Aluminum alloy having high abrasion resistance, spherical cap made of aluminum alloy, and preparation method of spherical cap

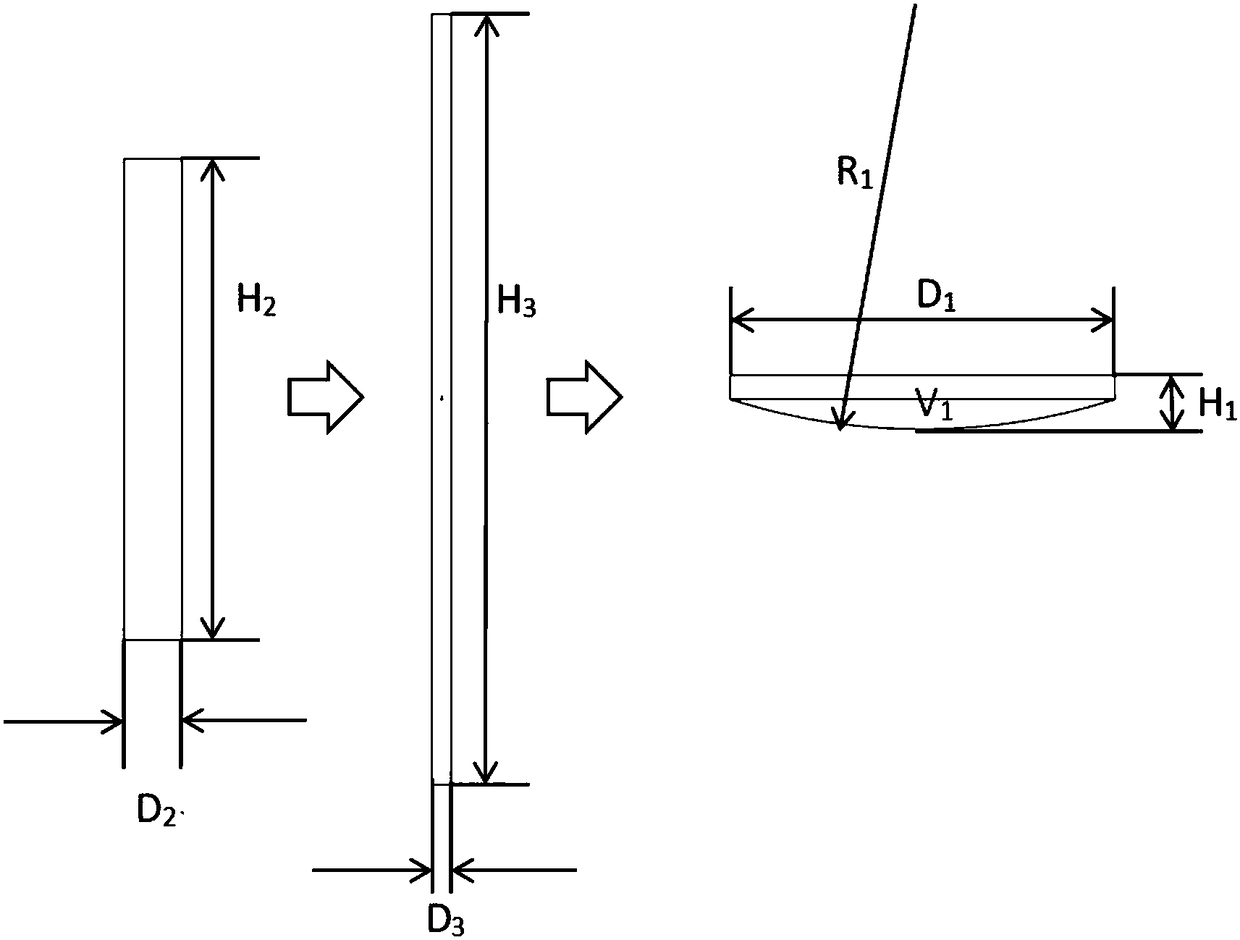

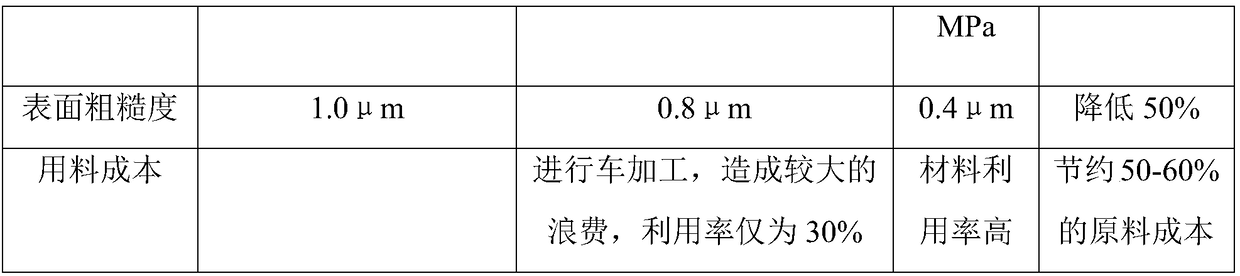

A high wear resistance, aluminum alloy technology, applied in anodic oxidation, construction, bridge construction, etc., can solve the problems of unsuitable forging processing, low material utilization rate, aluminum alloy with many pores, etc., to achieve the elimination of tensile stress and the utilization of materials The effect of high yield and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A high wear resistance aluminum alloy, including the following mass fractions of components:

[0046] Manganese 0.40%, magnesium 3.30%, chromium 0.25%, zinc 3.50%, copper 0.15%, silicon 0.30%, iron 0.40%, vanadium and titanium total 0.15%, the balance aluminum.

[0047] A method for preparing a spherical crown made of aluminum alloy with high wear resistance. The specific preparation process is as follows:

[0048] (1) Ingredients: select and weigh small pieces of pure aluminum, aluminum-manganese, aluminum-magnesium, aluminum-chromium, aluminum-zinc, aluminum-copper, aluminum-silicon, and Aluminum iron block, aluminum vanadium block and aluminum titanium block;

[0049] (2) Melting: After the pure aluminum block is melted by the aluminum melting furnace, it is transferred to the holding furnace through the launder, and the aluminum manganese block, aluminum magnesium block, aluminum chromium block, aluminum zinc block, aluminum copper block, aluminum silicon block, The alumin...

Embodiment 2

[0065] A high wear resistance aluminum alloy, including the following mass fractions of components:

[0066] Manganese 0.10%, magnesium 2.30%, chromium 0.15%, zinc 4.50%, copper 0.15%, silicon 0.10%, iron 0.20%, vanadium and nickel total 0.10%, molybdenum 0.05%, and the balance aluminum.

