Alkaline zinc-nickel alloy electroplating solution with high stability

A high-stability, nickel-alloy technology, applied in the field of electroplating, can solve problems such as current efficiency drop, and achieve the effects of reduced adsorption, high corrosion resistance, and low brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

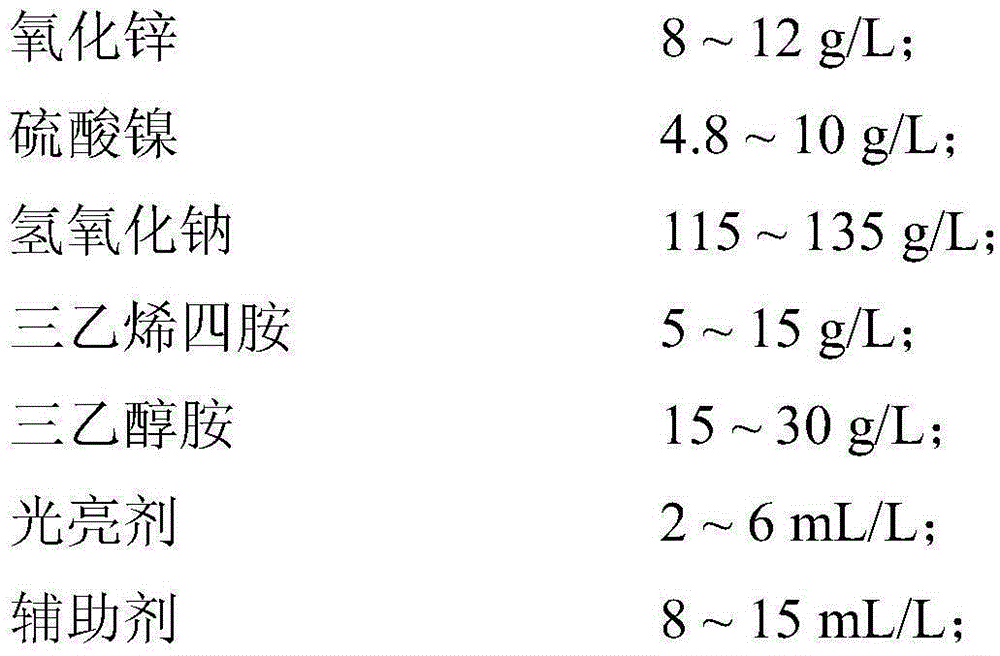

[0015] Alkaline zinc-nickel alloy rack plating process of the present invention is as follows:

[0016]

[0017] The alkaline zinc-nickel alloy plating solution described in the above process is prepared by the following method: add 120 g of sodium hydroxide to 500 g of water, then add 10 g of zinc oxide, stir to dissolve it, and this solution is A solution. Add 5g of nickel sulfate to 50g of water, stir to dissolve it, then add 8g of triethylenetetramine and 25g of triethanolamine, stir evenly, this solution is B solution. Add liquid B to liquid A and stir well. After cooling the plating solution, add 4mL of brightener and 10mL of auxiliary agent, and then add water to 1000mL.

[0018] The brightener is prepared by the following method: dissolve 30-60g of sodium metabisulfite in 750mL of water, then add 30-60g of 4-methoxybenzaldehyde, stir to dissolve, and then add 30-60g of sodium toluenesulfonate 1. Propanesulfonic acid pyridinium salt 30-60g, butyl etherate 10-50g an...

Embodiment 2

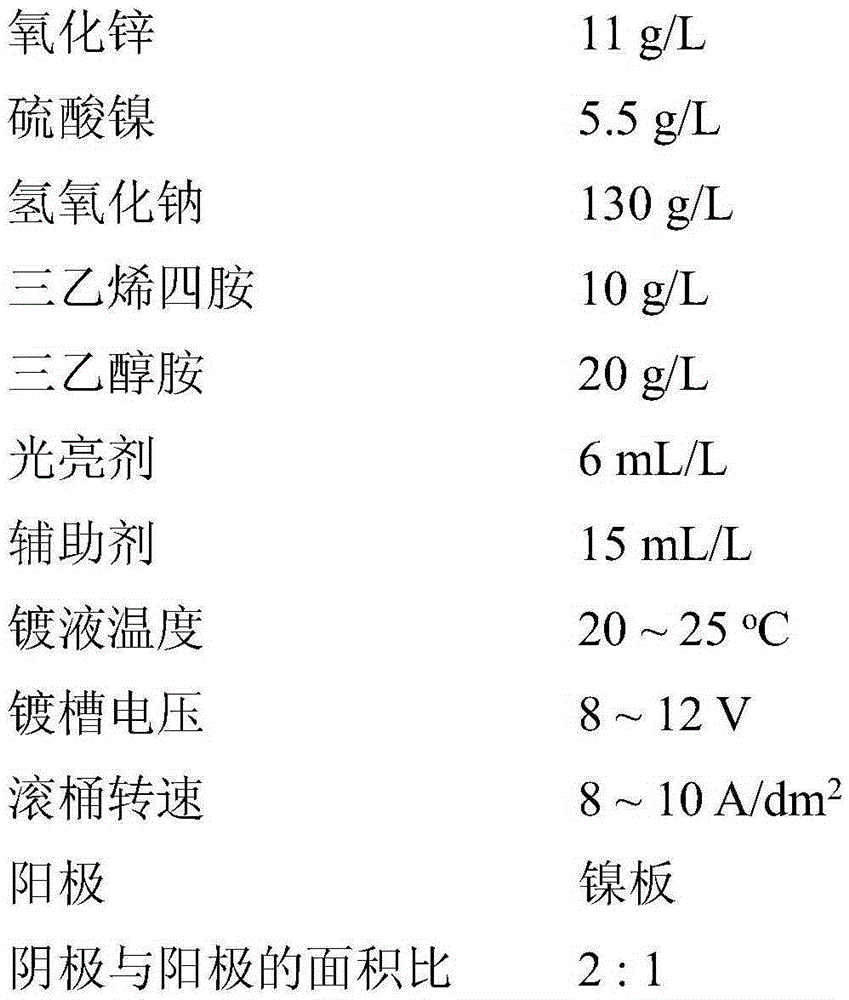

[0023] Alkaline zinc-nickel alloy barrel plating process of the present invention is as follows:

[0024]

[0025] The alkaline zinc-nickel alloy plating solution described in the above process is prepared by the following method: add 130 g of sodium hydroxide to 500 g of water, then add 11 g of zinc oxide, and stir to dissolve it. This solution is A solution. Add 5.5 g of nickel sulfate to 50 g of water, stir to dissolve it, then add 10 g of triethylenetetramine and 20 g of triethanolamine, and stir evenly. This solution is B liquid. Add liquid B to liquid A and stir well. After cooling the plating solution, add 6mL of brightener and 15mL of auxiliary agent, and then add water to 1000mL.

[0026] The preparation of the brightener and auxiliary agent described in this embodiment is the same as that in Example 1.

[0027] The prepared zinc-nickel alloy coating has less brittleness, greater adhesion and high corrosion resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com