Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Reduce production load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel method for producing ethanol with potato raw material

InactiveCN101245354AEfficient removalAchieve fermentationBiofuelsFermentationAlcohol productionEvaporation

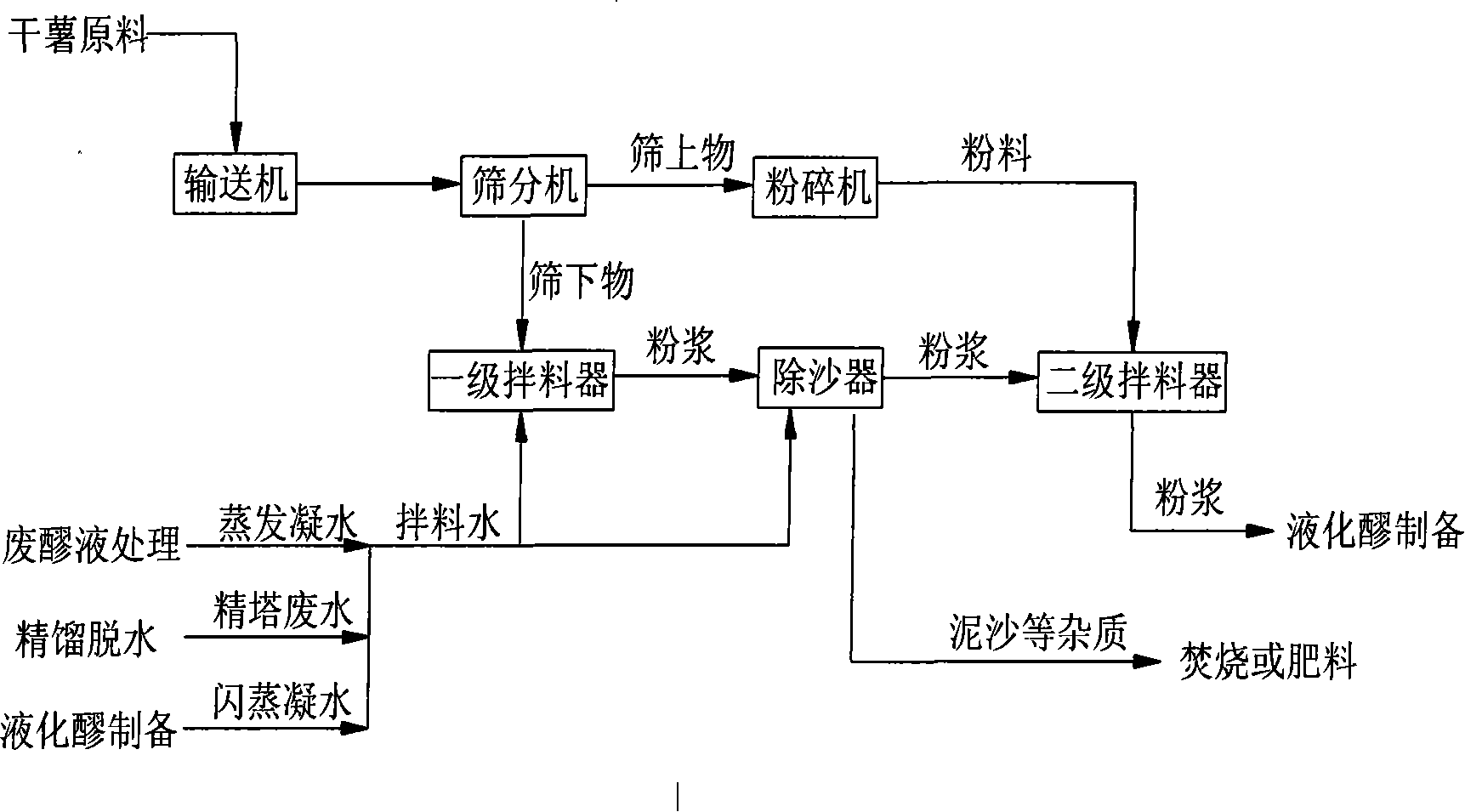

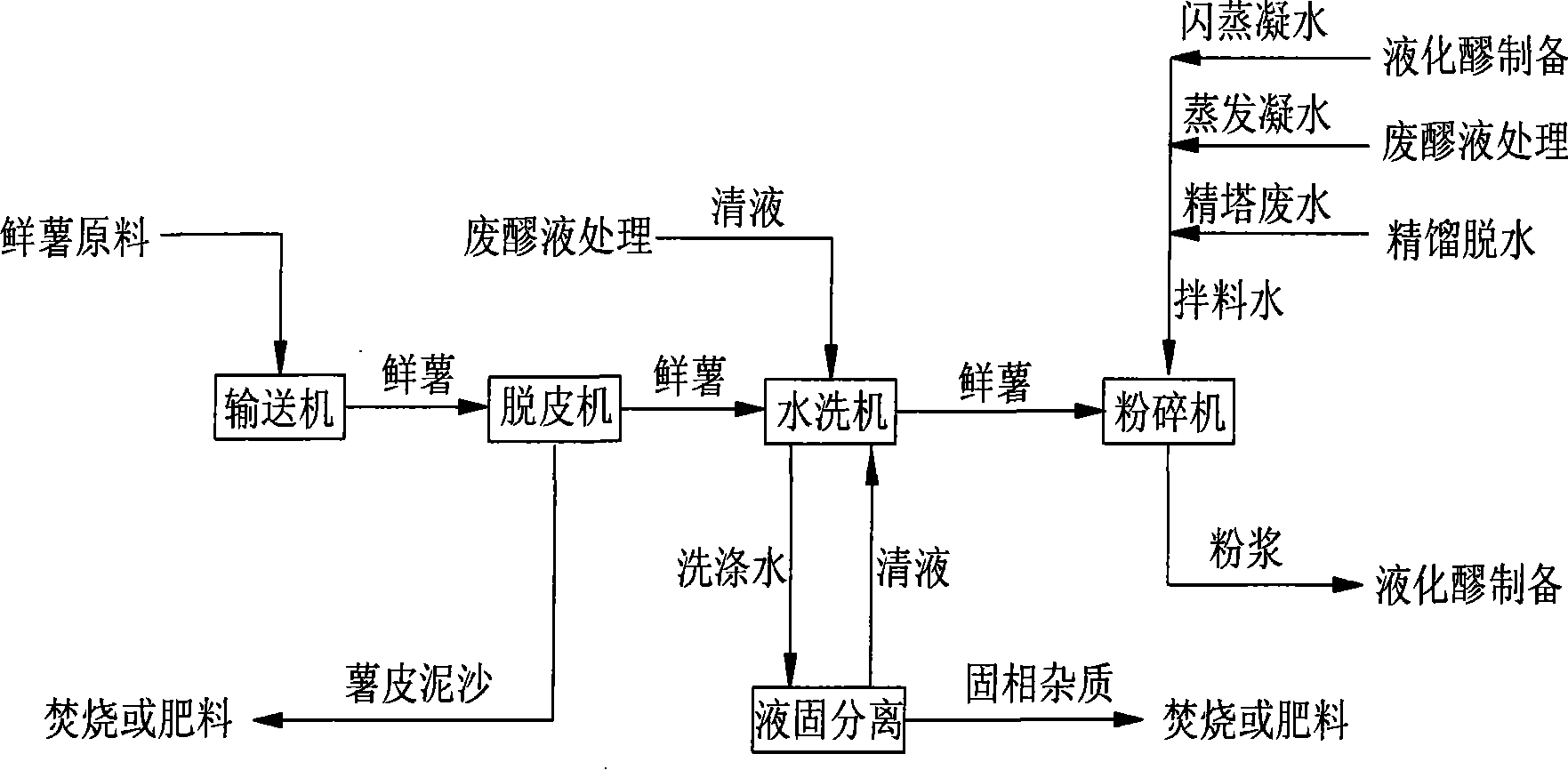

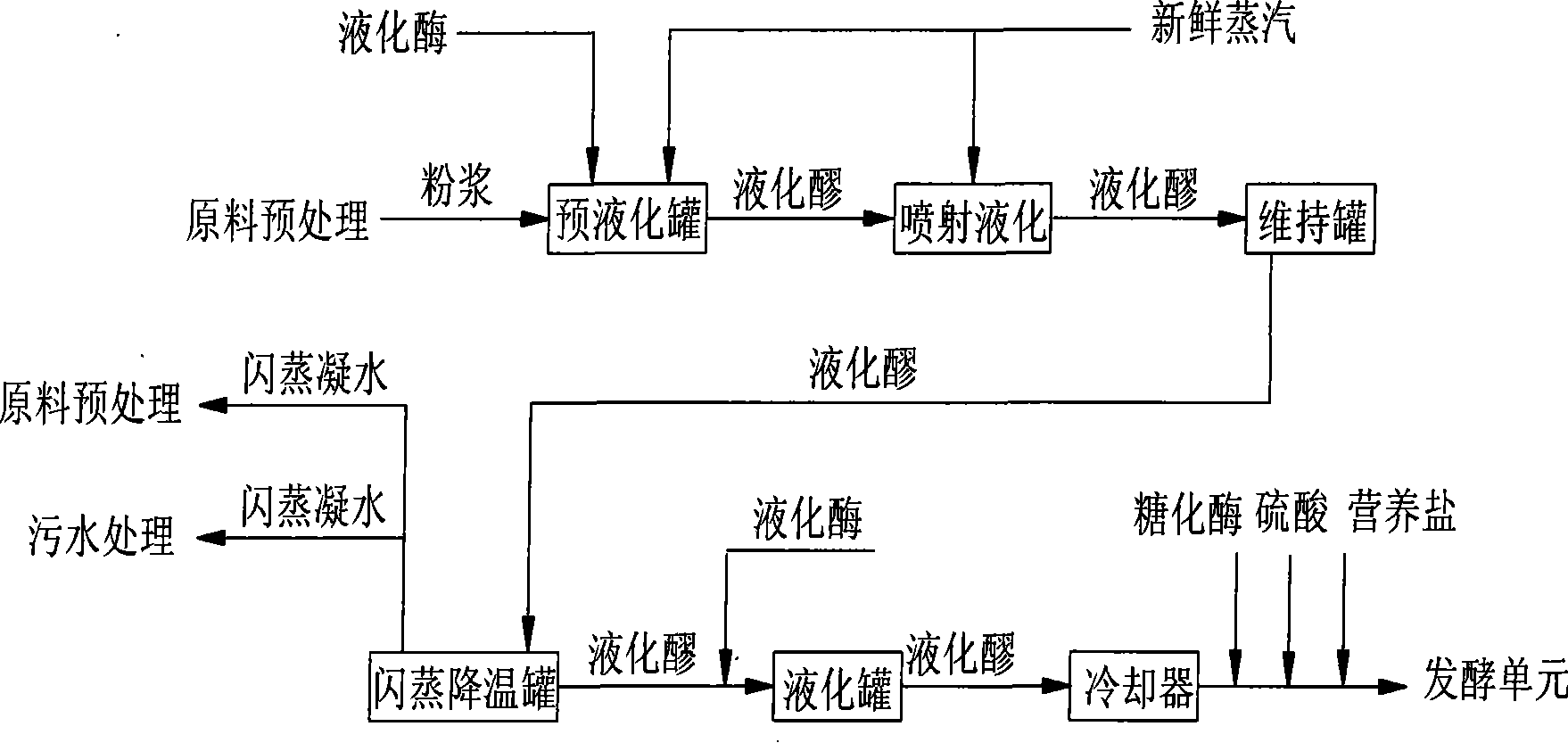

The invention relates to a new method for producing alcohol by using potato raw material, which is mainly characterized in that: the pretreatment process of the raw materials of the dry potato chips adopts the two-level pulp-making production technique, thin pulp with a relatively low viscosity obtained by the level one material stirring and pulp making undergoes sand removing operation process, the thin pulp is subject to the secondary material stirring and pulp making to obtain a thicker powder pulp; a washing water mixture containing potato skins and sands which is drained from a fresh potato raw material water washing machine is separated by a liquid-solid separation device, the obtained clean liquid is returned to the water washing machine for continuous circulating usage; the washing water with the alcohol degree of 5 to 12 percent which is drained from a tower kettle of a CO2 washing tower is arranged to a rectification dehydration unit together with fermented mash after adding base solution, so as to ensure the acid value and the oxidation time of the produced alcohol to be qualified; a part of the clean liquid which is drained when the waste mash of the crude tower passes through the solid-liquid separation device is directly sent to a fresh potato pretreatment unit as the supplementary water of the washing water of the water washing machine for washing the cassava, thus reducing the production load of the evaporation and the concentration of the clean liquid, and the supplementary water of the cleaning water of the water washing machine does not consume other water.

Owner:TIANJIN UNIV

Coking coal pretreatment method and special device thereof

InactiveCN101643657AIncrease productionQuality improvementGas current separationCoke ovensLiquid wastePretreatment method

