Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce the amount of inclusions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ladle top slag deoxidation modifier for ultralow carbon steel, and use method thereof

The invention relates to a ladle top slag deoxidation modifier for ultralow carbon steel, and a use method thereof. The technical problems of complex preparation process, high production cost and easyenvironment pollution during use of existing ladle top slag modifiers for ultralow carbon steel are mainly solved. The ladle top slag deoxidation modifier for ultralow carbon steel comprises 18-28 wt% of Al, 20-30 wt% of CaCO3, 3-7 wt% of CaO, 5-10 wt% of Al2O3, 5-9 wt% of CaF2, 5-8 wt% of MgO, 6 wt% or less of Na2CO3, and the balance of inevitable impurities; and the particle size of all components in the ladle top slag deoxidation modifier is less than or equal to 1 mm. The modifier can significantly improve the slag crusting problem of the ladle and improve the fluidity of molten steel.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

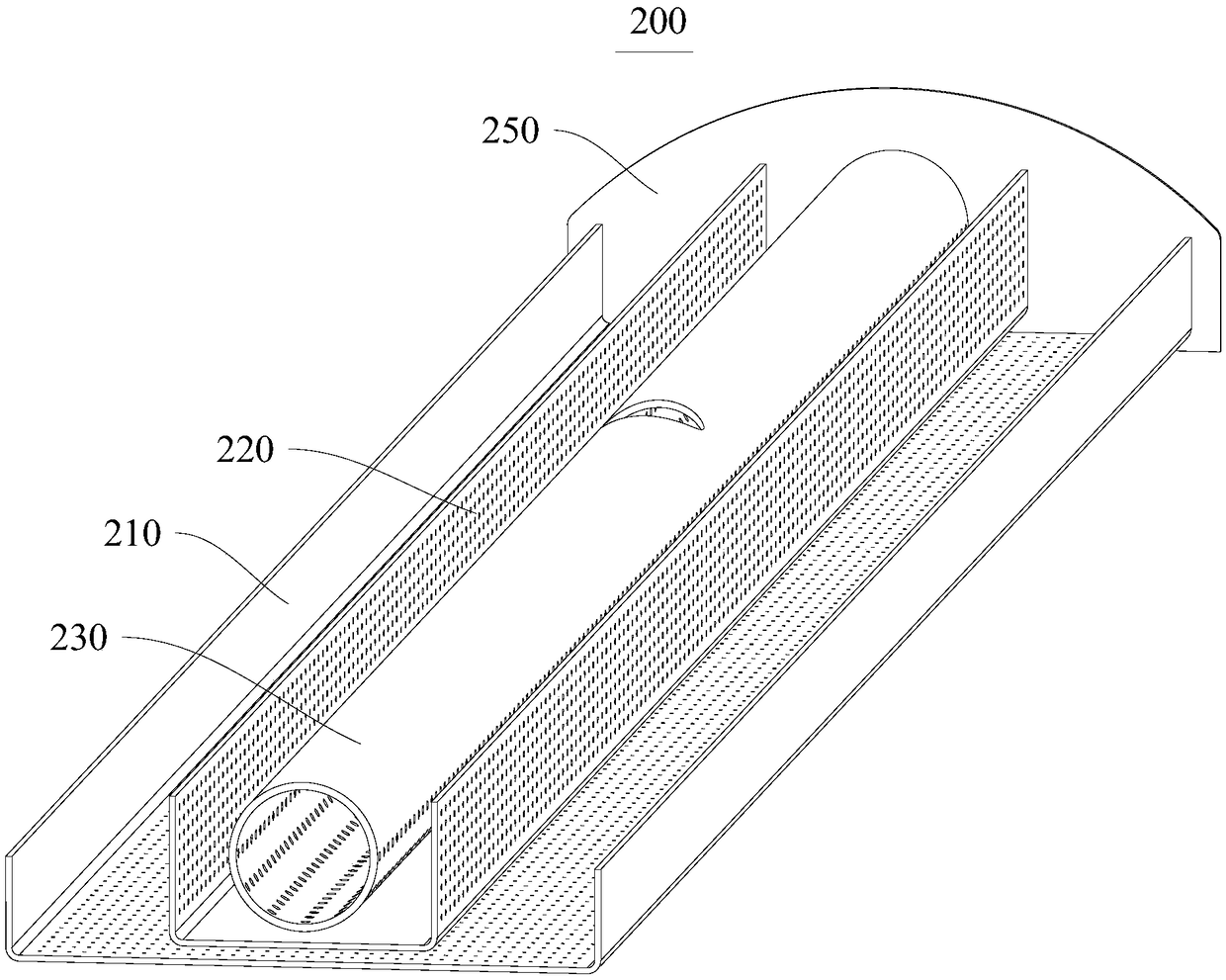

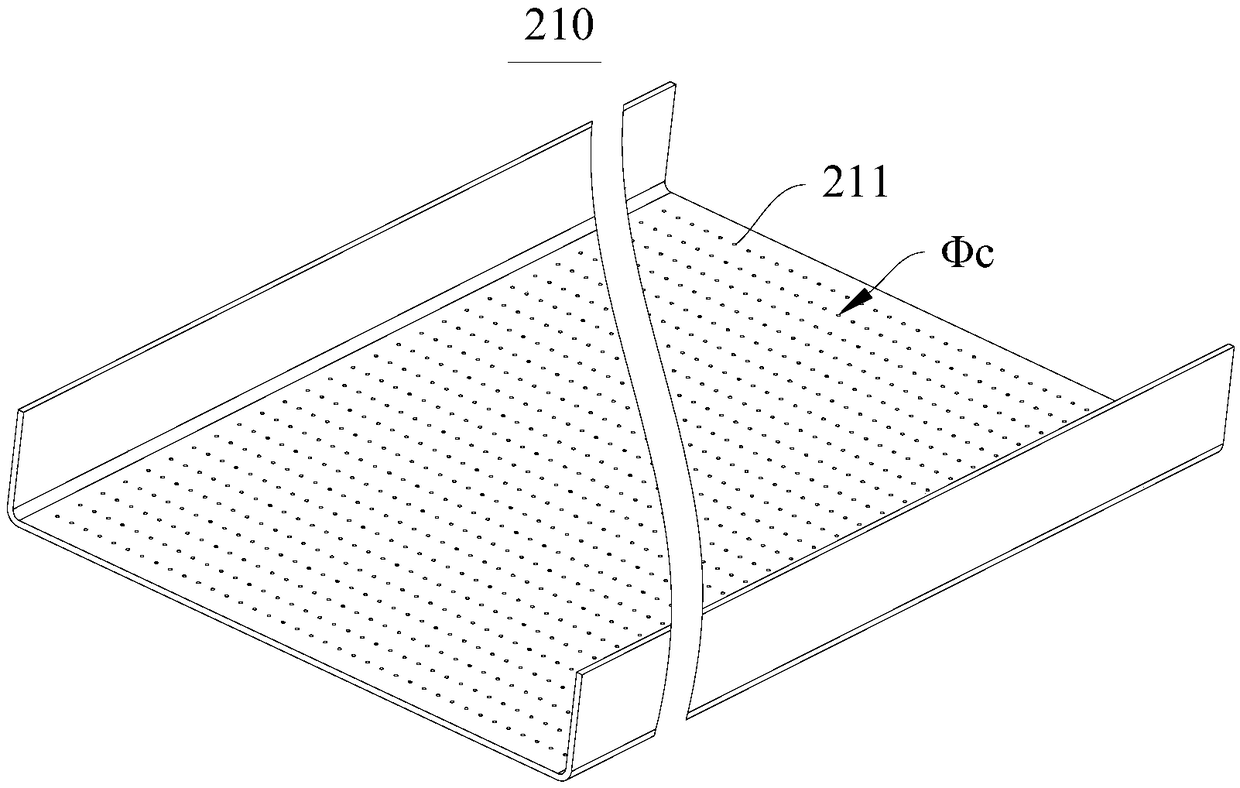

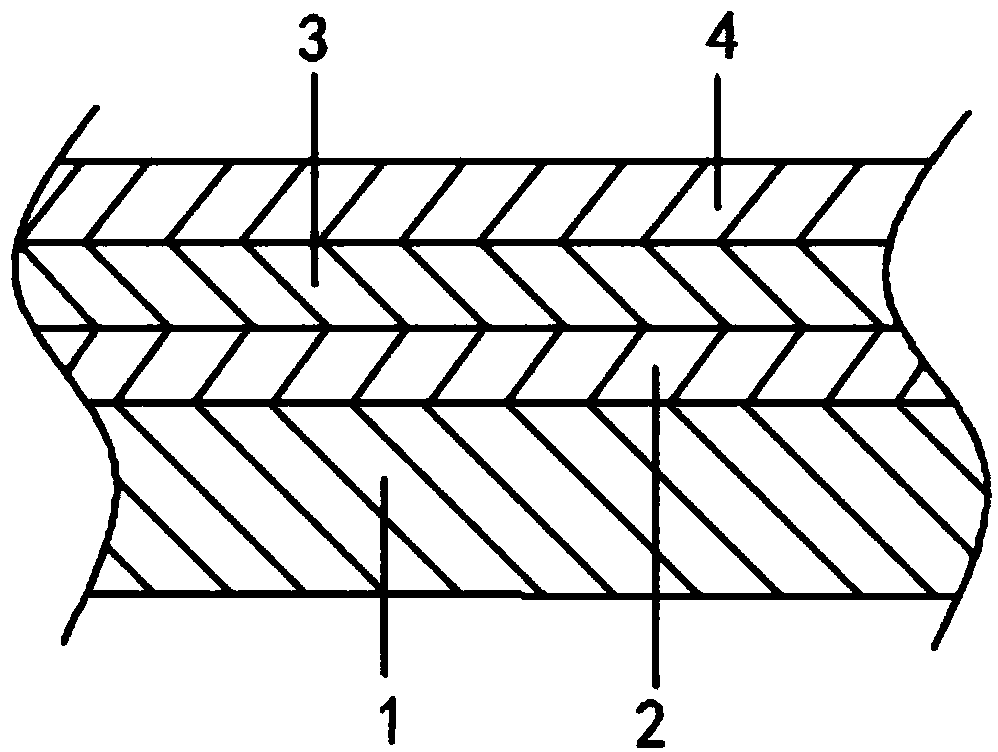

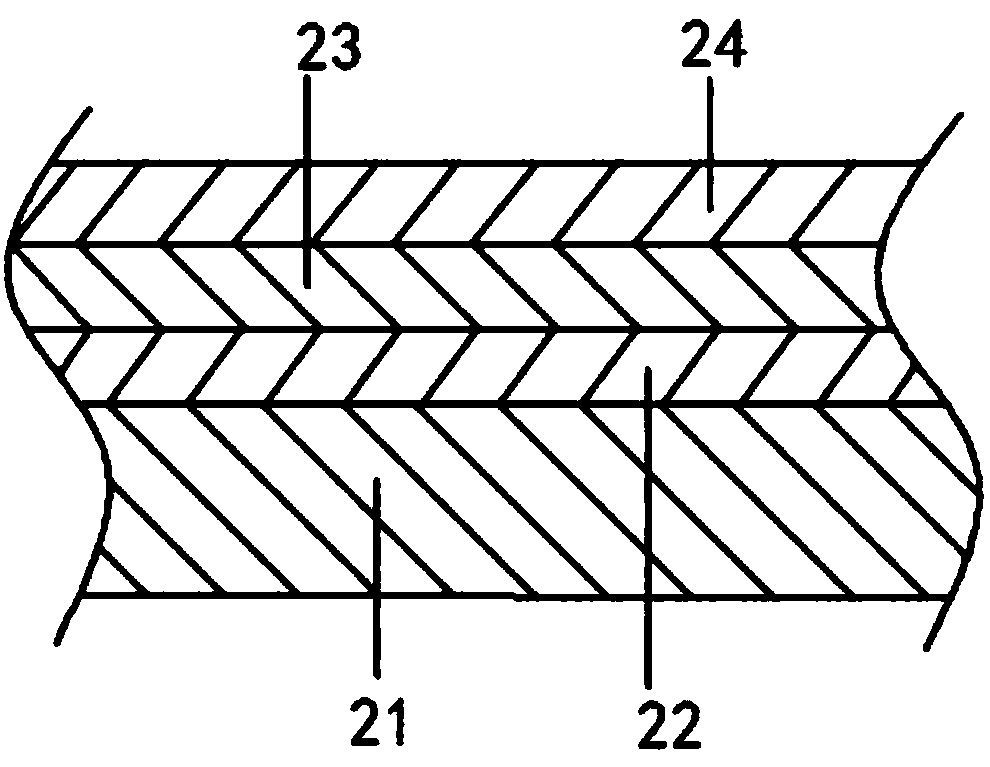

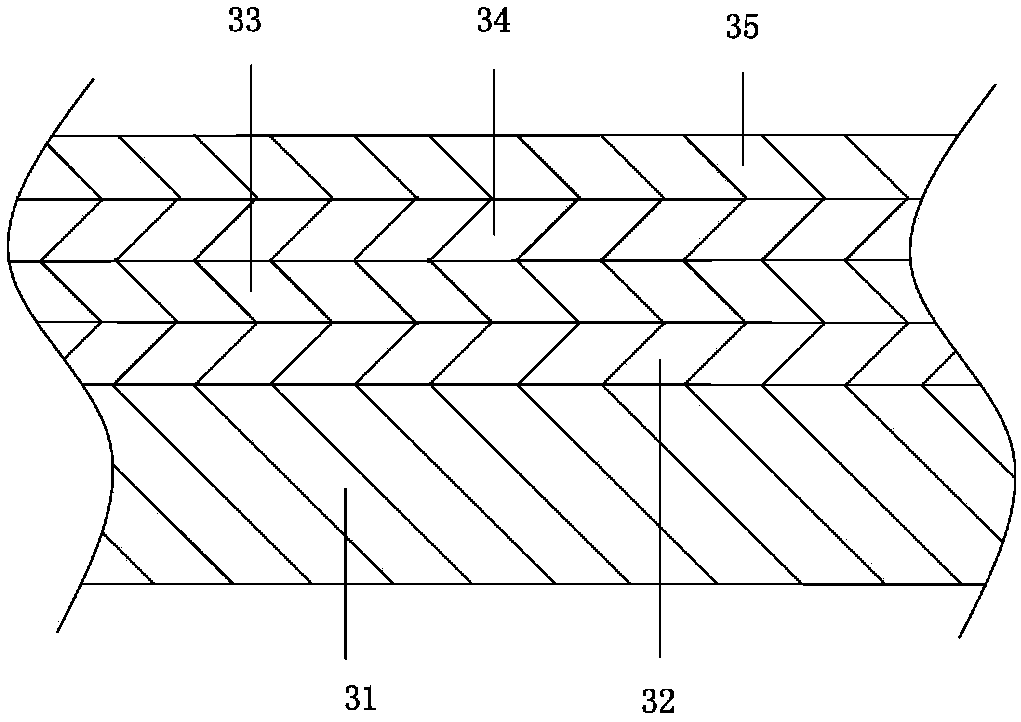

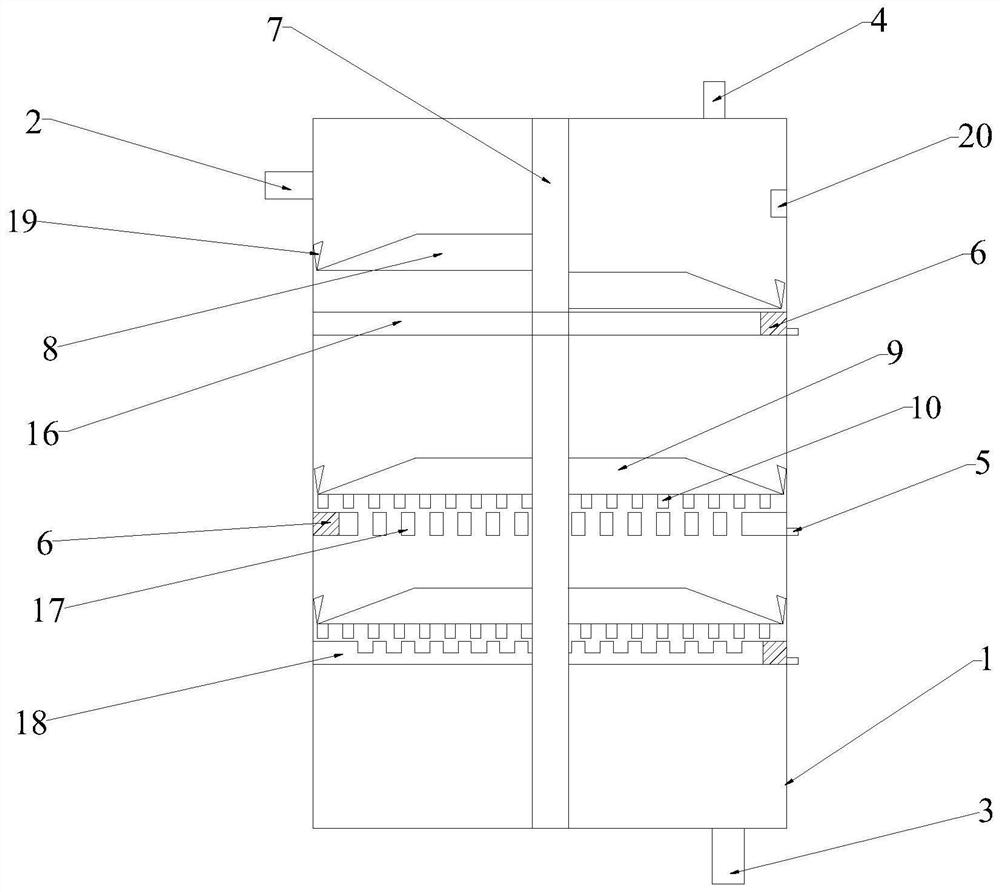

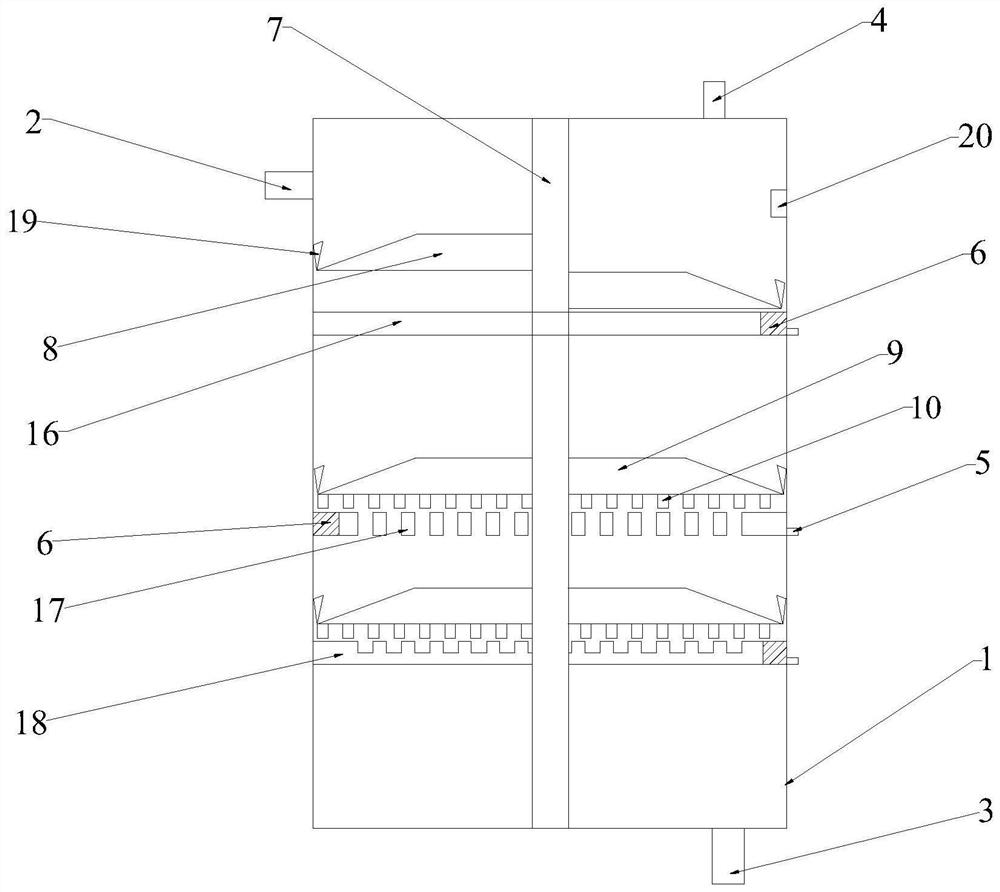

Liquid distributor, falling-film evaporator and air conditioner

PendingCN108709339AImprove heat transfer efficiencyPlay a buffer roleEvaporators/condensersStationary conduit assembliesLiquid stateEngineering

