Track steel having high strength, high abrasion resistance and long fatigue life, and production process for same

A technology with high wear resistance and fatigue life, applied in the field of crawler steel, can solve problems such as increasing the difficulty of smelting, and achieve the effects of improving comprehensive mechanical properties, reducing production costs, and improving fatigue performance and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

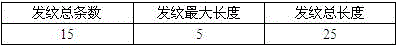

[0054] The chemical composition comparison between domestic patented steel 1 (publication number CN103805898A) and patented steel 2 (publication number CN103160729B) and the present invention is shown in Table 1 below.

[0055] Table 1 Chemical composition comparison (wt%)

[0056]

[0057] Prepared by the following production process:

[0058] 1) Converter smelting: smelting in a 90-ton or more top-bottom double-blown converter (the present invention uses a 90-ton top-bottom double-blown converter), using molten iron and scrap steel as raw materials at a mass ratio of 9:1 Primary smelting, double slag operation, to achieve pre-dephosphorization, adding 400kg of special refining slag, 400kg of quicklime, 100Kg of composite deoxidizer, metal manganese, silicon manganese, ferromanganese, medium carbon ferrochrome and other alloys for pre-deoxidation and initial composition Adjustment, use slag blocking and slag tapping to prevent phosphorus return;

[0059] The composite de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com