Biomass tar combustion system and method

A combustion system and combustion method technology, applied in coke ovens, petroleum industry, special forms of dry distillation, etc., can solve problems such as pyrolysis tar that is difficult to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

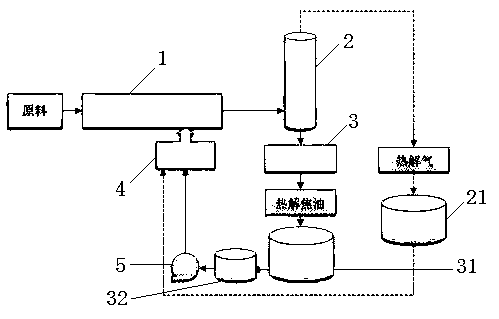

Embodiment 1

[0037] The storage tank volume of pyrolysis tar is 3m 3 , used for the buffer of pyrolysis tar in the oil production stage, and used for the concentrated combustion of pyrolysis tar.

[0038] Taking the pyrolysis project with a processing capacity of 350kg / h of biomass raw materials as an example, the project runs for 6 hours a day, the tar output is 10kg / h, the calorific value is 30MJ / kg, and the pyrolysis gas output is 150m 3 / h, calorific value is 15MJ / m 3 , adopt oil-based oil-gas co-combustion mode, 1kg tar ratio 1m 3 Pyrolysis gas, that is, in the process of concentrated combustion, 30kg of tar and 30m 3 Pyrolysis gas can meet the needs of equipment. It can realize continuous oil production operation for 16 days, and then focus on burning oil with gas for 6 days, a total of 22 days cycle.

[0039] The technical difficulty of the method of the present invention is: the secondary heating of the tar storage tank and the pipeline is required to ensure better fluidity; in...

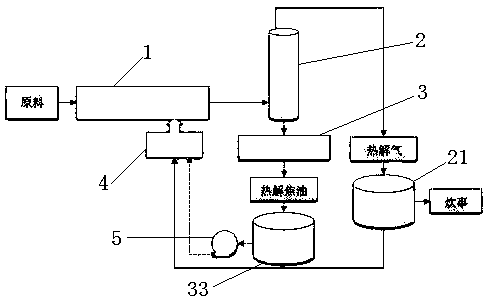

Embodiment 2

[0048] It is suitable for large-scale pyrolysis projects, with a processing capacity of at least 1t / h, a pyrolysis tar output of more than 30kg / h, and a pyrolysis gas output of 200m 3 / h above. When oil and gas are mixed and burned, the ratio of 1kg of pyrolysis tar is kept at 3m 3 The pyrolysis gas is mixed and burned, and the energy generated is supplied to the front-end pyrolysis equipment, and the excess pyrolysis gas enters the gas storage cabinet for cooking.

[0049] The technical difficulty of the method of the present invention is that the one, must have certain tar production to maintain system operation, and oil production should be more than 30kg / h, just can have a better atomization effect; The 2nd, the continuous separation of oil and water is comparatively difficult, here An oil-water separation tank or centrifuge with insulation can be added, and a small amount of water will not have a great impact on the combustion effect.

[0050] At present, air atomizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com