Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134 results about "Production engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production engineering is a combination of manufacturing technology, engineering sciences with management science. A production engineer typically has a wide knowledge of engineering practices and is aware of the management challenges related to production. The goal is to accomplish the production process in the smoothest, most-judicious and most-economic way.

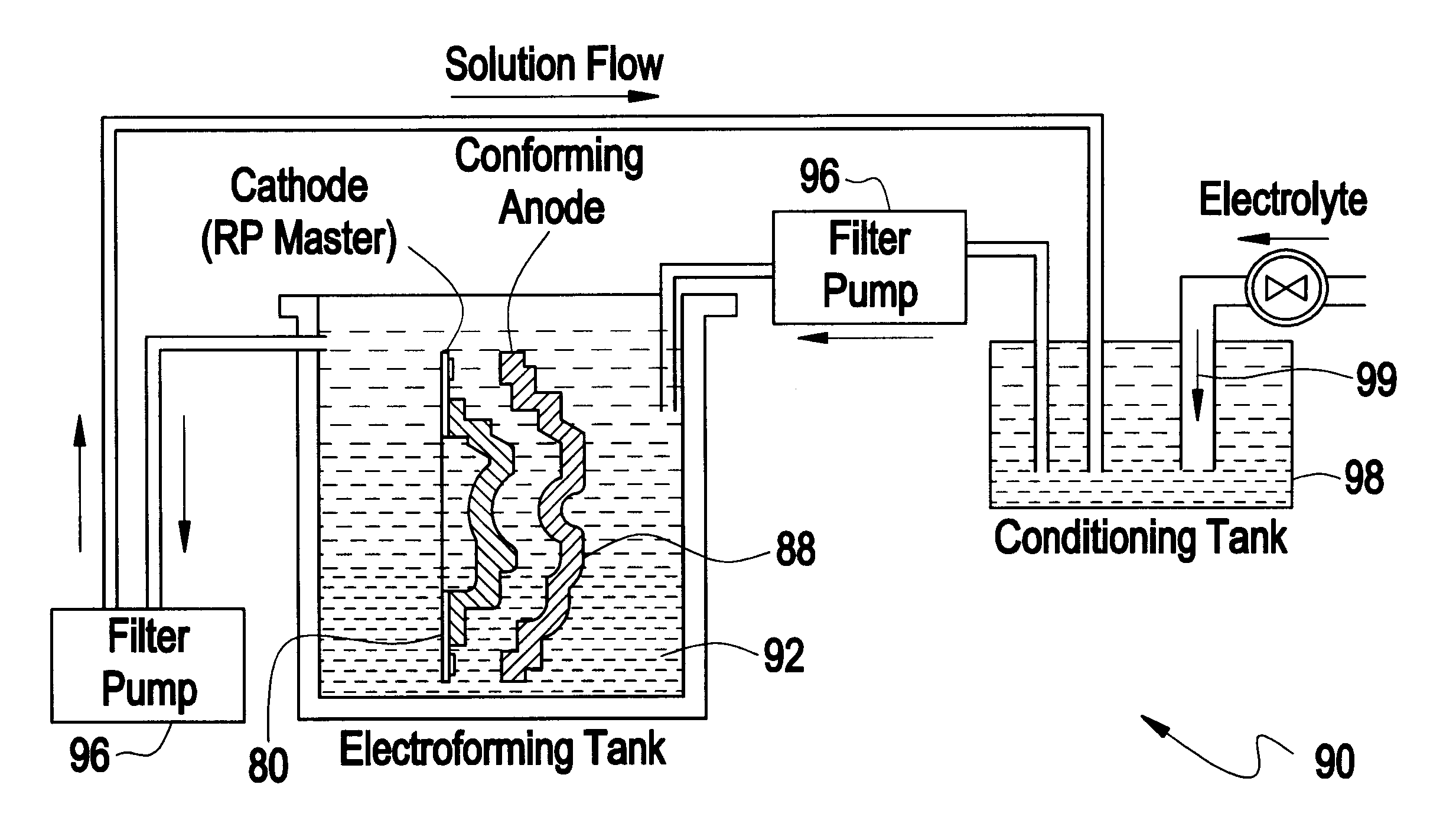

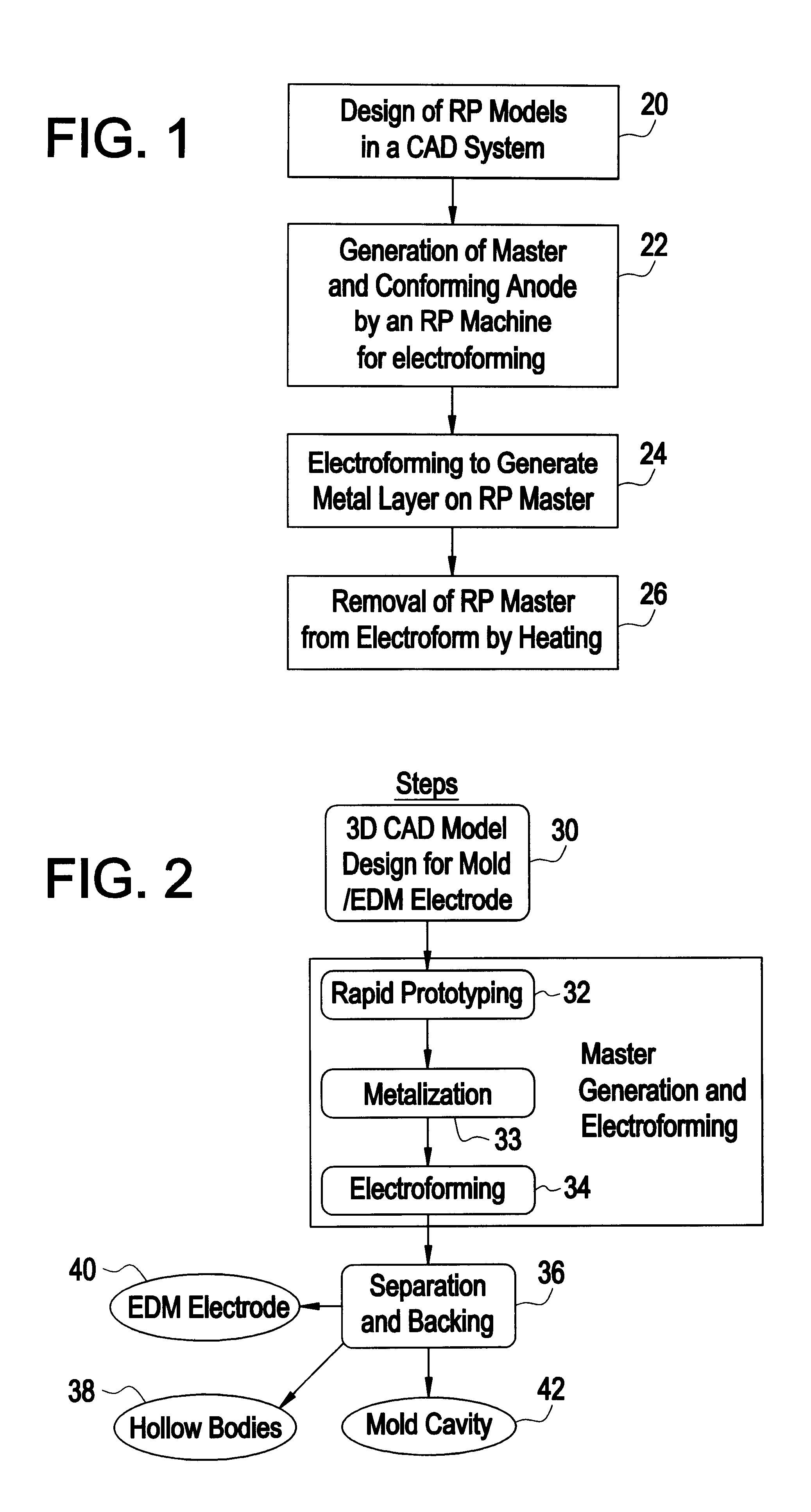

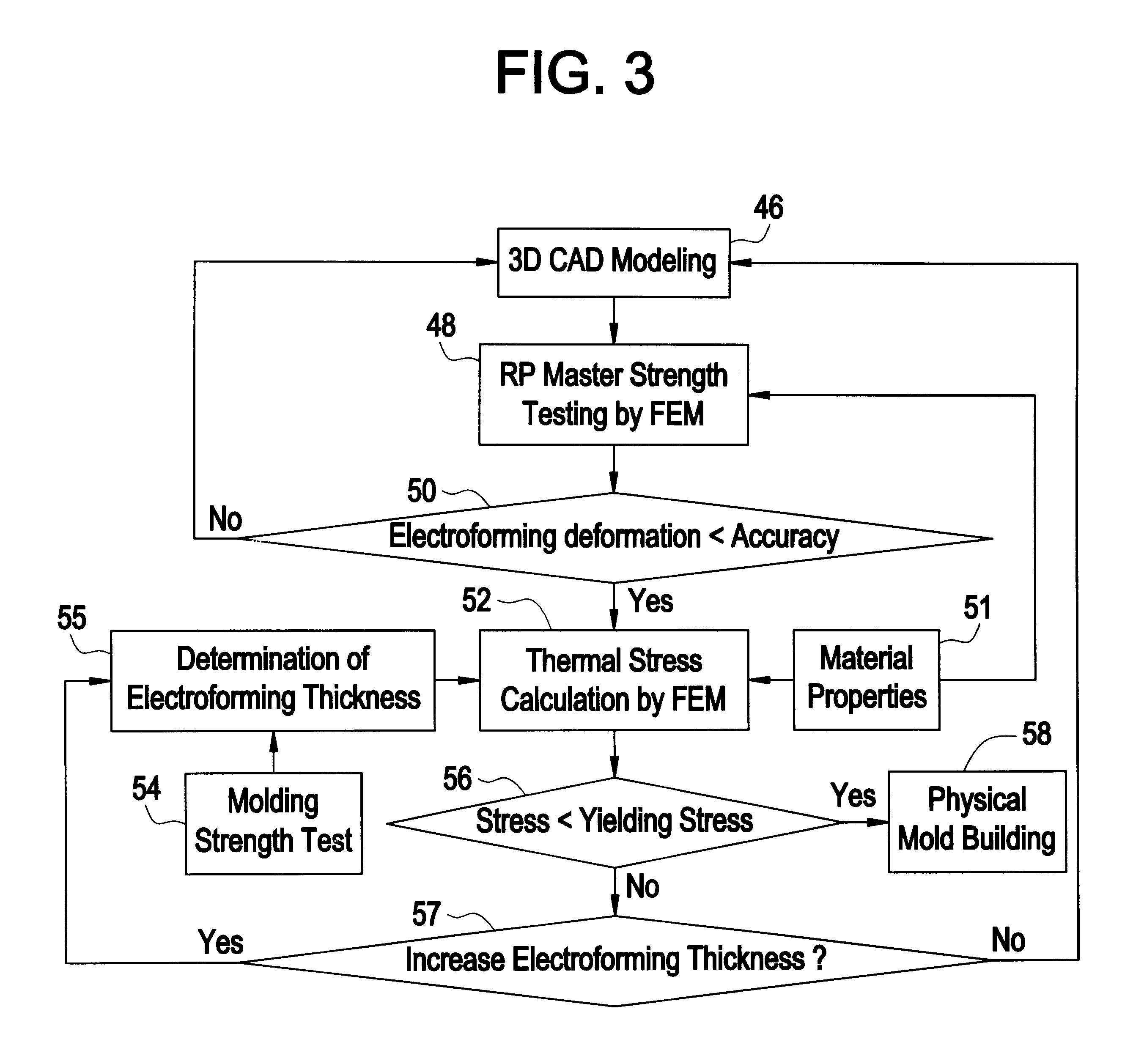

Rapid production of engineering tools and hollow bodies by integration of electroforming and solid freeform fabrication

InactiveUS6409902B1Stay in shapeAvoid insufficient thicknessAdditive manufacturing apparatusFoundry mouldsElectrolysisElement analysis

This invention describes a rapid tooling process that integrates solid freeform fabrication (SFF) with electroforming to produce metal tools including molds, dies, and electrical discharge machining (EDM) electrodes. An SFF part is metalized by electroless plating and then placed in an electroplating solution, where metal is deposited upon the part by electrolysis. When the desired thickness of metal has been reached, the SFF part is removed from the metal shell. The shell is then optionally backed with other materials to form a mold cavity, and EDM electrode, or other desired parts for tooling. Thermomechanical modeling and numerical simulation with finite element analysis (FEA) is used to determine the geometry of the SFF part and the electroform thickness for minimizing the manufacturing time and cost while satisfy the tooling requirement.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