[0067] A method for preparing a spherical crown made of aluminum alloy with high wear resistance. The specific preparation process is as follows:

[0068] (1) Ingredients: select and weigh small pieces of pure aluminum, aluminum-manganese, aluminum-magnesium, aluminum-chromium, aluminum-zinc, aluminum-copper, aluminum-silicon, and Aluminum iron block, aluminum vanadium block, aluminum nickel block and aluminum molybdenum block;

[0069] (2) Melting: After melting the pure aluminum in the aluminum melting furnace, it is transferred to the holding furnace through the launder, and sequentially added, aluminum manganese block, aluminum magnesium block, aluminum chromium block, aluminum zinc block, alumi...

Embodiment 3

[0079] A high wear resistance aluminum alloy, including the following mass fractions of components:

[0080] Manganese 0.20%, magnesium 3.10%, chromium 0.20%, zinc 4.00%, copper 0.15%, silicon 0.30%, iron 0.40%, vanadium 0.05%, titanium 0.05%, nickel 0.05%, and the balance aluminum.

[0081] A method for preparing a spherical crown made of aluminum alloy with high wear resistance. The specific preparation process is as follows:

[0082] (1) Ingredients: select and weigh small pieces of pure aluminum, aluminum-manganese, aluminum-magnesium, aluminum-chromium, aluminum-zinc, aluminum-copper, aluminum-silicon, and Aluminum iron block, aluminum vanadium block, aluminum titanium block and aluminum nickel block;

[0083] (2) Melting: After melting the pure aluminum in the aluminum melting furnace, it is transferred to the holding furnace through the launder, and the aluminum manganese block, the aluminum magnesium block, the aluminum chromium block, the aluminum zinc block, the aluminum cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com