Hyperbranched polyphosphate amide ester as well as preparation method and application thereof

A technology of polyphosphoramidate and branching degree, which is applied in the field of preparation of hyperbranched polyphosphoramidate and high-efficiency flame-retardant degradable polyester, which can solve the problems of large addition amount and non-degradable flame retardant, and achieve low viscosity , good rheological properties, and the effect of maintaining biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

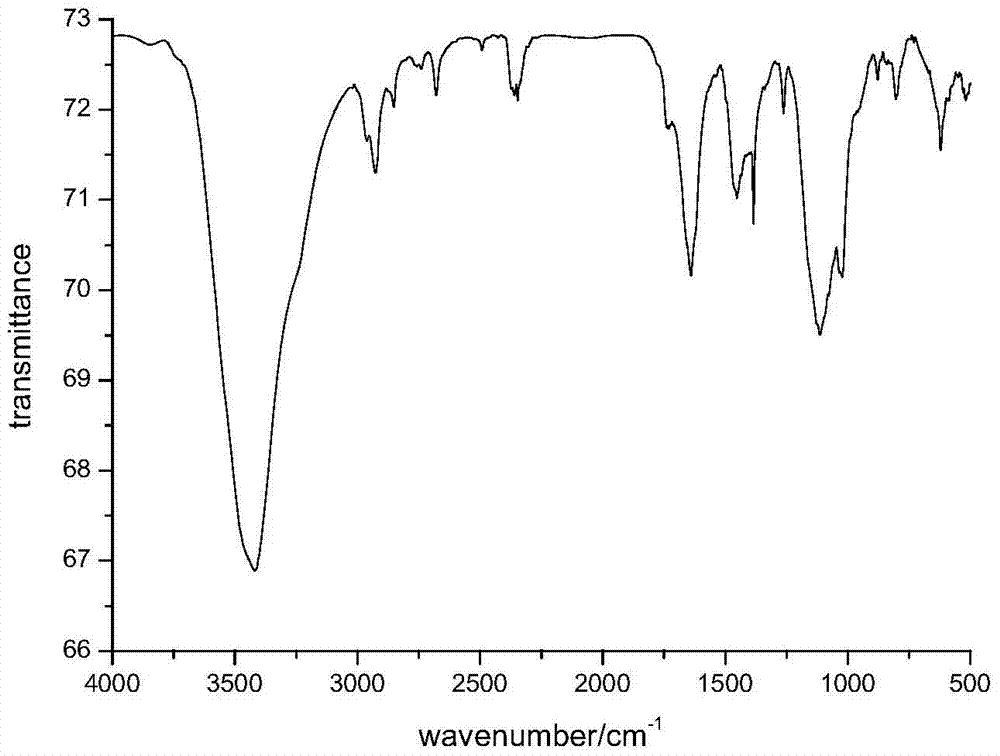

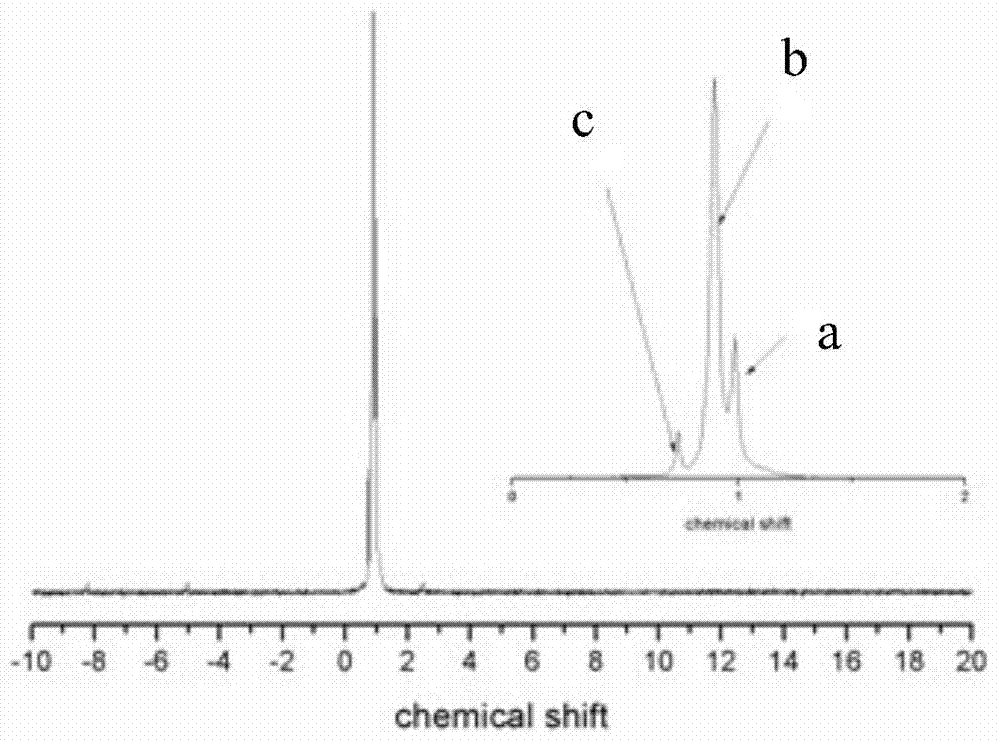

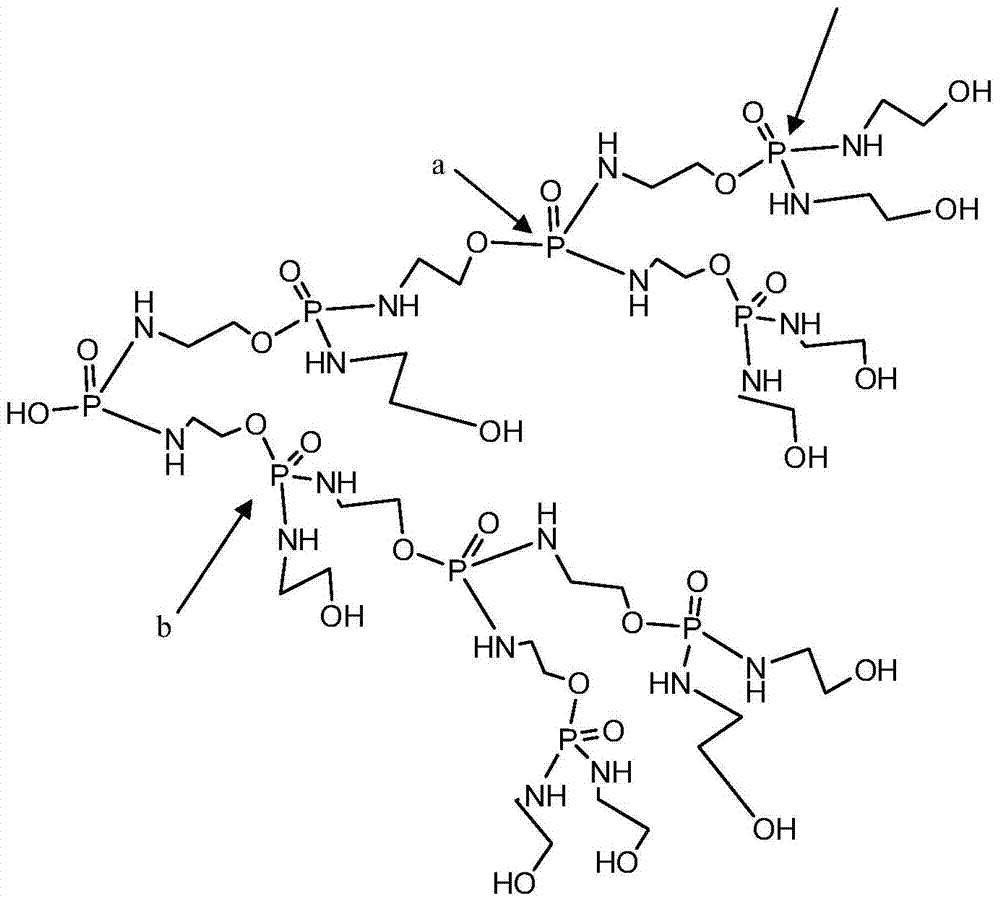

Method used

Image

Examples

Embodiment 1

[0034] The redistilled POCl 3 Add 0.28mol into 170mL of dry acetonitrile, and then pour them into a 500ml three-necked flask. Nitrogen gas is introduced into the system to maintain anhydrous state. Slowly add dropwise to the reaction system, and the dropping time is 1h~1.5h. After the dropwise addition, control the reaction temperature at 40°C for 24h. Then keep the system at 82°C for 24 hours. After the reaction was completed, acetonitrile was evaporated by rotary evaporation, dissolved by adding DMSO, filtered, and then this operation was repeated once.

[0035] Then add ether, filter, and take the filter cake. The filter cake is the desired product.

[0036]Preparation of polylactic acid and the synthesized hyperbranched polyphosphoramidate blend system Take 50g of PLA, bake at 80°C for 24 hours, then add 50g of PLA, antioxidant 1010 (0.2wt%), and add 0.5-5g of the above-mentioned hyperbranched For polyphosphoramidate, in a torque rheometer, the controlled temperature ...

Embodiment 2

