, and preparation method of spherical cap

ActiveCN108265211AImprove wear resistanceImprove corrosion resistanceAnodisationBridge structural detailsSurface layerMicrometer

The invention discloses an aluminum alloy having high abrasion resistance, a spherical cap made of the aluminum alloy, and a preparation method of the spherical cap. The aluminum alloy comprises the following components of, by mass fraction, 0.10-0.40% of Mn, 2.30-3.30% of Mg, 0.15-0.25% of Cr, 3.50-4.50% of Zn, 0.15% of Cu, less than or equal to 0.30% of Si, less than or equal to 0.40% of Fe, 0.15% of subgroup elements and the balance Al. The abrasion resistance and the corrosion resistance of an aluminum alloy spherical cap body are improved substantially; a series of problems such as high surface roughness are solved; a surface layer of the spherical cap subjected to rolling treatment, mechanical polishing and surface hard anodic oxidation treatment is a mirror surface, the surface hardness is raised to 300-500 HV, the surface roughness is not greater than 0.8 micrometer, the core hardness of a spherical cap component is 172-185 HB, the yield strength is 270-470 Mpa, the strength ofextension is 300-560 Mpa, the elongation percentage is 8-9%, and the wear rate is 3.4*10<-5> to 4.1*10<-5> mm / m under the conditions that the load is 10N and the speed is 10000 r / min; and the usability, the fatigue resistance and the strength of the spherical cap are improved obviously.

Owner:CHINA RAILWAY DESIGN GRP CO LTD +1

Heat-resistant abrasion-resistant double-phase stainless steel casting alloy material

InactiveCN104451428AImprove wear and corrosion resistanceExcellent heat resistance, wear resistance and corrosion resistanceSolution treatmentSmelting process

The invention relates to a heat-resistant abrasion-resistant double-phase stainless steel casting alloy material, and belongs to the technical field of steel and iron alloy materials. The heat-resistant abrasion-resistant double-phase stainless steel casting alloy material comprises the following components in percentage by mass: 0.15-0.45% of C, 25.0-28.0% of Cr, 4.0-6.0% of Ni, 0.5-1.0% of Mo, 0.05-1.5% of Nb, less than or equal to 1.0% of Mn, less than or equal to 1.5% of Si, less than or equal to 0.03% of P, less than or equal to 0.03% of S, less than or equal to 0.5% of C+N, less than or equal to 1.5% of Nb+V, and the balance of Fe and inevitable impurities. A solid-solution structure of the steel in the component range comprises ferrite and austenite, wherein the austenite accounts for 40-60%, the room-temperature tensile strength is 500-700 MPa, and the elongation percentage is more than 20%. The alloy material is prepared by a conventional smelting process method comprising the following steps: smelting ingredients, performing cast molding, performing solid-solution treatment at 1000-1200 DEG C and aging treatment at 700-900 DEG C, and performing mechanical processing. The alloy material has very good abrasion resistance at 650-950 DEG C and is a relatively good candidate material for manufacturing a mechanical grate for a garbage power station.

Owner:XINGHUA SPECIAL STAINLESS STEEL INST OF SHANGHAI UNIV

Manufacturing method of screw

The invention relates to a manufacturing method of a fastener, in particular to a manufacturing method of a screw, and belongs to the machining field of alloy materials. The manufacturing method of the screw comprises the steps that a screw blank is obtained by sequentially conducting normalizing treatment, machining and heat treatment on steel; the heat treatment involves carburizing treatment and tempering treatment, and during carburizing treatment, the temperature is firstly increased to 890-910 DEG C, preserved for 70-90 min, then decreased to 880-900 DEG C, preserved for 30-50 min, decreased to 820-840 DEG C, preserved for 20-40 min, and finally decreased to the room temperature through air cooling; the tempering treatment temperature is 150-180 DEG C, and the tempering treatment time is 100-140 min; and the finished screw can be obtained by sequentially conducting oil and rust removal, activating treatment, blackening and passivating treatment on the screw blank. After carburizing treatment is conducted on the screw alloy steel, the screw is provided with a hard and abrasion-resistant surface and a tough core and has high low-temperature impact toughness and good machinability; through surface blackening, the mechanical property of the screw is further improved, the Rockwell hardness (HRC) of the screw reaches 58-63, the layer depth of the screw is 0.7-1.0, and the service life of the screw is greatly prolonged.

