Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Remain biodegradable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biaxially oriented polylactic acid film with high barrier

ActiveUS7951438B2Improve barrier propertiesImprove metallized moisture and oxygen barrierSynthetic resin layered productsLaminationPolymer sciencePolyolefin

A metallized laminate film exhibiting improved moisture barrier property as well as maintaining a high bio-polymer content and degradability property is disclosed. The laminate film includes a first core layer of polylactic acid polymer and a second skin layer comprising a polyolefin metal receiving layer. The metal receiving layer or the core layer, or both, may be blended with an amount of polar-modified tie-resin to improve bonding. Alternatively, a discrete tie-resin layer may be interposed between the polyolefin metal receiving layer and the crystalline polylactic acid polymer core layer. The polyolefin metal receiving layer may be discharge-treated on the side opposite the core layer and metallized.

Owner:TORAY PLASTICS (AMERICA) INC

Preparation of antibacterial silver/chitosan nano fiber membrane

InactiveCN101297976AImprove mechanical propertiesRemain biodegradableSurgeryFilament/thread formingFiberStaphylococcus aureus

The invention discloses a preparation method of antibacterial silver / chitosan nano fibrous membranes, pertaining to the preparative technologies of nano composite fibrous membranes. The process of the method includes that a chitosan hexanoic acid solution, a silver nitrate aqoeous solution, a sodium borohydride water solution and an ethylene epoxide hexanoic acid solution are prepared and mixed to form compounded latex according to the volume ratios of the chitosan hexanoic acid solution and the silver nitrate aqoeous solution as well as an NaBH4 aqueous solution. The compounded latex and the ethylene epoxide hexanoic acid solution are mixed according to the volume ration to prepare a spinning solution, then the spinning solution is added into an injector in an electrostatic spinning device and electrostatic spinning is carried out to form the fibrous membrane. Crosslinking treatment is carried out to the fibrous membrane to obtain the antibacterial silver / chitosan nano fibrous membrane. The antibacterial silver / chitosan nano fibrous membrane of the invention has the advantages that the preparation process is simple; the prepared membrane material has broad-spectrum bactericidal property and comparatively high fatality rate to Bacillus coli, Bacillus subtilis, Staphylococcus aureus and Pseudomonas aeruginosa for 24 hours.

Owner:TIANJIN UNIV

Biodegradable aliphatic polyester / aromatic polyester multi-block copolymer and preparation method and application thereof

The present invention discloses a biodegradable aliphatic polyester / aromatic polyester multi-block copolymer and preparation method and application thereof. The copolymer is a AB-type multi-block copolymer composed of A chain segment and B chain segment; the number average molecular weight of the copolymer is 5,000-500,000, and the molecular weight distribution is 1-5; in the copolymer, the A chain segment is prepared by reacting C2-C12 aliphatic dibasic acids or esters, acyl chlorides, and anhydrides thereof with C2-C12 aliphatic diols; the B chain segment is prepared by reacting 1,2-propylene glycol with C8-C14 aromatic or alicyclic dibasic acids or esters, acyl chlorides, and anhydrides thereof. The present invention introduces rigid amorphous polyester chain segments into crystalline aliphatic polyesters to obtain a biodegradable aliphatic polyester / aromatic polyester multi-block copolymer, which maintains the biodegradability and at the same time improves the mechanical properties of aliphatic polyesters. In addition, the copolymer can be used as an environment friendly polymer material and an anti-impact modifier for biodegradable polymer materials such as poly(butylene succinate), polylactic acid, polyhydroxybutyrate, etc., and has high application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Biaxially oriented cavitated polylactic acid film

InactiveUS20120141766A1Low costRemain biodegradableSynthetic resin layered productsVacuum evaporation coatingPolystyreneMaterials science

Disclosed are biaxially oriented laminate films including a core layer including a blend of crystalline polylactic acid polymer and crystalline polystyrene. The films are biaxially oriented at low transverse direction orientation temperatures to impart a degree of cavitation around the crystalline polystyrene such that a white opaque cavitated appearance and lower film densities are obtained. The laminate films may further have additional layers such as a heat sealable layer disposed on one side of the core layer including an amorphous polylactic acid resin and / or a polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

Filling masterbatch used in biodegradable plastic, and preparation method thereof

InactiveCN102516723AGuaranteed DispersionAvoid reunionArtifical filament manufactureMasterbatchPolymer science

The invention discloses a filling masterbatch used in biodegradable plastic. The masterbatch is composed of components of, by mass: (A) 20.0-80.0% of biodegradable polyester, (B) 1.0-80.0% of a filling material, (C) 0.1-10.0% of a lubricating agent, (D) 0.1-5.0% of a high-temperature-resistant agent, and (E) 0.1-5.0% of a hydrolysis-resisting agent. The masterbatch is advantaged in that: (1) compatibility of the carrier is consistent with that of the biodegradable plastic, such that the filling masterbatch has excellent dispersity in the biodegradable plastic; (2) the obtained filling masterbatch satisfies an application requirement of biodegradable plastic En13432; when the filling masterbatch is mixed with biodegradable plastic, the biodegradation performance of the original material is completely maintained; (3) high temperature and hydrolysis resistances of the filling masterbatch are good, and the filling masterbatch has high physical mechanical properties; (4) with the filling masterbatch, while the cost of biodegradable plastic is reduced, physical chemical properties especially the biodegradation performance of the filled material are maintained.

Owner:KINGFA SCI & TECH CO LTD +2

Natural fiber/polylactic acid composite material and preparation method thereof

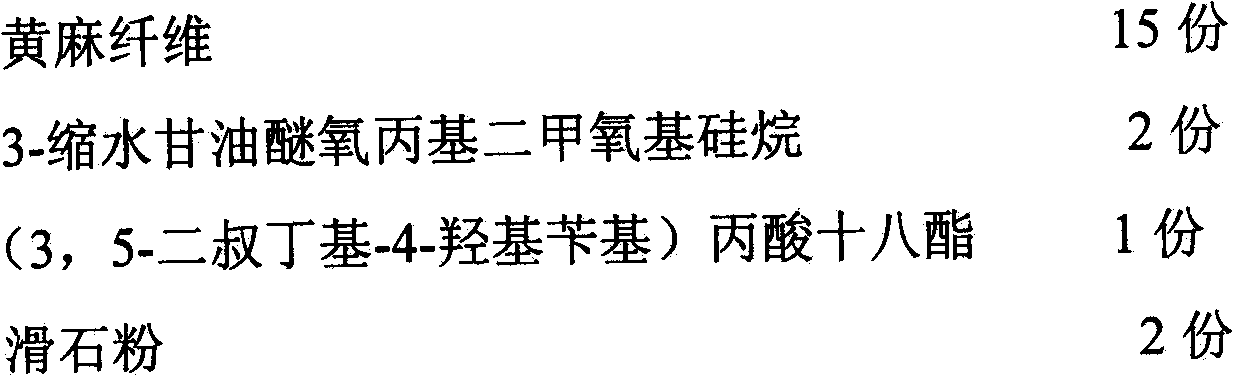

The invention relates to a natural fiber / polylactic acid composite material and a preparation method thereof. The natural fiber / polylactic acid composite material is prepared from the following components in parts by weight: 70 to 95 parts of polylactic acid, 5 to 30 parts of natural fiber, 0 to 5 parts of coupling agent, 0 to 2 parts of antioxidant and 1 to 5 parts of nucleating agent. The preparation method comprises the following steps: vacuum-drying the polylactic acid, the natural fibers and the nucleating agent at 60 to 100 DEG C for 6 to 12 hours, and removing moisture; weighing the components in parts by weight in proportion, blending all the raw materials in a blender for 5-10 minutes, extruding a mixture out of a twin-screw extruder at 160 to 200 DEG C, and performing cooling, grain-sized dicing and drying to obtain the natural fiber / polylactic acid composite material. Compared with the prior art, the natural fiber / polylactic acid composite material and the preparation method thereof have the advantages that the method is simple; the process is easy to implement; the composite material is high in performance, and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