[0039] The redistilled POCl 3 Add 0.28 mol to 170mL of dry acetonitrile, and then pour them into a 500ml three-necked flask. Nitrogen gas is passed through the system to maintain anhydrous state. The temperature of the reaction system is controlled at 0-2°C and stirred rapidly. Alcohol amine is slowly added dropwise to the reaction system, and the dropping time is 1h~1.5h. After the dropwise addition is completed, the reaction temperature is controlled at 40°C for 24h. After the reaction is completed, a mixture of 40mL acetonitrile and 80g pyridine is added dropwise. After completion, keep the system at 82°C for 24 hours. After the reaction was completed, acetonitrile was first spun off, and after the reaction was completed, the acetonitrile was spun off, DMSO was added to dissolve, filtered, and this operation was repeated once. Then add ether, filter, and take the filter cake. The filter cake is the desired product, then add ether, filter, and take the filter cake. T...

Embodiment 3

[0043] The redistilled POCl 3 Add 0.28 mol to 170mL of dry acetonitrile, and then pour them into a 500ml three-neck flask. Nitrogen gas is introduced into the system to maintain anhydrous state. Slowly add it dropwise to the reaction system, the dropping time is 1h~1.5h, after the dropwise addition is completed, control the reaction temperature at 40°C for 24h, after the reaction is completed, add 40mL acetonitrile and 70g diisopropylethylamine dropwise After dropping the mixture, keep the system at 82°C for 24 hours. After the reaction is completed, acetonitrile is first spun off, and then DMSO is added to dissolve. After the reaction is completed, acetonitrile is spun off, DMSO is added to dissolve, and the operation is repeated once. Then add ether, filter, and take the filter cake. The filter cake is the desired product. Then add ether, filter, and take the filter cake. The filter cake is the desired product.

[0044] Preparation of polylactic acid and the synthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Branching factor | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com