Owner:NINGBO RUIER AUTO PARTS CO LTD

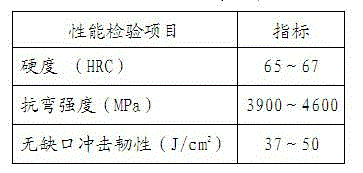

High-strength and high-abrasion-resistance brown aluminum oxide ceramic and preparation method thereof

PendingCN108793974ABeautiful and generous colorQuality improvementSilicon dioxideMechanical property

The invention discloses a high-strength and high-abrasion-resistance brown aluminum oxide ceramic and a preparation method thereof and belongs to the technical field of aluminum oxide ceramics and aims to solved the technical problems and remarkably improving the mechanical property of the ceramic under the situation that the firing temperature is not improved, decreasing raw materials, reducing the manufacturing cost and improving the production efficiency. According to the adopted technical scheme, the high-strength and high-abrasion-resistance brown aluminum oxide ceramic is prepared from,by weight, 1-3.5 parts of manganese dioxide, 1-3 parts of iron trioxide, 0.1-0.5 part of magnesium oxide, 0.5-1.5 parts of silicon dioxide, 0.5-2 parts of kaoline, 2-8 parts of calcium oxide, 2-5 parts of zirconium oxide, 0.3-0.8 part of cobaltic oxide, 1-3 parts of barium carbonate, 0.3-0.8 part of chromic oxide and 100 parts of aluminum oxide. The prepared high-aluminum ceramic product has darkand light-toned brown colors due to different ingredient contents and is attractive in appearance.