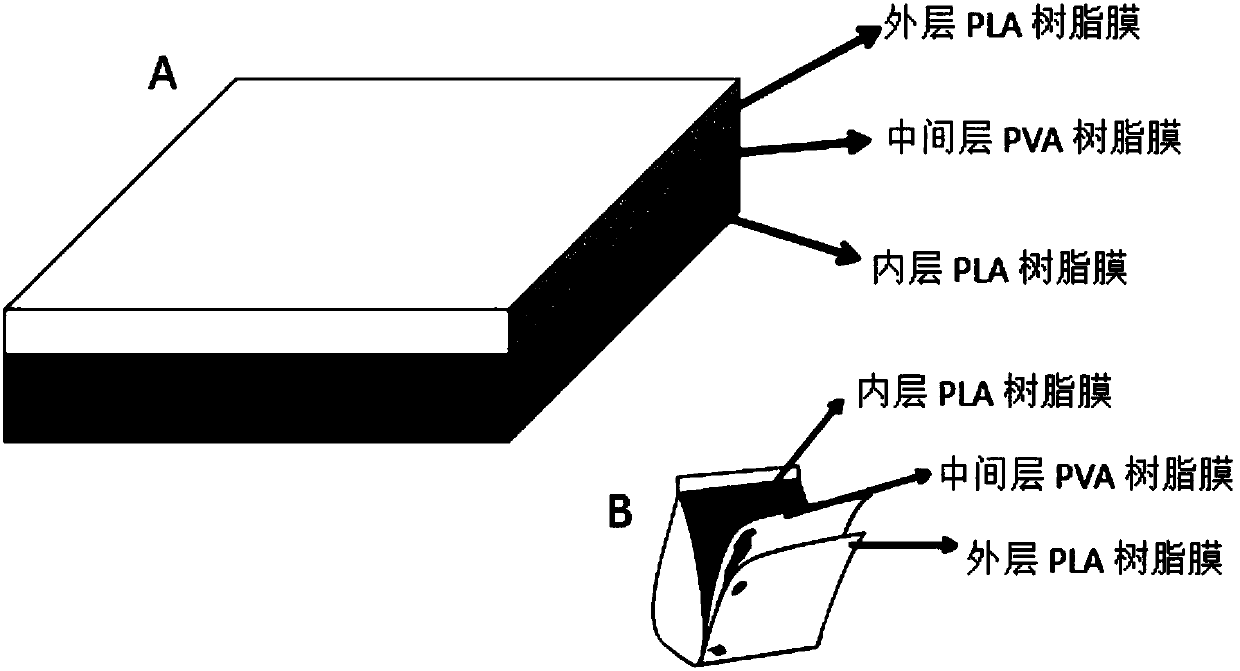

Degradable high barrier active preservative film and preparation method thereof

InactiveCN107627706ARemain biodegradableOvercome the disadvantage of moisture permeabilityFlexible coversWrappersPlastic packagingMoisture barrier

Belonging to the plastic packaging field, the invention in particular relates to a degradable high barrier active preservative film and a preparation method thereof. The degradable high barrier activepreservative film consists of an inner layer PLA resin film, a middle layer PVA resin film and an outer layer PLA resin film from the inside out in order, the inner layer PLA resin film, the middle layer PVA resin film and the outer layer PLA resin film all include a matrix and an assistant, and the inner layer PLA resin film also includes a bacteriostatic active ingredient. The degradable high barrier active preservative film provided by the invention has excellent moisture barrier properties, gas barrier properties, bacteria resistance, oil resistance and degradability, can effectively prevent moisture or oil loss, oxidation, corruption or degradation of food and fresh and raw food, extend the shelf life, and improve the quality guarantee effect.

Owner:SHANGHAI OCEAN UNIV

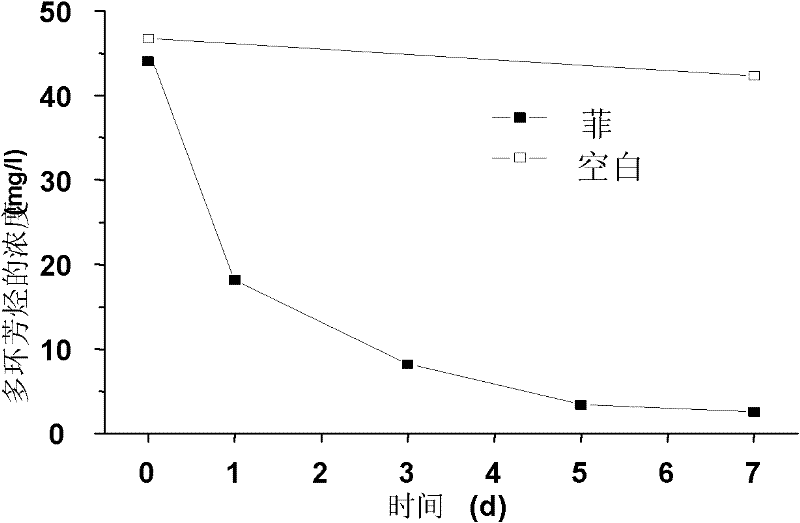

Pseudomonas aeruginosa and application thereof

InactiveCN102533589AStrong emulsifying abilityGood ability to degrade polycyclic aromatic hydrocarbonsBacteriaTransportation and packagingCarbon sourceResting Cell

The invention discloses a pseudomonas aeruginosa CCTCCM208114 and application of the pseudomonas aeruginosa in petroleum pollutant degradation. The pseudomonas aeruginosa provided by the invention has the following characteristics that: 1) the pseudomonas aeruginosa has high-efficient petroleum hydrocarbon degradation capability; 2) the pseudomonas aeruginosa is capable of co-metabolizing fluorene in an inorganic salt culture medium in the presence of n-tetradecane; 3) a resting cell system of the pseudomonas aeruginosa has good polycyclic aromatic hydrocarbon degradation capability and can tolerate high polycyclic aromatic hydrocarbon concentration; 4) the pseudomonas aeruginosa has a wide substrate spectrum; and 5) the pseudomonas aeruginosa grows in an LB (Luria Bertani) culture medium or an inorganic salt culture medium (straight-chain paraffin or polycyclic aromatic hydrocarbon serves as the unique carbon source and energy source) and can generate biological surfactant. The pseudomonas aeruginosa can be widely applied to the field of bioremediation of petroleum compound pollution and is suitable for large-area popularization and application.

Owner:DAQING OILFIELD CO LTD

Biodegradable toughened heat-resistant polylactic acid modified resin and preparation method thereof

The invention discloses biodegradable toughened heat-resistant polylactic acid modified resin and a preparation method thereof. The polylactic acid modified resin comprises the following raw materials in percentage by mass: 30%-90% of polylactic acid, 5%-65% of thermoplastic starch, 3%-40% of a completely biodegradable plant fiber and 1%-10% of an adjuvant, wherein the adjuvant is a lubricating agent, a coupling agent and an antioxidant. The method comprises the following steps: firstly drying various raw materials, adding to a high-speed mixer according to the ratio, and mixing for 5-30 minutes; and adding the obtained mixture to a twin-screw extruder, and plastifying, extruding and pelletizing to obtain the biodegradable toughened heat-resistant polylactic acid modified resin. The preparation method of the polylactic acid modified resin disclosed by the invention is simple in equipment requirements and technological process, low in cost, easy for large-scale production, economical and efficient; and the thermoplastic starch and the completely biodegradable plant fiber are added to polylactic acid matrix, so that the prepared product has relatively good heat resistance and impact property.

