Corrosion experiment and injury evaluation methods of engineering material under wind sand environment

A technology of engineering materials and evaluation methods, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of inability to effectively simulate the erosion and wear behavior of gas-solid two-phase flow, and achieve accurate and feasible test results, low research costs, and test results. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

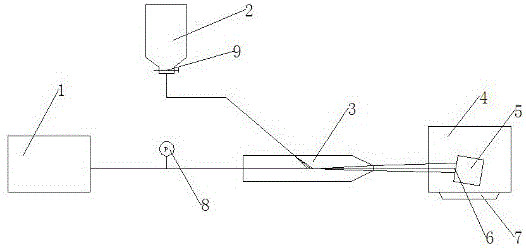

[0024] An engineering material erosion experiment in a wind-sand environment, including an experiment system and a method for operating the experiment system, wherein the experiment system includes a wind-sand environment simulation system and an erosion chamber 4, wherein the wind-sand environment simulation system is used to simulate the wind-sand environment, and the erosion The etching chamber 4 is used to fix the experimental specimen 5 .

[0025] Further, the wind and sand environment simulation system includes an air compressor 1, wherein the air compressor 1 is connected with the sandblasting gun 3, and the sandblasting gun 3 is connected with the sand box 2 and shoots the wind and sand in the gun to the test chamber in the erosion chamber. Part 5, wherein an airflow control valve 8 is arranged between the air compressor 1 and the sandblasting gun 3, and a sand volume control valve 9 is arranged between the sandblasting gun and the sand box 2; an anemometer 6 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com