The invention relates to a liquid distributor, a falling-film evaporator and an air conditioner. The liquid distributor comprises a liquid homogenizing tank and a liquid stopping tank, wherein the bottom wall of the liquid homogenizing tank is provided with a plurality of liquid distribution through holes; the top space of the liquid homogenizing tank communicates with an air exhaust channel of the falling-film evaporator; the liquid stopping tank is arranged above the bottom wall of the liquid homogenizing tank; the liquid stopping tank comprises two opposite side walls; the two opposite sidewalls of the liquid stopping tank are separately provided with a plurality of overflow through holes; the top space of the liquid stopping tank communicates with the air exhaust channel of the falling-film evaporator; and a refrigerant can be injected into the liquid stopping tank. The gas-liquid mixing refrigerant can be separately subjected to primary gas-liquid separation and secondary gas-liquid separation in a process of entering into the liquid stopping tank and the liquid homogenizing tank, so that inclusion contents of the gaseous refrigerant in the liquid-state refrigerant which flows out of the bottom wall of the liquid homogenizing tank can be effectively reduced, so that the phenomenon that a uniform and stable liquid film of the liquid-state refrigerant is formed on the surface of a heat exchange pipe is ensured, and the heat exchange efficiency of the falling-film evaporator is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Titanium alloy laser cladding surface reinforcing method

ActiveCN103668186AImprove surface qualityImprove organizationMetallic material coating processesHardnessWear resistance

The invention relates to a titanium alloy laser cladding surface reinforcing method which comprises the following steps: mixing the following components by weight: 50-100% of Co42 cobalt-based self-fluxing alloy powder, 0-50% of B4C0, 0-50% of SiC, 0-39% of TiN, 0-1.5% of Y2O and 0-1.5% of CeO2, uniformly blending the mixture powder into paste by using a sodium silicate solution, uniformly coating the paste mixture powder on the surface of a titanium alloy, keeping the coating uniform in thickness, drying in air naturally, and performing laser cladding on the coating on the surface of the titanium alloy. By the adoption of the method provided by the invention, the microstructure of a cladding layer can be improved, and the hardness and the wear-resistance of the cladding layer can be further improved.

Owner:SHANDONG UNIV

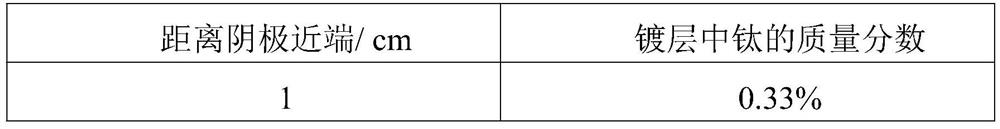

Acid non-cyanide cadmium-plating additive, preparation of plating solution and electro-plating process

ActiveCN106245071AReduce the amount of inclusionsImproves flexibility and corrosion resistanceComplex ionsAstronautics

The invention discloses an acid non-cyanide cadmium-plating additive, preparation of a plating solution and an electro-plating process. The plating solution comprises the following components: 35-40 g / L of cadmium chloride, 140-180 g / L of potassium chloride, 120-160 g / L of a complexing agent, 1.5-2.5 mL / L of a brightener, and 25-35 mL / L of an auxiliary agent. Electro-plating operation conditions comprise that the plating bath temperature is 15-35 DEG C, the negative electrode current density is 0.5-1.5 A / dm<2>, the area ratio of a negative electrode to a positive electrode is 2 to 1, and the positive electrode comprises two materials of a cadmium plate and an electro-plating high-density graphite plate. The advantages mainly comprise that a brightener and an auxiliary agent are prepared by adopting a high-performance electro-plating additive intermediate, the combined complexing agent and cadmium ions are used for generating polybasic complex ions, and the performance of the plating solution and the performance of a plating layer are improved; the plating solution of the process is stable and is easy to maintain, the current efficiency is relatively high, the deep plating ability is strong, the brittleness of the plating layer is small, the corrosion resistance is good, various properties meet requirements of the Ministry of Astronautics Industry standards QJ 453-1988 ''cadmium plating layer technology conditions'', and electroplating wastewater treatment results meet requirements of GB 21900-2008 ''electroplating pollutant discharge standards'' table 3.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

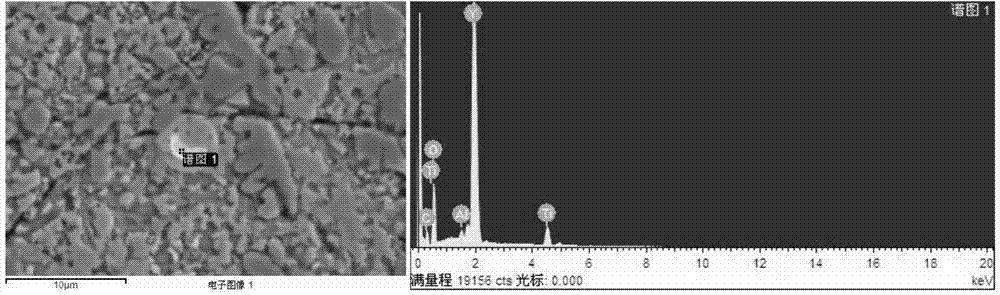

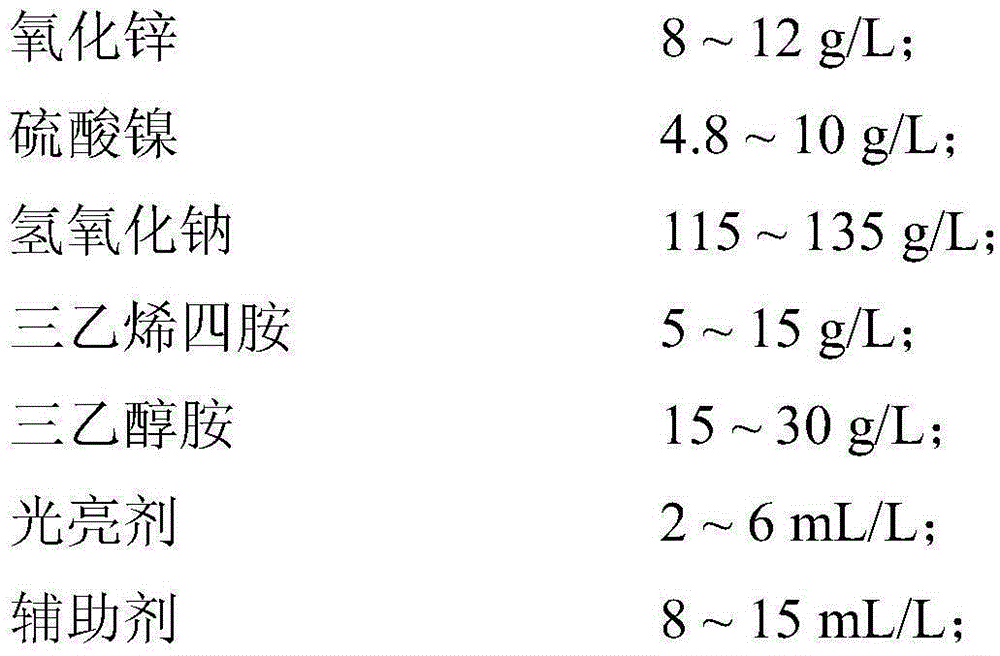

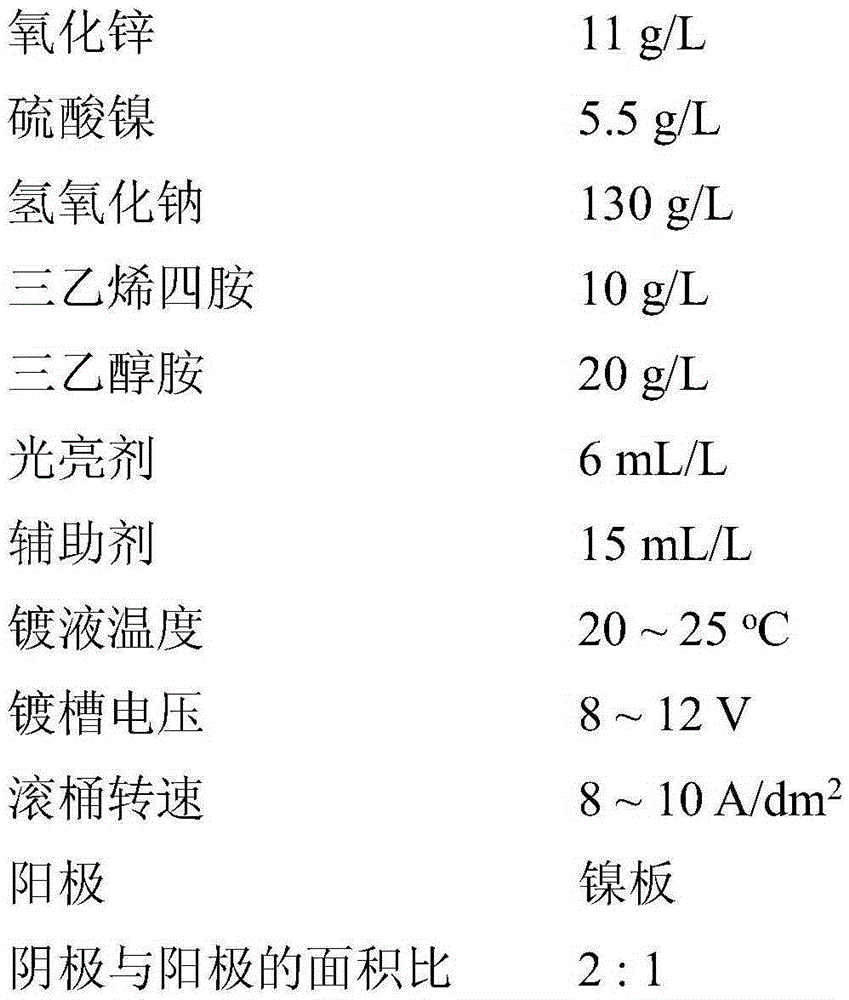

Alkaline zinc-nickel alloy electroplating solution with high stability

InactiveCN105239115AReduce the amount of adsorptionImprove stabilityPolyethylene polyamineDecomposition