Owner:SICHUAN UNIV

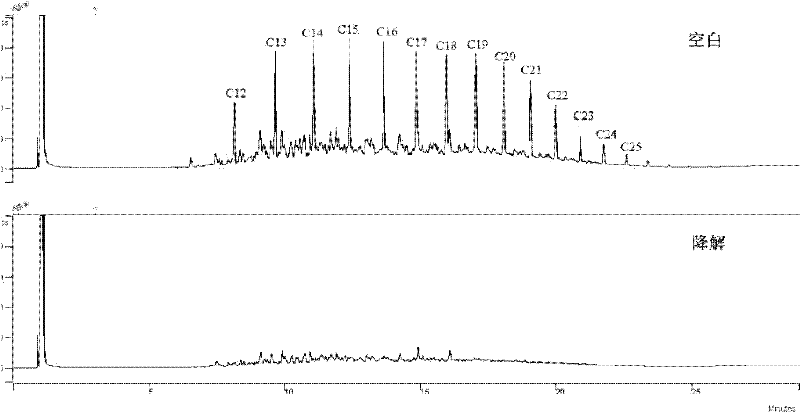

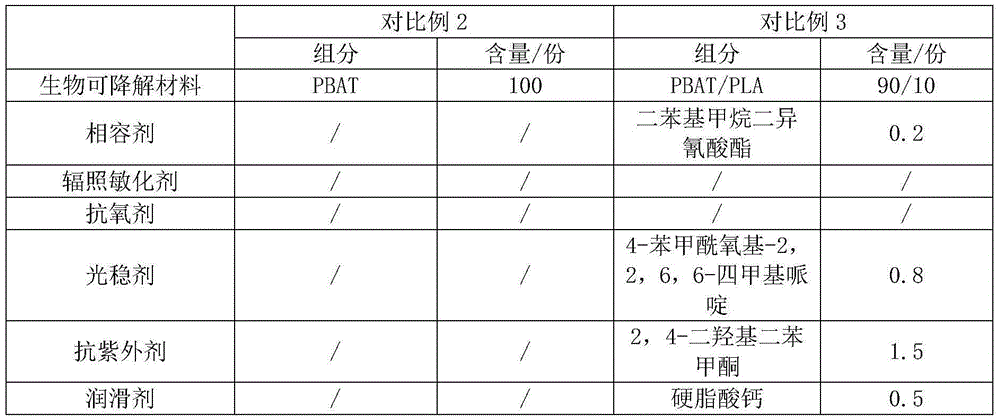

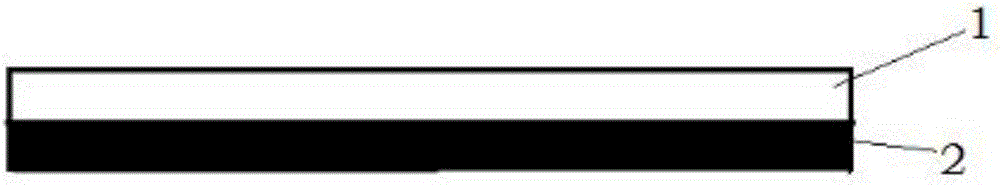

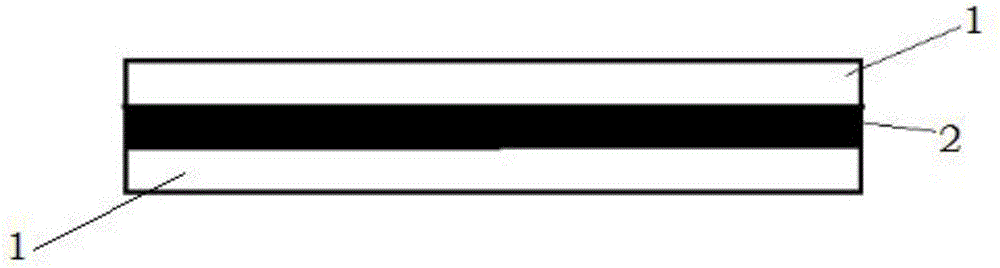

Biodegradable film based on irradiation modification and preparing method thereof

The invention discloses a biodegradable film based on irradiation modification and a preparing method thereof. The degradable film is composed of, by weight, 100 parts of biodegradable materials, 0-5 parts of compatilizer, 0.05-5 parts of irradiation sensitizing agents, 0.05-3 parts of antioxidants, 0.1-2 parts of light stabilizer, 0.1-3 parts of anti-ultraviolet agents and 0-2 parts of lubricating agents in a mixed mode. Compared with the prior art, the biodegradable film has the following advantages of having excellent mechanical strength, barrier performance, ageing resistance and the like, and being innovative, and application of the biodegradable film is expanded; the composite film keeps complete biodegradable performance, and has high application potentiality in medical science and environmental science, the composite film can replace petroleum-base general films to be used greatly, and environmental pressure is relieved. The preparing method is simple and easy to implement, the addition quantity of all the auxiliaries is small, cost is low, and the production process is controllable.

Owner:SHANGHAI HONGRUI CHEM PROD CO LTD

Method for preparing transparent heat-resistance polylactic acid modification material

ActiveCN102206406AChange in biodegradabilityHigh biodegradation rateThermal deformationPolymethyl methacrylate

The invention discloses a method for preparing a transparent heat-resistance polylactic acid modification material, in which three methods for improving the heat resistance of polylactic acid, namely a method for changing a polylactic acid crystal state by using a nucleating agent, a method for changing a polylactic acid molecular structure by the crosslinking of a chain extender and a method formixing the polylactic acid and high glass transition temperature (Tg) polymer materials, are adopted. The method comprises the following steps of: drying all raw material mixed complexes at 80 DEG C for 5 hours; and granulating or directly processing to form a transparent heat-resistance polylactic acid product. The polylactic acid modification material comprises the following raw materials in parts by weight: 100 parts of polylactic acid, 5-10 parts of chitin whisker polymethyl methacrylate coating, 0.5-2.0 parts of chain extender, 3-5 parts of oligomer polylactic acid, and 0.1-0.5 part of 3-(nonyl-phenyl) phosphite ester. By using the method, the thermal deformation temperature of the polylactic acid composite material is over 100 DEG C, and the biodegradability and the high transparency of the composite material are effectively maintained.

Owner:JIANGSU GUANGHUI PACKAGE +2

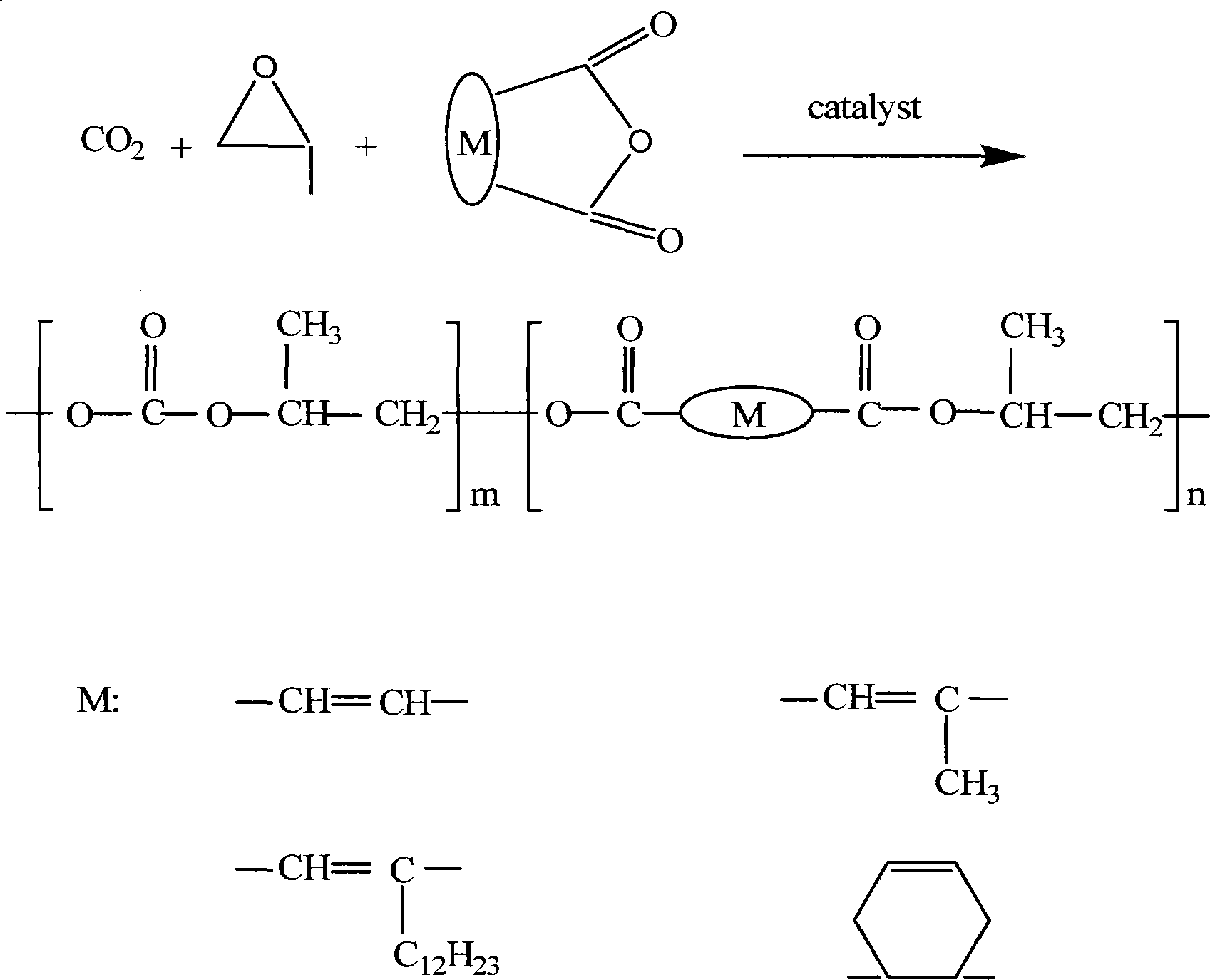

Cross-lined polymethyl ethylene carbonate polymer electrolyte membrane and preparation method thereof