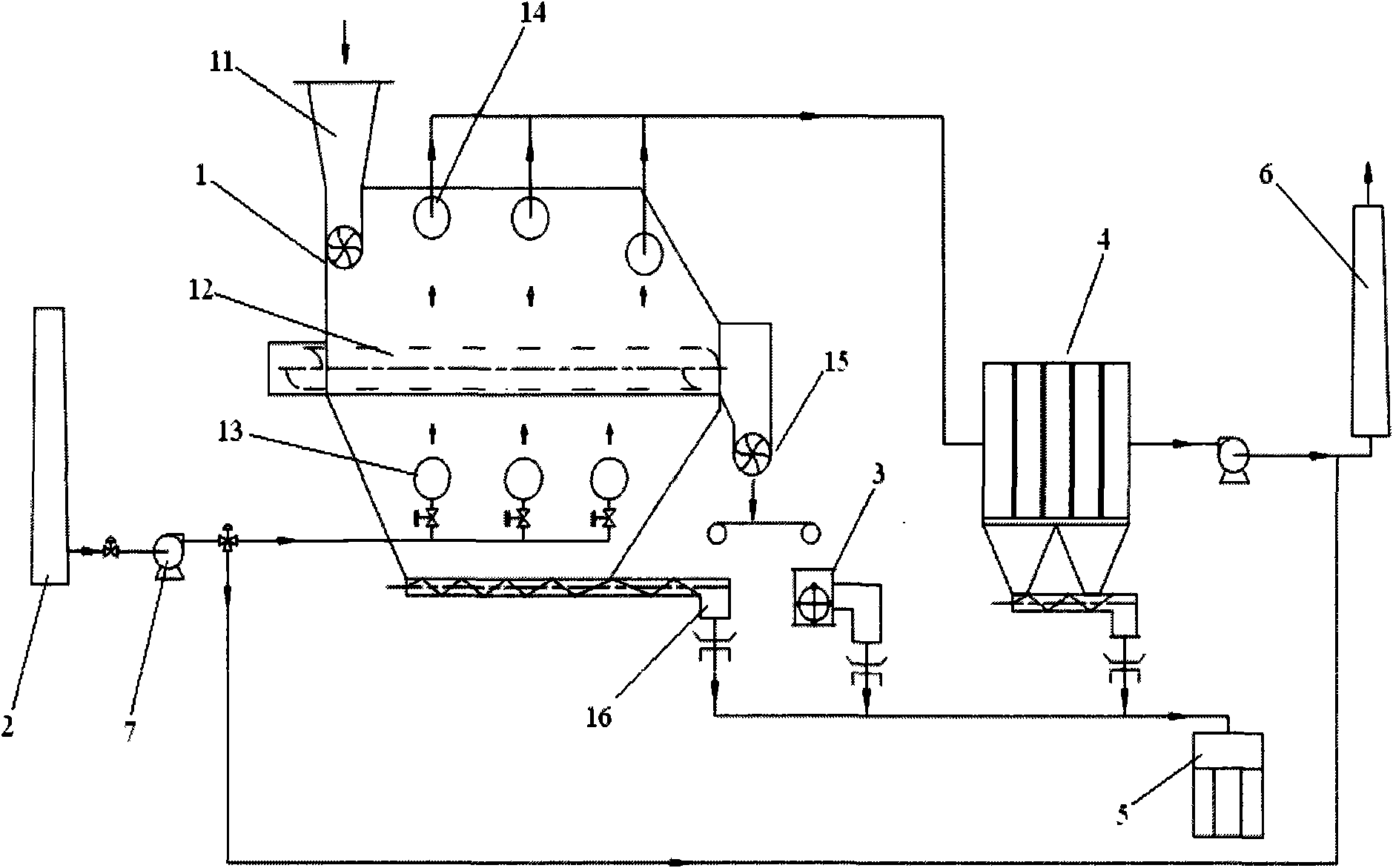

The invention discloses a coking coal pretreatment method and a special device thereof. The coking coal pretreatment method comprises the following steps: transferring blending coal for coking into a humidifying and classifying bed through a feeding device; blowing the blending coal for coking into a fluidization state with waste and heat gas; regulating and controlling moisture; fractionating the blending coal by grain sizes; reducing the moisture content of the bending coal to 6-8 percent with heat gas in the humidifying and classifying bed; dividing the coal into two grain size levels, wherein one grain size level is less than or equal to 3mm, and the other grain size level is greater than 3mm; discharging fine grain coal with a grain size which is less than or equal to 3mm from the humidifying and classifying bed, and transporting the fine grain coal to a pulverizer chamber for pulverization; and transporting the pulverized fine grain coal into a coal tower. The special device comprises the humidifying and classifying bed, a coke oven chimney, the pulverizer, the coal tower and a tail gas treating device. The coking coal pretreatment method can increase the output of a coke oven, improves the quality of the coking coal, reduces the energy consumption of the coke oven and the exhaust of waste gas and waste liquid, is applied to a coal pretreatment technology in a coking industry and can realize the purposes of energy saving, emission reduction and circular economy development.

