Method for preparing aluminum alloy surface composite gradient modified layer

A technology of aluminum alloy surface and modified layer, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of low equipment requirements, complex process, high cost, etc., and achieve high production efficiency and technology. Simple process and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Surface pretreatment of aluminum alloy materials: Cut the aluminum alloy into 30×30×5 mm in size by wire cutting, polish the surface of the sample with sandpaper, and then place it in distilled water and absolute ethanol for 6 minutes for ultrasonic cleaning and blow dry to obtain Aluminum alloy material after pretreatment.

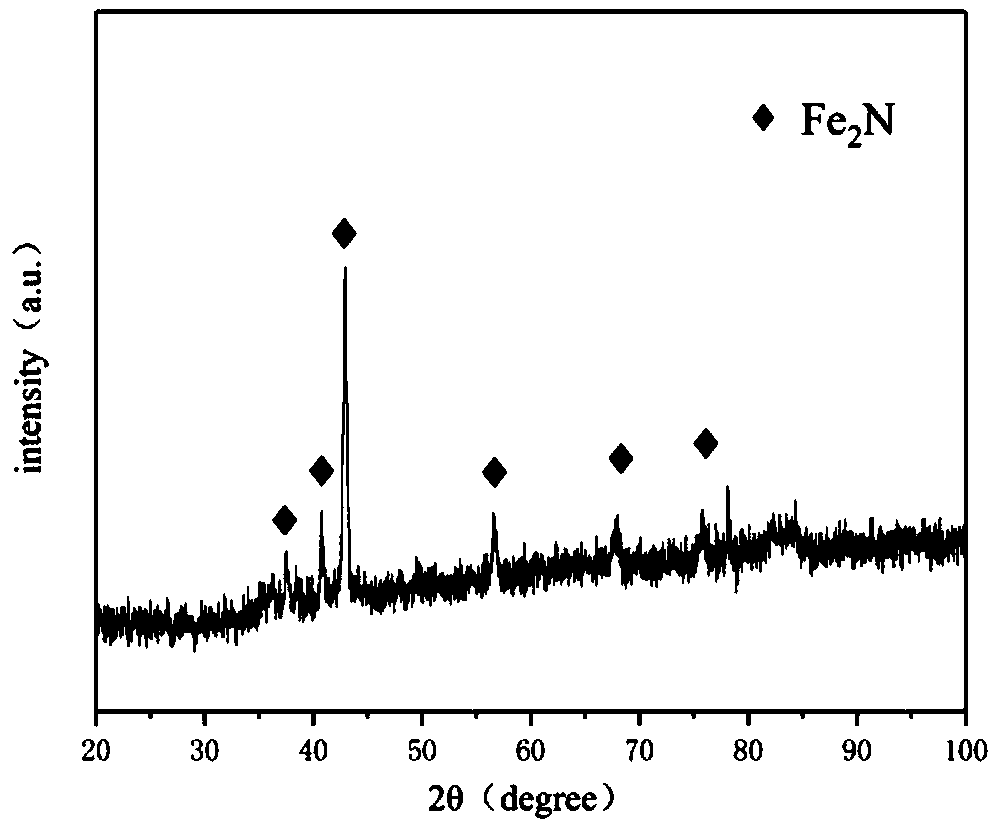

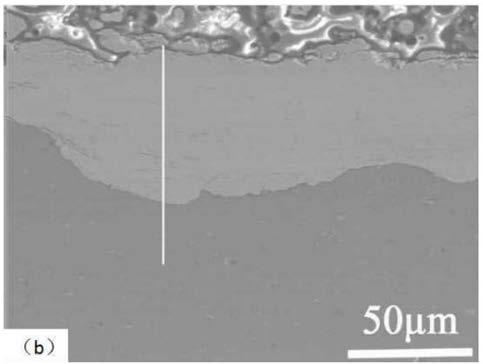

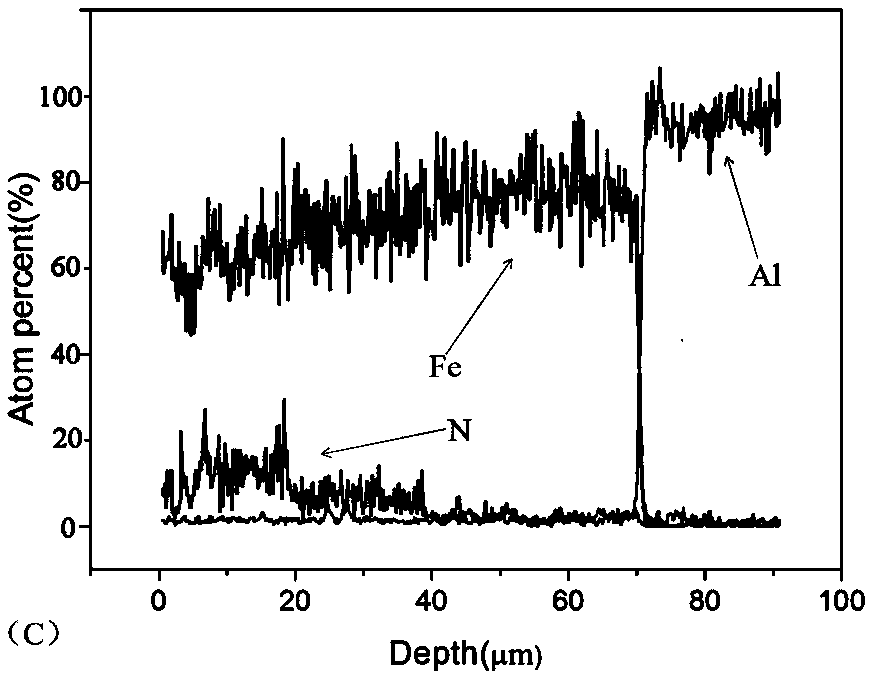

[0030] (2) Mechanical nano-alloying of the aluminum alloy surface: put the polished aluminum alloy material into the ball mill tank attached to the SPEX-8000M high-energy ball mill, put steel balls with a diameter of 6 mm in the sample chamber, and set the vibration head frequency to 50 Hz. At the same time, 1g of iron powder was added and treated for 1 hour. Observation by transmission electron microscope showed that the grain size of the alloyed Fe layer on the surface was refined to nanometer scale and was equiaxed and randomly distributed. The grain size was about 8-20nm. The thickness of the iron layer on the surface of the material is abo...

Embodiment 2

[0033] (1) Surface pretreatment of aluminum alloy materials: Cut the aluminum alloy into 30×30×5 mm in size by wire cutting, polish the surface of the sample with sandpaper, and then place it in distilled water and absolute ethanol for 6 minutes for ultrasonic cleaning and blow dry to obtain Aluminum alloy material after pretreatment.