The present invention discloses cross-linked polymethacrylic ethylene carbonic acid ester polymer electrolyte membrane and the preparation method. The polymer electrolyte membrane consists of cross-linked polymethacrylic ethylene carbonic acid ester polymer and electrolyte solution including conductive lithium salt and non-protonic solvent. The preparation method adopts carbon dioxide, epoxy dimethylmethane and unsaturated acid anhydride which are synthesized into polymethacrylic ethylene carbonic acid ester trivalent copolymer with special functional group under the role of catalyst dyadic carboxylic acid zinc. Then the trivalent copolymer is under the cross-linking reaction so as to get the dry polymethacrylic ethylene carbonic acid ester polymer membrane. Afterwards, the dry membrane is immerged into the liquid electrolyte solution for activation, thus obtaining the cross-linked polymethacrylic ethylene carbonic acid ester polymer electrolyte membrane. The polymer electrolyte membrane prepared by the present invention has the advantages of high mechanical performance, good thermal performance and high ion electric conduction. The present invention with low cost and simple process is applicable to the industrialized production.

Owner:SUN YAT SEN UNIV

Antibiotic degradable water retaining agent and preparation method thereof

The invention belongs to the field of polymer materials, and concretely discloses an antibiotic degradable water retaining agent and a preparation method thereof. The water retaining agent is prepared from acrylic acid, acrylamide, long-chain quaternary ammonium salt, kaolin and sodium alginate through a redox system aqueous solution polymerization technology with ammonium persulfate or potassium persulfate as an oxidant, sodium bisulfite as a reducing agent and N,N-methylenebisacrylamide as a cross-linking agent. Acrylic acid is neutralized with ammonia water or ammonium bicarbonate, so the problem of soil hardening induced by long-term application of a sodium base water retaining agent to soil is avoided, and nutrients are provided. Kaolin with low price and wide sources and biodegradable sodium alginate are introduced to a copolymerization system, so the preparation cost of the water retaining agent is effectively reduced, and the gelly strength, the water absorption rate, the salt resistance and the biodegradability of the water retaining agent are improved. A wide-spectrum antibiosis material is also introduced, so storage of the degradable water retaining and further prolongation of the service life of the water retaining agent are facilitated. The antibiotic degradable water retaining agent can be widely applied in the fields of agriculture, forestry, gardening, ecologic construction and desert treatment.

Owner:ZHONGKAI UNIV OF AGRI & ENG

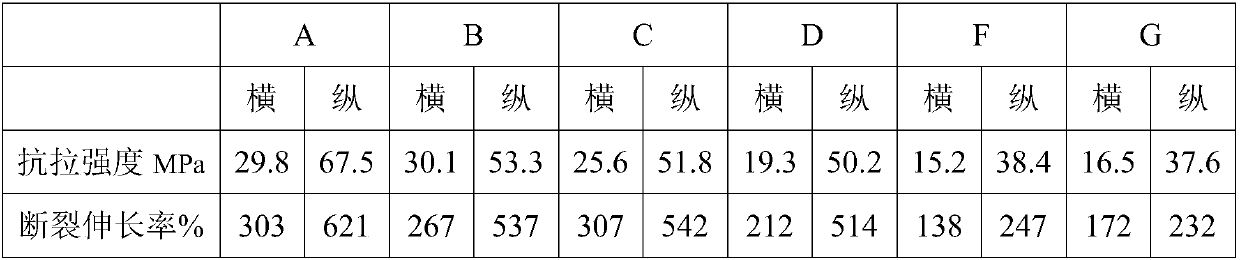

High-toughness high-water-steam-baffled completely-biodegraded composite multilayer film and preparation method thereof

InactiveCN106393919AHigh water vapor barrierImprove toughnessSynthetic resin layered productsFlat articlesWater vaporUltimate tensile strength

The invention relates to the technical field of polymer materials, and specifically relates to a high-toughness high-water-steam-baffled completely-biodegraded composite multilayer film and a manufacturing method thereof. The film comprises a structure from the second layer to the seventh layer and is composed of a PBAT based high-toughness high-barrier biodegradable material (A), a high-weatherability high-barrier biodegradable material (B), and a high-toughness functional biodegradable material layer (C). A multi-layer co-extrusion film blowing technology is adopted. Multiple material layers are compounded to prepare the film. The film is highly tough, the tensile strength can reach 18 MPa, the horizontal / vertical breaking elongation rate can reach more than 500%, no prominent difference exists in the vertical direction and the horizontal direction, the water steam baffling performance is strong, the water steam penetration rate of the film with a thickness of 10 [mu]m is 240 g / m2.24h; the processing performance is good, the minimal thickness of the film can reach 5 [mu]m; the processing equipment does not need frequent adjustment, and the film is used as a package film, an agricultural cover film, and the like.

Owner:SHANGHAI HONGRUI CHEM PROD CO LTD

Biomedical magnesium or magnesium alloy implantation material with multiple surface protection

