High-strength and high-abrasion-resistant low-expansion-coefficient aluminum-based alloy

A low expansion coefficient, aluminum-based alloy technology, applied in the field of aluminum-based alloys, to achieve excellent mechanical properties, excellent wear resistance and low expansion coefficient indicators, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment further illustrate the present invention.

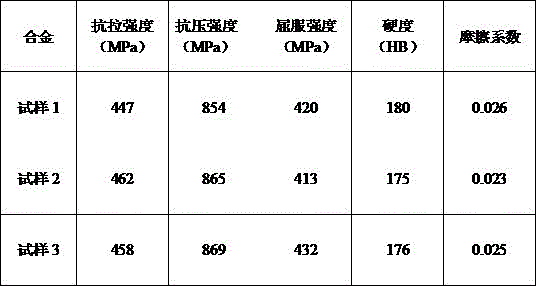

[0019] The three embodiments of the present invention are respectively cast according to the specific alloy composition in Table 1, and the technological process is as follows: aluminum ingots, zinc ingots, copper, bismuth, and silicon are melted, degassed, pressed into magnesium blocks, strontium is degenerated, titanium and boron are degenerated, rare earths are degenerated, and degassing is performed. Gas, slag, casting.

[0020] The specific process is: heating aluminum ingots, zinc ingots, copper, bismuth, and silicon, and other alloys in a resistance furnace, degassing after melting, pressing into magnesium blocks, strontium metamorphism, titanium boron metamorphism, and then rare earth metamorphosis, secondary degassing and slag removal Post-cast castings.

[0021] Table 1 Sample chemical composition (mass%)

[0022] alloy Al Cu Mg Bi Si Sr Ti B Ce Zn and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com