Owner:袁长胜

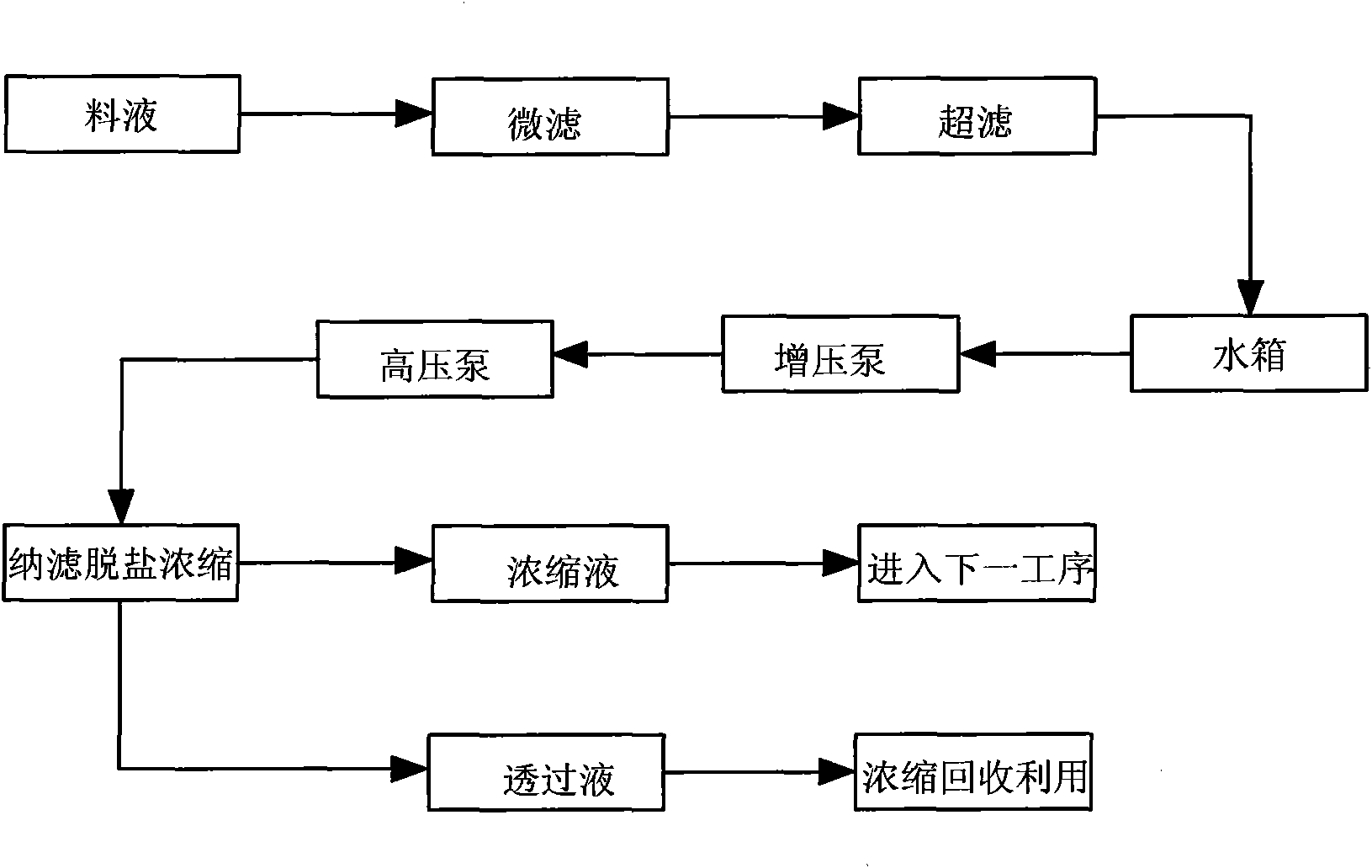

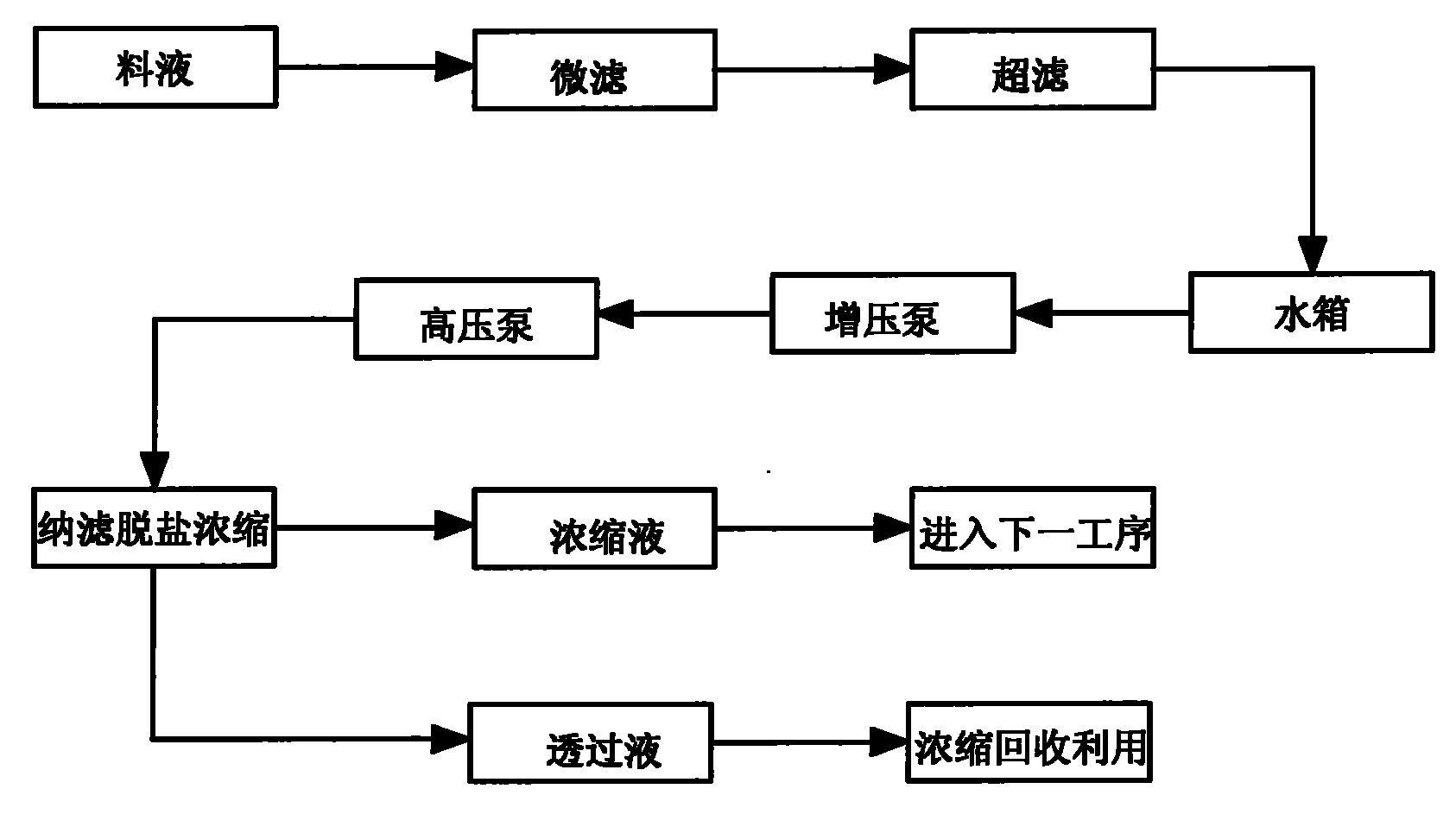

Method for desalination and concentration of medical intermediate

InactiveCN101773786AIncrease contentImprove the economic efficiency of the enterpriseSemi-permeable membranesChemistryAmount of substance

The invention relates to a method for desalination and concentration of a medical intermediate, which not only can simplify the original operational technology, but also can obtain higher purity products, and simultaneously reduces the productive cost of pharmaceutical industries. The method comprises the steps: removing matters such as macromolecular particles, organic matters, colloid and the like in raw material liquid through microfiltration and ultrafiltration, and then carrying out salt leaching and concentration by a nanofiltration constant volume desalination technology, directly drying the desalted concentrated liquor in vacuum or moving to the next process, and finally carrying out the selective recovery according to the economic value of the matters contained in a permeating liquid. The method has the advantages of not only realizing the double effect of desalination and concentration, increasing the content of effective matters, but also being capable of recycling the useful matters in the permeating liquid and increasing the economic benefit.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