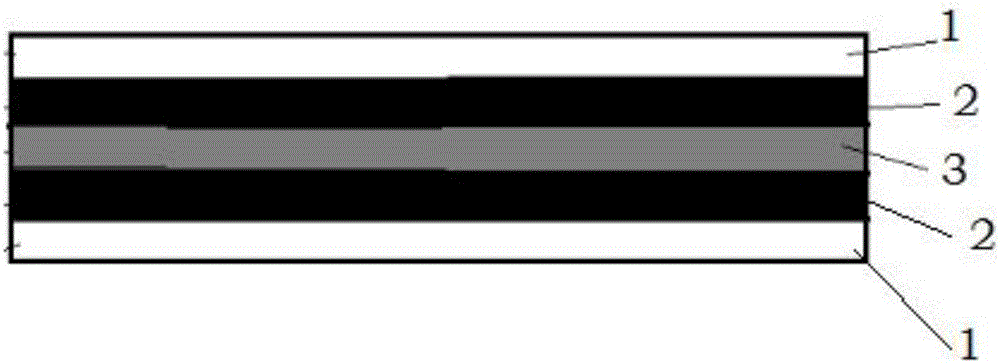

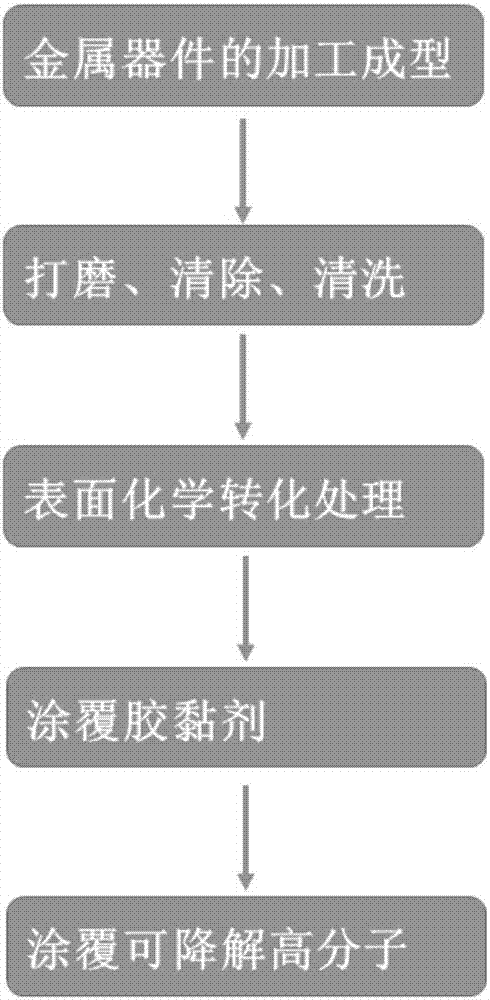

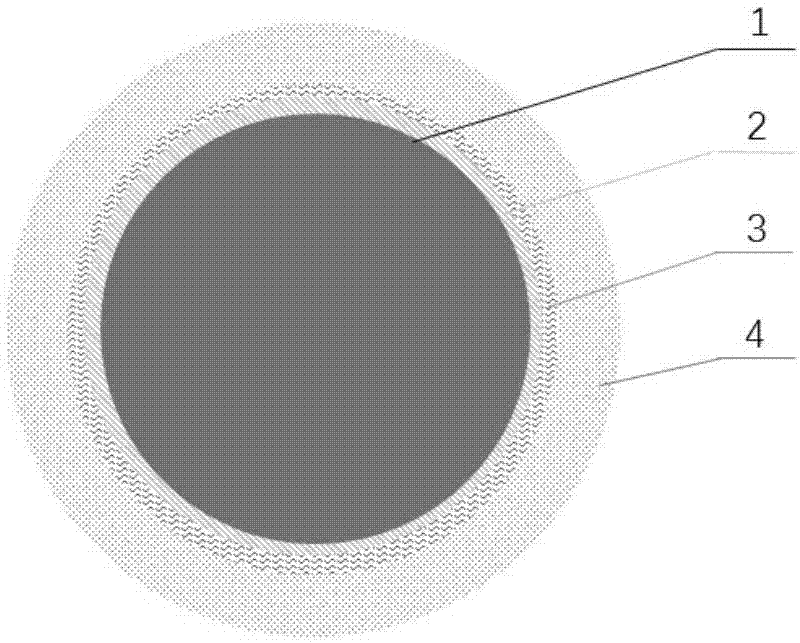

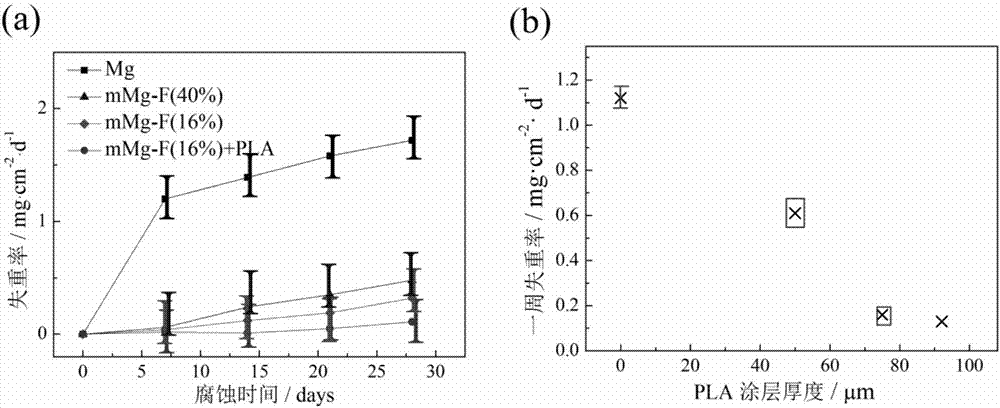

PendingCN107281543AImprove mechanical propertiesGood mechanical functionSurgeryMetallic material coating processesUltrasound attenuationInterventions therapy

The invention discloses a magnesium or magnesium alloy material or device with multiple surface protection layers and a production method. The magnesium or magnesium alloy material or device with multiple surface protection treatment has the aims that the initial mechanical attenuation of magnesium / magnesium alloy in a physiological environment is decelerated, the corrosion resisting property of the magnesium / magnesium alloy is improved, and the time of service is effectively prolonged. The protection treatment comprises the steps: 1) manufacturing a magnesium / magnesium alloy substrate, and cleaning the surface of the substrate; 2) carrying out chemical conversion treatment on the surface of the magnesium / magnesium alloy substrate, so as to grow a chemical conversion film, of which the thickness is several nanometers, on the surface of the substrate; 3) coating the chemical conversion film with an adhesive layer; 4) coating the outside surface of the adhesive layer with a degradable polymer film. The magnesium or magnesium alloy material or device with multiple surface protection treatment, provided by the invention, can be applied to biomedical implantation or intervention therapy and has the advantages of being good in initial corrosion resisting property in a human physiological environment, meeting clinical requirements of medical treatment and being finally in-vivo degradable.

Owner:NANJING NORMAL UNIVERSITY

Biodegradable toughened heat-resistant polylactic acid modified resin and preparation method thereof

The invention discloses a biodegradable toughened heat-resistant polylactic acid modified resin and a preparation method thereof. The polylactic acid modified resin of the present invention comprises the following raw materials by mass percentage: 30-90% polylactic acid, 5-65% thermoplastic starch, 3-40% fully biodegradable plant fiber, 1-10% auxiliary agent ; Wherein, auxiliary agent is lubricant, coupling agent and antioxidant. The raw materials are first dried, and then blended in a high-speed mixer according to the stated ratio for 5-30 minutes, and the resulting mixture is added to a twin-screw extruder for plasticization, extrusion, and granulation to obtain a biodegradable toughened heat-resistant polymer. Lactic acid modified resin. The preparation method of the polylactic acid modified resin of the present invention has simple equipment requirements and process flow, low cost, easy to realize large-scale production, and is economical and efficient; by adding thermoplastic starch and fully biodegradable plant fibers into the polylactic acid matrix, the product is guaranteed. Both good heat resistance and impact performance.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Preparation method of solid microbial inoculant

ActiveCN104371925AExtended storage timeHigh activityMicroorganism preservationIron powderSoil organic matter

The invention discloses a preparation method of a solid microbial inoculant. The method comprises the following steps: concentrating a strain culture solution, adding an inhibitor, uniformly mixing a certain amount of solid adsorbing carrier, drying the mixture, and adding a deoxidizer to obtain the solid microbial inoculant. The method can enhance the storage time and viability of the solid microbial inoculant and lower the preservation and transportation cost; and the inhibitor and iron powder deoxidizer are added to lower the microbiological contamination probability, prevent the residual organic matters of the strain culture medium from oxidation, lower the activity of the target strain to some extent and perform promotion functions on prolonging the storage time.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

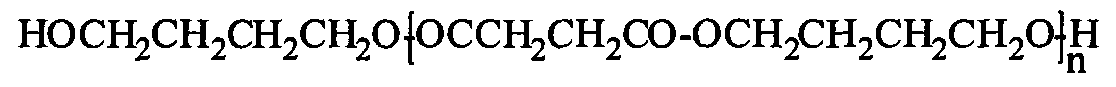

Blend for improving the brittleness and cold flowability of a carbon dioxide-propylene oxide copolymer and method for producing the same

InactiveUS20070117908A1Improve liquidityRemain biodegradableSynthetic resin layered productsSpecial tyresMaleic anhydrideCarbon dioxide

The present invention relates to improvement of the brittleness and cold flowability of a carbon dioxide-propylene oxide copolymer (PPC). The invention provides a blend comprising 50 to 98 parts by weight of a PPC; 2 to 50 parts by weight of a poly(butylenes succinate) (PBS) or poly(butylene succinate / adipate) (PBSA); 1 part by weight of a maleic anhydride, and 0.5 to 3.0 parts by weight of SiO2 and a method for producing the same. Compared with the pure PPC, the elongation rate at break of the blend of the invention increases by 3 to 15 times while the tensile strength maintains at 30 MPa or more. The blend of the PPC and PBSA can keep its dimension stably at 70° C., while the blend of the PPC and PBSA can keep its dimension stably at 55° C. No viscous flow occurs at these temperatures.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Biodegradable toughened heat-resistant polylactic acid modified resin and preparation method thereof