Owner:河津市锦浩特种陶瓷有限公司

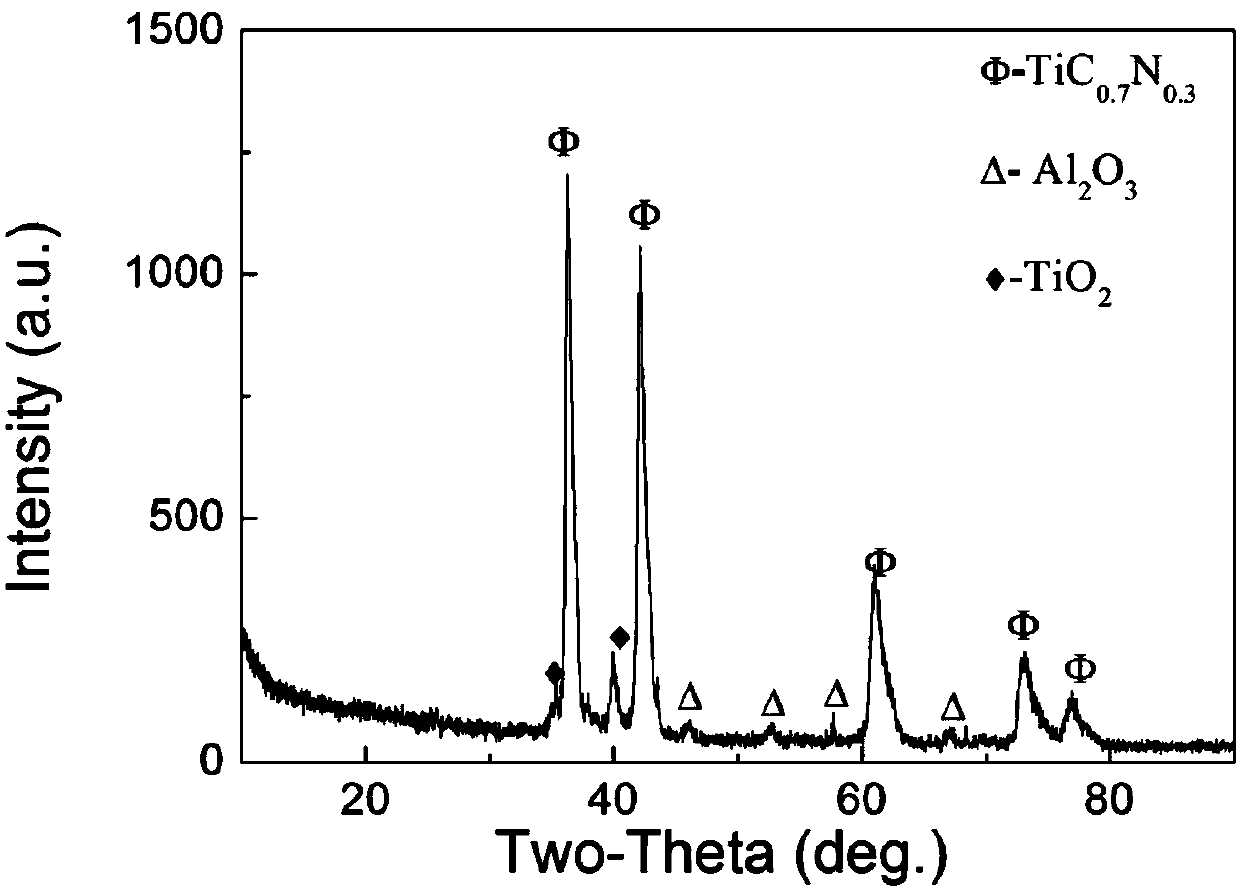

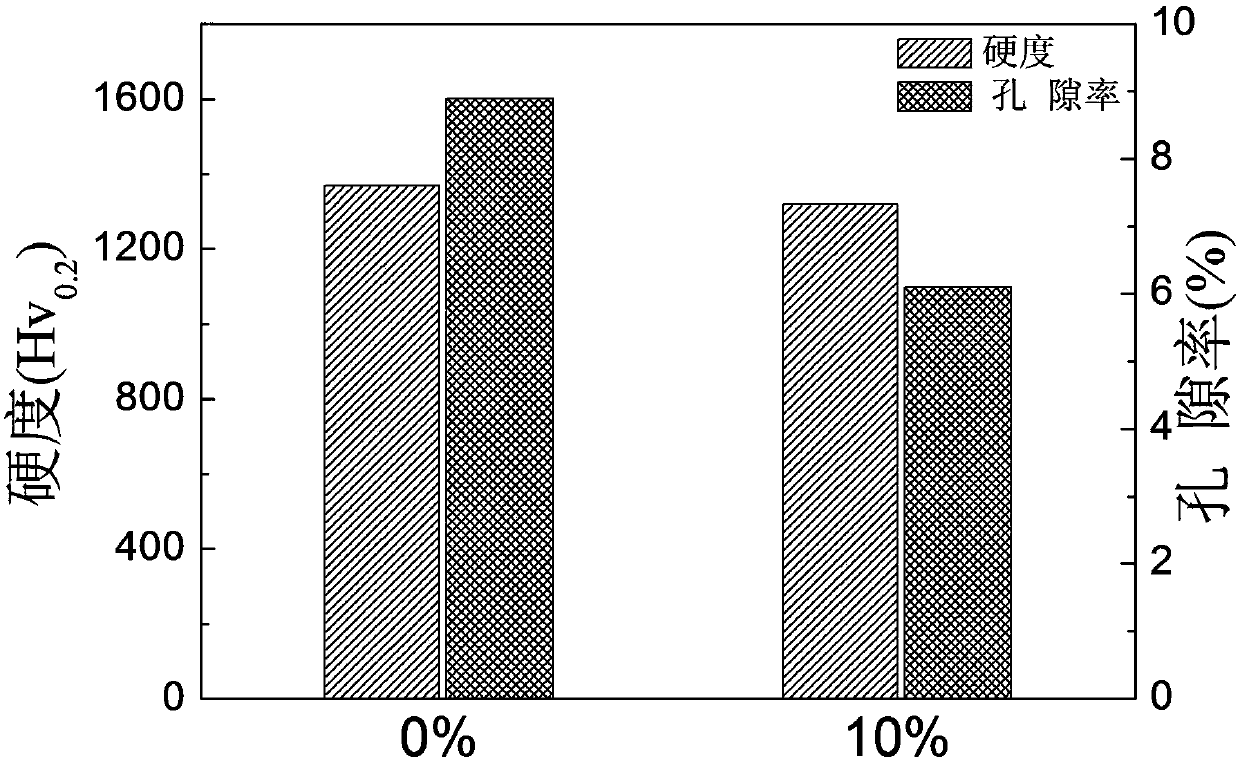

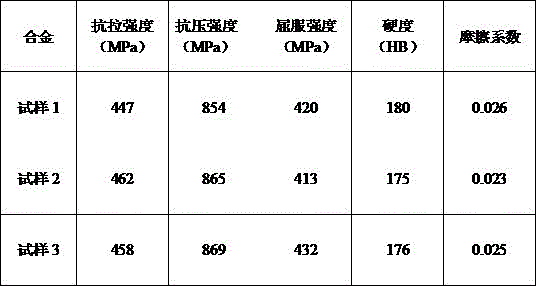

Preparation method for TiCN-Al2O3 ceramic composite coating

ActiveCN107653431AHigh hardnessImprove wear resistanceMolten spray coatingCeramic compositeWorking environment

The invention provides a preparation method for a TiCN-Al2O3 ceramic composite coating. The method comprises the following steps that 1, a base body sample is subjected to surface roughening treatment; 2, Ti-C composite powder and Al2O3 powder are mechanically stirred and mixed to obtain spray feeding composite powder; 3, the surface of a base body is pre-sprayed with self-melting alloy powder ofNi-10%wtAl to obtain a bonding bottom layer with the thickness 90-120 [mu]m; and 4, the surface of the bonding bottom layer is sprayed with the spray feeding composite powder to obtain the TiCN-Al2O3composite coating with the thickness 300-500 [mu]m. The plasma-sprayed TiCN-Al2O3 ceramic composite coating has excellent performance of high hardness and abrasion and corrosion resistance, is suitable for workpieces under the abrasion and corrosion working environment such as the fields of manufacturing of cars and machinery such as cutters, drill bits and molds, aerospace industry and the like,and has extremely wide application prospects.

Owner:HEBEI UNIV OF TECH

High-strength and high-abrasion-resistant low-expansion-coefficient aluminum-based alloy

The invention provides a high-strength and high-abrasion-resistant low-expansion-coefficient aluminum-based alloy.The alloy is aluminum-based alloy containing aluminum, zinc, copper, magnesium, bismuth, titanium, boron, strontium, rare earth and other inevitable impurity elements.The high-strength and high-abrasion-resistant low-expansion-coefficient aluminum-based alloy has good cutting performance, excellent mechanical properties, low expansion coefficient and low production cost, has the competitive advantages both at home and abroad and can replace brass, tin bronze and zinc-based alloy, and the production costs of enterprises are greatly reduced.