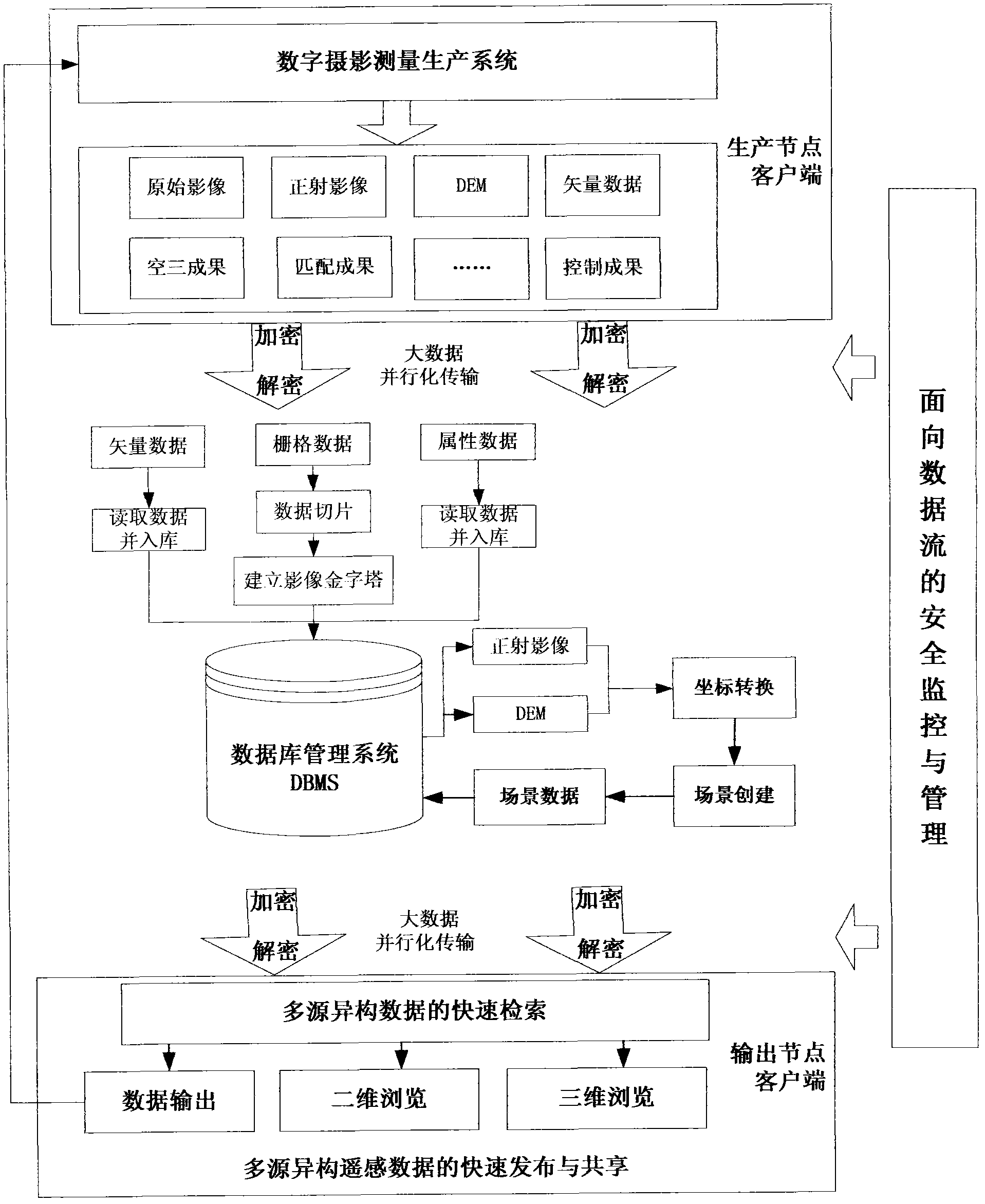

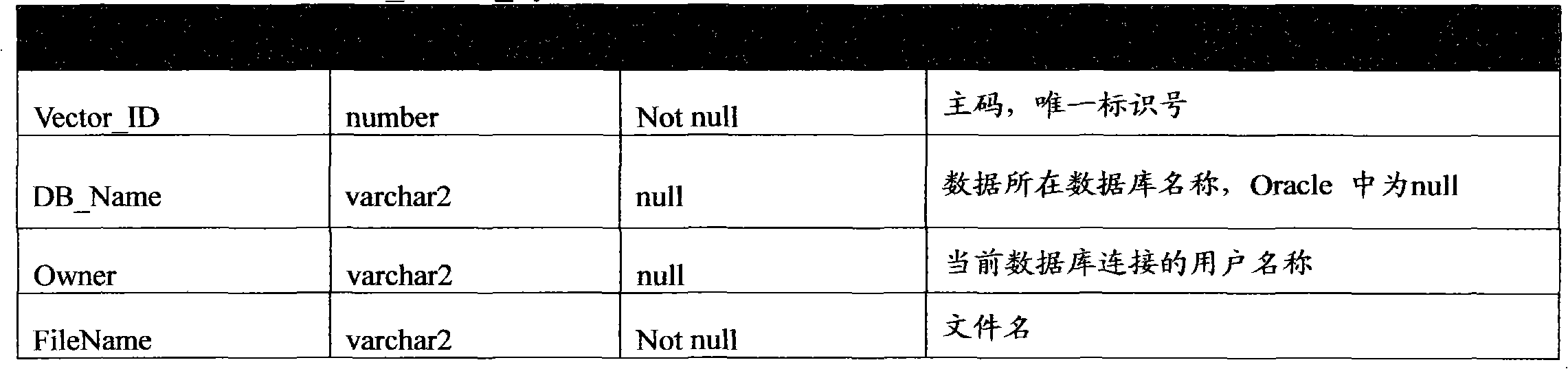

Method for managing multisource-isomerism aviation remote sensing data

InactiveCN102663057AQuick storageQuick searchSpecial data processing applicationsSensing dataAviation

The invention discloses a method for managing multisource-isomerism aviation remote sensing data, which comprises the following steps: (1) using geographic regions and production engineering as units so as to realize aviation remote sensing data storage and management; and realizing high-efficient data storage and management served for aviation remote sensing data products by technologies such as tiles and the like; and (2) using a method for dynamically generating a continuous detail level model, establishing a corresponding high-efficient mechanism, and realizing three-dimensional visual issuing and sharing of the aviation remote sensing data products automatically and high-efficiently. According to the invention, the method effectively solves integrated storage and management problems of multisource, multi-time-phase, isomerism aviation remote sensing data in a digital aviation photography measurement producing system.

Owner:苏州大地影像科技有限公司

Full-automatic commercial pure titanium smelting method adopting electron beam cold hearth furnace

The invention relates to a full-automatic TA1 smelting method adopting an electron beam cold hearth furnace and belongs to the technical field of production engineering application. The production method comprises the following steps: drying and putting titanium sponge into an Archimedean screw tube which is mounted into a feeding system of an electron beam cold hearth melting furnace (EB furnace for short), wherein different rotary speeds are set; when the degree of vacuum of the feeding system reaches 0.4-0.8 Pa and the degree of vacuum of a main smelting cold hearth reaches 0.05-0.8 Pa, starting the feeding system to feed the titanium sponge into the smelting cold hearth of a main smelting chamber; triggering an electron gun to melt the titanium sponge into liquid titanium which flows through a primary refining cold hearth and a main refining cold hearth and then into a rectangular withdrawing crucible; controlling the rotary speed of the Archimedean screw tube to control the feeding speed and scanning patterns so as to control the melting speed, and the ingot pulling rate thereby realizing full-automatic control. The method has the advantages of good ingoting quality, high one-step yield, low manufacturing cost, controllable production period, simplicity in operation, energy conservation, environmental protection and high repeatability.

Owner:YUNNAN TITANIUM IND

Serial data bus, motion system and method for the event-driven transmission of messages

InactiveCN1860742AImprove real-time performanceReduce error rateNear-field systems using receiversTransmission line coupling arrangementsProduction engineeringTransceiver

The invention relates to a serial data bus (10) comprising a data line (12) for transmitting electrical signals representing bit states and a plurality of multi-master subscribers (14, 16) between which messages can be exchanged via the data line (12) in an event-driven manner according to the broadcast principle. At least two subscribers (14, 16) have a transceiver head (18), inductively connected to the data line (12), via which contactless electrical signals (50) are picked up from the data line or transferred thereto. An amplifier (36) is galvanically connected to the data line (12) and is adapted to receive electrical signals (48) that have been inductively transferred by the at least two subscribers (14, 16) to the data line (12) and to feed them back to the data line (12) once amplified. Due to its inductive connection, the data bus is especially low-maintenance and also suitable for hazardous surroundings. The contactless connection makes the data bus (10) especially suitable for use in transport systems in production engineering and generally for use in systems comprising parts that are mobile relative one another and between which a data exchange is desired.

Owner:EISENMANN MASCHENBAU +1

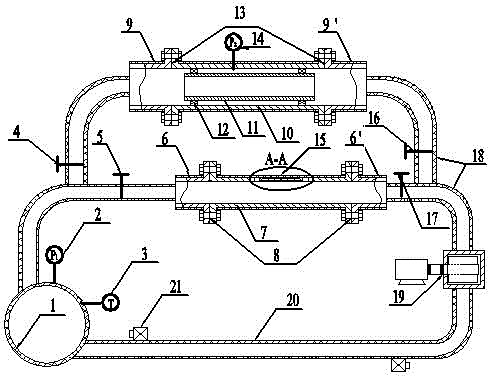

High-temperature high-pressure tubular-flow erosion corrosion experiment device

A high-temperature high-pressure tubular-flow erosion corrosion experiment device mainly includes: a high-temperature high-pressure kettle, a first pressure meter, a temperature meter, a sample test tube, an actual object test tube, a sample trough, a magnetic pump, a liquid transporting pipe, and an ultrasonic flow rate meter. The high-temperature high-pressure kettle is used for providing a fluid at certain temperature and under certain pressure. The actual object test tube is connected to a third joint and a fourth joint of the liquid transporting pipe through a second flange. An actual object tube is fixed in the actual object test tube through a first corrosion-resistant sealing ring. The sample test tube is connected to a first joint and a second joint of the liquid transporting pipe through a first flange. The sample trough, in which a sample is hung, is formed in the sample test tube. The magnetic pump is used for providing power to the experiment device for driving fluid circulation. The ultrasonic flow rate meter is used for testing the speed of the circulated fluid. The whole experiment device is made of corrosion-resistant alloy and a heat insulation layer covers external walls of all parts, so that temperature loss is avoided. The device is suitable for drilling production engineering of petroleum and natural gas.

Owner:SOUTHWEST PETROLEUM UNIV

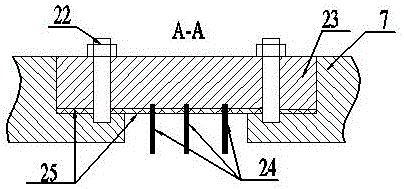

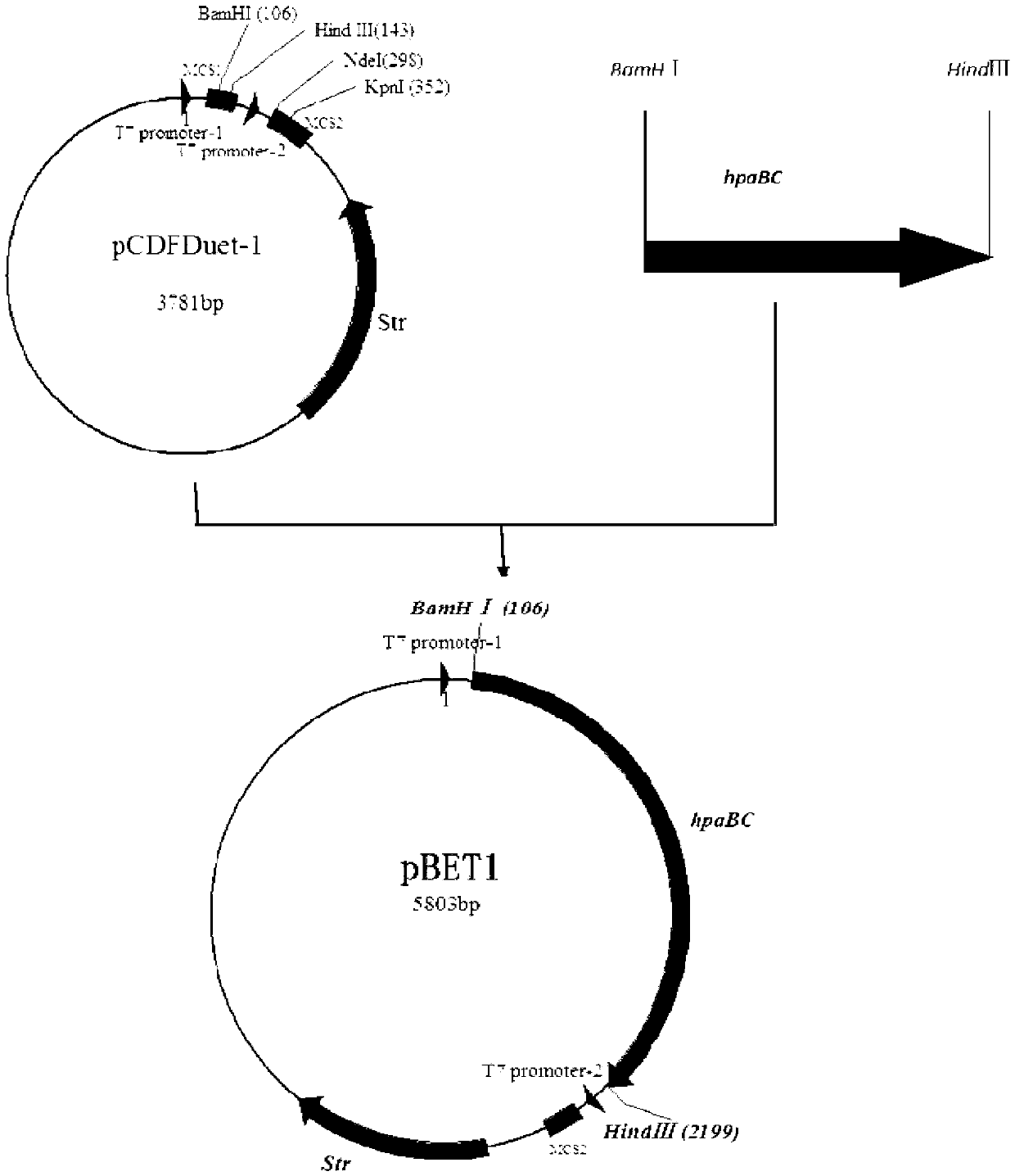

Method for improving biosynthesis of levodopa

InactiveCN103122361AOptimizing BioprocessingIncrease productionBacteriaMicroorganism based processesEscherichia coliBiotechnology