The invention discloses a biodegradable toughened heat-resistant polylactic acid modified resin and a preparation method thereof. The polylactic acid modified resin comprises the following raw materials by mass: 30-90% of polylactic acid, 5-65% of thermoplastic starch, 3-40% of fully biodegradable plant fibers and 1-10% of auxiliary agents, wherein the auxiliary agents are composed of a lubricant,a coupling agent and an antioxidant. The above raw materials are dried at first and then added into a high-speed mixer for blending for 5-30 minutes, and the obtained mixture is added into a twin-screw extruder for plastification, extrusion and granulation so as to prepare the biodegradable toughened heat-resistant polylactic acid modified resin. The preparation method of the invention is low inrequirements on equipment, simple in process flow, low in cost, easy to realize mass production, economic and highly efficient; and good heat resistance and impact properties of the produced resin areensured by adding the thermoplastic starch and fully biodegradable plant fibers into a polylactic acid matrix.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Hyperbranched polyphosphate amide ester as well as preparation method and application thereof

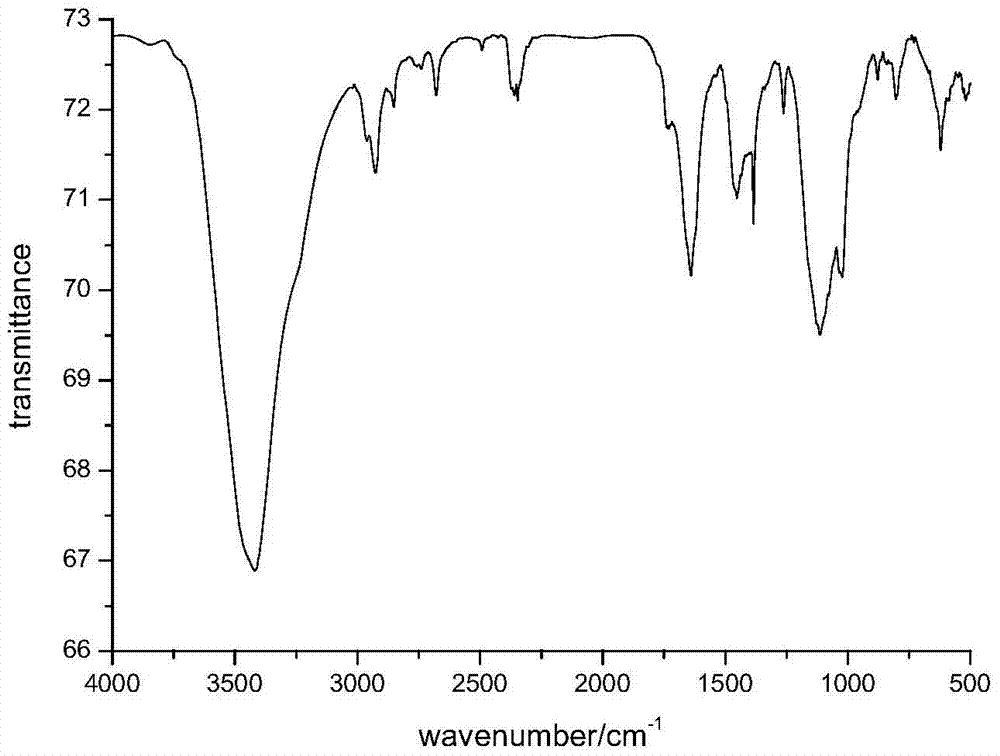

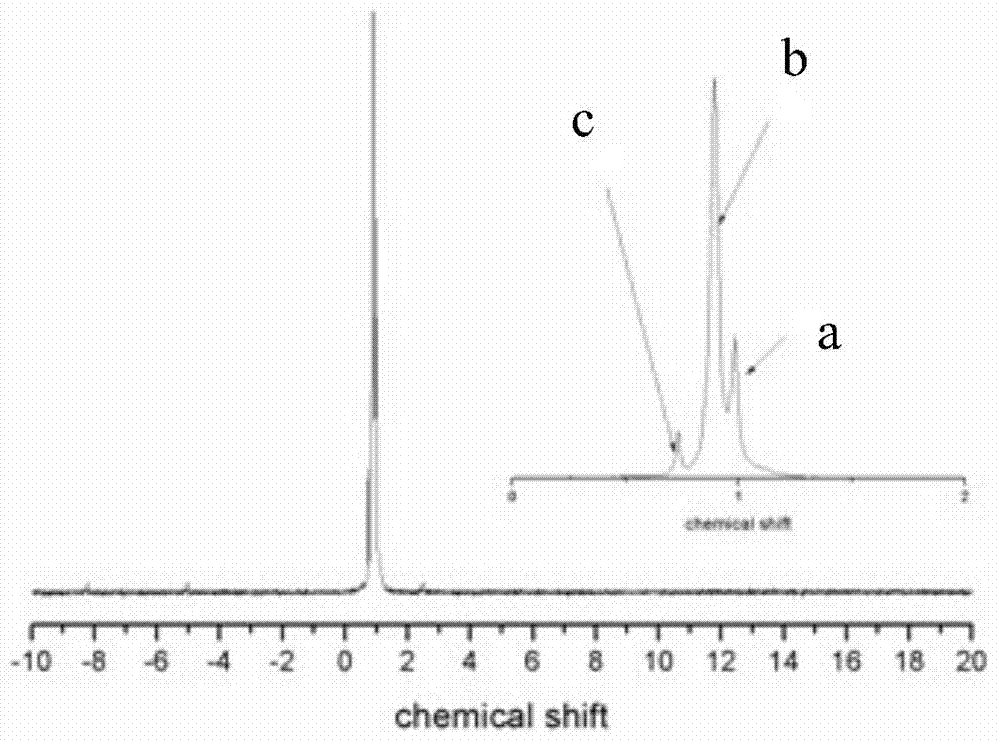

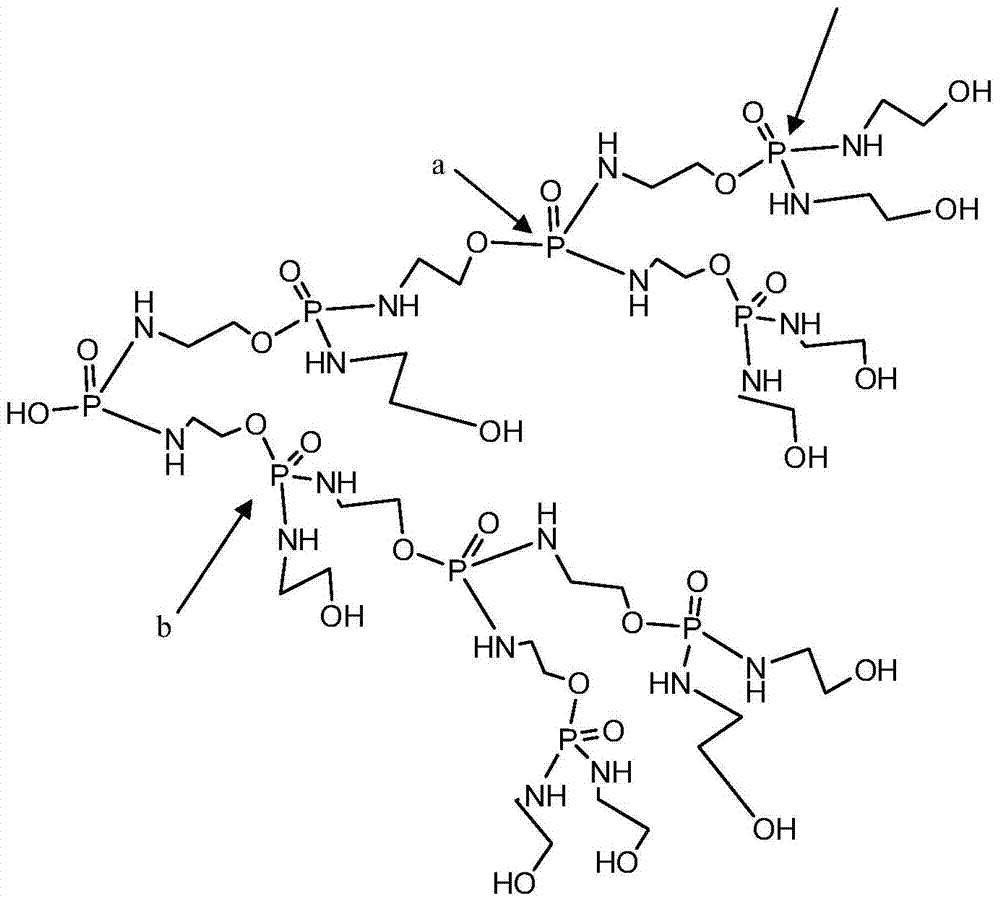

InactiveCN103360605BLow viscosityImprove liquidityGroup 5/15 element organic compoundsFiberPolymer science