Owner:海阳鹏程压铸厂

Downhole oilfield tubulars

The installation and use of abrasion and corrosion resistant polyolefin and polyolefin blend liners in the production or injection string of a well is shown. The lining is employed for the principal purpose of reducing wear or corrosion on the tubing string or wear on the associated production equipment. In a preferred embodiment of the invention, the polymer liner is characterized by polypropylene material, which is abrasion resistant and which has a coefficient of friction that is lower that the coefficient of friction of metal tubing. Also, disclosed herein are tubular goods and tubular good liners which decrease or eliminate friction and mechanical wear and decrease or eliminate chemical corrosion to the walls of the tubular good. The liners may include a diffusion barrier, an adhesive, and a friction and wear resistant layer.

Owner:WAGON TRAIL VENTURES

High-strength abrasion-proof steel plate capable of soldering without thermal treatment and method of producing the same

The invention relates to a high-strength wearproof steel plate which can be welded through no heat treatment and is applied to the industry of manufacturing various mechanical equipments, and a preparation method. The preparation method comprises the following steps: 1. smelting: a flat ingot is smelted and poured through an electric furnace; in the smelting process, the S amount and the P amount are controlled so as to ensure the quality of molten steel; and 2. rolling: the molten steel is poured to the flat ingot and is rolled; in steel rolling, the rolling control and the cooling control are actualized, that is, in the initial rolling stage, the pressing amount of a pass and the corresponding deformation amounts of two phase regions of the late stage are enlarged as possible, thereby ensuring the thinning of crystal grains, improving strength and comprehensive mechanical performance and controlling cooling in straightening. Through reasonable composition design, the product and the method adopt a special process technology of rolling control and cooling control and have relatively low price.