The invention discloses a method for improving biosynthesis of levodopa. The method comprises the following steps of: (1) using SEQ ID No.1 and SEQ ID No.2 as the primers, using an E.coli BL21 strain as the template, amplifying and recycling so as to obtain a hpaBC gene segment, conducting double digestion on a pCDFDuet-1 plasmid and the hpaBC gene segment, connecting and preparing a recombinant plasmid pBET1; (2) introducing the recombinant plasmid pBET1 into host escherichia coli so as to obtain transformed host cells; and (3) selecting the transformed host cells so as to obtain a levodopa production engineering bacteria single colony, taking 1ml of the levodopa production engineering bacteria single colony and putting into 100ml of a first culture medium, cultivating and measuring OD600, adding an isopropyl-beta-D-sulfo-pyran galactoside water solution and ascorbic acid, continuing cultivating and measuring the content of the levodopa. By utilizing the method disclosed by the invention, the output of the levodopa is increased, the production cost is lowered, and the operation process is simplified.

Owner:TIANJIN UNIV

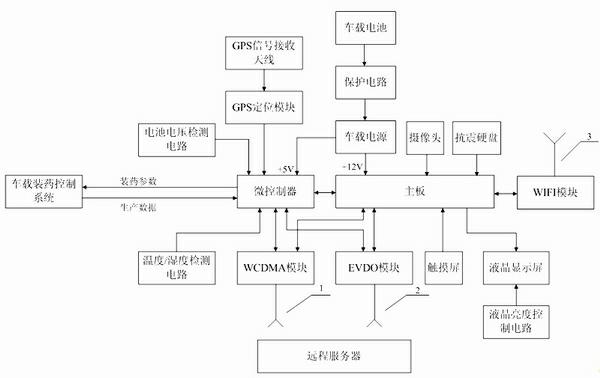

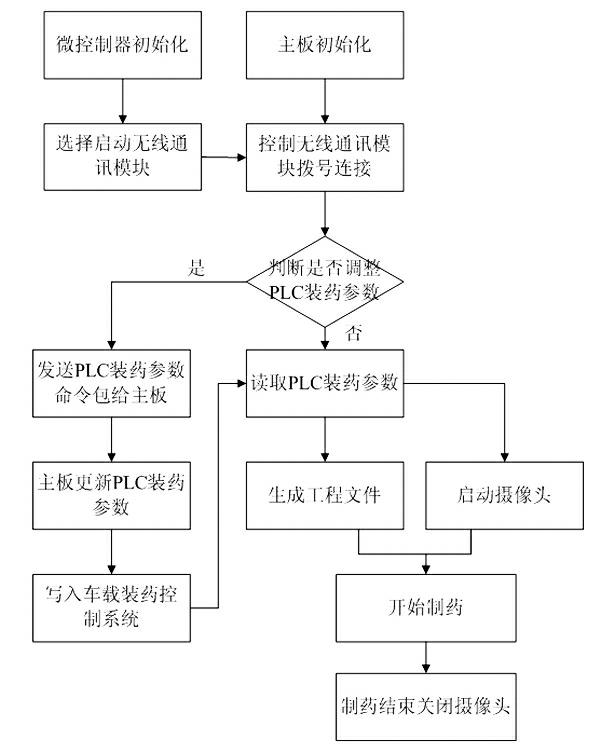

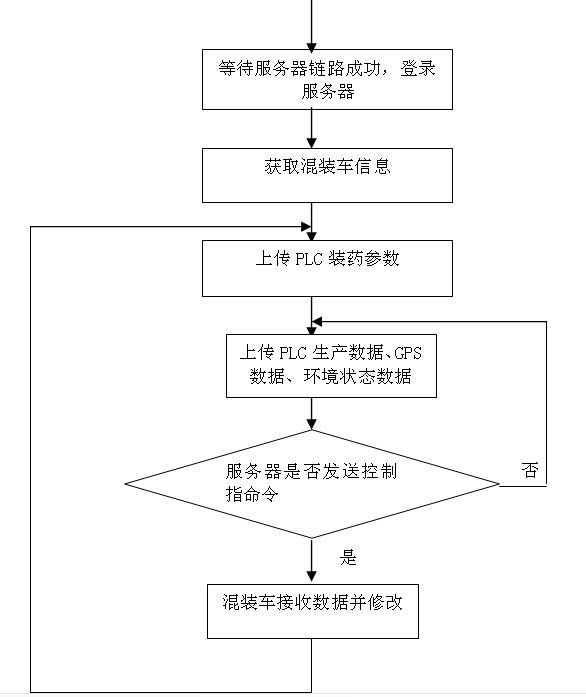

On-site mixed explosive charging vehicle monitoring device and method

ActiveCN102213575ARealize wireless controlRealize long-distance wireless communicationBlastingMicrocontrollerProgrammable logic controller

The invention discloses an on-site mixed explosive charging vehicle monitoring device and an on-site mixed explosive charging vehicle monitoring method and belongs to the technical field of industrial control. The monitoring device comprises a microcontroller, a mainboard, a camera, a wireless communication module and a wireless communication antenna, wherein the mainboard reads programmable logic controller (PLC) charging parameters, generates a project file, controls the explosive preparing process and starts the camera; video images provided by the PLC charging parameters and the camera are uploaded through the wireless communication module and the wireless communication antenna in turn; and PLC production data generated in the explosive preparing process is analyzed by the microcontroller, transmitted to the mainboard and uploaded through the wireless communication module and the wireless communication antenna in turn. In addition, global position system (GPS) data provided by a GPS module is resolved by the microcontroller, transmitted to the mainboard and uploaded through the wireless communication module and the wireless communication antenna in turn. By the device, the mixed explosive charging vehicle construction process is remotely monitored and accurately positioned.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

Microwave geodimeter

InactiveCN101162268AHigh resolutionSmall frequency differenceMachines/enginesLevel indicatorsMicrowave methodDisplay device

A microwave geodimeter relates to a distance measuring device, in particular to a high-accuracy noncontact distance measuring device with microwave method, mainly suitable for measuring material lever or liquid lever in containers or storehouses in industrial production engineering. The invention provides a microwave geodimeter which can realize a high-resolution distance measuring by using the prior electric elements. The invention comprises a transmitting device, a receiving device and a signal processing device. The transmitting device is provided with a first clock signal generator, a second clock signal generator, a pulse generator, a local oscillator, a switch, a power amplifier, a ring coupled circuit and an antenna. The receiving device is provided with an antenna, a ring coupled circuit and a low-noise amplifier; the input of the low-noise amplifier is connected with the output of the ring coupled circuit of the receiving device. The signal processing device is provided with a receiving / transmitting switch unit, a filter, a second clock signal generator, a pulse generator, a sampling smoothing circuit, a peak value testing circuit, a microprocessor and a display device.

Owner:XIAMEN UNIV

Gelled material for soil solidification

The invention provides a gelled material for soil solidification, belonging to the technical field of gelled materials. The gelled material comprises the following raw materials in percentage by mass: 20-40% of aluminum dreg micropowder, 30-50% of slag micropowder, 5-20% of fly ash, 10-15% of desulfurized gypsum and 1-5% of additive. The aluminum dreg micropowder adopted by the gelled material disclosed by the invention is aluminum-containing solid waste generated during production engineering of electrolytic aluminum, so that the waste is reused, the cost is saved, and the environment can be protected.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Annular pressure downhole control valve

PendingCN107701147AExtended service lifeImprove the safety of useDrilling rodsWell/borehole valve arrangementsCouplingEngineering

The invention discloses an annular pressure downhole control valve, and belongs to the technical field of oil-gas well engineering. The annular pressure downhole control valve is designed to solve theproblem of annular pressure anomaly in an oil-gas well. The annular pressure downhole control valve comprises a coupling and an outer cylinder which is in fit connection with the coupling; the coupling and the outer cylinder are matched to form a first accommodating cavity and a second accommodating cavity, the first accommodating cavity communicates with a casing pipe, and the second accommodating cavity communicates with the exteriors of the first accommodating cavity and the casing pipe to form a one-way flow channel; and the second accommodating cavity is internally provided with a valvecore which can move along the inner wall of the second accommodating cavity to open or close the one-way flow channel. According to the annular pressure downhole control valve, the abnormal annular pressure in oil-gas well completion and production engineering can be alleviated, integrity and production safety of a wellbore are ensured, the structure is simple, the machining cost is low, and the cost of controlling the annular pressure can be effectively reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Construction, expression and application of genetic engineering bacteria for high-production of beta-alanine

InactiveCN103898033AImprove synthesis abilityIndustrial Application AdvantagesBacteriaFermentationBiotechnologyL-Aspartate

The invention provides new genetic engineering bacteria used for producing beta-alanine, having strong synthetic ability and having higher enzyme activity, construction, expression and purification of the high-production engineering bacteria, and methods for synthesis of beta-alanine respectively through whole cell transformation and fermentation liquid direct transformation. A synthetic method comprises the steps: an L-aspartic-alpha-alanine decarboxylase (PanD) gene of lactobacillus plantarum is obtained by a gene engineering method and has the gene sequence number of NC-004567.2, the gene is constructed into a high-efficiency expression vector, then the high-efficiency expression vector is transformed into recipient bacteria, and thus the genetic engineering bacteria for producing beta-alanine are obtained. The genetic engineering bacteria are subjected to fermentation culture, 80 g / L of a substrate can be transformed by whole cells, and the beta-alanine content reaches 59.7 g / L; and the substrate is directly added into a fermentation liquid, the transformation concentration can reach 10 g / L, the beta-alanine content reaches 6.8 g / L, and the synthetic ability is higher than that of conventional reported genetic engineering bacteria.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Design method of middle blank and prefabricating blank during conical shell forgeable piece forming process

ActiveCN101537468ASmall machining allowanceControl taperMetal-working apparatusSpecial data processing applicationsNuclear powerHydrogenation reaction

The invention relates to a design method of a middle blank and a prefabricating blank during a nuclear power and hydrogenation reaction chamber conical shell forgeable piece forming process, which belongs to the filed of forging and is suitable for the production engineering and a manufacturing process of nuclear power and hydrogenation reaction chamber conical shell forgeable piece forming. The invention adopts a method of combining an analysis method and finite element modeling to develop a dimension relational expression of the prefabricating blank, the middle blank and a final forgeable piece during the nuclear power and hydrogenation reaction chamber conical shell forgeable piece forming process and provides the design method of the middle blank and the prefabricating blank. The design method and a design formula of the middle blank and the prefabricating blank during the nuclear power and hydrogenation reaction chamber conical shell forgeable piece forming process are suitable for producing significant parts, such as megawatt nuclear power conical shells, large-sized hydrogenation reaction chamber conical shells, and the like; when the middle blank and the prefabricating blank designed by the design method are adopted to produce conical shell forgeable pieces, the middle blank and the prefabricating blank designed by the design method can nicely control the conicity of the conical shell forgeable pieces, thereby solving the problem of the difficult forming and the unreliable machining dimension precision of traditional conical shell forgeable pieces.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