The invention discloses a hyperbranched polyphosphate amide ester and a preparation method of flame-retardant biodegradable polyester thereof. The hyperbranched polyphosphate amide ester is prepared in the following steps: firstly reacting such A3 monomers as phosphorus oxychloride with such BB' monomers as methanolamine, ethanolamine and propanolamine under the protection of nitrogen, and then, adding a catalyst and an acid binding agent to perform a polycondensation reaction to generate the hyperbranched polyphosphate amide ester through one-pot method. The molecular structure of the prepared hyperbranched polyphosphate amide ester simultaneously contains a phosphate bond and a phosphamide bond, and the prepared hyperbranched polyphosphate amide ester is biodegradable, so that when 2wt% of the synthesized hyperbranched polyphosphate amide ester is added in biodegradable polyester, the oxygen index reaches 30-35%, and UL-94 passes V-0 level. The prepared flame-retardant biodegradable polyester prepared by the invention keeps the biodegradability of the whole system, and the fire-retardant biodegradable polyester has better nucleation property. The flame-retardant biodegradable polyester can be used as fiber, engineering film and injection shaped piece.

Owner:SHANGHAI JIAOTONG UNIV

Oxidized chitosan quaternary ammonium salt and preparation method thereof

The invention discloses an oxidized chitosan quaternary ammonium salt and a preparation method thereof. The oxidized chitosan quaternary ammonium salt is a substance formed by selectively oxidizing the 2,3- carbon-carbon bonds in the chitosan quaternary ammonium salt saccharide unit into formyl groups. The preparation method comprises the following steps: selectively oxidizing carbon-carbon bonds of the chitosan quaternary ammonium salt in a dark place by using sodium periodate, stopping the reaction, purifying and drying to obtain the high-purity oxidized chitosan quaternary ammonium salt. The oxidized chitosan quaternary ammonium salt contains both high-reaction-activity formyl groups and quaternary ammonium groups, and thus, has the crosslinking and antimicrobial / antibacterial functions, thereby being a new-generation functional crosslinking agent. The oxidized chitosan quaternary ammonium salt can be widely used as a biological crosslinking agent, chemical coupling agent, microsphere crosslinking agent, immobilized enzyme crosslinking agent or the like, and can also be used for retanning, color fixation and the like in leather industry.

Owner:SICHUAN UNIV

Preparation method of cross-linking antibacterial acellular matrix material

ActiveCN106215239ALow antigenicityIncrease the degree of cross-linkingProsthesisCross-linkAcellular matrix

The invention discloses a preparation method of a cross-linking antibacterial acellular matrix material. Oxidized chitosan quaternary ammonium salt is cross-linked with an acellular matrix material, multiple aldehyde groups on oxidized chitosan quaternary ammonium salt are cross-linked with active groups on the acellular matrix, the structural stability of the material is improved, meanwhile, chitosan quaternary ammonium salt is grafted in the acellular matrix material, and therefore excellent antibacterial and bacteriostatic performance is provided for the acellular matrix material. According to the method, cross-linking and providing of the antibacterial performance of the material are combined, the preparation method is a preparation method of the novel functional acellular matrix material, and the method can be widely applied to the field of biological materials.

Owner:SICHUAN UNIV

Biodegradable foamed material and method for utilizing biodegradable foamed material to manufacture heat-resistant foamed lunch box

The invention relates to a biodegradable foamed material and a method for utilizing the biodegradable foamed material to manufacture a heat-resistant foamed lunch box. The biodegradable foamed material is prepared from the following raw materials in parts by mass: 100 parts of polylactic acid, 0.1-5 parts of a chain extender, 0.1-5 parts of a cross-linking agent, 0.1-5 parts of an antioxidant and0.1-5 parts of other additives. The technical scheme has the technical effects that the problems of poor heat resistance of the polylactic acid and poor processing performance of cross-linked polylactic acid are solved, and meanwhile the biodegradable performance of the heat-resistant foamed lunch box is maintained.

Owner:温州信环生物材料科技有限公司

Fully degradable ceramic-imitated straw flowerpot and manufacture method thereof

The invention discloses a fully degradable ceramic-imitated straw flowerpot and a manufacture method of the flowerpot. The manufacture method comprises the following steps: using crushed straw powder as materials, adding a gelatin adhesive, wherein the weight ratio of the straw powder to the gelatin adhesive is 1 to 0.5-0.8; mixing the materials, and then thermo-forming to obtain the fully degradable ceramic-imitated straw flowerpot. The industrial gelatin adopted in the invention is modified in a cross-linking manner by silane coupling agent Kh-550, zinc chloride and a borax composite modifier; the advantages of the silane coupling agent Kh-550, zinc chloride and the borax composite modifier are used for achieving a good effect. Hydroxide radical in the gelatin protein is closed to reduce the water solubility of the gelatin; a peptide chain of the gelatin protein is lengthened to generate part coordination compound, so that the flexibility of the gelatin is reinforced, and the degradation characteristic of the glue solution is kept. The fully degradable ceramic-imitated straw flowerpot product is applied to domestic urban landscaping, landscape modeling and beautifying, ecological tourism, holiday villages, families, units, public places, catering industry, wine shops, hotels, conference rooms, offices, schools, clubs, hospitals, villages, and the like.

Owner:漳浦中龙红麻籽贸易有限公司

Modified polylactic acid, preparation method and application thereof

InactiveCN102250451AGood compatibilityWide variety of sourcesSurgeryProsthesisElastomerPolymer science

The invention discloses a modified polylactic acid (PLA), its preparation method and application. The preparation method of the modified polylactic acid comprises the steps of: reacting polylactic acid with epoxidized natural rubber (ENR) by a solution co-blending method or a melt extrusion method so as to obtain blends, annealing the blends, thus obtaining the modified polylactic acid. In the method, biodegradable polylactic acid is taken as the raw material, and the natural elastomer NR (natural rubber) or ENR is added through the solution co-blending method or melt extrusion method. By controlling the NR / ENR content and epoxidation degree, the melt extrusion temperature, the annealing temperature and annealing time, etc., the method adjusts the crystallinity, crosslinking degree and phase separation of PLA, so that the weakness of poor toughness of PLA is made up substantially, and the thermostability of PLA is improved. Thus, the processibility of PLA is improved. Characterized by simple process, easy operation and probable enforcement in production, the method provided in the invention provides a new choice for adjusting the properties of PLA.

Owner:INST OF CHEM CHINESE ACAD OF SCI

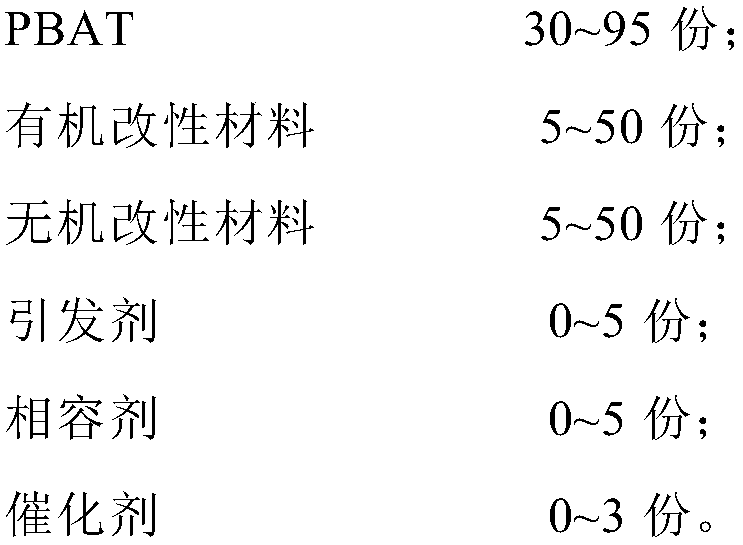

Pbat-based biodegradable composites with high water vapor barrier properties

The invention provides a PBAT-based biodegradable composite material with high vapor barrier property. The composite material comprises the following components: PBAT, organic modification material, inorganic modification material, an initiator, a compatilizer and a catalyst. Compared with the prior art, the PBAT-based biodegradable composite material has the following beneficial effects: the compatibility and dispersity of the inorganic material in PBAT can be greatly improved by bridging PBAT with the inorganic material; the bridging action, generated due to combination of the compatilizer and the initiator, of the inorganic material is partially directionally distributed by layers in a blending system, the pass route of water molecules can be prolonged, and the motion time of the water molecules in the material can be prolonged, so that the water retention property of the material can be remarkably improved, the water vapor permeability of the composite material 10mum thin film material is reduced to 320g / m<2>.24h from 280g / m<2>.24h of the original-specification thin film, which is obviously superior to the similar materials.