Owner:SHENYANG HEAVY MACHINERY GROUP

High-strength, shock-resistant and abrasion-resistant mechanical paint

ActiveCN104845473AStrong weather resistanceGood corrosion resistanceAnti-corrosive paintsPolyester coatingsSolventCorrosion resistant

The invention discloses a high-strength, shock-resistant and abrasion-resistant mechanical paint. The paint comprises raw materials of, by weight, 55 parts to 60 parts of core shell fluorinated polyacrylates, 15 parts to 18 parts of styrene-acrylic emulsion, 8 parts to 12 parts of alkyd resins, 7 parts to 10 parts of modified silicon dioxide, 5 parts to 7 parts of mica powder, 3 parts to 5 parts of modified starch, 2.8 parts to 3.5 parts of chlorinated rubber, 2 parts to 3 parts of organic bentonite, 2 parts to 3 parts of sodium carboxymethylcellulose, 0.3 part to 0.5 part of calcium stearate, 0.8 part to 1.2 parts of coalescing agents, 1.2 parts to 1.5 parts of defoamers, 3 parts to 6 parts of pigment, 0.7 part to 1 part of defoamers, 0.5 part to 0.8 part of advection agents, 0.03 part to 0.05 part of mildew preventives and 42 parts to 45 parts of solvents. The paint is high in strength, shock resistance and abrasion-resistant performance.