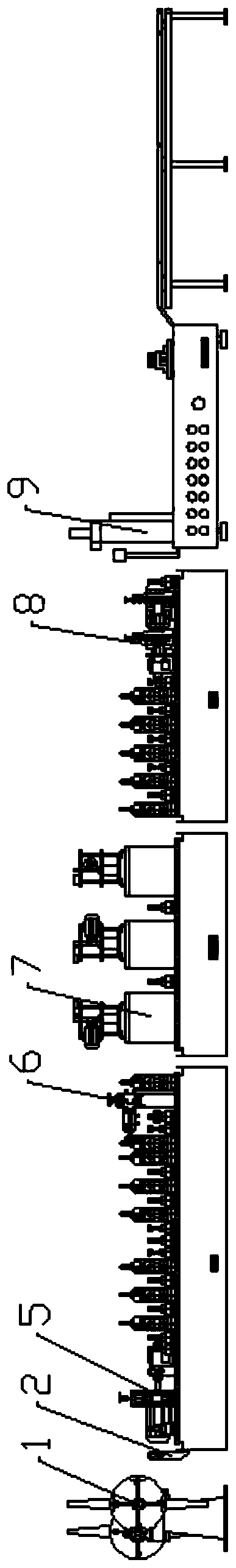

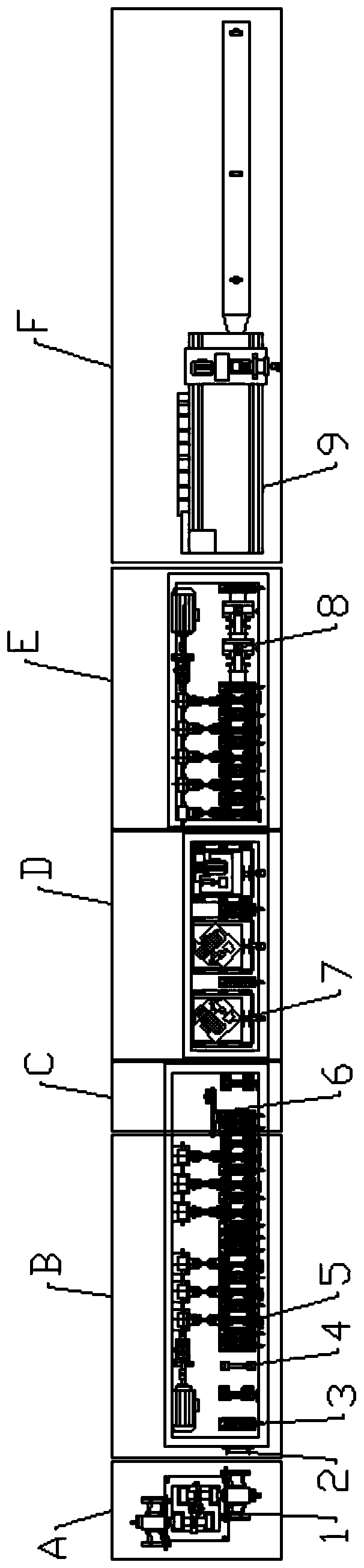

Pipe making machine

PendingCN109909756AEasy to unloadHigh unwinding efficiencyOther manufacturing equipments/toolsSheet steelPipe fitting

The invention discloses a pipe making machine which comprises an unwinding area, a forming area, a welding area, a polishing area, a straightening area and a cutting area. The unwinding area, the forming area, the welding area, the polishing area, the straightening area and the cutting area are sequentially arranged along a roll material steel plate conveying direction. An unwinding shelf is placed in the unwinding area and is used for placing roll material steel plates; multiple groups of pipe fitting forming mechanisms are placed in the forming area and are used for gradually forming the steel plates into round pipes; and a welding mechanism is placed in the welding area and is used for welding gaps on the round pipes. The pipe making machine has the beneficial effects that (1) by applying the unwinding shelf to the pipe making machine, materials can be conveniently unwinded and winded, so that the material unwinding and winding efficiency is high, and the 'zero' time for replacementcan be realized by adopting double-station unwinding; and (2) by adopting the side wheel seat forming mechanism, a right-and-left threaded screw rod drives two slide block nuts to gather together toward the middle or be separated toward two sides at the same time, so that the position of a forming mould is quickly adjusted; and the positions of the upper ends of two fixed shafts are adjusted andlimited through an adjusting assembly, so that the position stability of the forming mould in production engineering is ensured.

Owner:全南阳城机械制造有限公司

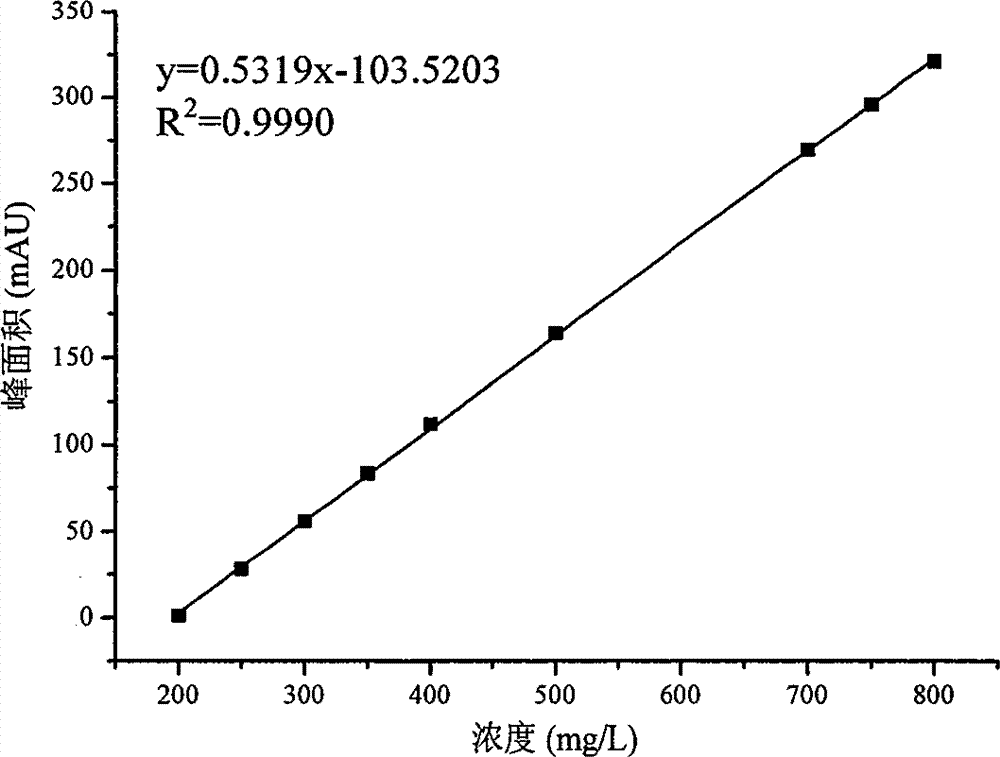

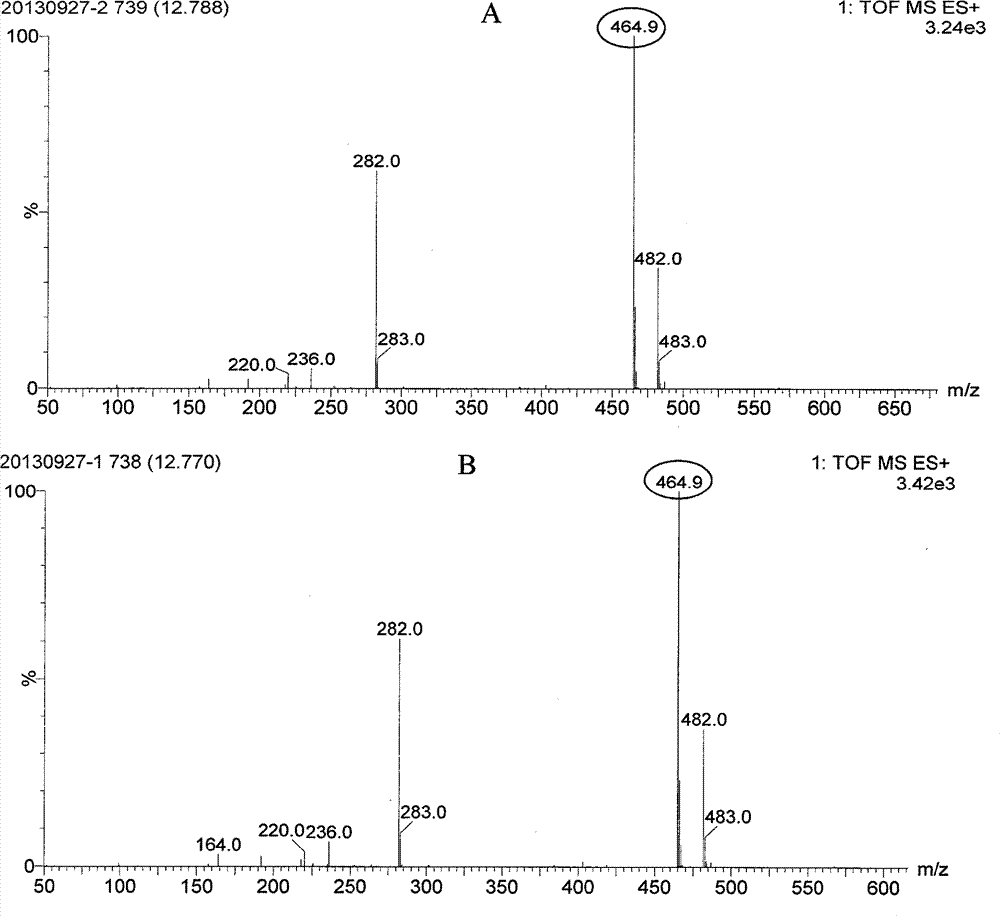

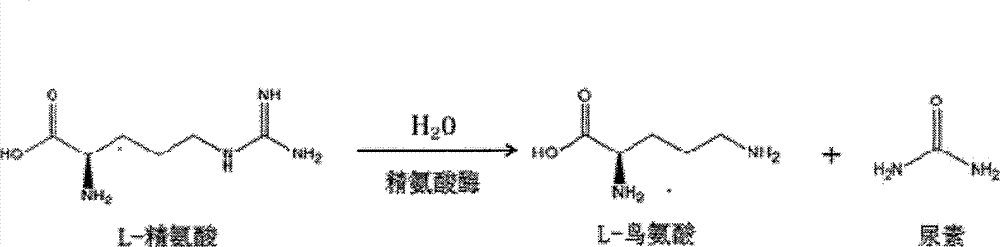

Construction of arginase production engineering bacteria and application of arginase production engineering bacteria in production of L-ornithine

InactiveCN103923936AIncrease vitalityMeet the needs of industrial scale productionBacteriaFermentationEscherichia coliBiotechnology

The invention describes a construction method of arginase production engineering bacteria and application of the arginase production engineering bacteria in production of L-ornithine by transformation of L-arginine, and belongs to the technical field of biological engineering. According to the method, by means of molecular biology, thermophilic bacteria Bacillus caldovelox (DSM411) is cloned to obtain arginase gene, a constructed expression plasmid is transfected into E.coli BL21 (DE3), and expression vector high-copy recombine ant arginase-containing engineering bacteria pET28a-ARG is obtained by kanamycin resistance plate screening. The enzyme can still show high activity after induced expression in E.coli. The bacteria obtained by fermentation can be directly used for transformation without breaking, in the condition of 60 DEG C, the engineering bacteria has higher permeability, and is more conducive to the substrate uptake and product release, the reaction speed is greatly improved, the transformation period is only 2-4h, the ornithine yield can reach 120.1g / L, and the transformation rate is 98.9%.