The invention discloses an alkaline zinc-nickel alloy electroplating solution with high stability. The alkaline zinc-nickel alloy electroplating solution comprises 8-12 g / L of zinc oxide, 4.8-10 g / L of nickel sulfate, 115-135 g / L of sodium hydroxide, 5-15 g / L of triethylene tetramine, 15-30 g / L of triethanolamine, 2-6 mL / L brightening agents and 8-15 mL / L of additives. The brightening agents comprise sodium toluene sulphonate. The additives are composed of sodium toluene sulphonate, polyvinyl alkylimine, polyethylene-polyamine and epoxy chloropropane condensation compounds, sodium 2-ethylhexyl sulfate and sodium metavanadate. According to the alkaline zinc-nickel alloy electroplating solution, the cosolvent, namely the sodium toluene sulphonate is adopted, so that the solubility of additive decomposition products in the electroplating solution is improved, and the impurity adsorption quantity on the surface of a plated part and the impurity inclusion quantity in a plating layer are reduced. Besides, the brightening agents and the additives are reasonably selected and combined, so that the performance of the electroplating solution and the performance of the plating layer are improved, the current efficiency of the electroplating solution is stable, and the plating layer is low in brittleness, large in adhesive force and high in corrosion resistance.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

High-calcium non-silicon aluminium calcium magnesium ferrous alloy for steel-smelting deoxidization and method for preparing the same

The invention discloses a high-calcium no-silicon aluminum-calcium-magnesium-ferric alloy used for steelmaking deoxidization. According to the weight proportion of the components, Ca is more than 15 percent but less than or equal to 28 percent, the proportion of Al to Ca is 1-2:1, 2-6 percent of Mg, the rest is Fe. The optimization scope is 18-25 percent of Ca, the proportion of Al to Ca is 1-1.3:1, 2-4 percent of Mg, the rest is Fe. A preparation method is that: aluminum, calcium, magnesium, low-carbon steel scrap are chosen as raw materials; the materials are smelted into aluminum-magnesium and aluminum-calcium master alloys in a low-frequency furnace; the materials continue being smelted in a high-frequency furnace and aluminum-iron metal liquid is obtained; the master alloy is pressed into the deep of the aluminum-iron metal liquid under a meshed high-temperature resistance container to be melted and at last the master alloy is cast under the protection of argon gas. The obtained alloy can be used for the final deoxidation in smelting low-carbon low-silicon al-killed steel, and can lower the harmful effect of the deoxidation product Al2O3 with good effect in integral deoxidation.

Owner:郭庆成

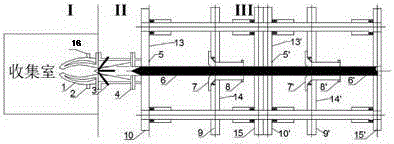

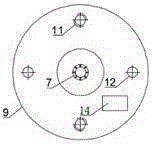

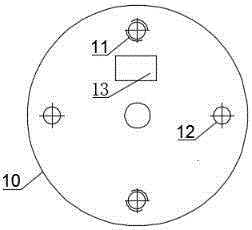

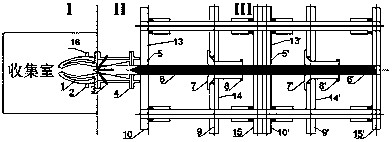

Device and method for continuously manufacturing metal powder through multi-electrode plasma arcs

ActiveCN105252012AFacilitate mechanized productionReduce powder manufacturing costsPhysicsElectric arc

The invention relates to a device and method for continuously manufacturing metal powder through multi-electrode plasma arcs. The device and method are characterized in that raw material rods enter a plasma arc generator electrode inner cavity of a heating area through a feeding opening in a feeding device; three electrodes of the plasma arcs are used for evaporating the metal raw material rods into fogging plasma bodies, namely, rods, wires or ceramic rods with the same powder materials are manufactured, wherein the raw material rods are located in the center, and the arcs are located on the periphery; and inert gas flow is used for blowing fogging metal fog into a collecting device, and the fogging metal fog is rapidly cooled and solidifies into powder along with rapid reduction of the temperature and the air pressure. Convenience is brought to mechanized production, and the powder manufacturing cost is greatly reduced. Through adjustment of parameters such as the plasma arc output heat and the protection gas pressure, the powder granularity can range from 0.1 micrometer to 100 micrometers. One-time molding of powder manufacturing is achieved.

Owner:CHANGCHUN UNIV OF TECH

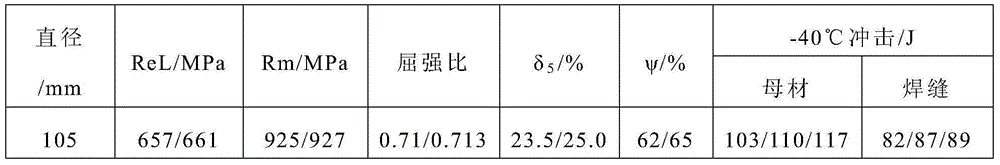

Steel for R4-grade mooring cables and preparation method thereof

InactiveCN103882346AReduce C contentAvoid organizational transformationTemperature control deviceChemical compositionHigh intensity

The invention discloses a steel for R4-grade mooring cables and a preparation method thereof. The steel comprises the following components in percentage by weight: 0.15-0.24% of C, 0.15-0.30% of Si, 1.2-1.60% of Mn, at most 0.025% of P, at most 0.025% of S, at most 0.02% of Cu, 0.8-1.3% of Cr, 0.70-1.30% of Ni, 0.2-0.50% of Mo, 0.02-0.05% of Al, at most 0.0050% of As, at most 0.0050% of Sb, at most 0.0050% of Sn, at most 0.0050% of N, at most 0.0020% of O, at most 0.0020% of H, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: molten iron desulfurization, converter smelting, argon blowing, LF (ladle furnace) refining, RH vacuum treatment, continuous casting, square billet heating, rolling, air cooling and nondestructive flaw detection. The steel for R4-grade mooring cables has the advantages of high strength, high toughness, low cost and corrosion resistance.

Owner:武汉钢铁有限公司

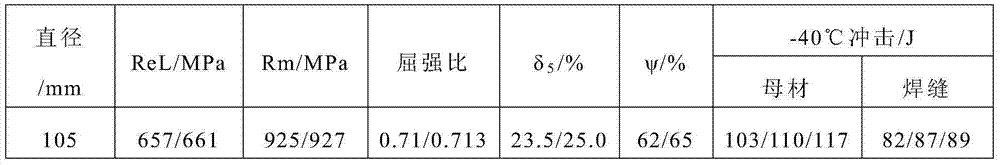

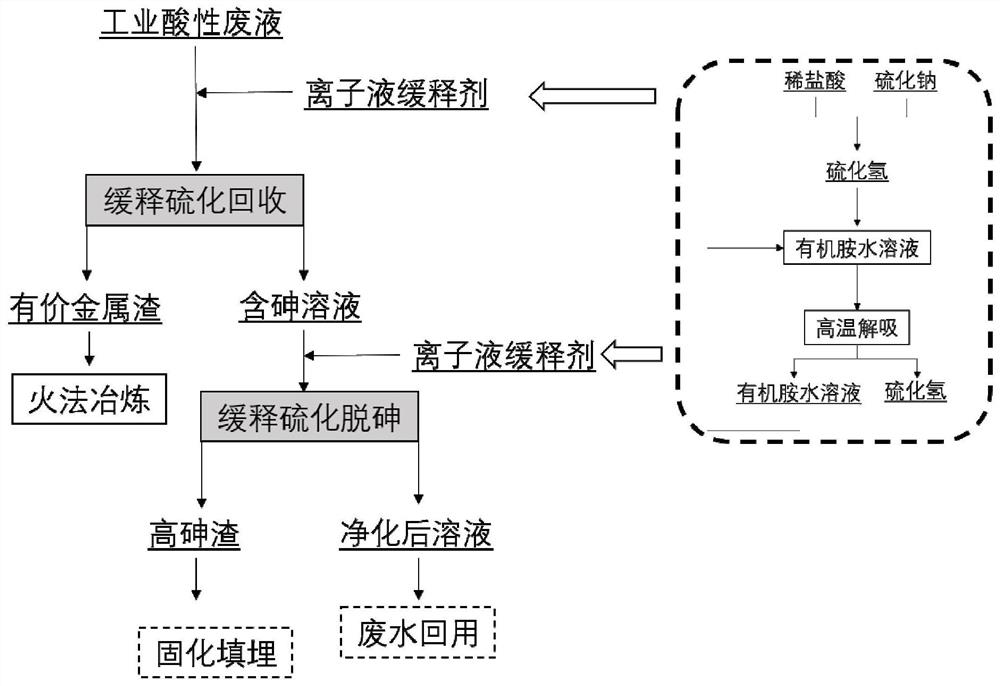

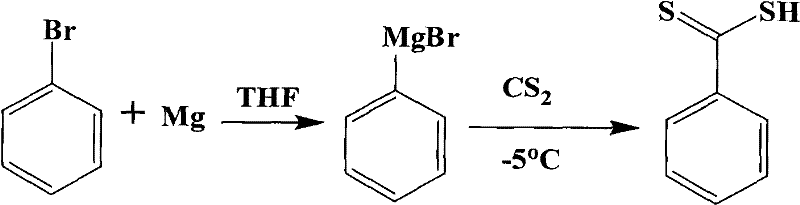

Method for recycling multiple metals through resource cooperative treatment of copper smelting white smoke dust and waste acid

PendingCN113088708AThe operation process is simpleLow costArsenic oxides/hydroxides/oxyacidsProcess efficiency improvementSlagSulfidation

The invention discloses a method for recycling multiple metals through resource cooperative treatment of copper smelting white smoke dust and waste acid. The method comprises two routes of waste acid leaching of the copper smelting white smoke dust and waste acid gradient slow-release vulcanization. The method comprises the following steps of adopting waste acid leaching in the copper smelting white smoke dust, enabling leachate to have a replacement reaction by using active arsenic sulfide slag for copper precipitation, carrying out waste acid gradient slow-release vulcanization to obtain the active arsenic sulfide slag, carrying out reduction and cooling crystallization on an arsenic-rich solution after replacement and copper precipitation to obtain an arsenic dioxide product and a crystallization mother solution, and returning the crystallization mother solution to the process of preparing the active arsenic sulfide slag; and carrying out multi-metal extraction and wastewater purification and recycling on waste acid gradient slow-release sulfurized liquid. According to the method, products obtained through the two routes are interactively utilized to form closed circulation, waste recycling in the whole system is achieved, zero emission can be achieved in the whole process, the method is simple in process and low in cost, comprehensive resource recycling of valuable metal elements and arsenic in the waste acid and the copper smelting white smoke dust is achieved, and industrial application is facilitated.