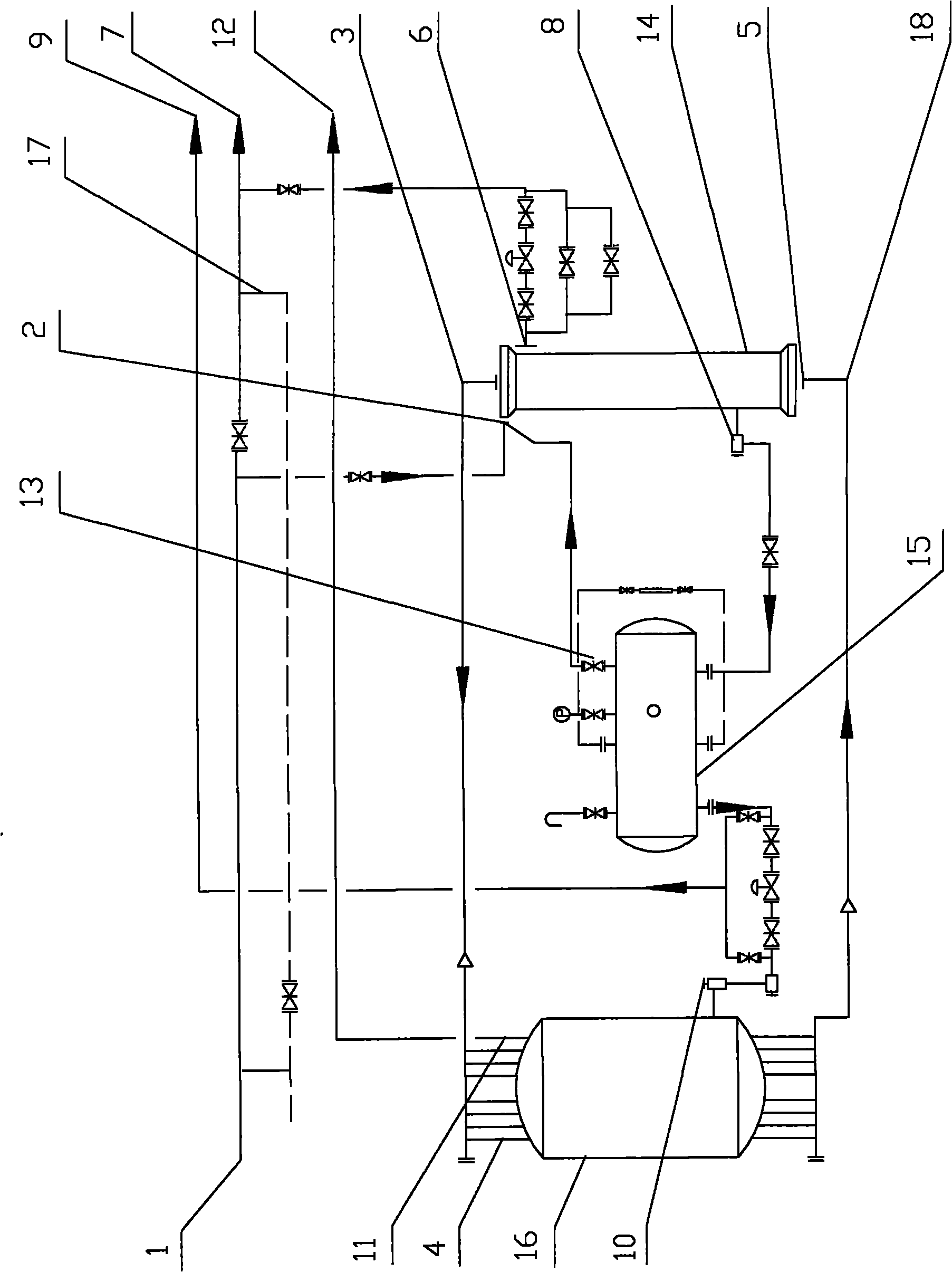

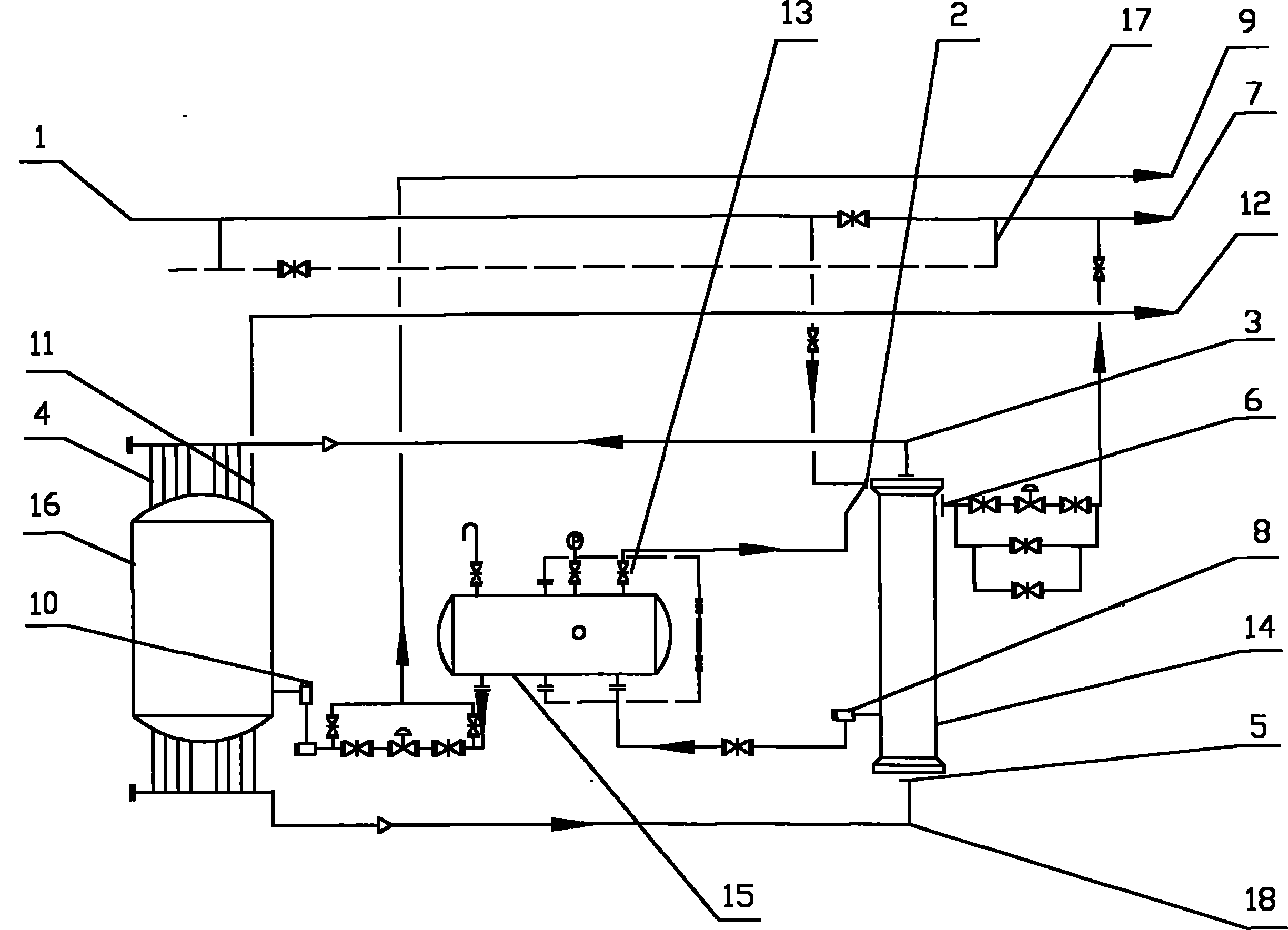

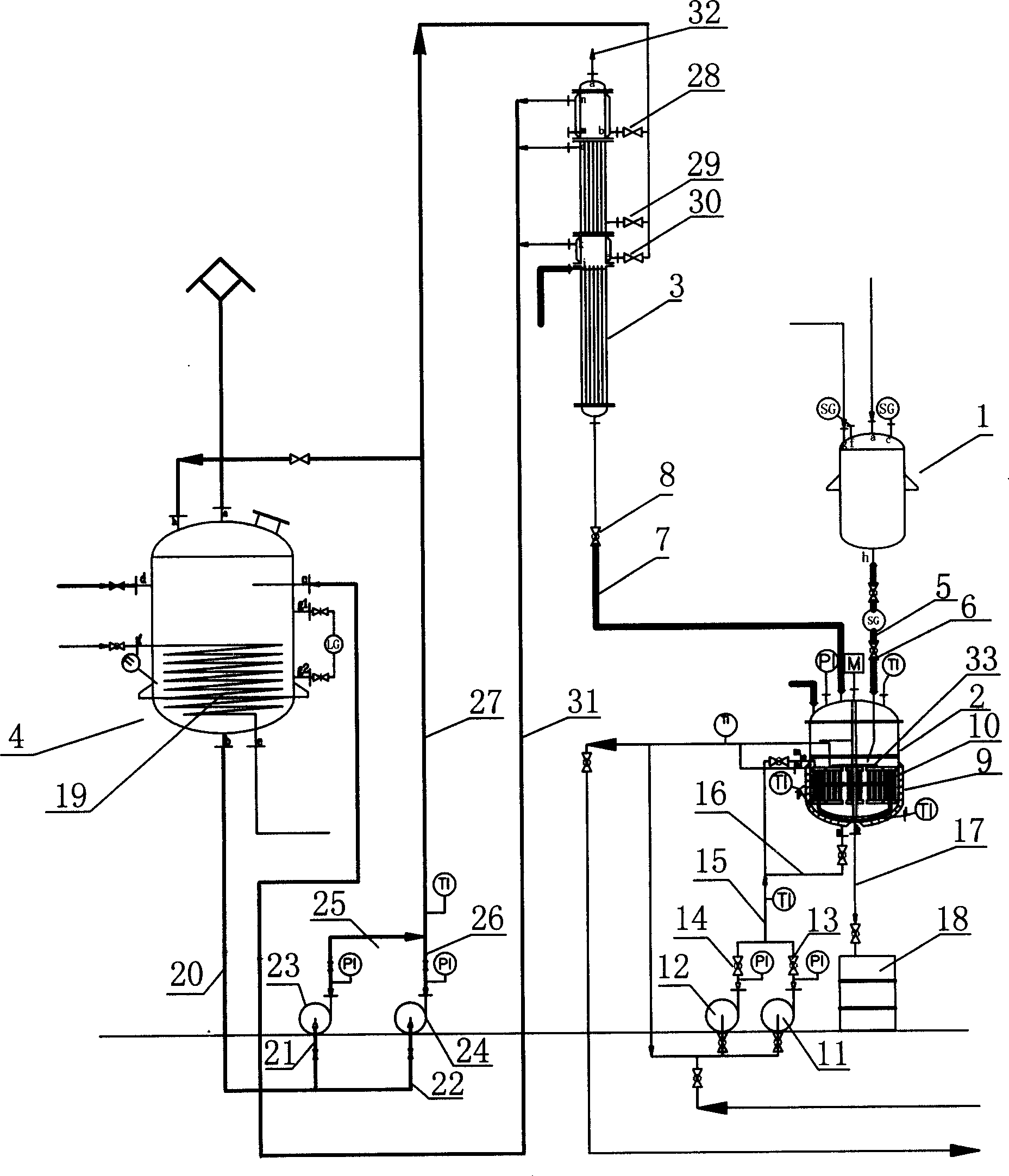

Ammonia-cooled ammonia reclamation method and mating device thereof

InactiveCN101955192AReduce energy consumptionReduce material consumptionAmmonia preparation/separationGas phaseEvaporation

The invention discloses an ammonia-cooled ammonia reclamation method and a mating device thereof. Gas phase ammonia in purge gas is condensed into liquid ammonia by using the principle of ammonia decompressed evaporation and refrigeration, and the separated liquid ammonia is used as a refrigerant for continuously cooling the gas phase ammonia in the purge gas, over and over again. The eliminated high-pressure equipment and pipelines which still can be continuously used in the ammonia synthesis process are used for decompression to form an ammonia-cooled ammonia reclamation device, wherein the device comprises a purge gas pipeline, a cold and heat exchanger, an ammonia evaporation condenser and a liquid ammonia storage tank; and the formed ammonia-cooled separation circulating process in the purge gas is characterized in that: the liquid ammonia prepared from the purge gas is conveyed into the ammonia evaporation condenser and evaporated into gaseous ammonia so as to obtain a large amount of cold energy, and the gaseous ammonia in the purge gas is continuously cooled so as to fulfill the purpose of separating the gas phase ammonia in the purge gas. The device has the advantages of energy conservation, low investment and good usability.