Owner:JIANGNAN UNIV

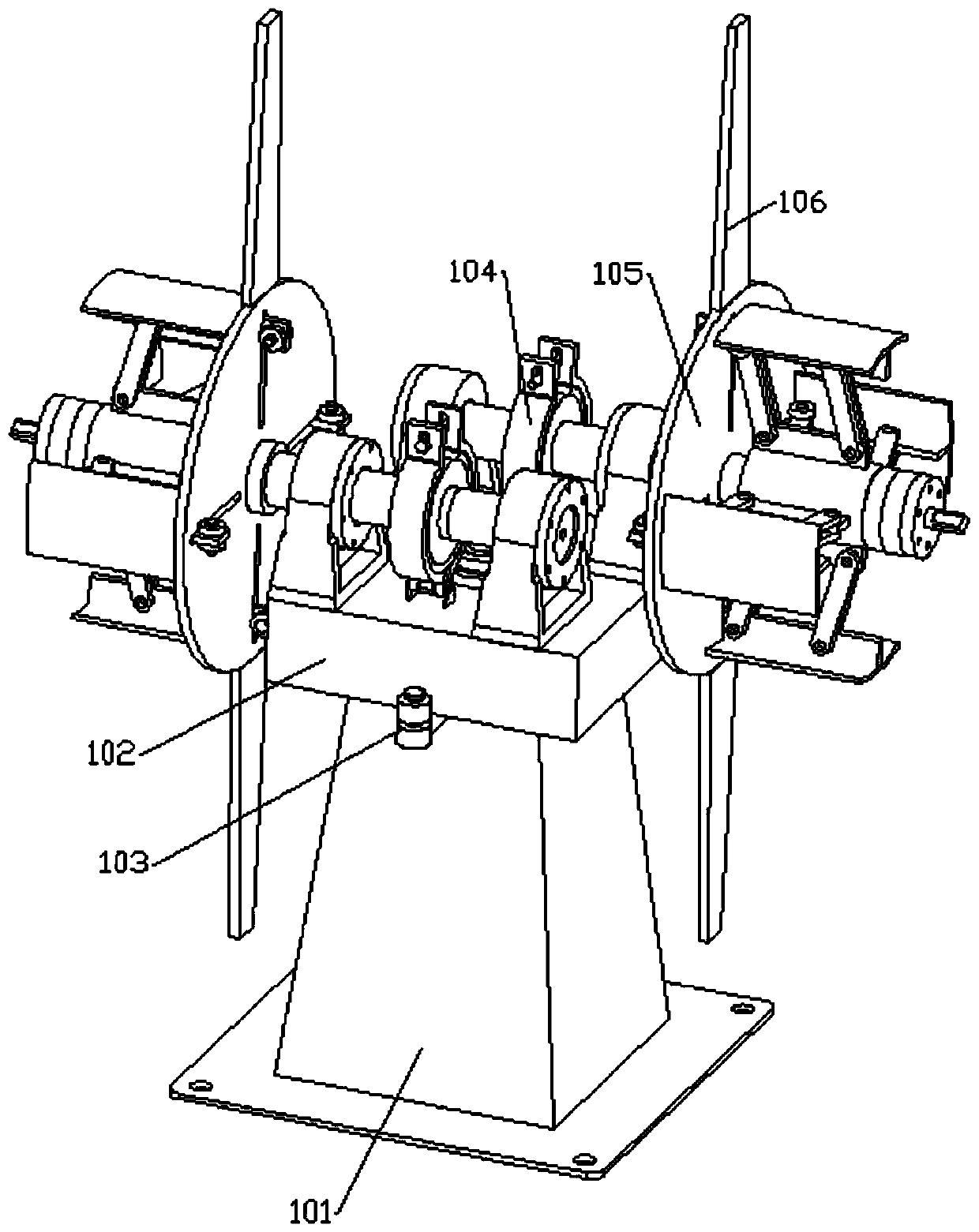

Test device for flexible life of coiled tubing

InactiveCN105823629AAccurately Obtain Bending Fatigue LifeMachine part testingMaterial strength using repeated/pulsating forcesInternal pressureReciprocating motion

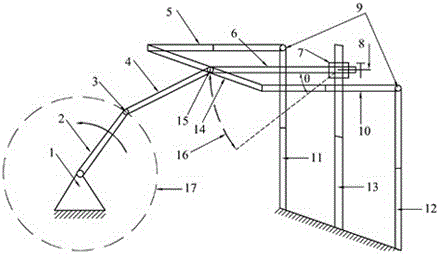

The present invention provides a test device for the flexible life of a coiled tubing. The device comprises a motor, a crank, a first rotating hinge, a connecting rod, a first hydraulic rod, second rotating hinges, a coiled tubing, a clamp, an air inlet, a second hydraulic rod, a first support, a second support, a third support, a crossbeam and a connection shaft. The crank, the connecting rod and the coiled tubing form a crank and rocker mechanism; the first hydraulic rod and the second hydraulic rod which are configured to apply tension load to the coiled tubing are able to rotate around the second rotating hinges and drive the coiled tubing to rotate back and forth along the swing locus; the air inlet is configured to apply internal pressure to the coiled tubing; the motor is started, the crank is configured to drive the coiled tubing under the action of internal pressure and the tension load to do reciprocating motion along the swing locus, and the degree of crook and the angle of the swing locus of the coiled tubing are changed by changing the length of the crank, so that the flexural fatigue characteristic test of the coiled tubing in different conditions are realized. The test device for the flexible life of a coiled tubing is suitable for the field of the petroleum and natural gas drilling and production engineering technology.

Owner:SOUTHWEST PETROLEUM UNIV

Oil-gas well tubular column annulus extreme pressure prediction method

The invention provides an oil-gas well tubular column annulus extreme pressure prediction method. The method includes the steps of obtaining tubular column pressure state information, obtaining the safest tubular column external pressure model when the given tubular column internal pressure value is included in the tubular column pressure state information, obtaining the safest modulator tube internal pressure model when the given tubular column external pressure value is included in the tubular column pressure state information, comparing the tubular column external pressure model and / or the tubular column internal pressure model with the tubular column external pressure value and / or the tubular column internal pressure value in the tubular column pressure state information, and judging whether a current tubular column is safe or not according to the comparison result. In this way, by predicating the minimum allowable pressure, the maximum allowable pressure and the safest pressure of the gas-well tubular column annulus, the gas production engineering scheme design and the gas well safe production management and control are guided; by predicting the balance pressure of the oil-gas well fracturing tubular column annulus, safety of fracturing tubular columns is ensured.

Owner:PETROCHINA CO LTD

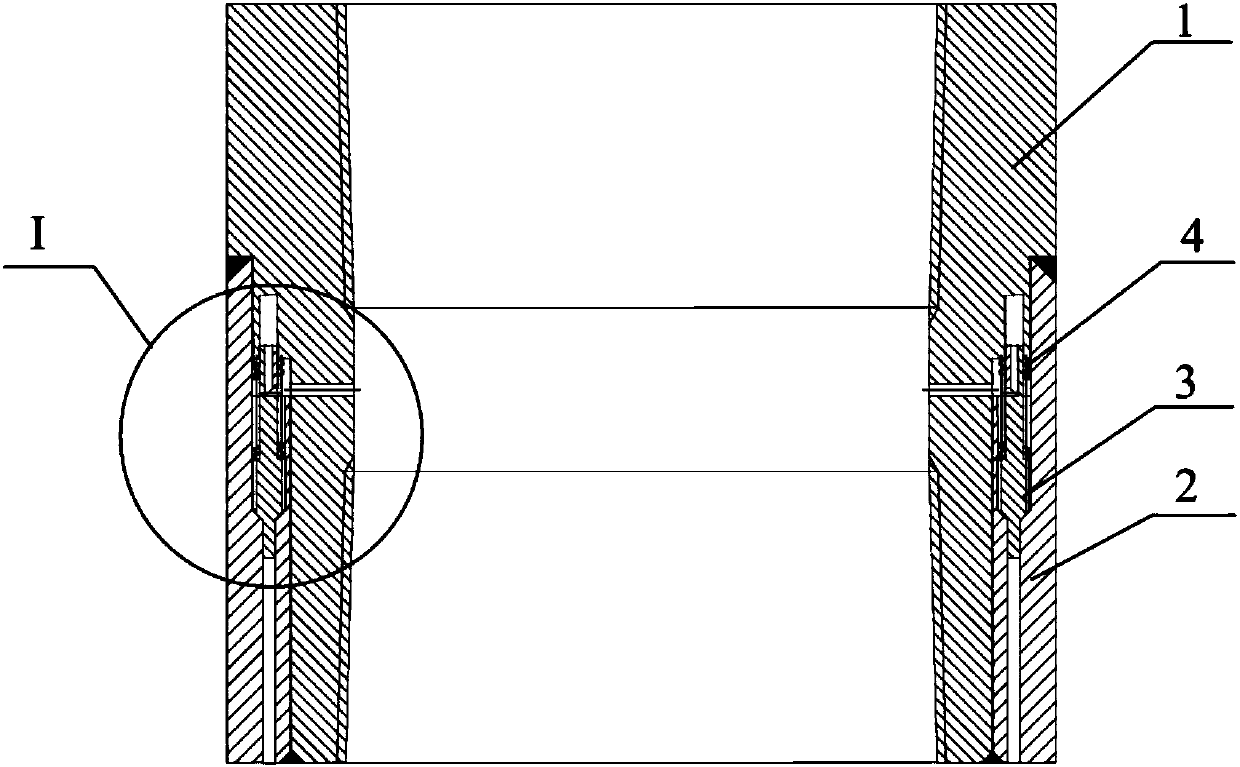

A method of manufacturing a polarization-maintaining optical fiber

InactiveCN102295407AReduce manufacturing costLow costGlass making apparatusGlass fibre productsPolarization-maintaining optical fiberElliptical polarization

A method for manufacturing an elliptical-clad polarization-maintaining optical fiber. The technical scheme of the present invention is as follows: 1. MCVD process is used to manufacture a preformed rod with a stress layer; 2. Quartz slices with a certain thickness and width equal to the width of the preformed rod are assembled on both sides of the preformed rod, and then inserted into a correspondingly configured quartz sleeve ; 3. After the combined optical fiber preform is cleaned, it is drawn on an optical fiber drawing tower to make an elliptical-clad polarization-maintaining optical fiber. The cross-sectional structure of the elliptical-clad polarization-maintaining optical fiber is respectively an outer cladding (12), a stress action area (13), an inner cladding (14) and a core layer (15) from outside to inside, and is characterized in that: the stress action area (13 ) is elliptical in shape, and the ellipticity is above 2.5:1. The advantages of the present invention are: 1. The outer pieces are made of high-purity quartz, and the cost is relatively low, so the production cost of the polarization-maintaining optical fiber is reduced and the production efficiency is improved. 2. Reduce the problem of preform cracking in the production process. Because if there is a non-circularly symmetrical stress zone in the preform, the probability of the preform bursting will be greatly increased.

Owner:北京玻璃研究院有限公司

Body-side suspension strut bearing for wheel suspensions

InactiveUS7857335B2Especially durableEasy to manufactureYielding couplingSpringsMobile vehicleUniversal joint

The invention relates to a body-side suspension strut bearing for wheel suspensions of motor vehicles, with a suspension strut which consists at least of a telescoping shock absorber and a bearing spring, and which is supported by way of a shock absorber bearing on the body and by way of another bearing on the wheel suspension elements of the motor vehicle, there being a joint between the body and the suspension strut. A suspension strut bearing which is favorable in terms of construction, production engineering and function, is achieved by the joint being formed by a universal joint with two crossing axes of rotation.

Owner:AUDI AG

On-line modified producing method for engineering plastics

InactiveCN101016411AUniform natureQuality improvementSievingScreeningMolten stateEngineering plastic

The invention discloses a preparing method to produce engineering plastics on line modify, which comprises the following steps: getting finite molecular weight molten state polymer through continuous polymerization; delivering to twin-screw extruder on line directly; adding right amount auxiliary agent based on the demand of product; mixing evenly through twin-screw extruder; squeezing; getting the product. This invention possesses merits of low power, low preparing cost and stable quality, which can be used to produce engineering plastics product.

Owner:SHEN MA INDUSTRY CO LTD +1

Circuit arrangement for reading out, evaluating and reading in again a charge state into a memory cell

A circuit arrangement includes a bit line (10), a reference bit line (12), a sense amplifier with two cross-coupled CMOS inverters, which in each case comprise an n-channel transistor (20, 22) and a p-channel field-effect transistor (30, 32), and also, at the respective source terminals, two voltage sources (40, 42), of which the voltage source (40) linked to the n-channel field-effect transistors can be driven from a lower through to an upper potential and the voltage source (42) linked to the p-channel field-effect transistors (30, 32) can be driven from the upper through to the lower potential. With this circuit arrangement, it is possible to store three different charge states in the memory cell (4) on the bit line (10) if the threshold voltages (UTH1, UTH2) at the transistors are chosen to be greater than half the voltage difference between the lower and upper voltage potentials. This can be achieved by production engineering or, for example, by changing the substrate bias voltage. The third charge state can be utilized for binary logic or for detecting a defect in the memory cell (4).