Owner:CENT SOUTH UNIV

Double steelmaking tundish continuous casting heat number in-depth study method

The invention relates to the technical field of double steelmaking tundish continuous casting heat number study, and discloses a double steelmaking tundish continuous casting heat number in-depth study method. The method comprises the following steps that 1) firstly, a reasonable and effective tundish baking system is formulated, the tundish baking time is controlled to be 2 h to 3 h, a capping production mode is adopted on a tundish, and therefore when baking is needed, the casting waiting time is effectively shortened through capping, a cover plate can be pulled to be open when the tundish needs to be stopped, the tundish cooling waiting time and the temperature drop are shortened, and the tundish baking temperature during casting is ensured to be higher than or equal 900 DEG C. By meansof the double steelmaking tundish continuous casting heat number in-depth study method, the double steelmaking tundish continuous casting heat number is wholly and effectively improved, the overall double steelmaking tundish continuous casting heat number in-depth study method is clear and explicit in step, operation is simple, the service life of the tundish can be effectively prolonged, meanwhile, the double steelmaking tundish continuous casting heat number is greater than or equal to 90 furnaces, the production cost of steelmaking is reduced, and implementation by a user is facilitated.

Owner:成渝钒钛科技有限公司

Acid cyanide-free cadmium plating additive, plating solution preparation and electroplating process

The invention discloses an acid non-cyanide cadmium-plating additive, preparation of a plating solution and an electro-plating process. The plating solution comprises the following components: 35-40 g / L of cadmium chloride, 140-180 g / L of potassium chloride, 120-160 g / L of a complexing agent, 1.5-2.5 mL / L of a brightener, and 25-35 mL / L of an auxiliary agent. Electro-plating operation conditions comprise that the plating bath temperature is 15-35 DEG C, the negative electrode current density is 0.5-1.5 A / dm<2>, the area ratio of a negative electrode to a positive electrode is 2 to 1, and the positive electrode comprises two materials of a cadmium plate and an electro-plating high-density graphite plate. The advantages mainly comprise that a brightener and an auxiliary agent are prepared by adopting a high-performance electro-plating additive intermediate, the combined complexing agent and cadmium ions are used for generating polybasic complex ions, and the performance of the plating solution and the performance of a plating layer are improved; the plating solution of the process is stable and is easy to maintain, the current efficiency is relatively high, the deep plating ability is strong, the brittleness of the plating layer is small, the corrosion resistance is good, various properties meet requirements of the Ministry of Astronautics Industry standards QJ 453-1988 ''cadmium plating layer technology conditions'', and electroplating wastewater treatment results meet requirements of GB 21900-2008 ''electroplating pollutant discharge standards'' table 3.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

Method for preparing polycarbonate

The invention relates to a method for preparing polycarbonate. The method utilizes an interface method, and comprises the steps of: mixing alkaline aqueous solution of one or more dihydroxy aromatic hydrocarbons and organic solution of carbonyl chloride(phosgene); controlling the pH value to be between 9 and 12.5 in the whole process; and performing an interfacial polymerization reaction of a phenol chain terminator, the dihydroxy aromatic hydrocarbons and the phosgene in the presence of a catalyst, namely an amphiphilic block copolymer to prepare the polycarbonate. The method utilizes the amphiphilic block copolymer as the catalyst for preparing the polycarbonate by the interface method, which can increase the utilization rate of the carbonyl chloride, reduce the consumption of the carbonyl chloride, and improve the utilization rate of bisphenol; the catalyst can promote the rapid transformation of chloroformate and obtain a polycarbonate product with low inclusion amount of dihydroxy aromatic compounds; and no phenol precipitations are precipitated after a wastewater phase is acidified, and a catalyst material can be treated and recovered by adopting a conventional method.

Owner:CHINA NAT BLUESTAR GRP CO LTD

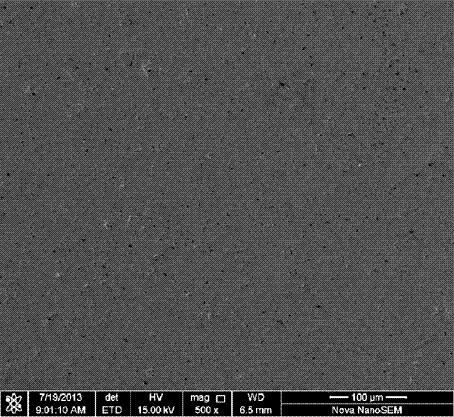

Preparation method of metal surface plating layer structure applicable to ocean severe corrosion environment

ActiveCN108385138AReduce the amount of inclusionsReduce difficultyMetallic material coating processesCyanideRare earth

The invention belongs to the field of electroplating, and particularly relates to a preparation method of a metal surface plating layer structure applicable to an ocean severe corrosion environment. The preparation method of the metal surface plating layer structure applicable to the ocean severe corrosion environment comprises the following steps of S1, pretreating a metal matrix; S2, preparing anon-cyanide cadmium plating layer; S3, preparing a rare-earth modified chromate low-chromium passivation layer; and S4, preparing a hydroxyl graphene modified confining bed. The plating layer prepared through the method provided by the invention is good in corrosion resistance, capable of remarkably prolonging the service life of the metal matrix, and suitable for the ocean severe corrosion environment.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

A device and method for continuously producing metal powder by multi-electrode plasma arc

The invention relates to a device and method for continuously manufacturing metal powder through multi-electrode plasma arcs. The device and method are characterized in that raw material rods enter a plasma arc generator electrode inner cavity of a heating area through a feeding opening in a feeding device; three electrodes of the plasma arcs are used for evaporating the metal raw material rods into fogging plasma bodies, namely, rods, wires or ceramic rods with the same powder materials are manufactured, wherein the raw material rods are located in the center, and the arcs are located on the periphery; and inert gas flow is used for blowing fogging metal fog into a collecting device, and the fogging metal fog is rapidly cooled and solidifies into powder along with rapid reduction of the temperature and the air pressure. Convenience is brought to mechanized production, and the powder manufacturing cost is greatly reduced. Through adjustment of parameters such as the plasma arc output heat and the protection gas pressure, the powder granularity can range from 0.1 micrometer to 100 micrometers. One-time molding of powder manufacturing is achieved.

Owner:CHANGCHUN UNIV OF TECH

Preparation of ionic liquid slow-release agent and method for purifying arsenic and heavy metal wastewater by using ionic liquid slow-release agent

PendingCN113072155AIncrease profitReduce use costWater contaminantsWater/sewage treatment by flocculation/precipitationEnvironmental chemistrySulfide

The invention discloses a method for purifying arsenic and heavy metal wastewater by using an ionic liquid slow-release agent, which comprises the following steps: introducing hydrogen sulfide gas into an organic alcohol amine aqueous solution to carry out a hydrogen sulfide adsorption reaction to obtain an ionic liquid slow-release agent; and heating the ionic liquid slow-release agent to perform a hydrogen sulfide desorption reaction, introducing the desorbed hydrogen sulfide into acid wastewater containing arsenic and heavy metals, and performing a vulcanization reaction to obtain arsenic and heavy metal sulfide precipitates. According to the method, deep purification of the heavy metal acid wastewater and recovery of valuable metals can be achieved, pollution of H2S to the environment and danger and instability of hydrogen sulfide gas in the storage and transportation process are avoided, and the method is simple and convenient in operation process and beneficial to industrial application.

Owner:CENT SOUTH UNIV

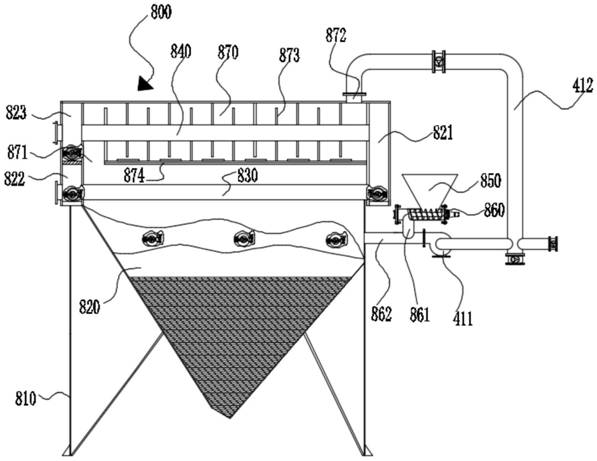

Treatment mechanism for effectively controlling inclusions in nicotine extract steam

ActiveCN113457325AEffective controlExtended pathGas treatmentUsing liquid separation agentProcess engineeringNicotine

A treatment mechanism for effectively controlling inclusions in nicotine extract steam comprises a nicotine extract evapo-separated machine and a spraying chamber, the nicotine extract evapo-separated machine comprises a feeding port, a discharging port, a steam inlet, a steam outlet and a plurality of steam discs, and inner cavities of the steam discs are communicated with the steam inlet. Nicotine extract sequentially passes through the feed port and the plurality of steam discs to reach the discharge port, wherein evaporation components in the nicotine extract flow out from the steam outlet; a steam inlet, a treated steam outlet and a spraying head are arranged in the spraying chamber, and the treated steam outlet is formed above the spraying head; a steam outlet of the nicotine extract evapo-separated machine is communicated with the spraying chamber, and steam passes through the steam inlet and the spraying head and then reaches the treated steam outlet. The device is simple in structure and obvious in impurity removal effect, and is used for spraying extracted steam to remove impurities in the extracted steam. Meanwhile, a plurality of steam discs are arranged, so the steam extraction path is prolonged, and the quantity of impurities in the finally extracted steam is reduced. In the production process of extracted steam, steam inclusions are effectively controlled after production.

