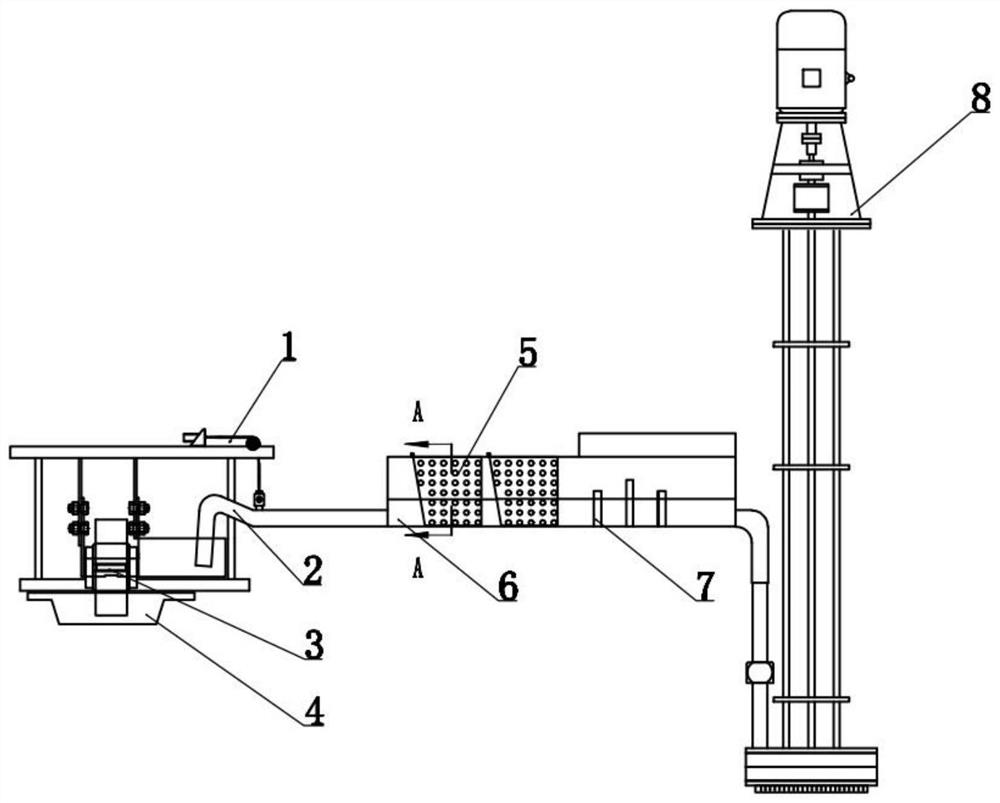

Automatic casting device with residue buffering and filtering functions

A functional and automatic technology, applied in the field of metal ingots, can solve the problems of affecting product quality, difficult to remove the side walls and edges of metal ingots, and unqualified metal ingot products, etc., to improve production efficiency, improve product qualification rate, The effect of reducing the amount of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

