Treatment mechanism for effectively controlling inclusions in nicotine extract steam

A technology of extract and nicotine, which is applied in the field of treatment mechanism for effectively controlling the inclusions in the vapor of nicotine extract, can solve the problems of affecting production, affecting the nicotine conversion rate, solvent recovery rate, production safety, etc. Simple, improved production safety, and the effect of reducing the amount of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

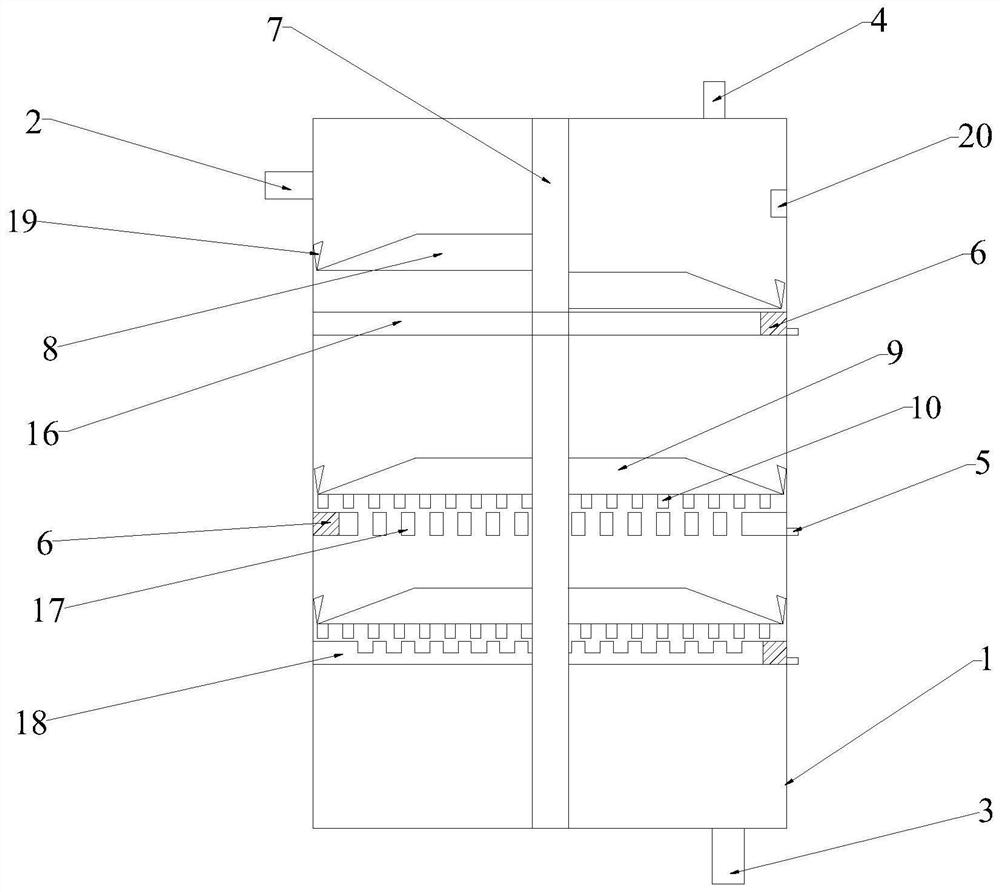

[0039] This embodiment discloses a treatment mechanism for effectively controlling the inclusions in the nicotine extract steam, such as figure 1 As shown, it includes a nicotine extract steamer and a spray chamber 22. The nicotine extract steamer includes a feed port 2, a material outlet 3, a steam inlet 5, a steam outlet 4 and several steam outlets. tray, the inner chamber of the steam tray communicates with the steam inlet 5, and the nicotine extract passes through the feed port 2 and several steam trays to the discharge port 3 in turn, and the evaporated components flow out from the steam outlet 4; the spray The chamber 22 is provided with a steam inlet 22a, a treated steam outlet 22b and a shower head 22c, and the treated steam outlet 22b is arranged above the shower head 22c; The spray chamber 22 is connected, and the steam reaches the treated steam outlet 22b after passing through the steam inlet 22a and the shower head 22c. In this embodiment, the leaching solvent of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com