Owner:安庆凯锐化工科技有限公司

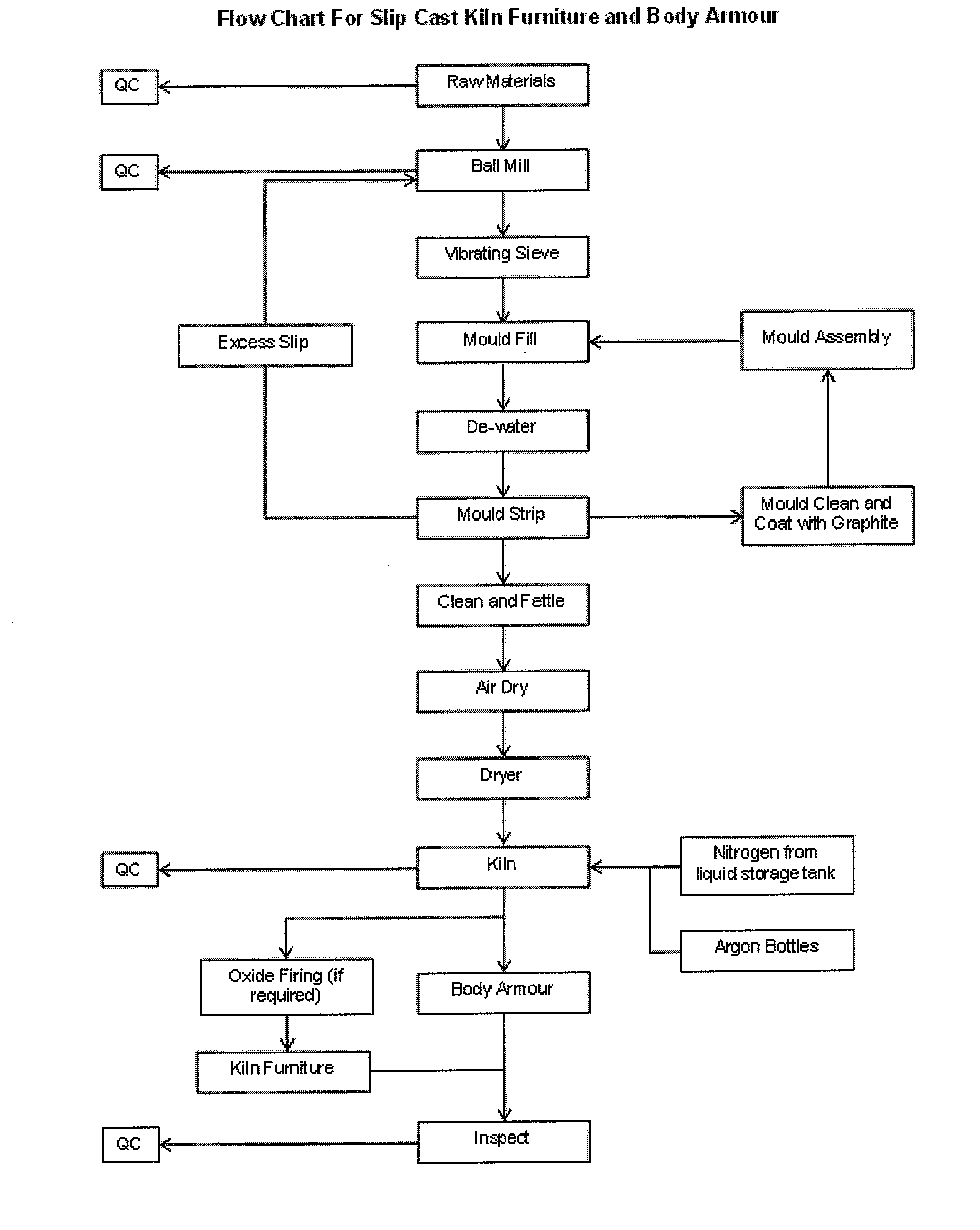

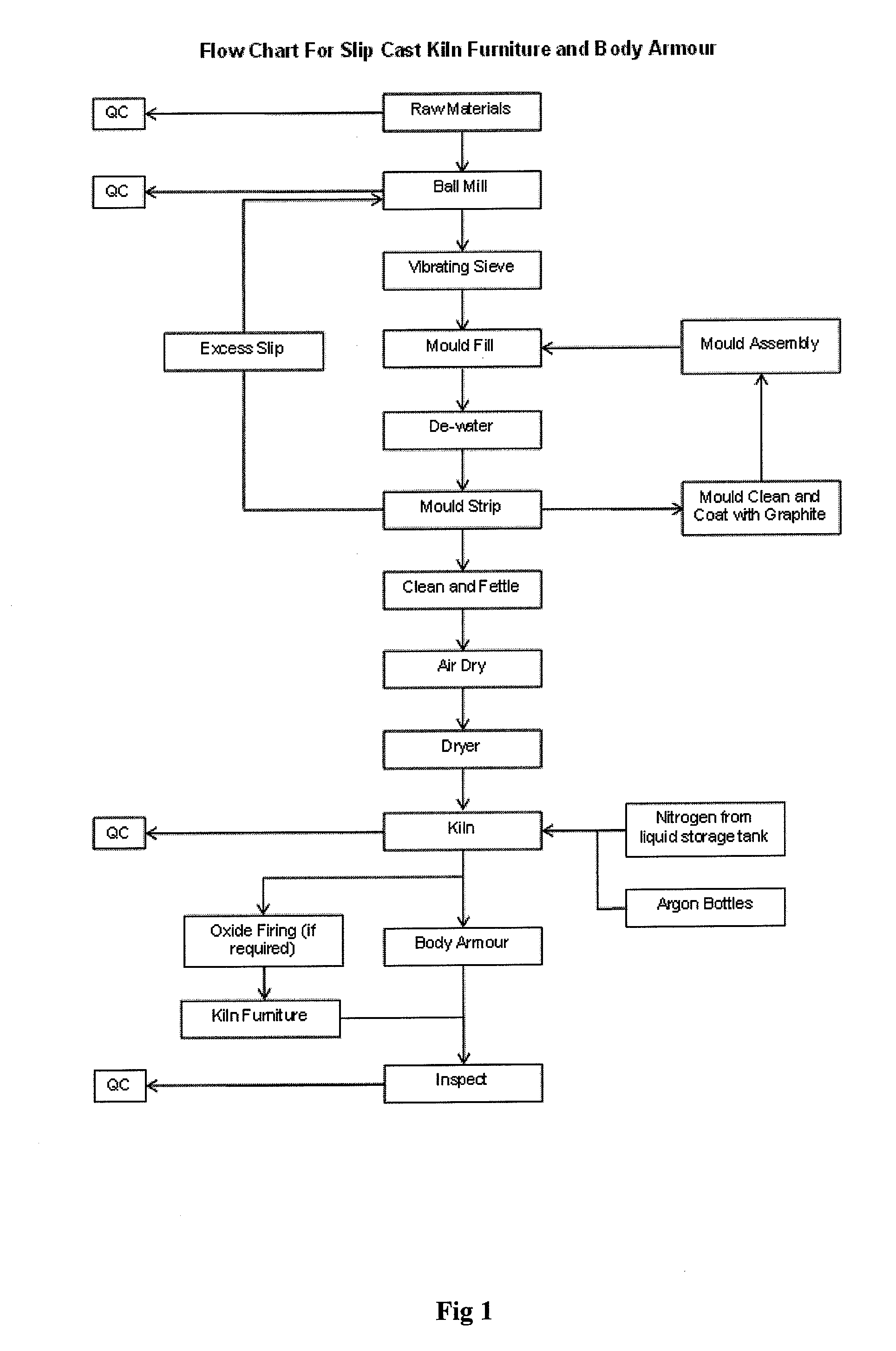

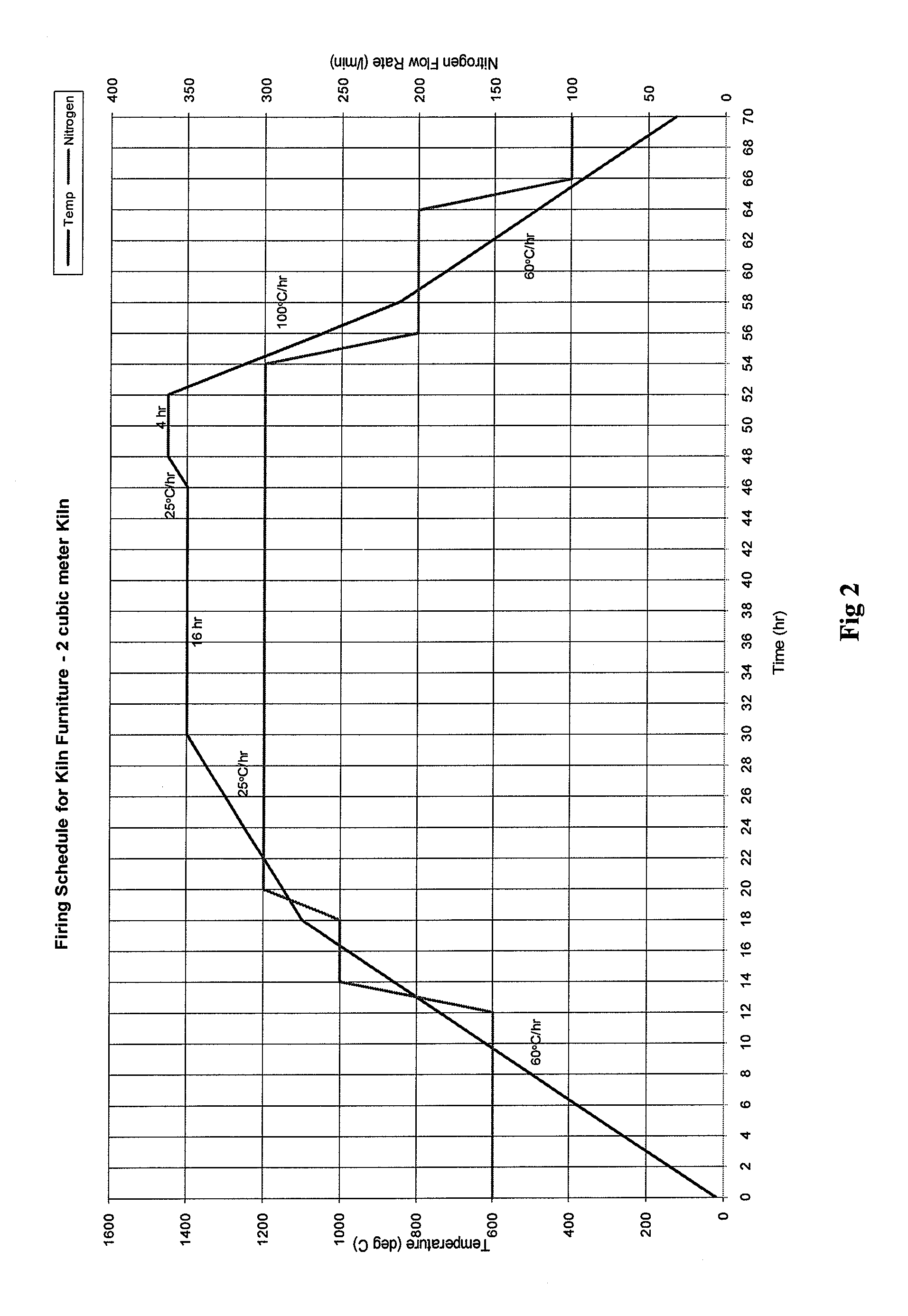

Sialon bonded silicon carbide material

A silicon carbide based material exhibiting high strength, good thermal shock resistance, high resistance to abrasion and being chemically stable to harsh environmental conditions is described. The carbide Ball Hill ceramic comprises a β-SiAlON bonding phase in which sintering is facilitated by at least one rare earth oxide sintering agents incorporated within the Vibrating Sieve batch admixture as starting materials. The residual rare earth sintering aid being chosen so as to impart good mechanical and refractory properties.

Owner:CAPITAL REFRACTORIES LTD

Processing technology for high-abrasion-resistance aluminium alloy foaming mould casting

The invention discloses a processing technology for a high-abrasion-resistance aluminium alloy foaming mould casting, and the processing technology comprises the following four steps of: burdening, smelting, casting and carrying out heat treatment. According to the processing technology disclosed by the invention, appropriate amounts of rare earth elements such as Y, Pr and Nd are added