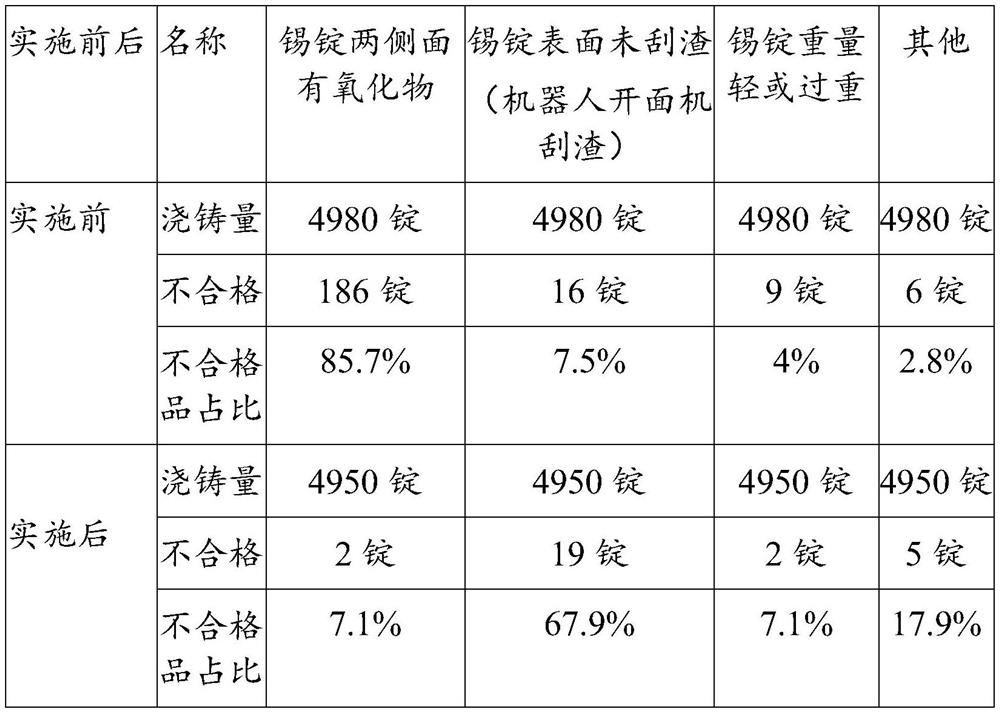

[0047] The casting process of embodiment 1 refined tin ingot

[0048] Put the quantitative pump 8 into the refined tin liquid heat preservation pot, and then connect the liquid injection end bracket 1 with the probe to the linear ingot casting machine. After the casting mold 4 is preheated, start the linear casting machine and start the quantitative pump.

[0049]When the device is used for casting for the first time, because part of the tin liquid pumped by the quantitative pump is blocked by the buffer baffle 7 and remains in the buffer transition box 6, the first casting mold cannot be filled, and the first ingot is used as the Handling of defective products. Afterwards, with the movement of the linear ingot casting mold, the probe on the liquid injection end bracket 1 detects the next empty casting mold and sends a feedback signal to the quantitative pump 8 for a quantitative delivery. From the second quantitative delivery, since the buffer transition box 6 has stored the...

Embodiment 2

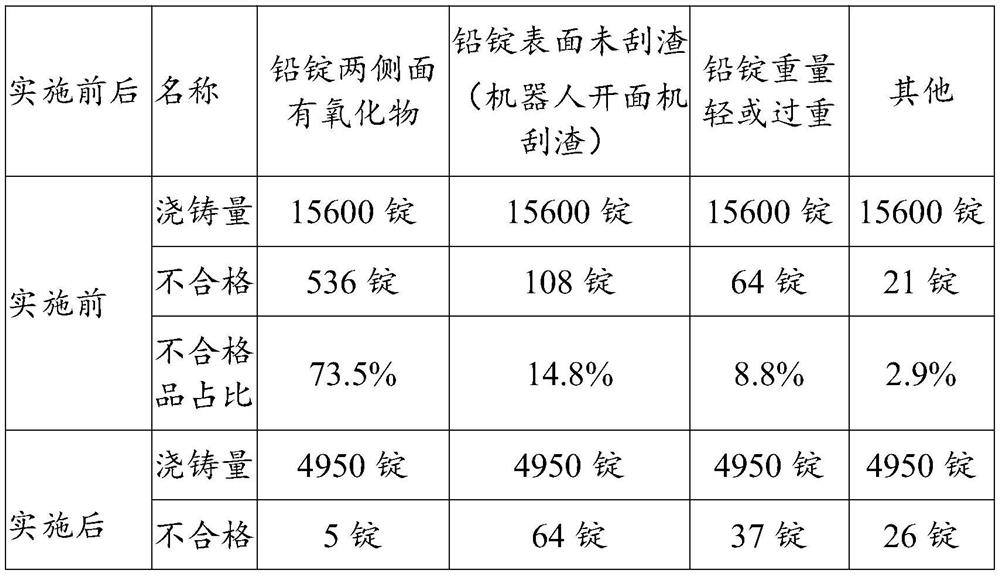

[0052] Example 2: Casting process of refined lead ingot

[0053] Put the quantitative pump 8 into the lead liquid heat preservation pot, and then connect the liquid injection end bracket 1 with the probe to the linear ingot casting machine. After the mold 4 is preheated, start the linear casting machine and start the quantitative pump.

[0054] During the first casting, because part of the lead liquid pumped by the quantitative pump is blocked by the buffer baffle 7 and remains in the buffer transition box 6, the first casting mold cannot be filled, and the first ingot is regarded as unqualified. product processing. Afterwards, with the movement of the linear ingot casting mold, the probe on the liquid injection end bracket 1 detects the next empty casting mold and sends a feedback signal to the quantitative pump 8 for a quantitative delivery. From the second quantitative delivery, since the buffer transition tank 6 has stored lead liquid, the lead liquid entering the transit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com