Owner:SHANGHAI HONGRUI CHEM PROD CO LTD

Anti-bacteria heat-proof polylactic acid tableware and manufacture method thereof

ActiveCN107201015AImprove mechanical propertiesLow costTable equipmentsHeat resistanceCarboxylic salt

The invention discloses anti-bacteria heat-proof polylactic acid tableware, which is prepared from polylactic resin, oxide, viscose fiber, initiator and alkyl ether carboxylate. The invention also discloses a preparation method for the anti-bacteria heat-proof polylactic acid tableware. The anti-bacteria heat-proof polylactic acid tableware has the advantages of simple preparation technology flow, easiness in control, low composite material cost, good heat resistance and high anti-bacteria performance, is biodegradable and can be used in fields including the tableware, food, medical packaging materials and the like.

Owner:CHONGQING JINHAOMEI MELAMINE PROD CO LTD

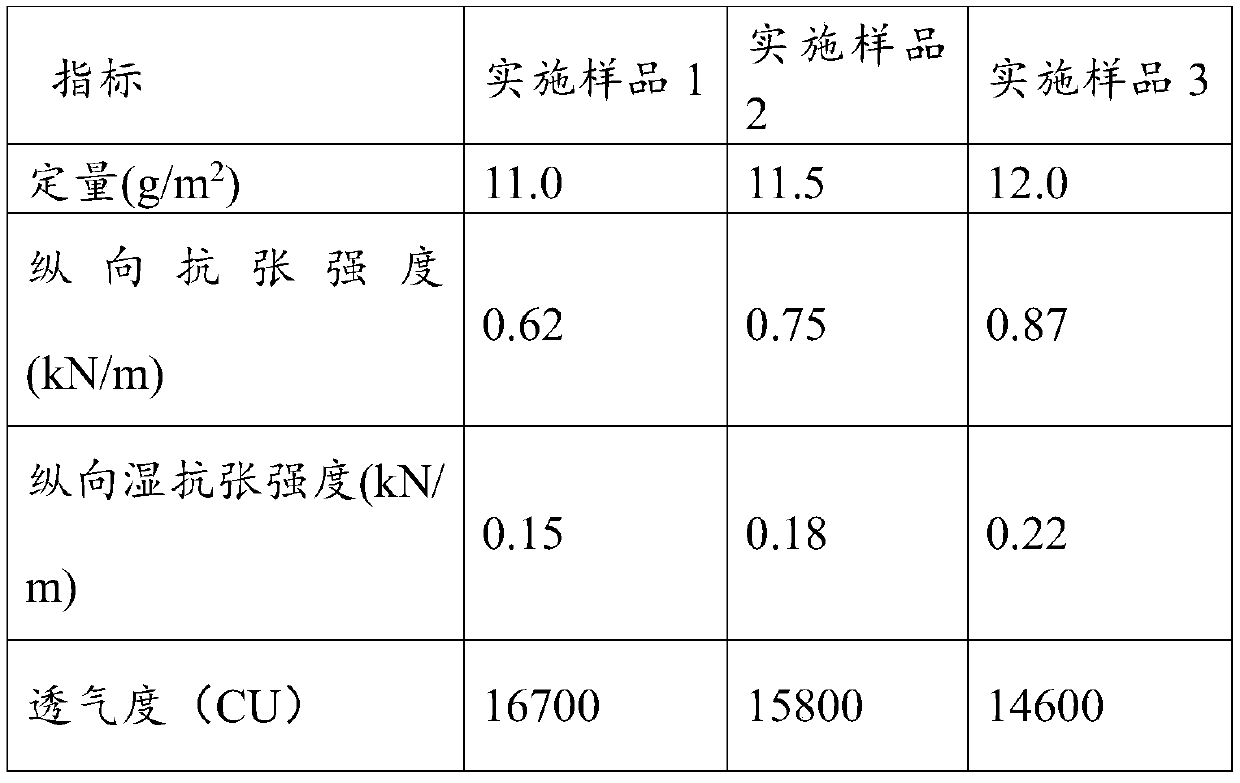

Light-weight green non-heat-seal type tea leaf filter paper and preparation method thereof

ActiveCN110924228AImprove toughnessSoft touchReinforcing agents additionPaper/cardboardFiberRolling paper

The invention relates to the field of papermaking, in particular to non-heat-seal type tea leaf filter paper. The filter paper is prepared by mixing paper mulberry bark pulp, bleached softwood pulp and viscose acetal fibers for papermaking, green natural polymer assistants are selected as chemical assistants added into the pulp, and the filter paper has the characteristics of complete natural circulation and biological decomposition. The invention also discloses a preparation method of the tea leaf filter paper. The preparation method comprises the following steps: (1) pulping; (2) preparing pulp; (3) forming on a net; (4) squeezing; (5) drying; and (6) slitting the roll paper. The tea leaf filter paper prepared by the preparation method has good dry and wet strength, uniformity and softness and high air permeability, is beneficial to permeation of tea fragrance, is light in weight, can save packaging cost for users, and has higher market competitiveness.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Cross-lined polymethyl ethylene carbonate polymer electrolyte membrane and preparation method thereof

The present invention discloses cross-linked polymethacrylic ethylene carbonic acid ester polymer electrolyte membrane and the preparation method. The polymer electrolyte membrane consists of cross-linked polymethacrylic ethylene carbonic acid ester polymer and electrolyte solution including conductive lithium salt and non-protonic solvent. The preparation method adopts carbon dioxide, epoxy dimethylmethane and unsaturated acid anhydride which are synthesized into polymethacrylic ethylene carbonic acid ester trivalent copolymer with special functional group under the role of catalyst dyadic carboxylic acid zinc. Then the trivalent copolymer is under the cross-linking reaction so as to get the dry polymethacrylic ethylene carbonic acid ester polymer membrane. Afterwards, the dry membrane is immerged into the liquid electrolyte solution for activation, thus obtaining the cross-linked polymethacrylic ethylene carbonic acid ester polymer electrolyte membrane. The polymer electrolyte membrane prepared by the present invention has the advantages of high mechanical performance, good thermal performance and high ion electric conduction. The present invention with low cost and simple process is applicable to the industrialized production.

Owner:SUN YAT SEN UNIV

Environment-friendly acrylate modified waterborne polyurethane printing ink and preparation method thereof

The invention relates to the technical field of ink, and discloses environment-friendly acrylate modified waterborne polyurethane printing ink and a preparation method thereof. The printing ink comprises the following components in parts by weight: acrylate modified waterborne polyurethane, modified nano titanium dioxide, a defoaming agent, a dispersing agent and water. The preparation method comprises the following steps: adding the acrylate modified waterborne polyurethane, the defoaming agent and the deionized water into a stirring kettle, conducting stirring for 30-50 minutes at the stirring speed of 400-500 r / min, adding the modified nano titanium dioxide and the dispersing agent, and conducting stirring for 20-30 minutes at the stirring speed of 600-800 r / min, thereby obtaining the printing ink. The waterborne polyurethane printing ink prepared by the invention has the advantages of environmental protection, high solid content and excellent water resistance; and besides, the nanotitanium dioxide pigment added into the ink can be uniformly dispersed in a water-based medium, and an acrylate modified water-based polyurethane binder cannot be subjected to photocatalytic degradation, so that the service life of the ink is prolonged.

Owner:ZHEJIANG HUABAO INK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com