Owner:HUBEI HENO BIOLOGICAL ENG CO LTD

Aluminum calcium composite deoxidizer

The invention involves an aluminum calcium composite deoxidizer which is used for treating molten stainless steel. The aluminum calcium composite deoxidizer is characterized in including (by weight percentage) calcium more than 10% and lower than or equal to 15%, aluminum more than 40% and lower than or equal to 50%, carbon more than 0 and lower than or equal to 0.50%, phosphorus more than 0 and lower than or equal to 0.045%, sulfur more than 0 and lower than or equal to 1.00%, and iron in balance. The aluminum calcium composite deoxidizer is used after the reduction stage of stainless steel smelting, for deep deoxidation treatment to the molten stainless steel, has lower manufacture cost, and can reduce total oxygen content and impurity content in the stainless steel slab and improve the purity of the molten steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Potassium chloride cyanide-free titanium alloy plating solution, its preparation method and electroplating process

The invention discloses a potassium chloride cyanide-free cadmium titanium alloy plating solution and a preparation method and electroplating process of the potassium chloride cyanide-free cadmium titanium alloy plating solution. The plating solution per liter comprises 20-35g of cadmium chloride, 80-140g of a complexing agent, 120-200g of potassium chloride, 1-5g of sodium fluoride, 2-5mL of a titanium salt supplement, 1-3mL of a brightening agent, 20-40mL of an auxiliary agent and 5-15mL of a displacement agent. According to the electroplating operation conditions, the pH value of the plating solution is 6.5-7.5, plating bath temperature is 20-35 DEG C, the cathode current density is 0.5-2A / dm<2>, and the area ratio of a cathode to an anode is 2:(1-3). The plating solution is stable, convenient to maintain and small in process hydrogen brittleness, and a cadmium titanium alloy coating is excellent in corrosion resistance and good in market prospect.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

A vacuum induction melting method for copper-manganese master alloy with high manganese content

The invention discloses a vacuum induction smelting method for a high-manganese-content copper-manganese intermediate alloy. The method comprises the steps that firstly, copper and manganese are placed in a crucible of a vacuum induction smelting furnace to be subjected to primary vacuum pumping, and then preheating treatment is conducted; secondly, raw materials obtained after preheating treatment are refined, copper-manganese alloy melt is obtained, and inflation of argon serving as protective gas is conducted for heating; thirdly, the heated copper-manganese alloy melt is cast, and a copper-manganese intermediate alloy cast ingot is formed; and fourthly, the copper-manganese intermediate alloy cast ingot is placed in an aluminum oxide brick or aluminum oxide sand to be subjected to aircooling to the room temperature, and the high-manganese-content copper-manganese intermediate alloy is obtained. According to the method, the vacuum induction smelting furnace is inflated with the high-purity argon in the copper-manganese raw material preheating process, after being exhausted, gas adsorbed to the surfaces of the raw materials including the copper and the manganese is mixed with the argon, accordingly, oxygen partial pressure in the furnace is reduced, the phenomenon of oxidization slagging of the manganese element in the smelting process is avoided, and accordingly, the content of the manganese element in the copper-manganese intermediate alloy is larger than 30% and does not exceed 50%.

Owner:西安诺博尔稀贵金属材料股份有限公司

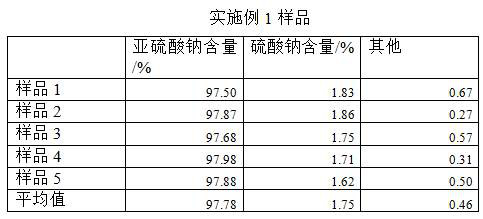

Preparation method of sodium sulfite

ActiveCN112939028AReduce the amount of inclusionsGuaranteed absorptionAlkali metal sulfite preparationSulfite saltSodium hydrogen sulphite

The invention provides a preparation method of sodium sulfite, and relates to the technical field of industrial chemical engineering. The preparation method of sodium sulfite comprises the following steps: (1) collecting flue gas for preparing sulfuric acid, and then filling the collected flue gas into a sodium hydroxide solution to obtain a first mixed solution; (2) filtering the first mixed solution, and performing solid-liquid separation to obtain a second mixed solution; (3) putting the second mixed solution into a reaction container with a gas guide tube, and then adding sulfuric acid to react to generate sulfur dioxide; (3) weighing the mass of the collected sulfur dioxide, and adding the sulfur dioxide into the first sodium carbonate solution to obtain a sodium hydrogen sulfite solution; (4) adding a second sodium carbonate solution into the sodium hydrogen sulfite solution in the step (3), and completely reacting to obtain a sodium sulfite solution; and (5) carrying out evaporative crystallization on the sodium sulfite solution to obtain sodium sulfite crystals. Sodium sulfite with the purity of 97.6% or above can be obtained, and no complex intermediate product is generated in the whole process.

Owner:宣城市楷昂化工有限公司

mo of a nickel base alloy as the binder phase 2 nib 2 Base cermet and preparation method thereof

The invention discloses a Mo2NiB2 base metal ceramic with a nickel base alloy serving as a binding phase. The Mo2NiB2 base metal ceramic is prepared from multiple of MoB powder, NiB powder, Mo powder, B powder and Ni powder. By weight, 3.5-7 parts of B, 31.5-65 parts of Mo and 28-65 parts of Ni are mixed, and a proper amount of glucose, a proper number of binding agent and a proper number of dispersion medium are added in the mixture. The invention further discloses a preparing method of the Mo2NiB2 base metal ceramic. The preparing method includes the steps that multiple of the MoB powder, the Nib powder, the Mo powder, the B powder and the Ni powder are evenly mixed with the glucose, the binding agent and the dispersion medium to obtain sizing; spray drying and pelletizing are conducted; the powder is treated in the hydrogen atmosphere at the temperature being 900-1100 DEG C; and then the powder is packed into a machined cover to be subjected to hot isostatic pressing, wherein the temperature ranges from 1100 DEG C to 1300 DEG C, and the pressure ranges from 100 MPa to 200 MPa. The prepared Mo2NiB2 base metal ceramic material is small in oxide inclusion amount, high in material strength and high in toughness, and a blank is shrunk evenly and regularly in the hot isostatic pressing process and is not likely to twist or deform.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

High-calcium non-silicon aluminium calcium magnesium ferrous alloy for steel-smelting deoxidization and method for preparing the same

The invention discloses a high-calcium no-silicon aluminum-calcium-magnesium-ferric alloy used for steelmaking deoxidization. According to the weight proportion of the components, Ca is more than 15 percent but less than or equal to 28 percent, the proportion of Al to Ca is 1-2:1, 2-6 percent of Mg, the rest is Fe. The optimization scope is 18-25 percent of Ca, the proportion of Al to Ca is 1-1.3:1, 2-4 percent of Mg, the rest is Fe. A preparation method is that: aluminum, calcium, magnesium, low-carbon steel scrap are chosen as raw materials; the materials are smelted into aluminum-magnesium and aluminum-calcium master alloys in a low-frequency furnace; the materials continue being smelted in a high-frequency furnace and aluminum-iron metal liquid is obtained; the master alloy is pressed into the deep of the aluminum-iron metal liquid under a meshed high-temperature resistance container to be melted and at last the master alloy is cast under the protection of argon gas. The obtained alloy can be used for the final deoxidation in smelting low-carbon low-silicon al-killed steel, and can lower the harmful effect of the deoxidation product Al2O3 with good effect in integral deoxidation.

Owner:郭庆成

A kind of preparation method of gold-silver-copper alloy ingot

The invention relates to a preparing method for an AuAgCu alloy cast ingot. The preparing method comprises the following steps that firstly, AuAg intermediate alloy cast ingot preparing is conducted;secondly, the surface defects of an AuAg intermediate alloy cast ingot are removed, a strip is prepared through rolling, after the strip is shorn into sheets, thorough cleaning and airing are conducted, and AuAg intermediate alloy sheets are obtained; thirdly, Au and oxygen-free Cu are arranged in an aluminum oxide crucible of a vacuum medium-frequency induction smelting furnace, the AuAg intermediate alloy sheets are placed in a charging hopper of the vacuum medium-frequency induction smelting furnace, smelting and casting forming is conducted, and the AuAgCu alloy cast ingot is obtained. Bymeans of the preparing method, the quality of the AuAgCu alloy cast ingot is obviously improved, and the problem about segregation of the rich Cu phase and the rich Ag phase due to component segregation of structures of the AuAgCu alloy cast ingot is solved; and the defects of internal shrinkage, air holes, inclusions and the like of the cast ingot are reduced, and AuAgCu plates and strips excellent in quality and high in yield can be better machined in the later period.

Owner:西安诺博尔稀贵金属材料股份有限公司

A processing mechanism for effectively controlling inclusions in nicotine extract steam

ActiveCN113457325BEffective controlExtended pathGas treatmentUsing liquid separation agentThermodynamicsProcess engineering

A processing mechanism for effectively controlling inclusions in nicotine extract steam, including a nicotine extract steamer and a spray chamber, and a nicotine extract steamer including a material inlet, a material outlet, and a steam inlet , a steam outlet and a number of steam trays, the inner chamber of the steam tray is connected with the steam inlet, the nicotine extracts pass through the feed inlet and several steam trays to the outlet in turn, and the evaporated components flow out from the steam outlet; the spray chamber It is provided with a steam inlet, a treated steam outlet and a spray head, and the treated steam outlet is set above the spray head; the steam outlet of the nicotine extraction off-line is connected with the spray chamber, and the steam passes through the steam inlet, spray After showering, it reaches the treated steam outlet. Spray the extracted steam to remove the inclusions. The structure is simple and the removal effect is obvious. At the same time, multiple steam pans are also set to extend the path of steam extraction and reduce the amount of inclusions in the final extraction steam. Effectively control steam inclusions during and after extraction steam generation.