[0034](2) Mechanical nano-alloying of the aluminum alloy surface: put the polished aluminum alloy material into the ball mill tank attached to the SPEX-8000M high-energy ball mill, put steel balls with a diameter of 6 mm in the sample chamber, and set the vibration head frequency to 50 Hz. At the same time, 1g of iron powder was added and treated for 1 hour. Observation by transmission electron microscope showed that the grain size of the alloyed Fe layer on the surface was refined to nanometer scale and was equiaxed and randomly distributed. The grain size was about 8-20nm. The scanning electron microscope test shows that the thickness of the ...

Embodiment 3

[0037] (1) Surface pretreatment of aluminum alloy materials: Cut the aluminum alloy into 30×30×5 mm in size by wire cutting, polish the surface of the sample with sandpaper, and then place it in distilled water and absolute ethanol for 6 minutes for ultrasonic cleaning and blow dry to obtain Aluminum alloy material after pretreatment.

[0038] (2) Mechanical nano-alloying of the aluminum alloy surface: put the polished aluminum alloy material into the ball mill tank attached to the SPEX-8000M high-energy ball mill, put steel balls with a diameter of 8mm in the sample chamber, and set the vibration head frequency to 50Hz. At the same time, 2g of iron powder was added and treated for 1 hour. Observation by transmission electron microscope showed that the grain size of the alloyed Fe layer on the surface was refined to nanometer level and was equiaxed and randomly distributed. The grain size was about 8-20nm. The scanning electron microscope test shows that the thickness of the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com