Owner:甘肃金昌化学工业集团有限公司

CO2 gas-striping parallel /serial connection medium-pressure urea energy-saving and yield-increasing novel technology

ActiveCN103819365AThe effect of increasing production is obviousGood energy saving effectUrea derivatives preparationOrganic compound preparationUreaDecomposition

The invention provides a CO2 gas-stripping parallel / serial connection medium-pressure urea energy-saving and yield-increasing novel technology. The conventional CO2 gas-stripping urea technology equipment is parallelly connected to a medium-pressure decomposition system, is serially connected to a medium-pressure pre-separator and an evaporation pre-condensation system, and is added with a medium-pressure methylamine recycling system. In a urea synthesis tower, materials are divided into two parts according to a certain ratio, one part of the materials is transported to the medium-pressure decomposition system and is subjected to processes of flash separation, liquid rectification, thermal decomposition, and CO2 air stripping; the other part of the materials is discharged from a CO2 stripping tower, then is decompressed, and finally is subjected to flash separation in the medium-pressure pre-separator; the urine in the medium-pressure system is decompressed and then transported to a low-pressure rectification tower; the medium-pressure decomposition gas phase and the low-pressure methylamine are mixed and transported to the heat utilization section shell pass of an evaporation pre-condensation device, and the urine in the tube pass is heated to evaporate and thus is condensed by utilizing the heat generated by bubbling reactions. The CO2 air-stripping parallel / serial connection medium-pressure urea energy-saving and yield-increasing novel technology can increase the production capacity by 30 to 60% or more compared to that of original CO2 air-stripping urea device, and has the advantages of simple technology process, convenient operation control, reduction on steam and electricity consumption, and high reconstruction investment profit.

Owner:王庆锋 +1

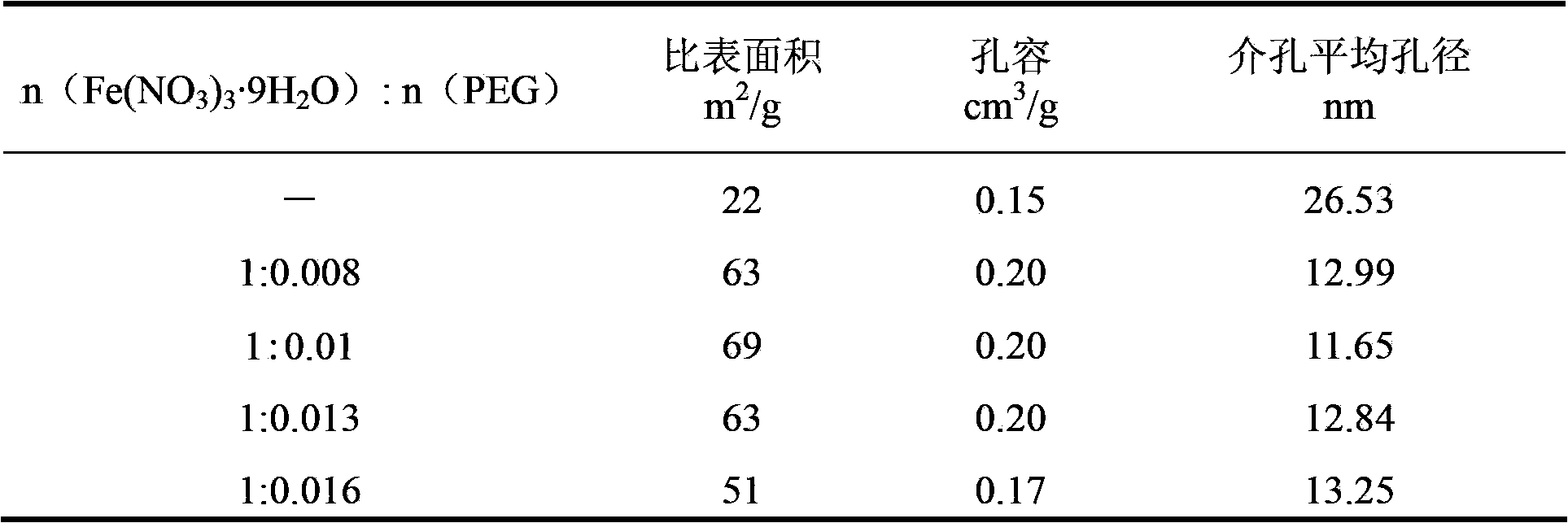

Preparation method of high-efficiency porous iron oxide desulfurizing agent

InactiveCN103418233AIncrease mass transfer rateSimple processDispersed particle separationWater vaporSurface-active agents

A preparation method of a high-efficiency porous iron oxide desulfurizing agent is provided. The method comprises the steps: with Fe(NO3)3.9H2O and an alkali as main reactants and under the action of a surface active agent or polyalcohol as a structure-directing agent, a solid state reaction method is adopted to prepare the porous iron oxide desulfurizing agent for purification of hydrogen sulfide and other typical stench waste gases. The specific surface and the pore structure of the desulfurizing agent can be controlled by the type and the adding amount of the structure-directing agent, the adding amount of the alkali and other factors. The obtained desulfurizing agent shows higher desulfurization performance in a system with a high airspeed and with or without the presence of water vapor, wherein the one-time sulfur capacity can be as high as 26.6% in the presence of the water vapor and is far higher than the sulfur capacity of a current industrial iron oxide desulfurizing agent. At the same time, the solid state reaction method not only has simple process, but also is more environmentally friendly, and greatly reduces the sewage discharge amount and the production load of a subsequent sewage treatment device.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for separating magma in producing soda process

InactiveCN1472139AIncrease production capacityReduce production loadCarbonate preparationSodium bicarbonateSlurry

A process for separating crystal slurry in the production of sodium carbonate includes such steps as synthesizing sodium bicarbonate crystal in carbonizing tower, discharging the crystal slurry, hydraulic cyclone separating, alkali filtering to obtain solid and calcining. Its advantage is low load of alkali filter to increase its productivity by 20%.

Owner:JIANGSU DEBANG CHEMICAL INDUSTRY GROUP CO LTD

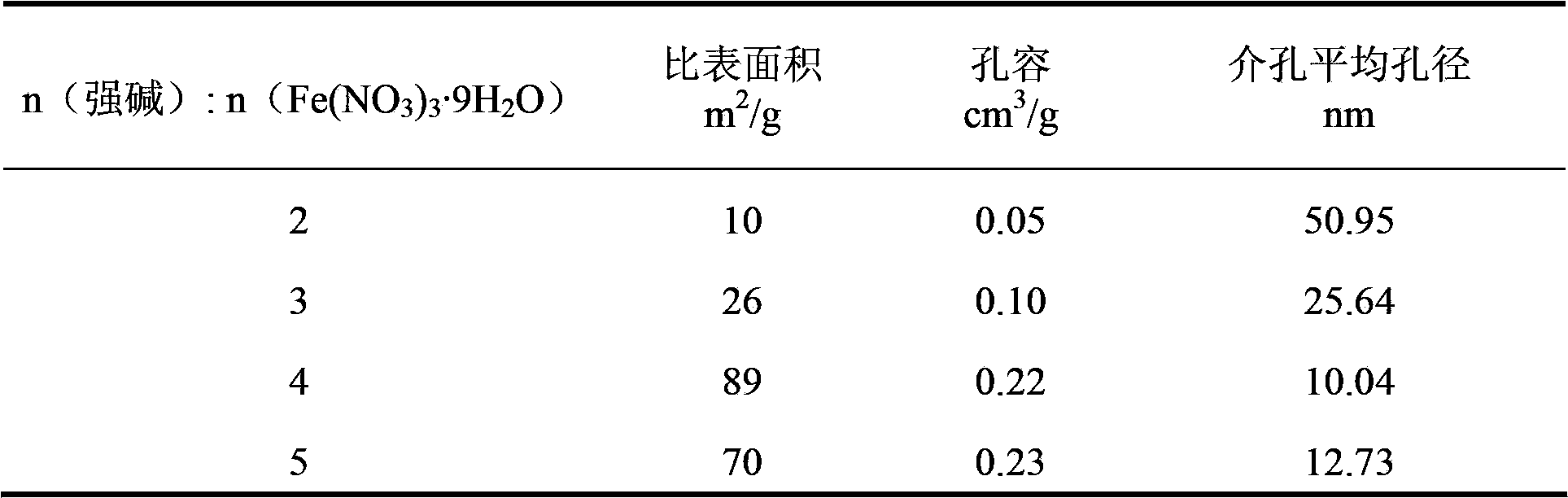

System for producing natural gas by electrolytic hydrogen production and gas synthesis from coal

InactiveCN104531246ALow investment costAddressing the need for high-purity hydrogenGaseous fuelsElectrolysisMethanation

The invention relates to a system for producing natural gas by electrolytic hydrogen production and gas synthesis from coal. The system comprises a coal preparation unit, wherein the coal preparation unit is connected with a gasification furnace, a crude coal gas outlet of the gasification furnace is connected with an inlet of a first absorption tower, a main circuit of a first absorption tower outlet is connected with a low temperature methanol washing unit through a conversion unit, an auxiliary circuit of the first absorption tower outlet is connected with a power plant, and the electric energy is directly supplied to an electrolytic water hydrogen production unit; a circulating sewage outlet of the gasification furnace is connected with the electrolytic water hydrogen production unit through a second absorption tower, a hydrogen outlet of the electrolytic water hydrogenation unit is connected with a methanation unit after being combined with a low temperature methanol washing unit outlet, and an oxygen outlet of the electrolytic water hydrogen production unit is connected with a corresponding device. By adopting the system, not only can the requirement of high-purity hydrogen for the reduction of methanation catalyst be met, but also the hydrogen-carbon ratio in the synthesis gas of a conversion working section can be supplemented by adopting the hydrogen with relative high purity, the load produced by the conversion working section in the conventional coal natural gas process can be reduced, and the utilization rate of carbon can be increased.