Owner:POLARIS INNOVATIONS LTD

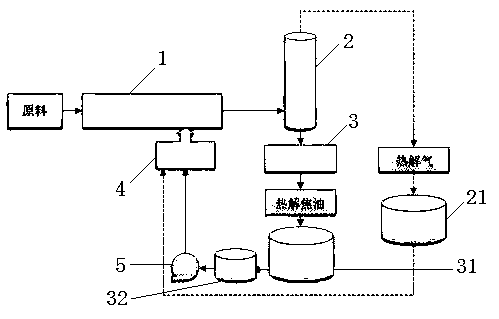

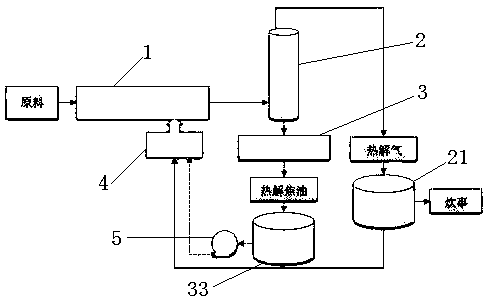

Biomass tar combustion system and method

PendingCN109082288AAvoid disadvantagesAtomization fitIndirect heating destructive distillationSpecial form destructive distillationEngineering productionChar

The invention discloses a biomass tar combustion system and method, belongs to the technical field of biomass pyrolysis, and aims to solve the problem that pyrolysis oil of pyrolytic carbon gas-oil co-production engineering. The biomass tar combustion system comprises a pyrolysis reaction furnace, a gas-liquid separator, an oil-water separator, a pyrolysis gas buffer tank and a combustor, whereinthe pyrolysis reaction furnace is connected with the gas-liquid separator; the lower end of the gas-liquid separator is connected with the oil-water separator; the upper end of the gas-liquid separator is connected with the pyrolysis gas buffer tank; the oil-water separator is connected with the combustor; and the output end of the combustor is connected with the pyrolysis reaction furnace. The centralized biomass pyrolysis tar combustion system in an embodiment of the invention is simple in technological process and is convenient to operate. A continuous pyrolysis oil-gas cofiring system in another embodiment takes pyrolysis gas as a main combustion material, tar only serves as a combustion-supporting material and is sprayed into the system, combustion is sufficient, fire cut can be avoided, and flue gas discharge reaches the standard easily.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

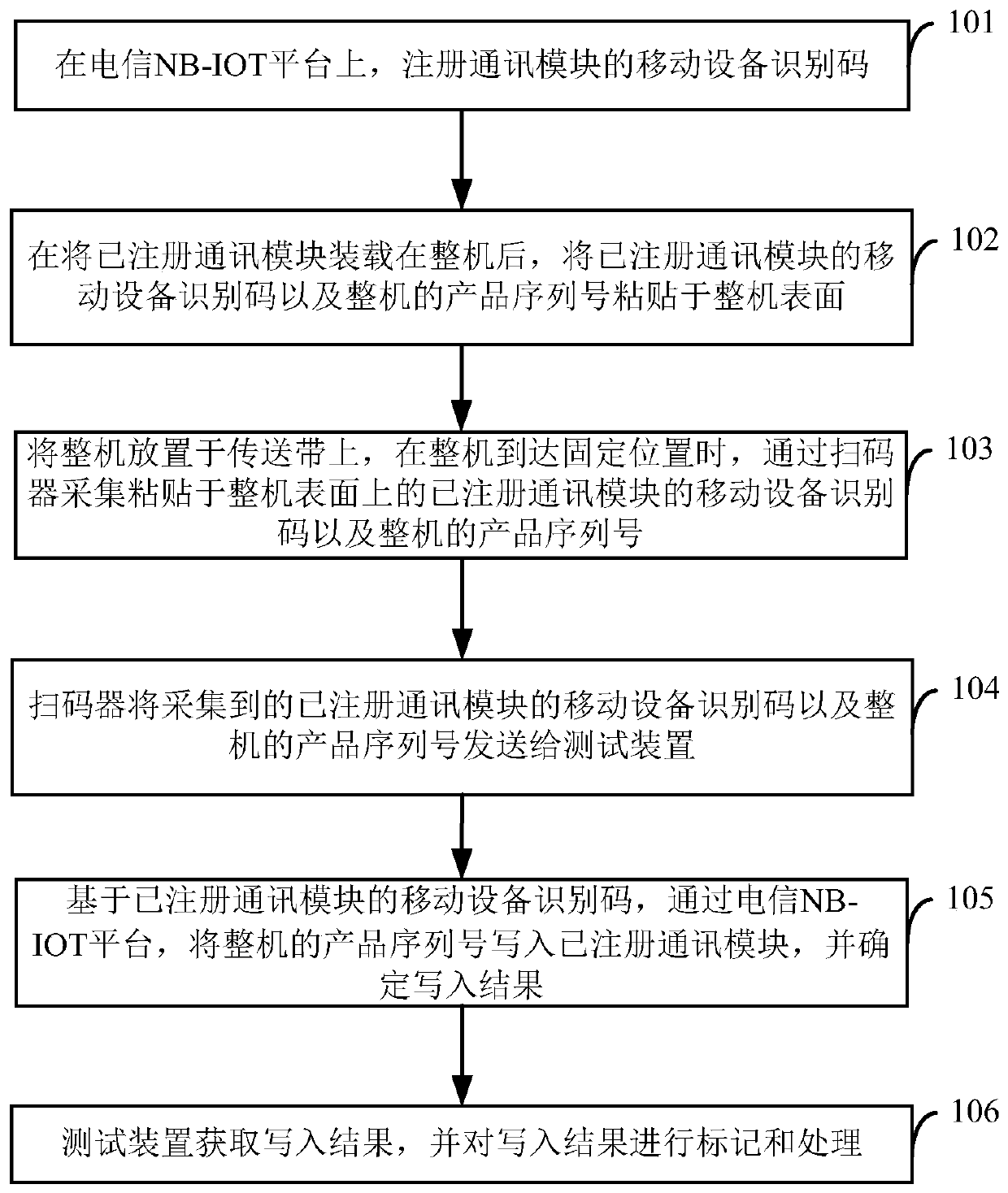

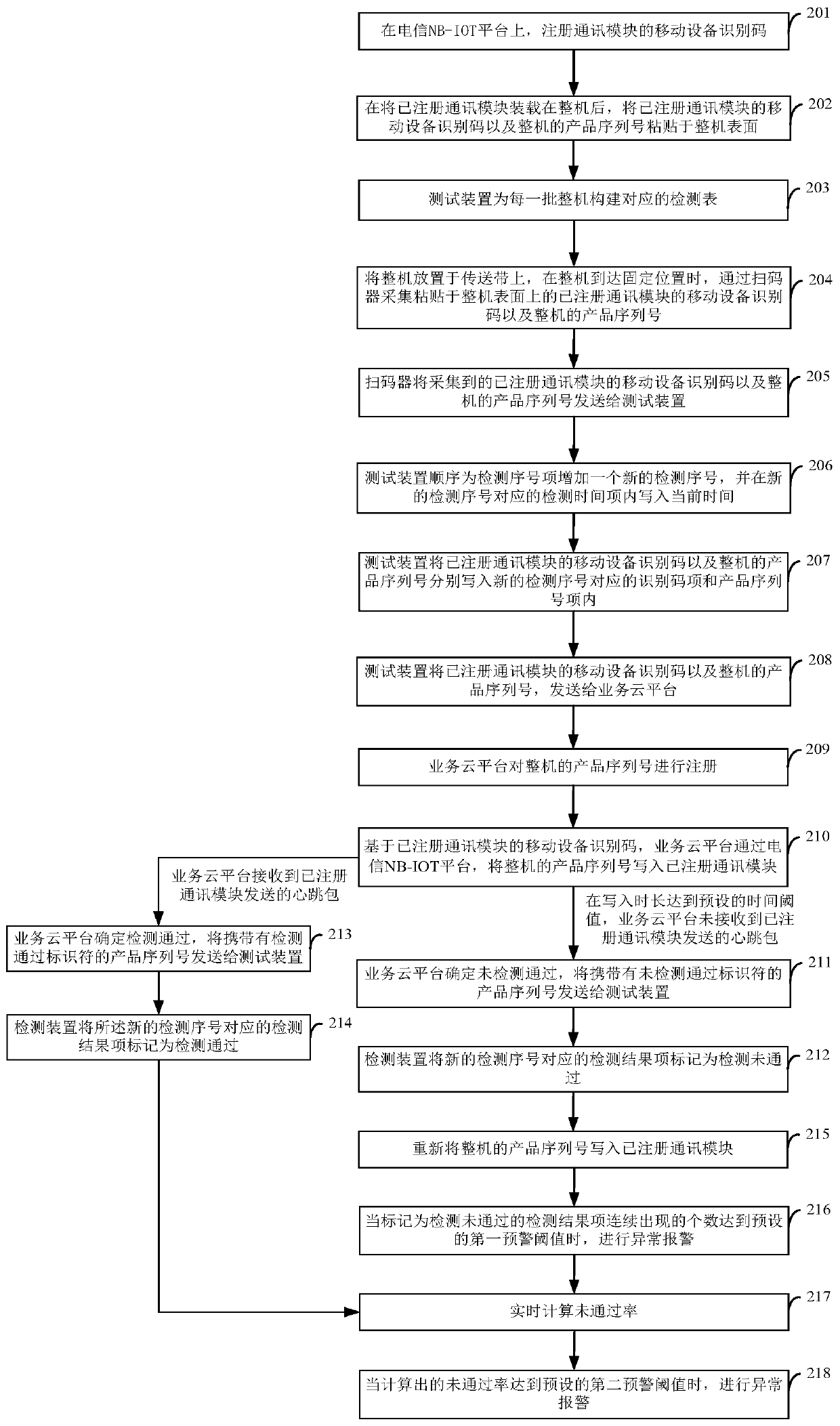

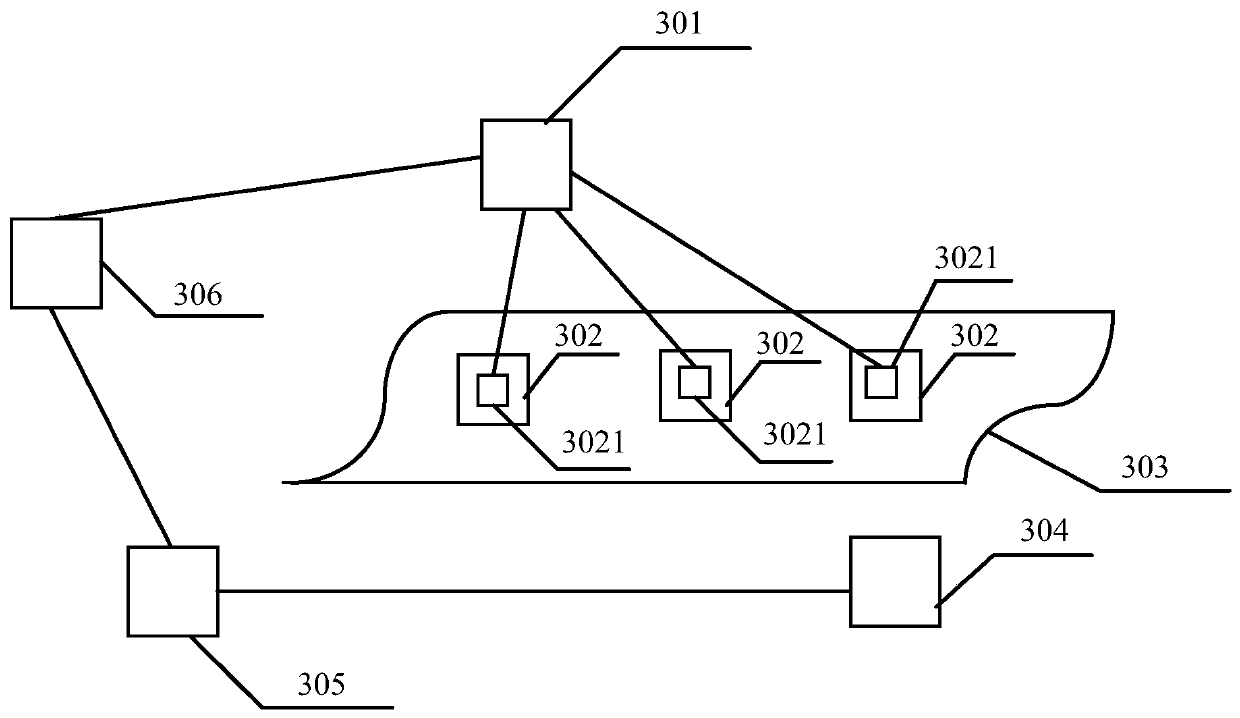

A communication module detection method and system based on NB-IOT Internet of Things

InactiveCN109818827AWire connection avoidanceImprove test efficiencyData switching networksTest efficiencyMobile equipment identifier

The invention provides a communication module detection method and system based on NB-IOT Internet of Things.. The method comprises the following steps of: at a telecommunication NB-IOT platform, a mobile device identification code of the communication module is registered, and after the registered communication module is loaded on the whole machine, the mobile device identification code of the registered communication module and the product serial number of the whole machine are pasted on the surface of the whole machine; A complete machine is placed on a conveyor belt, when the complete machine reaches a fixed position, a code scanner collects a mobile device identification code of a registered communication module and a product serial number of the complete machine, and sends the mobiledevice identification code of the registered communication module and the product serial number of the complete machine to a testing device; the Telecommunications NB-IOT platform writes the productserial number of the whole machine into a registered communication module and determines a writing result; And the test device marks and processes the writing result. According to the scheme providedby the invention, the whole machine production project is tested, and meanwhile, the test efficiency can be effectively improved.