Owner:HUBEI HENO BIOLOGICAL ENG CO LTD

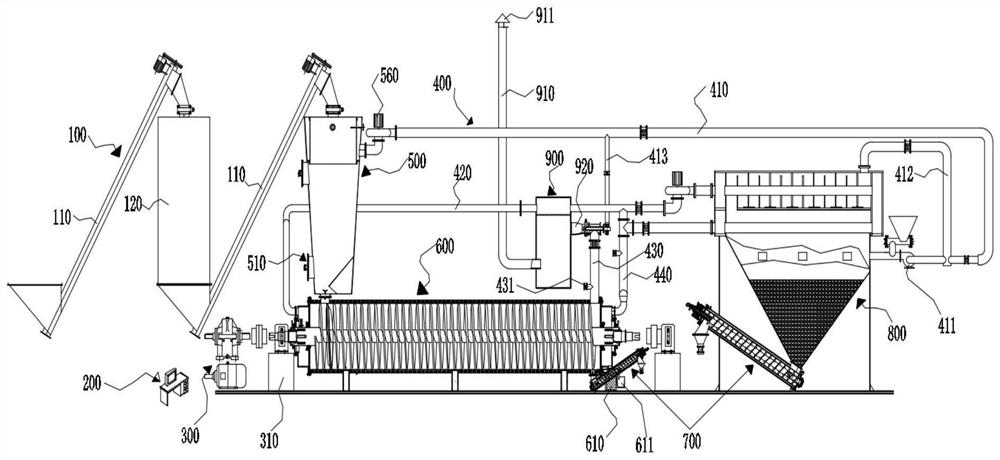

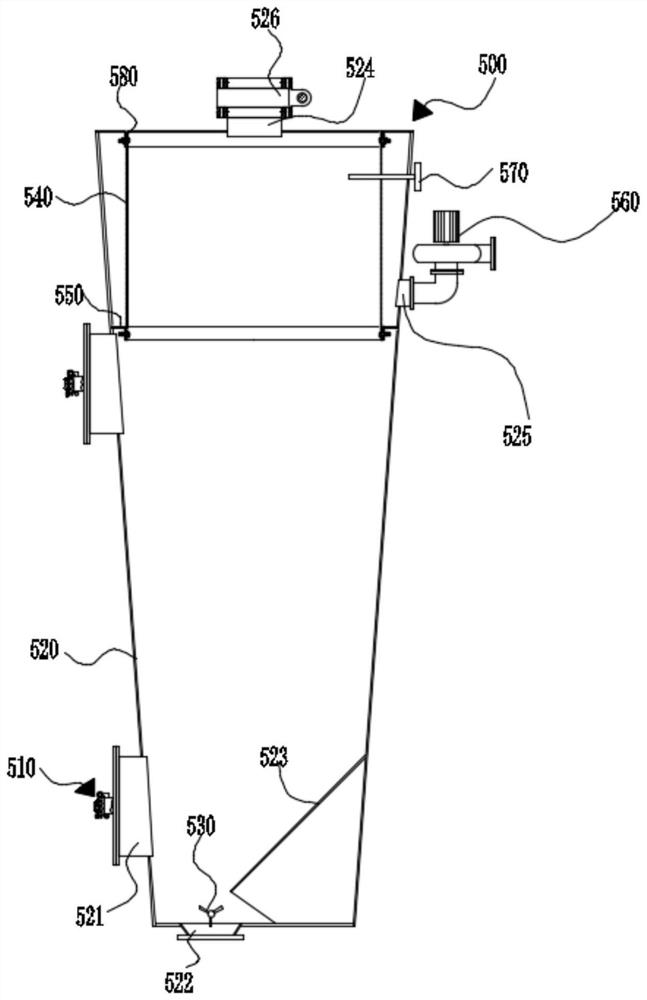

Solid fuel destructive distillation production process

InactiveCN111778052AReduce the amount of inclusionsAvoid enteringBiofuelsLiquid hydrocarbon mixture productionCarbon monoxide detectorAir pump

The invention aims to provide a solid fuel destructive distillation production process, which comprises the following steps: a, preparing materials: firstly, selecting solid biomass fuel, and preparing sufficient fuel for a curve hot blast stove and destructive distillation equipment according to a plan; b, starting system devices such as a DCS electric control cabinet system, instruments and meters, and opening all specified normally-open electric control valves; c, sealed feeding: starting feeding augers, feeding qualified fuel into a stock bin from a first feeding auger, then feeding the qualified fuel into a fuel filter by a second feeding auger, and pushing the qualified fuel into a barrel of a destructive distillation machine by a kick-out device according to a specified feeding amount, and meanwhile, starting a fuel filter heat exchange air output pipe fan and a carbon monoxide detector to supply a gasification medium to the curve hot blast stove; and d, sealed air supply: starting a rotary sealing element air pump pressure-stabilizing sealed operation system.

Owner:安徽林农时代科技有限公司

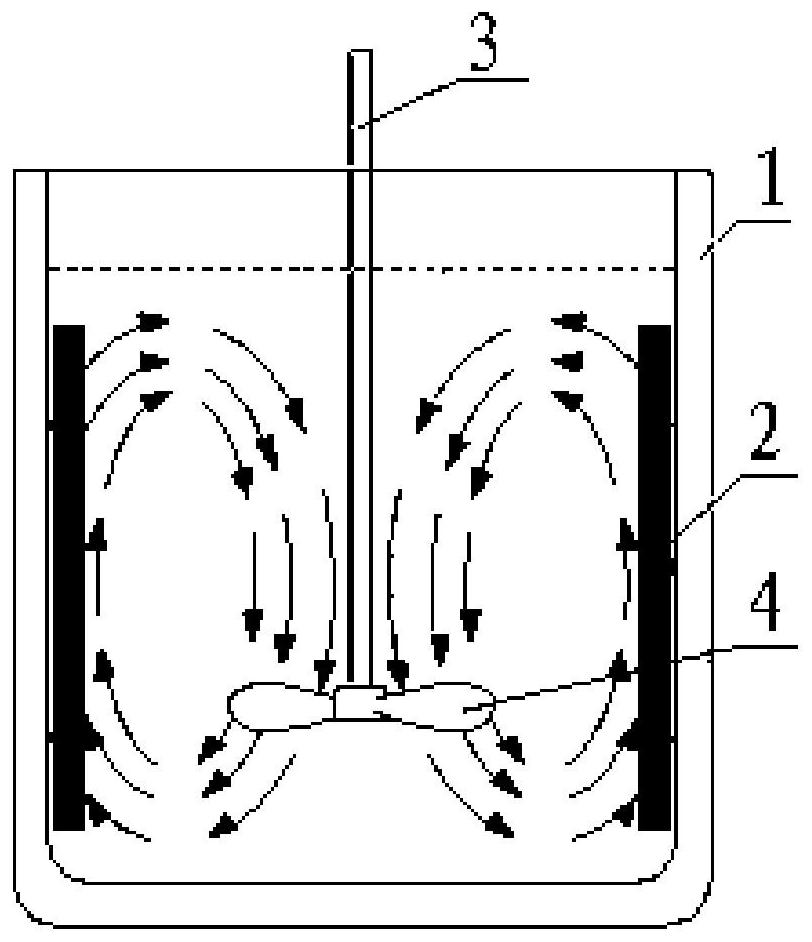

A compound refining method for zirconium-containing magnesium alloy

The invention discloses a composite refining method for zirconium-containing magnesium alloy, including the steps of a, adding magnesium ingots in a first heating device and melting the magnesium ingots into molten magnesium; b, adding alloy-element ingots in the molten magnesium to obtain an intermediate magnesium melt; c, adding magnesium-zirconium intermediate alloy in the intermediate magnesium melt, stirring continuously in a stirring device to obtain an alloy melt; d, removing floating slags on the surface of the alloy melt; e, adding a flux for refining into the alloy melt; f, adding gas for refining into the alloy melt through a gas delivery device; g, cooling the alloy melt to the casting temperature. As alloys containing no zirconium alloy and magnesium intermediate alloy are processed respectively, deposited zirconium element particles are returned to the alloy intermediate melt to be molten, and solubility of zirconium in the alloy intermediate melt can be increased, zirconium yield is also increased, while production cost is lowered.

Owner:SICHUAN UNIV

Method for preparing polycarbonate

Owner:CHINA NAT BLUESTAR (GRP) CO LTD

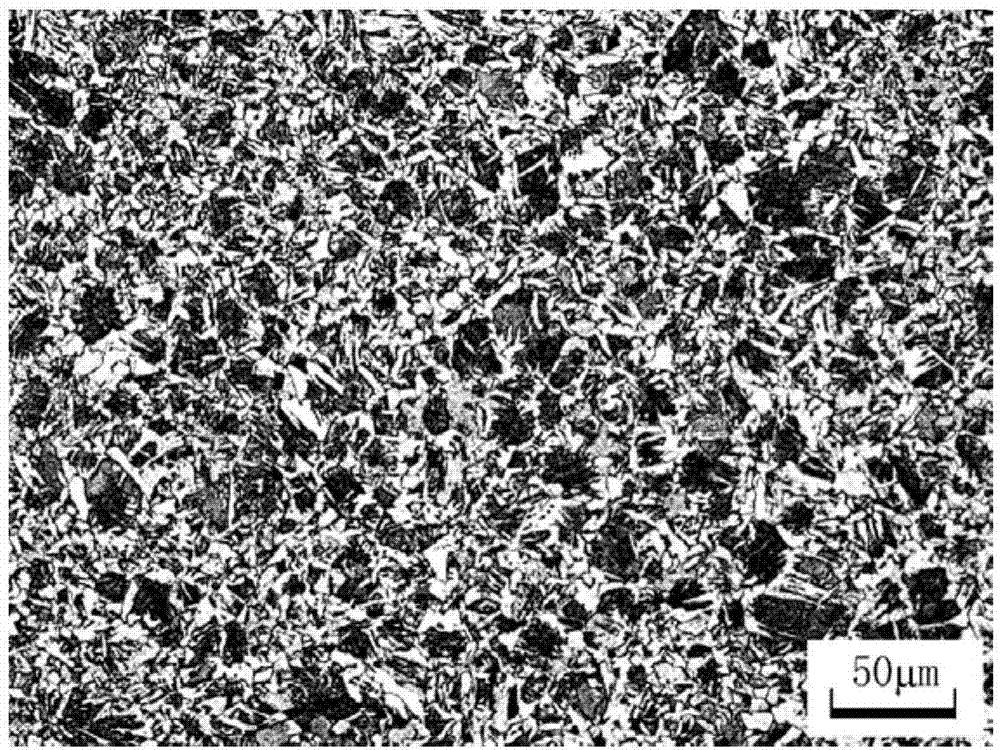

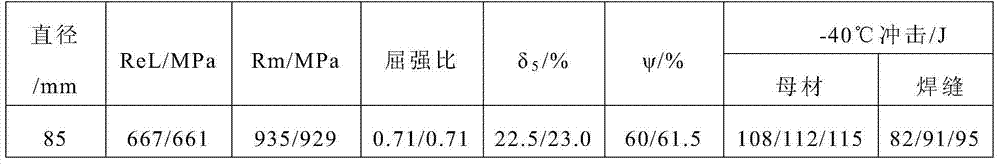

R4 grade steel for mooring chain and its preparation method

InactiveCN103882346BReduce C contentAvoid organizational transformationTemperature control deviceChemical compositionHigh intensity

The invention discloses a steel for R4-grade mooring cables and a preparation method thereof. The steel comprises the following components in percentage by weight: 0.15-0.24% of C, 0.15-0.30% of Si, 1.2-1.60% of Mn, at most 0.025% of P, at most 0.025% of S, at most 0.02% of Cu, 0.8-1.3% of Cr, 0.70-1.30% of Ni, 0.2-0.50% of Mo, 0.02-0.05% of Al, at most 0.0050% of As, at most 0.0050% of Sb, at most 0.0050% of Sn, at most 0.0050% of N, at most 0.0020% of O, at most 0.0020% of H, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: molten iron desulfurization, converter smelting, argon blowing, LF (ladle furnace) refining, RH vacuum treatment, continuous casting, square billet heating, rolling, air cooling and nondestructive flaw detection. The steel for R4-grade mooring cables has the advantages of high strength, high toughness, low cost and corrosion resistance.