Owner:HUANENG CLEAN ENERGY RES INST +1

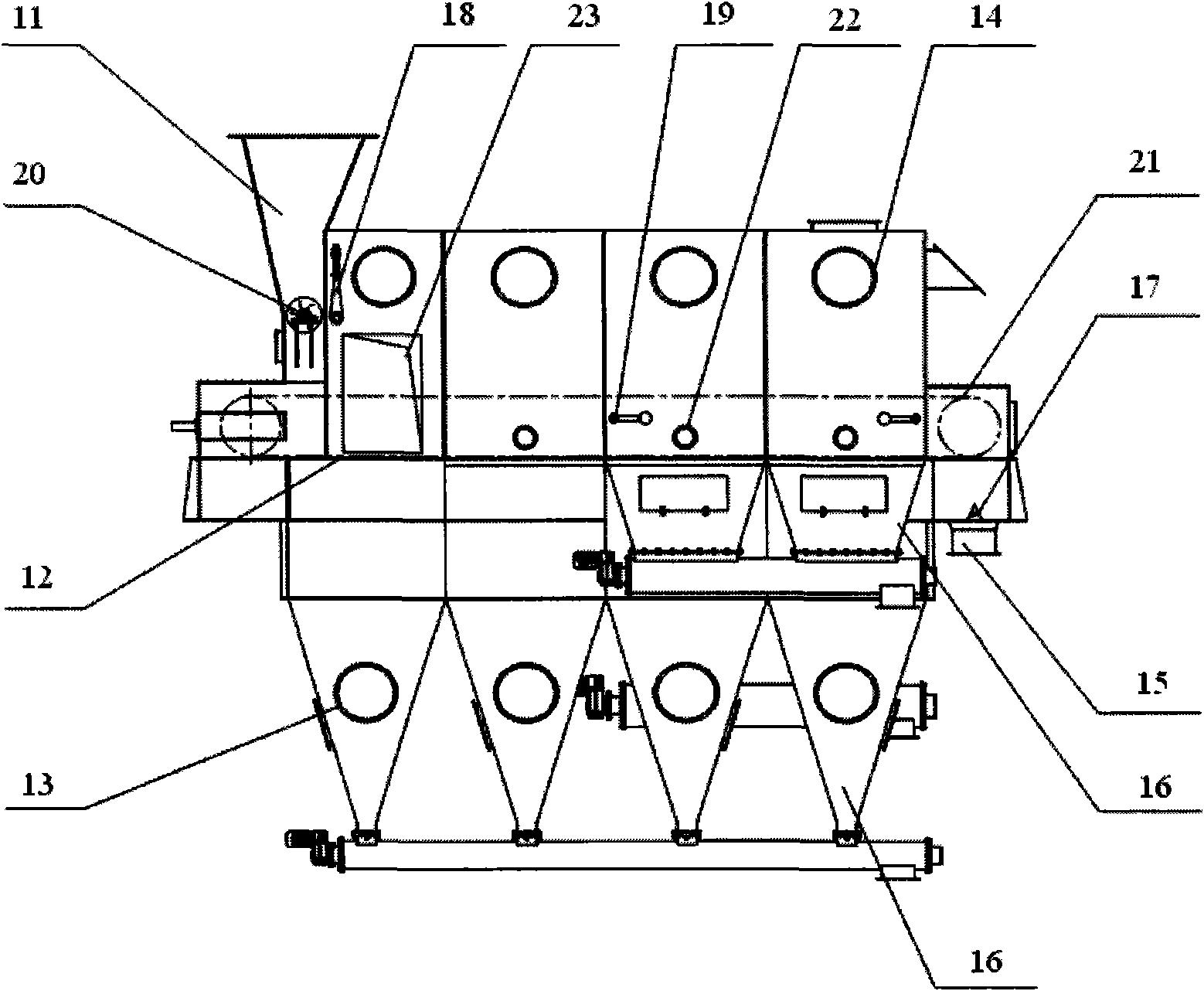

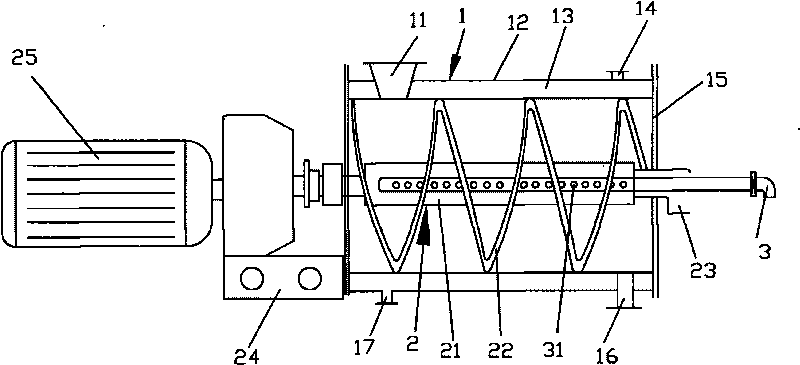

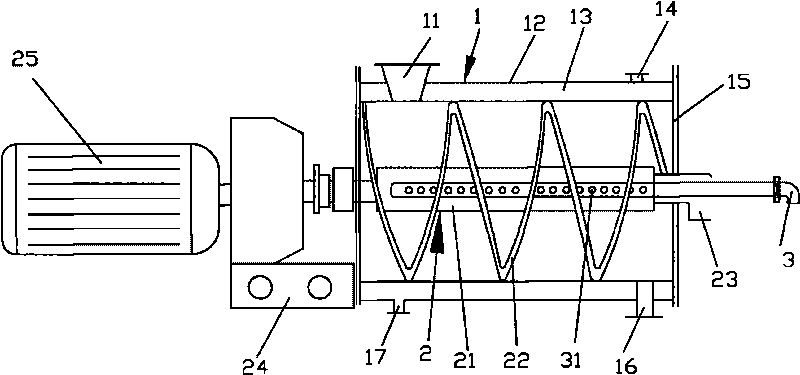

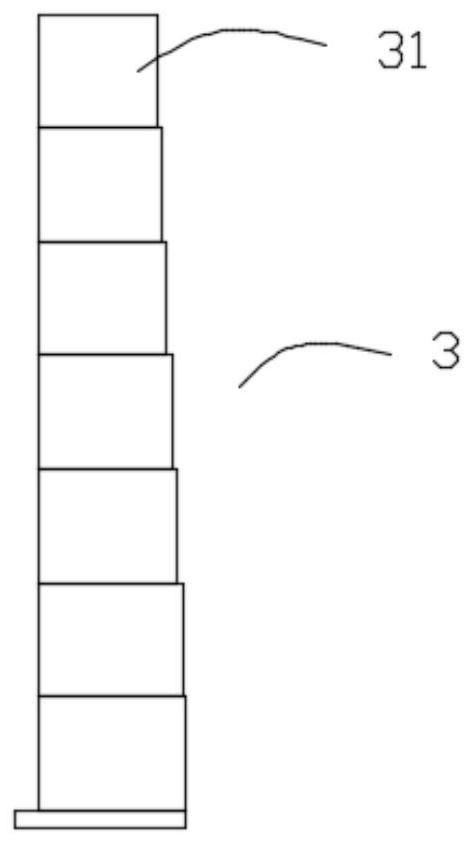

Production technology for bakelite powder and pre-thermoplastic machine thereof

The invention discloses production technology for bakelite powder and a pre-thermoplastic machine thereof. The production technology comprises the steps of: mixing component raw materials, crushing the mixture into powder, stirring the powder uniformly, and adding the powder into an open type plastic purificating set for rubber mixing. The production technology is characterized by adding the powder which is stirred uniformly into a sealed pre-thermoplastic machine for preheating first to make the powder change into slightly fused particles and blocks, and then conveying the particles and blocks to the open type plastic purificating set for rubber mixing. The production technology and the pre-thermoplastic machine thereof effectively solve the problem that a conventional process has flying dust during the rubber mixing of the open type plastic purificating set further to seriously pollute the environment for a long time; and at the same time, the production technology makes a pre-thermoplastic working procedure of a powder raw material which is originally performed in a high-power open type plastic purificating set separated and performed in the pre-thermoplastic machine with a low-power sealing state in advance, which not only greatly reduces the production load of the high-power open type plastic purificating set, but also improves heat utilization rate and thermal efficiency, reduces production energy consumption, and improves production efficiency.

Owner:湖州美卡科技有限公司

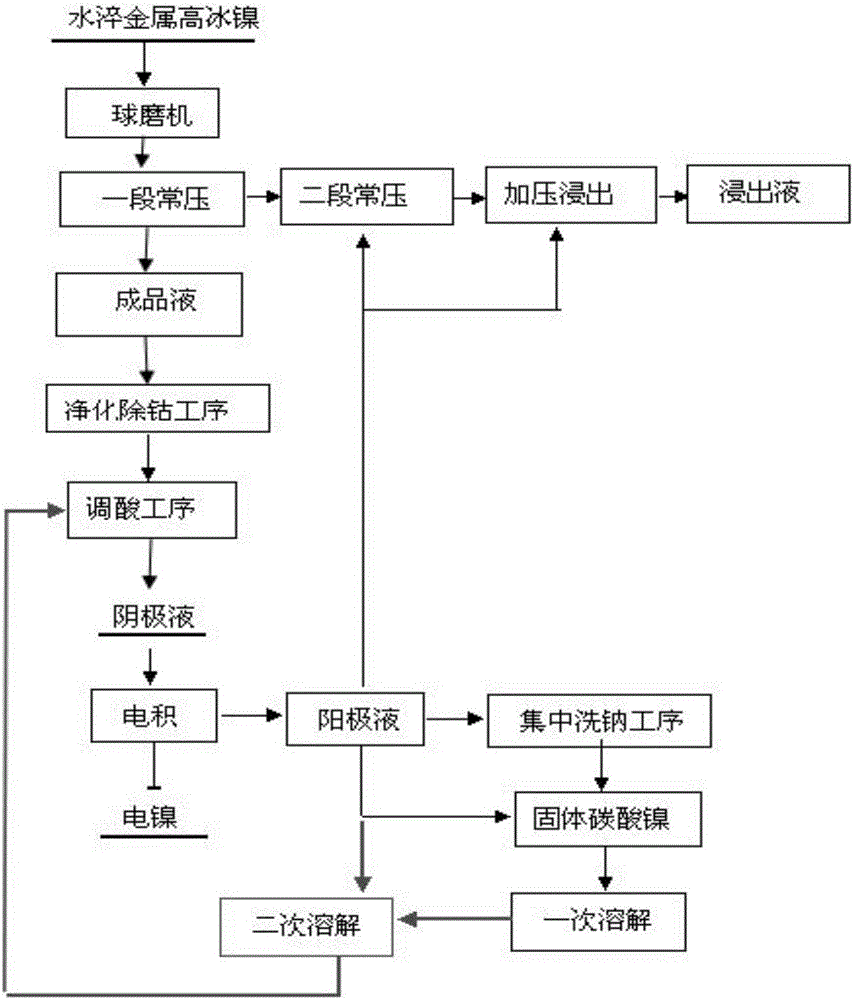

Wet process preparation technique of nickel

ActiveCN106756101AIncrease productionLow cycle costPhotography auxillary processesProcess efficiency improvementPregnant leach solutionNickel deposition

The invention discloses a wet process preparation technique of nickel. The technique comprises the steps that water quenching is conducted on metallized high-nickel matte; ball milling is conducted, deposition is conducted through a thickener, first-section normal pressure is applied, first-section leaching liquid, namely the finished liquid, is subjected to cobalt removal through NIOOH prepared through electrooxidation, purified cobalt-removed post-liquid is obtained through liquid-solid separation, acid adjustment is conducted for electrodeposition, and electro nickel is obtained; and electrodeposition post-liquid is subjected to sodium washing and nickel deposition so that Na+ in a solution can be removed, then anode liquid is mixed with NiCO3 to prepare cathode liquid, then the cathode liquid and the cobalt-removed post-liquid are mixed, subjected to acid adjustment and directly subjected to electrodeposition, and the electro nickel is obtained. The anode liquid and nickel return liquid are converted into the cathode liquid, so that the step that the anode liquid returns to a leaching system is omitted, an original complex and lengthy circulation path is replaced by internal short-path circulation, the circulation cost of the solution is greatly reduced, the yield of the cathode liquid is increased, production loads of a grinding and leaching plant are relieved, and meanwhile, the acid amount of the system can be balanced.

