Equipment and method for preparing supercritical carbon dioxide microemulsion and fly ash particle compound dispersion

A technology of carbon dioxide and fly ash, which is applied in the direction of chemical instruments and methods, bulk chemical production, drilling compositions, etc., can solve the problems of short fluidity control action time, difficulty in injecting nanoparticles, and high cost of nanoparticles , to achieve the effects of reducing the amount of adsorption, improving dispersion, and improving oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

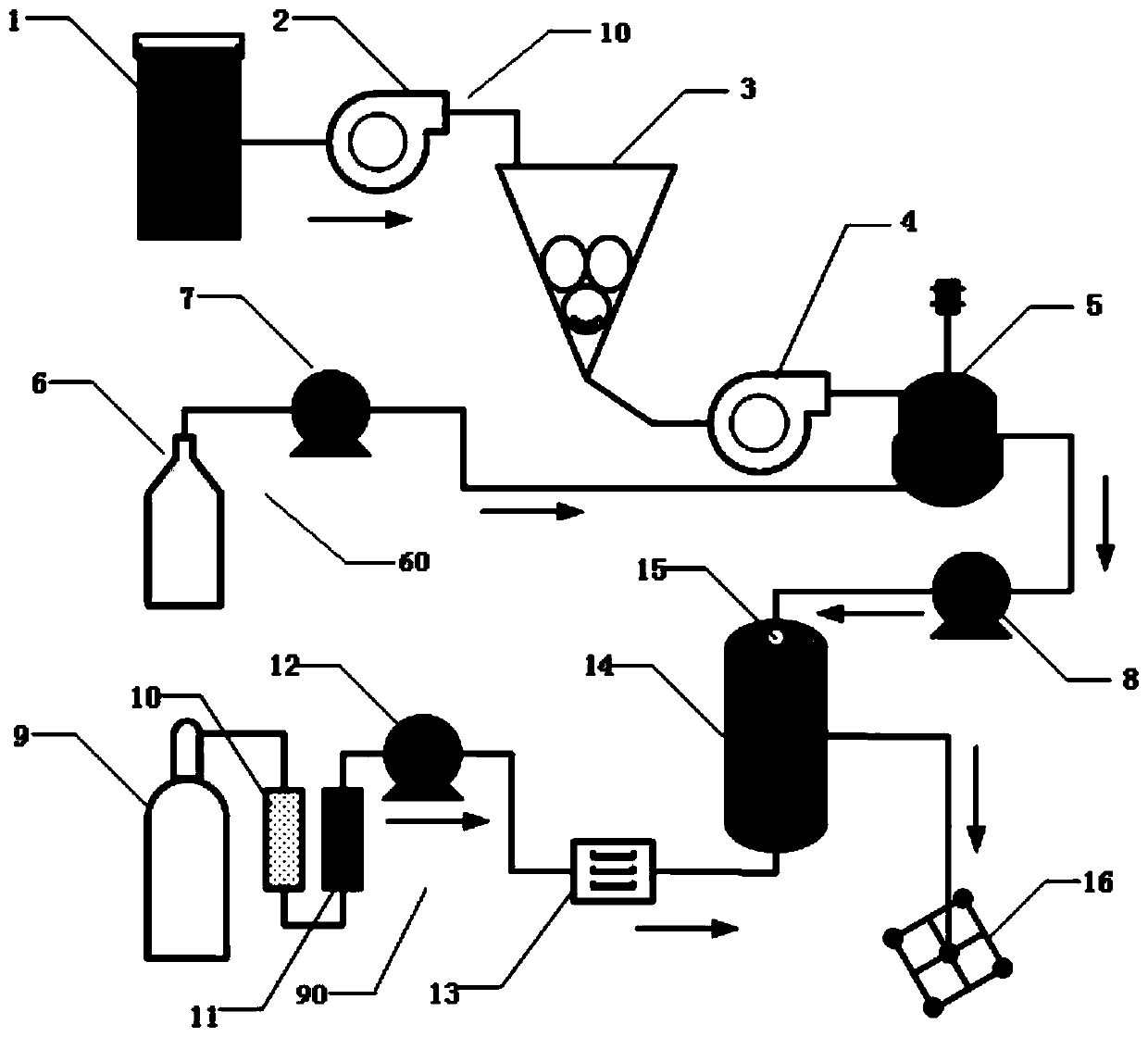

[0051] The present invention also provides a method for preparing a composite dispersion of supercritical carbon dioxide microemulsion and fly ash particles, the method comprising the following steps:

[0052] (1) Grinding the fly ash particles to obtain fly ash nanoparticles;

[0053] (2) The fly ash nanoparticles and the surfactant solution are ultrasonically stirred and mixed to obtain the fly ash nanoparticles-surfactant solution dispersion;

[0054] (3) Drying, liquefying, boosting and heating the carbon dioxide gas successively to obtain supercritical carbon dioxide that is boosted and heated, and injecting the supercritical carbon dioxide that is boosted and heated from the bottom of the contact tower into the contact tower;

[0055] (4) The fly ash nanoparticle-surfactant solution dispersion liquid is atomized and sprayed at the top of the contact tower, and the supercritical carbon dioxide of the boosted temperature injected from the bottom of the contact tower Mixin...

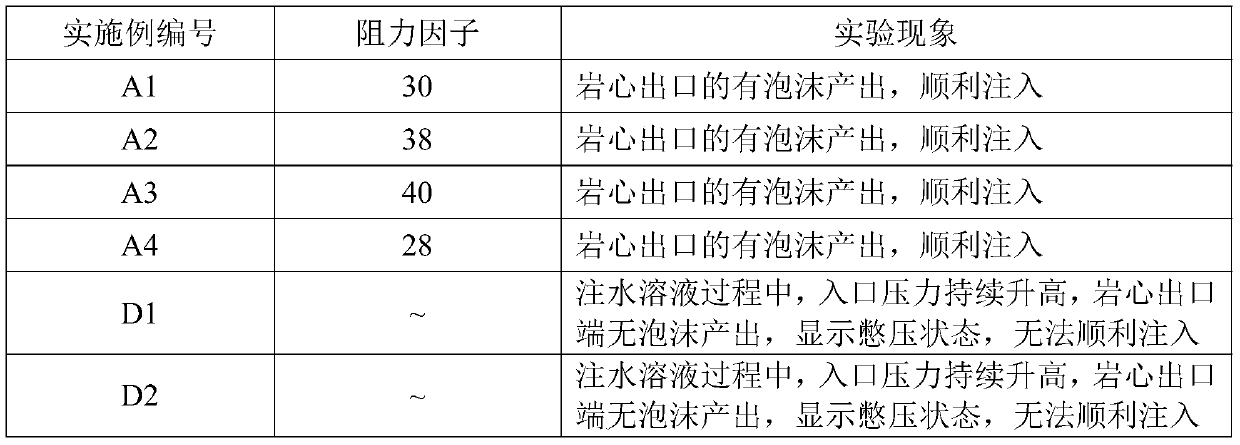

Embodiment 1

[0073] (1) Grinding the fly ash particles in the grinding device 3 to obtain fly ash nanoparticles with a particle size of 10 nm;

[0074] (2) The fly ash nanoparticles and anionic surfactant dioctyl sodium sulfosuccinate solution are ultrasonically stirred and mixed in the ultrasonic stirring section (5) to obtain fly ash nanoparticles-surfactant agent solution dispersion;

[0075] (3) Carbon dioxide gas is dried, liquefied, pressurized and heated successively in the supercritical carbon dioxide supply unit (90), to obtain supercritical carbon dioxide with boosted pressure and heated, and the supercritical carbon dioxide with boosted pressure and heated Temperature is 50 DEG C, pressure is 30MPa, and the supercritical carbon dioxide of gained pressurization heating is injected in the described contact tower (14) from the bottom of contact tower (14);

[0076] (4) The fly ash nanoparticle-surfactant solution dispersion liquid is atomized and sprayed through the atomizing nozz...

Embodiment 2

[0078] (1) Grinding the fly ash particles in the grinding device 3 to obtain fly ash nanoparticles with a particle size of 200nm;

[0079] (2) The fly ash nanoparticles and anionic surfactant dioctyl sodium sulfosuccinate solution are ultrasonically stirred and mixed in the ultrasonic stirring section (5) to obtain fly ash nanoparticles-surfactant agent solution dispersion;

[0080] (3) Carbon dioxide gas is dried, liquefied, pressurized and heated successively in the supercritical carbon dioxide supply unit (90), to obtain supercritical carbon dioxide with boosted pressure and heated, and the supercritical carbon dioxide with boosted pressure and heated Temperature is 45 ℃, and pressure is 25MPa, and the supercritical carbon dioxide of gained pressurization heating is injected in the described contact tower (14) from the bottom of contact tower (14);

[0081] (4) The fly ash nanoparticle-surfactant solution dispersion liquid is atomized and sprayed through the atomizing nozz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com