Owner:SICHUAN HONGMEI INTELLIGENT TECH CO LTD

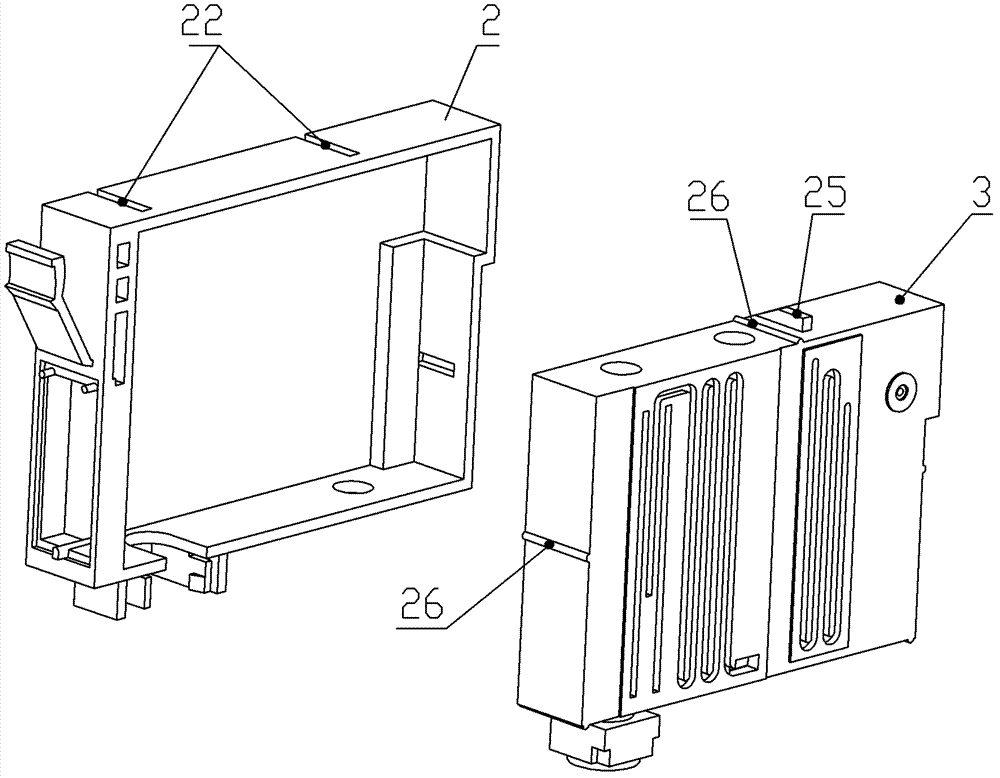

Assembling-type ink-jet printer ink box

InactiveCN103192607AReduce in quantityQuality stabilizationPrintingEngineering productionWorking hours

The invention disclose an assembling-type ink-jet printer ink box which comprises an outer shell and an ink box body, wherein the outer shell and the ink box body are matched with each other after formed independently, the outer shell is provided with an opening which is used for placing of the ink box body, the ink box body is provided with an ink containing portion, an ink supply portion, an ink supply path, a snake-shaped groove and the like, the ink containing portion stores ink, the ink supply portion ensures continuous supply of the ink, the ink supply path ensures the stable ink supply, and the snake-shaped groove is arranged for injection of air. Compared with the prior art, the assembling-type ink-jet printer ink box is an epoch-making high-quality ink box product, a porous body is not used, production engineering is reduced, production efficiency is improved, quality of the ink box is stabilized, the residual ink is reduced, and production cost is lowered. Meanwhile, when the outer shell and the ink box body are assembled, any tools and equipment are not needed, operators only need easy operation and assembly of the outer shell and the ink box body can be finished, the outer shell and the ink box body have different functions, components are simple in structure, the functions are integrated, and working hours are reduced. Due to the fact that production and assembly are easy, quality and efficiency are improved by a large margin.

Owner:SHENZHEN PRINTKING CONSUMABLES

Horizontal well no-throttle straddle-type double-sealing single-grip fracturing process

InactiveCN105178934AHigh temperature resistanceHigh pressure indexFluid removalSealing/packingHorizontal wellsSand blasting

The invention belongs to the technical field of oilfield production engineering, relates to a horizontal well no-throttle straddle-type double-sealing single-grip fracturing process, and solves the technical field of the existing technology that the throttle construction emission is small and the pressure bearing index is low, and can satisfy the large-scale fracturing construction requirements. A well-connected device is put into a sleeve 2 and then a fracturing layer, a Y211 packer 8 is set, and then a pipe pole is pressed down and then a Y111 packer 6 is set, and a large sand-amount sand spraying device 7 works and fracturing is started. After fracturing, the pipe pole is lifted upwards, a pressure balance valve 3 opens, the device is continuously lifted upwards and the Y211 packer 8 and the Y111 packer 6 are released. The setting and the releasing adopt the mechanical way, the construction efficiency is high, the pressure bearing index is high, and the horizontal well no-throttle straddle-type double-sealing single-grip fracturing process is more suitable for large-scale multi-stage multi-group fracturing construction.

Owner:PETROCHINA CO LTD +1

Method and device for prediction while drilling of gas reservoir output

The invention belongs to the technical field of oil and gas exploration and development, and particularly relates to a method and device for prediction while drilling of gas reservoir output. The method for prediction while drilling of the gas reservoir output, namely the natural gas output, comprises the steps of establishing a gas reservoir output prediction model according to gas reservoir dataof a drilled well; predicting the gas reservoir output of a drilling well according to the established gas reservoir output prediction model through the gas reservoir data of the drilling well; and analyzing the potential capacity of the drilling well. The device for prediction while drilling of the gas reservoir output comprises a prediction model establishing module and a prediction analysis module. The natural gas content in broken rock is recovered through the drilling data, logging data and the like, the recoverable gas content index is figured out, and on this basis, the well natural gas output is predicted according to the total volume of a reservoir stratum within the gas production radius range. The method can be applied to assessment of the overall mining potential of the natural gas drilling well and a gas reservoir in the development stage and provides a basis for completion program design and gas production engineering ground construction.

Owner:SINOPEC SSC +3

Circuit arrangement for reading out, evaluating and reading in again a charge state into a memory cell

A circuit arrangement includes a bit line (10), a reference bit line (12), a sense amplifier with two cross-coupled CMOS inverters, which in each case comprise an n-channel transistor (20, 22) and a p-channel field-effect transistor (30, 32), and also, at the respective source terminals, two voltage sources (40, 42), of which the voltage source (40) linked to the n-channel field-effect transistors can be driven from a lower through to an upper potential and the voltage source (42) linked to the p-channel field-effect transistors (30, 32) can be driven from the upper through to the lower potential. With this circuit arrangement, it is possible to store three different charge states in the memory cell (4) on the bit line (10) if the threshold voltages (UTH1, UTH2) at the transistors are chosen to be greater than half the voltage difference between the lower and upper voltage potentials. This can be achieved by production engineering or, for example, by changing the substrate bias voltage. The third charge state can be utilized for binary logic or for detecting a defect in the memory cell (4).

Owner:POLARIS INNOVATIONS

Novel engineering production pressure calibrator

The invention discloses a novel pressure calibrator for engineering production, which includes an oil pipe, a piston cavity and a stepping motor. The oil pipe is connected with a measuring tube, and a pressure valve is arranged under the measuring tube, and one of the measuring tubes is connected with a pressure gauge to be calibrated. , the measuring tube on the left side of the pressure gauge to be calibrated is provided with an oil cup, and the measuring tube on the left side of the oil cup is provided with a piezoelectric sensor. The motor is connected with the coupling through the gear transmission mechanism, the coupling is connected with the lead screw, the right side of the stepping motor is connected with the manual crank, and the sliding guide rail is set under the stepping motor, and the pressurized piston is connected with the lead screw. This device is equipped with a precision pressure gauge on the oil pipe to realize the comparison between the calibration instrument and the instrument to be calibrated. The calibration accuracy is high, and the standard pressure can be generated by electric and manual methods. It is flexible, light, and has high work efficiency. Cost saving, safe and reliable.

Owner:TIANJIN SENRAN ENG COST CONSULTING

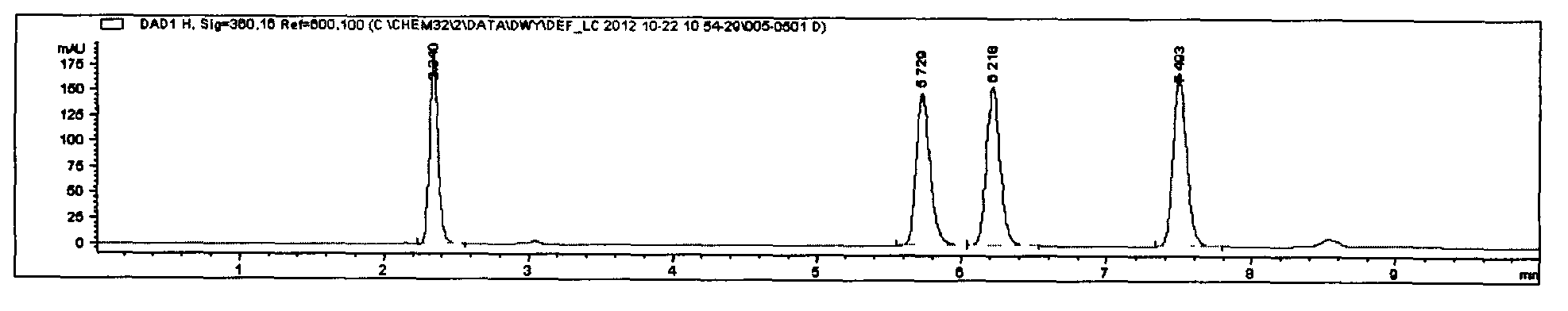

Production installation for a chemical or pharmaceutical product

ActiveUS20150301522A1Simplifies information interchangeOperational securityProcess control/regulationSampled-variable control systemsProcess moduleEngineering production

A production installation having at least two process modules (P1, . . . , Pn) that can be connected to one another for production engineering purposes and a communication network (2), wherein each process module (P1, . . . , Pn) has an electronic device by means of which the respective process module (P1, . . . , Pn) can be connected to the communication network (2) for communications engineering purposes and is set up to control and / or regulate the respective process module (P1, . . . , Pn) to independently carry out a particular process section of the production.

Owner:SUZHOU SKYWELL HEALTHCARE INFORMATION CO LTD

Method and device for determining influence degree and storage medium

InactiveCN109002420AImprove regulation efficiencyComplex mathematical operationsOil productionPetroleum

The invention discloses a method and a device for determining the influence degree, and a storage medium, belonging to the field of oil production and gas production engineering of the petroleum industry. The invention respectively determines a fitting straight line corresponding to each production parameter by acquiring system efficiency of each oil and gas well in a plurality of oil and gas wells, and neutralizing production data of each oil and gas well and a plurality of production data corresponding to a plurality of production parameters one by one. Since the slope of the fitting straight line corresponding to each production parameter can reflect the variation trend between each production parameter and the system efficiency of the oil and gas well, the influence degree of each production parameter on the system efficiency of the oil and gas well can be determined based on the fitting straight lines corresponding to the plurality of production parameters respectively. The invention avoids the malpractice that the field workers only take measures against the specific production parameters which affect the system efficiency of oil and gas wells in the process of adjusting oiland gas wells, and thus improves the adjustment efficiency of oil and gas wells.

