Method and system of in-situ ore leaching and leachate discharge of ion adsorption type ore

An ion adsorption type, in-situ leaching technology, applied in the direction of improving the process efficiency, can solve the problems of entering a large amount of air, air leakage in the vacuum system, uneven ore body, etc., to improve the vacuum degree of the system, improve the recovery rate, Improve the effect of vacuum outlet area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 is used to illustrate the efficiency of adopting the method of the present invention to carry out in-situ leaching ore extraction.

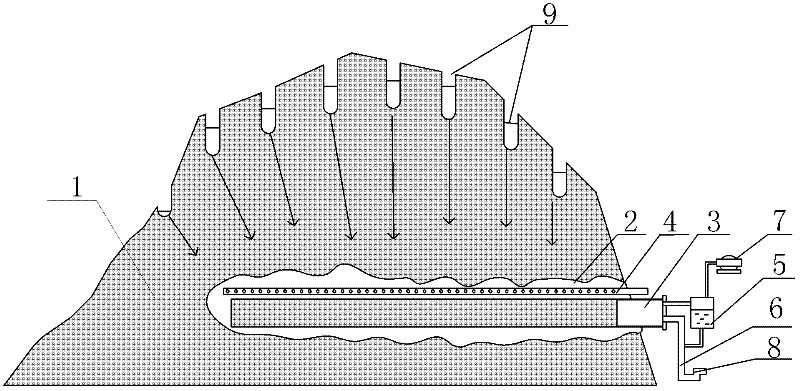

[0033] like figure 1 As shown, a 3×3m bottom plate is prepared for the simulated ore body bedrock, and there are small holes for water seepage on the bottom plate. According to the actual situation of the ore body, the ore soil is piled up on the simulated bedrock bottom plate to make an ion-adsorption type ore body model . Install a liquid injection pipe (equivalent to the liquid injection well 9) on the surface of the ore body model according to the in-situ leaching process, then excavate a horizontal well at the bottom of the ore body model, and set a rigid PVC porous pipe with a 200-mesh filter screen in the horizontal well as a vacuum The liquid outlet pipe 3 and the PE pipe parallel to the vacuum outlet pipe 3 are used as the porous grouting pipe 4 (5mm holes are opened every 0.05 meters on the pipe), the vacuum outlet ...

Embodiment 2

[0038] Example 2 is used to illustrate the efficiency of adopting the method of the present invention to carry out in-situ leaching ore extraction.

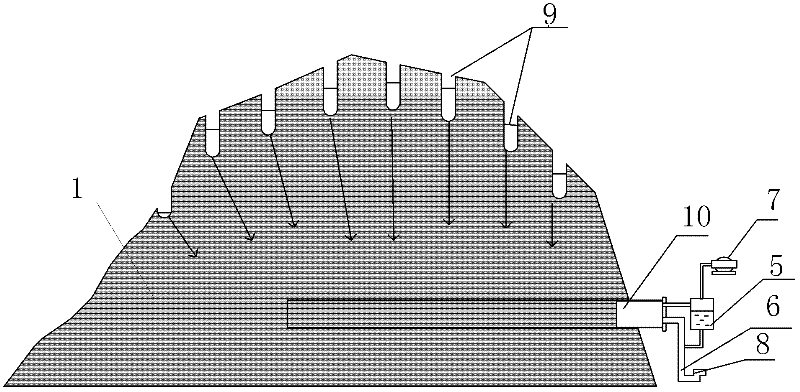

[0039] like figure 2 As shown, a 1×1m bottom plate is prepared for the bedrock of the simulated ore body, and there are small holes for water seepage on the bottom plate. According to the actual situation of the ore body, the ore soil is piled up on the bottom plate of the simulated bed rock to make an ion-adsorption type ore body model . According to the in-situ leaching process, a PE material injection pipe (equivalent to the liquid injection well 9) is installed on the surface of the ore body model, and a microporous ceramic tube 10 with an aperture of 0.5-2 μm is installed at the bottom of the ore body model, and the microporous ceramic One end of the pipe 10 is closed, and the other end is connected to the gas-water separator 5, and the gas-water separator 5 is connected to the vacuum system 7. Turn on the vacuum system 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com