Light-weight green non-heat-seal type tea leaf filter paper and preparation method thereof

A non-heat-sealable, tea filter paper technology, applied in chemical instruments and methods, filter paper, separation methods, etc., can solve the problems of shortage of papermaking raw materials, low paper strength, high cost, etc., to improve market competitiveness, paper quality Uniform softness, saving packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

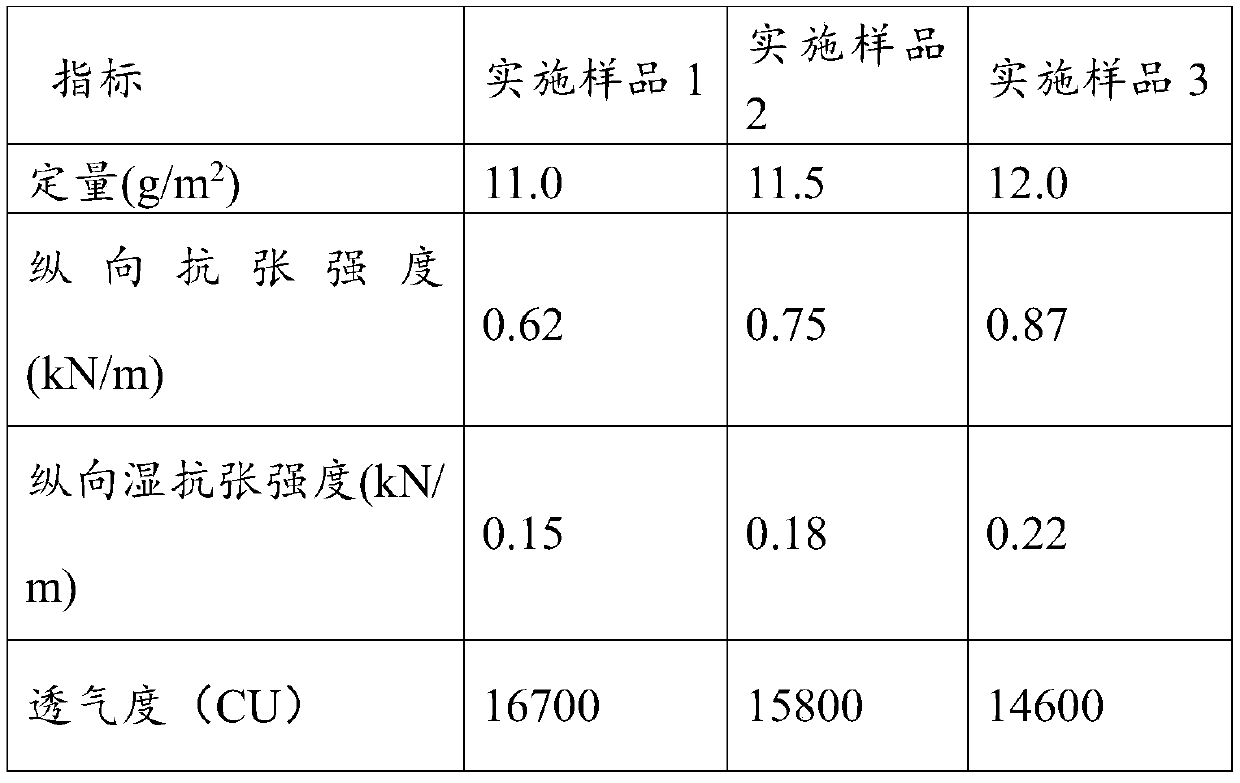

Examples

Embodiment 1

[0020] A method for preparing lightweight green non-heat-sealable tea filter paper, comprising the steps of:

[0021] (1) Beating: Three fiber pulps are beaten respectively, the concentration of the bark pulp is 5%, and the conical refiner beats until the degree of beating is 45°SR; the concentration of the full chlorine-free bleached coniferous wood pulp is 4%, and the double disc refiner beats The controlled beating degree is 42°SR; the concentration of viscose fiber pulp is 0.6%, and the volt type beater is beaten until the beating degree is 15°SR. The beaten pulp is mixed according to the mass ratio, and treated with a leveling refiner for 30s.

[0022] The said bark fiber is prepared by chemical thermo-mechanical method, the bark is first mechanically rubbed to remove the black bark on the surface to obtain the white bark, which is cut into small sections of 20 mm to 30 mm; the white bark is pretreated with biological enzymes for 8 hours , washed; then 4% NaOH and 2% H 2...

Embodiment 2

[0031] A method for preparing lightweight green non-heat-sealable tea filter paper, comprising the steps of:

[0032] (1) Beating: Three kinds of fiber pulp are beaten respectively, the concentration of the bark pulp is 4%, and the conical refiner beats until the degree of beating is 45°SR; the concentration of the full chlorine-free bleached coniferous wood pulp is 5%, and the double disc refiner beats The controlled beating degree is 42°SR; the concentration of viscose fiber pulp is 0.8%, and the beating degree is 15°SR with a volt type beater.

[0033] The said bark fiber is prepared by chemical thermo-mechanical method, the bark is first mechanically rubbed to remove the black bark on the surface to obtain the white bark, which is cut into small sections of 20 mm to 30 mm; the white bark is pretreated with biological enzymes for 8 hours , washed; then 4% NaOH and 2% H 2 o 2 Treat at 80°C for 60-80 minutes, and finally use a twin-screw press to make pulp, with a screw spe...

Embodiment 3

[0042] A method for preparing lightweight green non-heat-sealable tea filter paper, comprising the steps of:

[0043] (1) Beating: Three kinds of fiber pulp are beaten separately, the concentration of the bark pulp is 3%, and the conical refiner beats until the degree of beating is 45°SR; the concentration of the full chlorine-free bleached coniferous wood pulp is 6%, and the double disc refiner beats the pulp The controlled beating degree is 42°SR; the concentration of viscose fiber pulp is 1.0%, and the beating degree is 15°SR with a volt type beater.

[0044] The said bark fiber is prepared by chemical thermo-mechanical method, the bark is first mechanically rubbed to remove the black bark on the surface to obtain the white bark, which is cut into small sections of 20 mm to 30 mm; the white bark is pretreated with biological enzymes for 8 hours , washed; then 4% NaOH and 2% H 2 o 2 Treat at 80°C for 60-80 minutes, and finally use a twin-screw press to make pulp, with a sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com