Owner:武汉钢铁有限公司

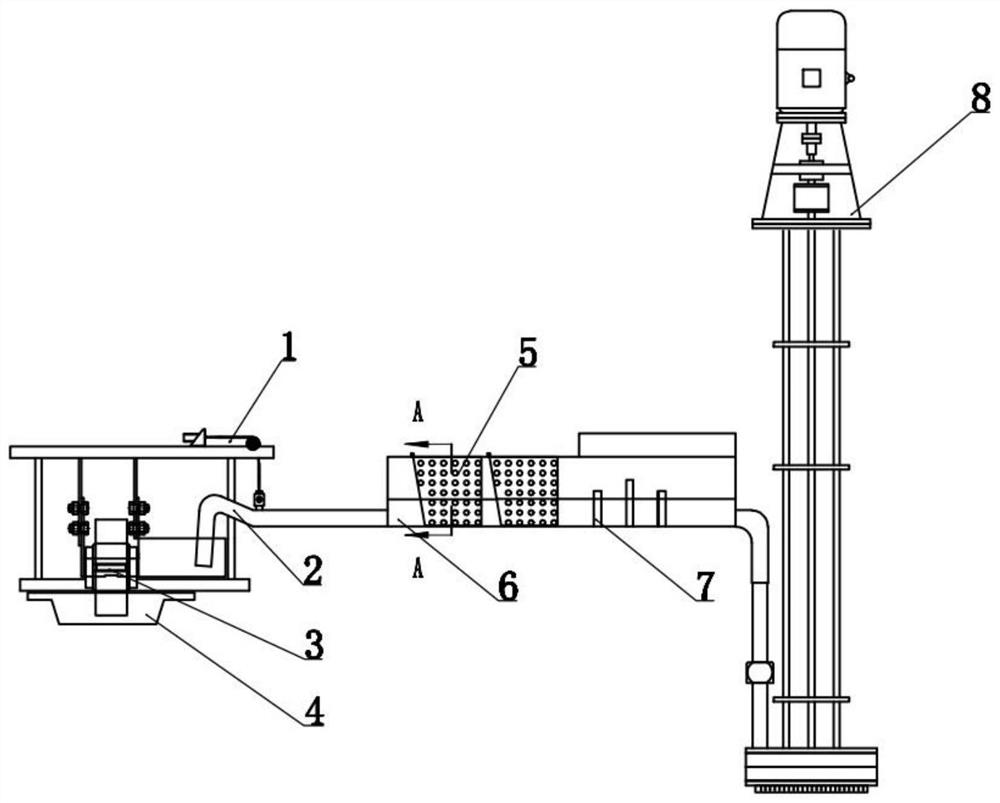

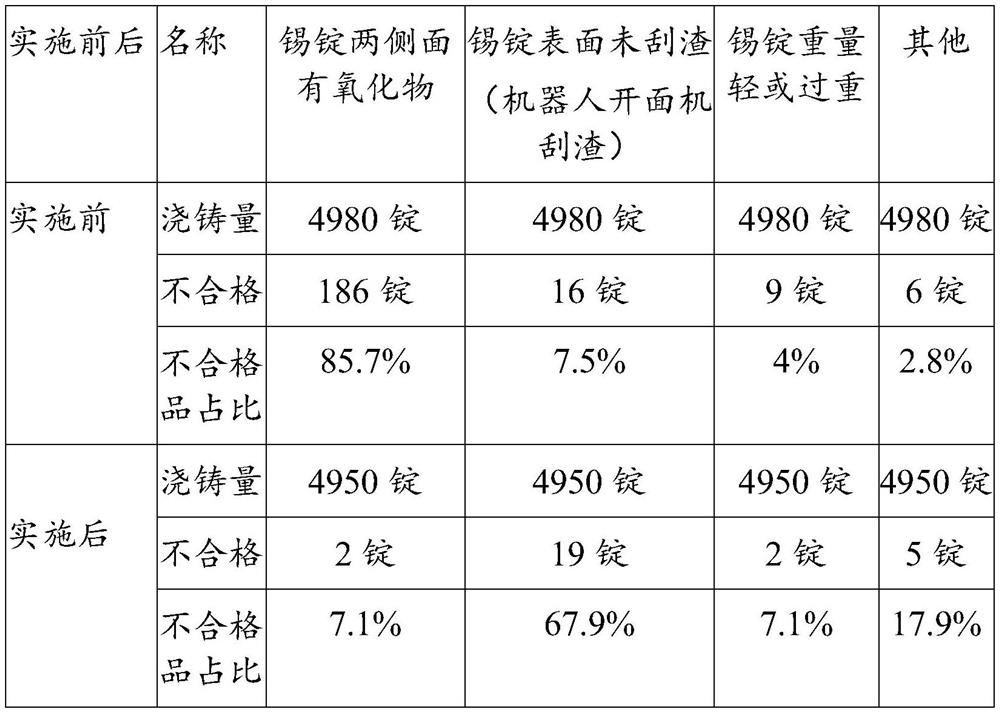

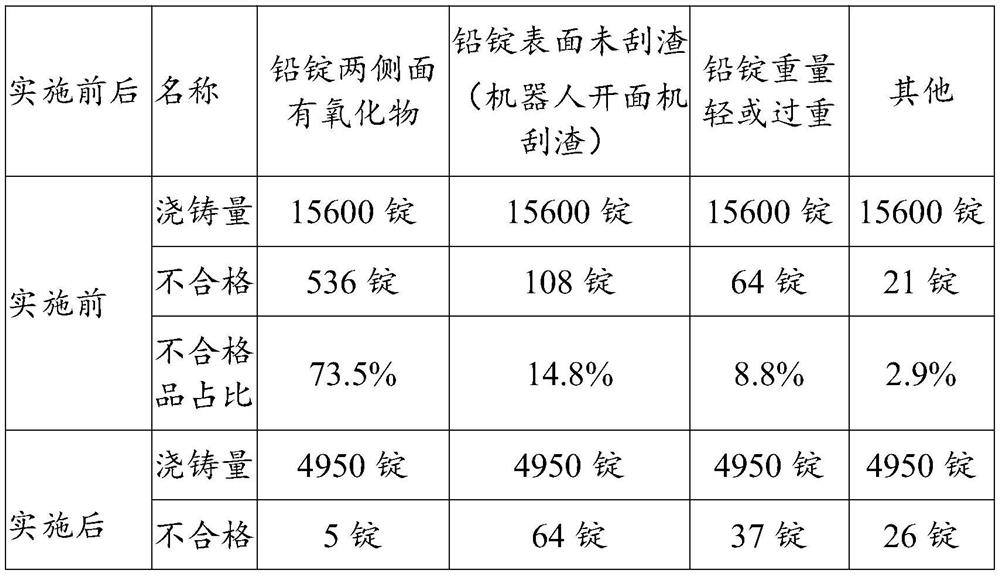

Automatic casting device with residue buffering and filtering functions

PendingCN114535551AReduce fluid pressureInject evenlyMolten metal supplying equipmentsCasting cleaning apparatusControl engineeringProcess engineering

The invention discloses an automatic casting device with buffering and residue filtering functions. The automatic casting device comprises a liquid injection end support with a probe, a duck head infusion tube, a wind wheel type casting liquid outlet device, a casting mold and a metering pump. The duck head infusion tube extends into the liquid injection end bracket with the probe, and the other end of the duck head infusion tube is fixedly connected with the bottom end of the metering pump; the wind wheel type casting liquid outlet device is fixed inside the liquid injection end bracket with the probe, and the duck head infusion tube extends into the wind wheel type casting liquid outlet device; the casting mold is fixed to the bottom end of the liquid injection end support of the probe, and the bottom end of the wind wheel type casting liquid outlet device is connected with the top end of the casting mold. After buffering and residue filtering are conducted through the device, the product percent of pass of an automatic casting assembly line is increased, the product returning rate is reduced, and then the production work efficiency is improved. The device is widely suitable for the casting process of low-melting-point metal product ingots such as tin, lead and zinc.

Owner:YUNNAN TIN CO LTD TIN BRANCH

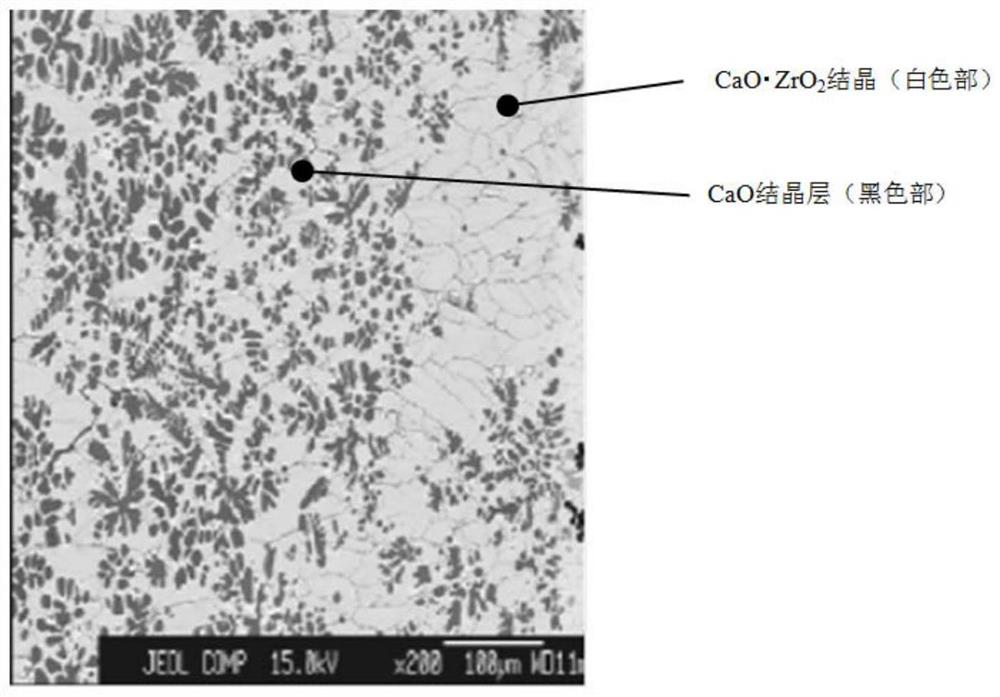

CaO-ZrO2 composition, method for producing CaO-ZrO2 composition, CaO-ZrO2-containing refractory material, and casting nozzle

ActiveCN114514212AEasy to operateImprove qualityMelt-holding vesselsCharge manipulationPhysical chemistryRefractory

The ZrO2-CaO-C refractory material provided by the invention has remarkable hydration resistance and self-fluxing resistance, so that the ZrO2-CaO-C refractory material has corrosion resistance and can maintain high adhesion resistance for a long time. This refractory material contains a CaO-ZrO2 composition which contains a CaO component in an amount of 40 to 60 mass% inclusive, has a CaO / ZrO2 component mass ratio of 0.67 to 1.5 inclusive, contains a eutectic structure of CaO crystals and CaZrO3 crystals, and has a width of the CaO crystals, which can be observed in the cross-sectional structure, of 50 [mu] m or less.

Owner:KROSAKI HARIMA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com