Owner:PETROCHINA CO LTD

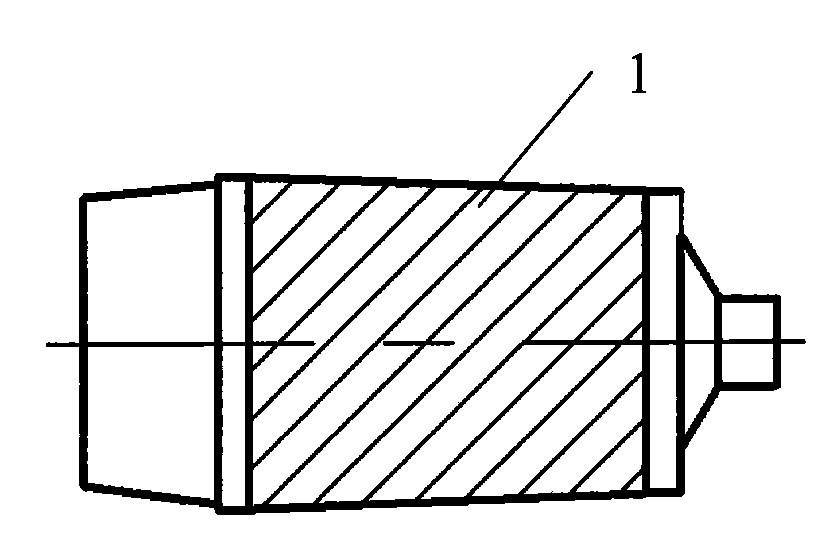

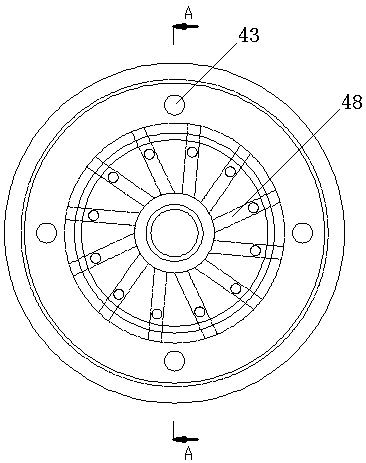

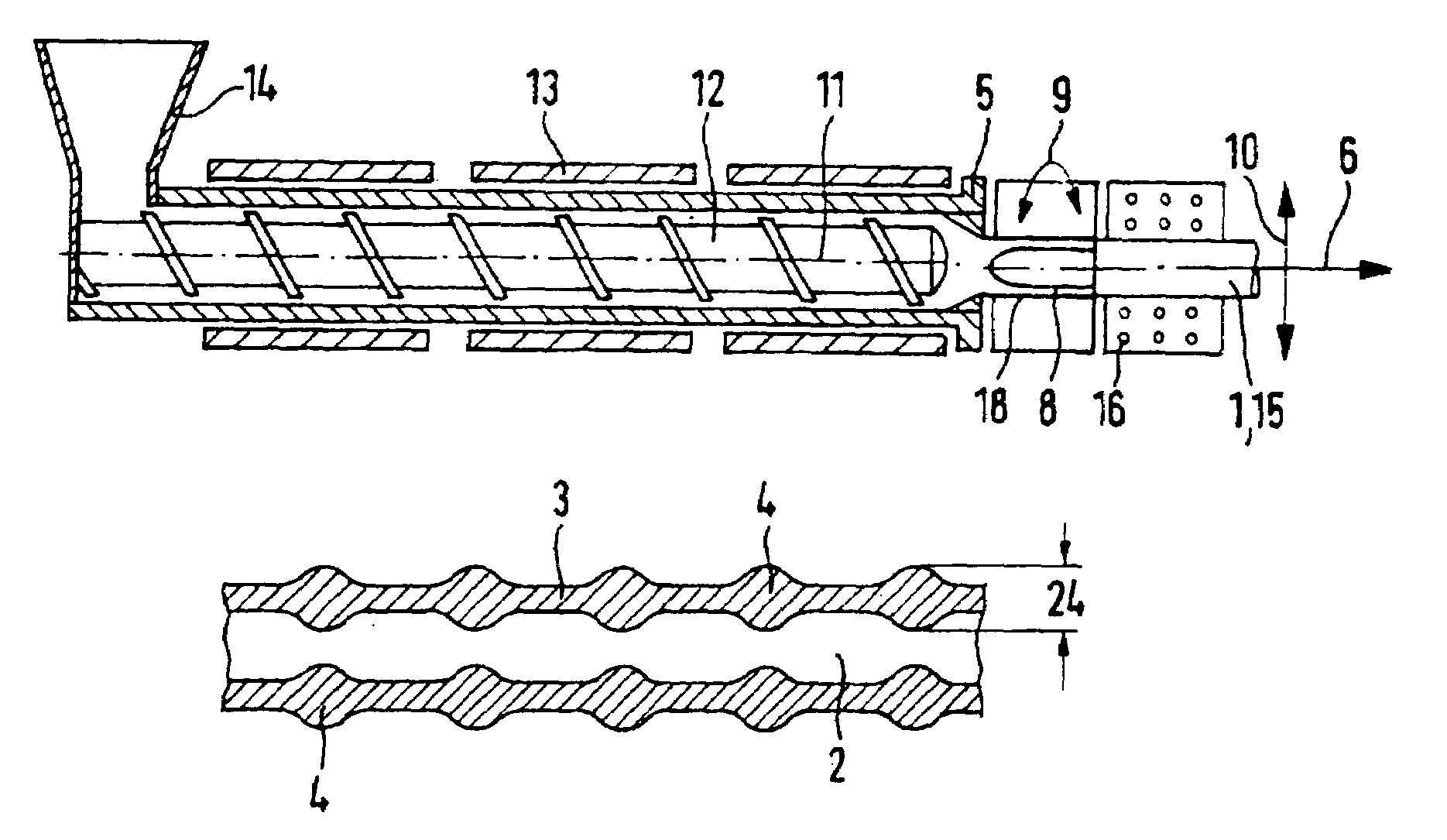

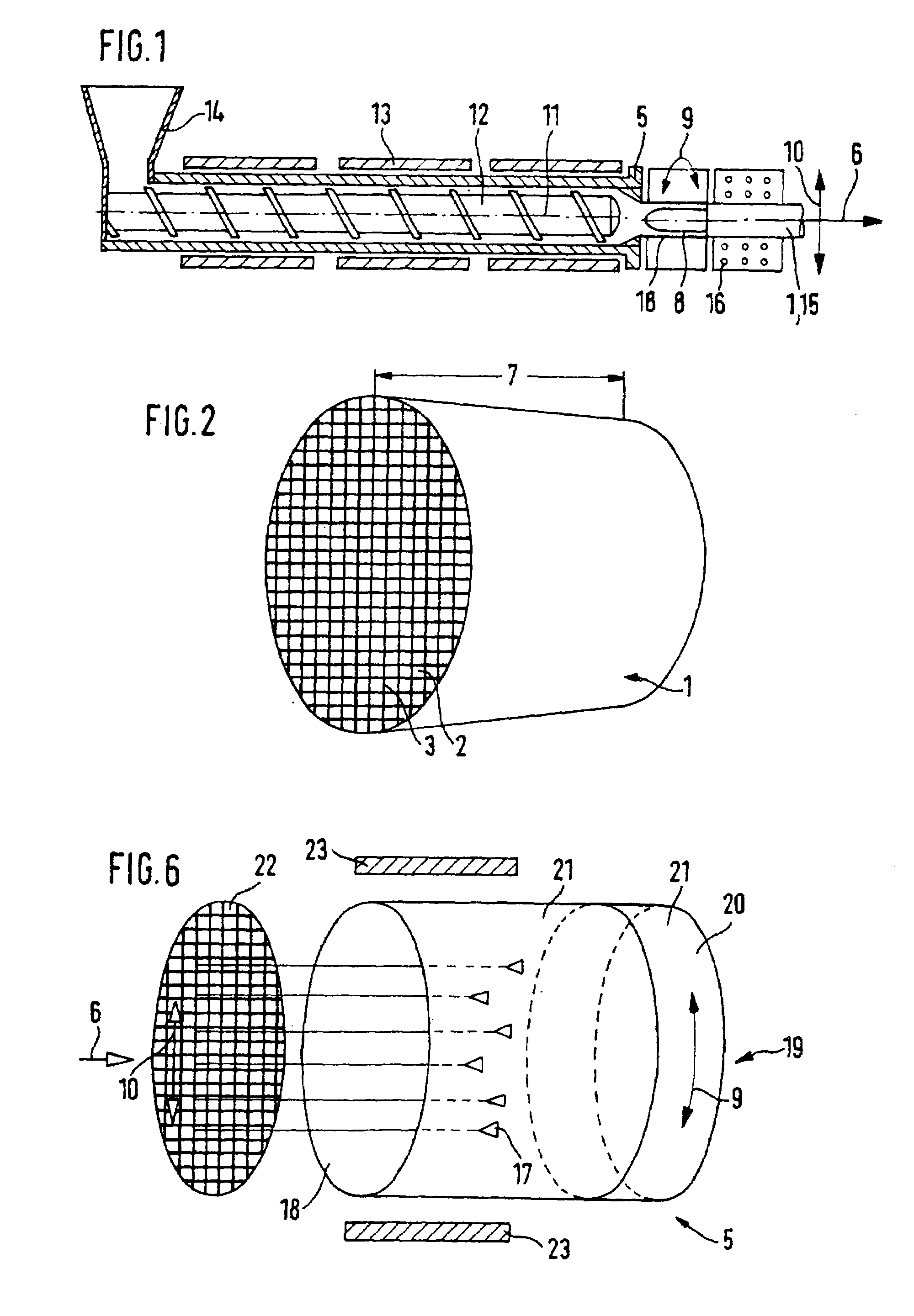

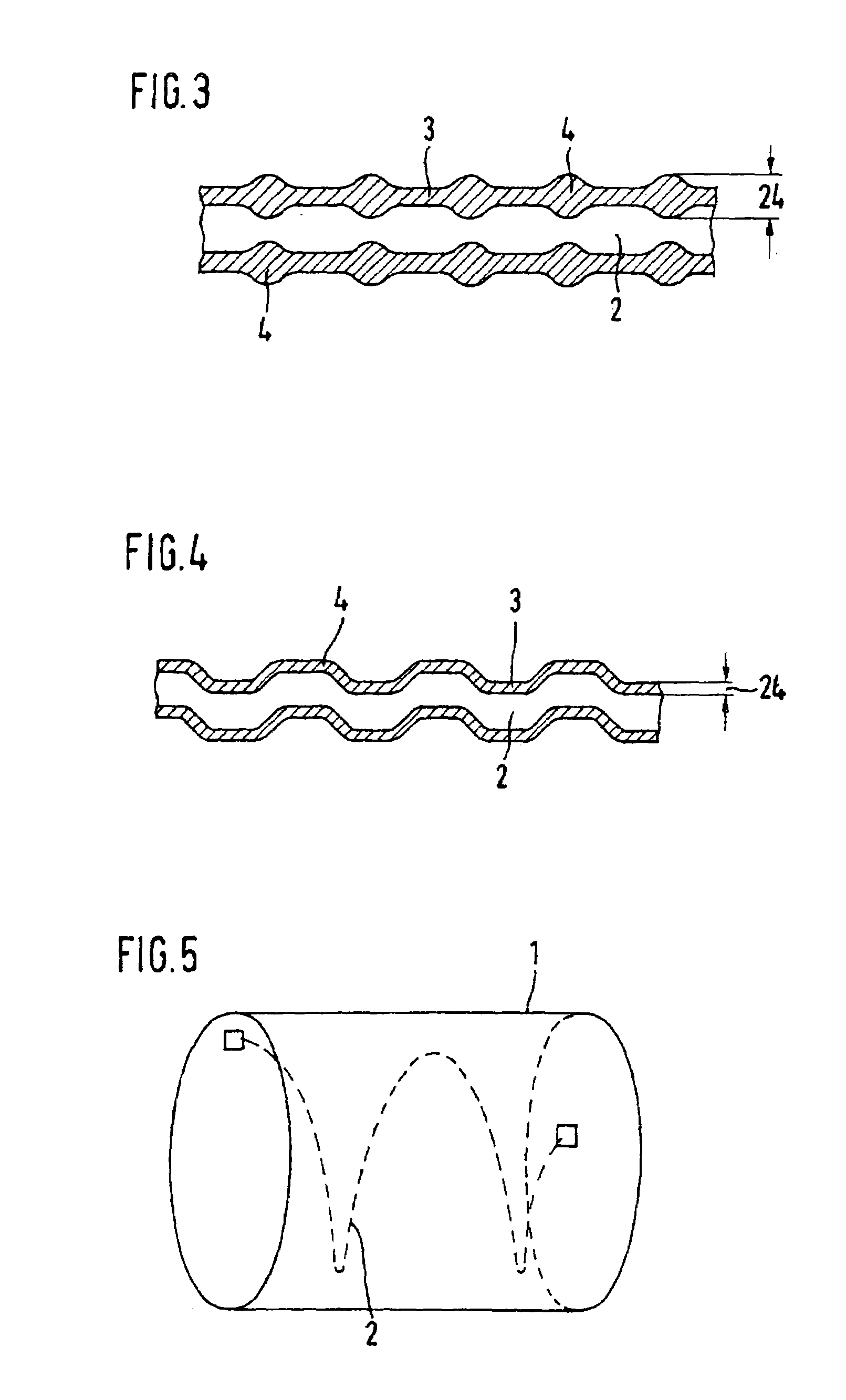

Process for producing extruded honeycomb bodies and extrusion die

InactiveUS7169341B2Improve reliabilityProduction is possibleCatalyst carriersExhaust apparatusHoneycombInternal combustion engine

A process is provided for producing extruded honeycomb bodies with passages, in particular as catalyst carrier bodies for the cleaning of exhaust gas from an internal combustion engine. The passages are bounded by wall regions which are at least partly provided with structures. The honeycomb body is extruded with an extrusion die in such a way that an additional relative movement between the honeycomb body and the extrusion die takes place, leading to a deformation of the wall regions of the passages. An extrusion die for producing extruded honeycomb bodies includes a multiplicity of secured profiled pins and a housing, which together form an extrusion mask. The extrusion mask is variable during the production process, so that wall regions with the structures can be formed. Honeycomb bodies which have structures in the interior that are suitable for influencing a stream of fluid flowing through can therefore be produced in a manner which is simple in terms of production engineering.

Owner:EMITEC GESELLSCHAFT FUR EMISSIONSTECHNOLOGIE MBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com