in aluminium alloy, the content of hydrogen in the aluminium alloy is reduced, and the plasticity, heat resistance, abrasion resistance and high temperature strength of the aluminium alloy are improved. An aluminium alloy refrigerator foaming mould casting processed by adopting the processing technology disclosed by the invention has the advantages of good mechanical properties, high strength, good heat resisting property, good usability, good internal structure compactness, no pore or peeling, high abrasion resistance, high oxidation resistance, low expansion coefficient and the like.

Owner:CHUZHOU DIMENGDE MOLD MFG

Manufacturing method for large-caliber abrasion-resistant corrosion-resistant ternary composite reducer pipe

InactiveCN103411096ASolve the problem that the ceramic layer cannot be processedPrevent wear and corrosion failureCorrosion preventionPipe protection against corrosion/incrustationInorganic particleAdhesive

The invention relates to a manufacturing method for a large-caliber abrasion-resistant corrosion-resistant ternary composite reducer pipe. The nominal diameter (DN) of the reducer pipe is 600mm-1200mm, and reducer pipe is used for a large-caliber ternary composite pipeline for transporting corrosive wearing, erosive wearing, abrasion scaling, composite corrosion media and the like. A manufacturing process for manufacturing an abrasion-resistant corrosion-resistant composite layer on the inner surface of the reducer pipe and a manufacturing method include the step that 1 a self-propagating high-temperature centrifugal synthesis (SHS) reaction is conducted through a gradient method in a segmentation mode step by step, and reaction products TiB2 / ZrB2-Al2O3 and Fe are distributed on the inner surface of the reducer pipe effectively; 2 abrasion-resistant materials are used for filling the spaces among the gradients and mainly composed of abrasion-resistant inorganic particles and modified resin composite adhesives; 3 inner surface pouring forming is conducted through a model vacuum pouring process. By means of the large-caliber abrasion-resistant corrosion-resistant ternary composite reducer pipe, combination force of a lining composite layer and an outer steel pipe interface is strong, mechanical impact resistance is high, abrasion resistance and corrosion resistance are good, the service life is long, and important project value is achieved.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com