Owner:新疆新鑫矿业股份有限公司

Novel method for recycling ammonia synthesis cold energy in synthetic ammonia system

ActiveCN103754894ASolve overpressureFix security issuesAmmonia preparation/separationAmmonia storageEngineering

The invention discloses a new method for recycling ammonia synthesis cold energy in a synthetic ammonia system. The method comprises the following steps that gas ammonia delivered by an ice maker is condensed into liquid ammonia via a condenser; the liquid ammonia enters an ammonia storage tank condenser to exchange heat with liquid ammonia discharged from the synthetic ammonia system; the liquid ammonia subjected to heat exchange enters a liquid ammonia storage tank for supplying ammonia to a synthetic ammonia cooler; the liquid ammonia discharged from the synthetic ammonia system is for downstream user use after being reheated. The method disclosed by the invention has the advantages that the problems that the ammonia storage tank in the refrigerating process of a synthetic ammonia device in summer production is overpressured and the environment is polluted by the gas ammonia discharged into the atmosphere are solved; the steam consumption of a steam turbine for driving the ice maker is reduced; the production is stabilized; the benefit is increased.

Owner:GNSG ANHUI HONG SIFANG

Method for reducing acid content of dimethyldichlorosilane hydrolysate

ActiveCN106397474AProportionally largeRealize green and clean productionSilicon organic compoundsHydrolysateChloride

Belonging to the field of chemical engineering, the invention relates to a method for reducing the acid content of a dimethyldichlorosilane hydrolysate. The method includes the steps of: (a) subjecting the dimethyldichlorosilane hydrolysate and a calcium chloride aqueous solution to countercurrent mixing and washing; (b) then continuously contacting the hydrolysate with a hydrochloric acid mass fraction gradually reduced aqueous phase, and performing full washing. On the basis of washing, the method provided by the invention introduces calcium chloride to increase the proportion of the hydrolysate and water, realizes rapid layering of the two, avoids emulsification phenomenon during washing, and improves the washing and acid removing effects. In addition, the method provided by the invention significantly reduces the consumption of washing water and lowers the production load, and the calcium chloride can be recycled, thus achieving green and clean production.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

Integral front door lock body assembly

InactiveCN106522698AIncrease the function of electric door openingPrevent escapePower transmission/actuator featuresElectrical locking actuatorsEngineeringTorsion spring

The invention discloses an integral front door lock body assembly. The integral front door lock body assembly comprises a lock body sub assembly, a lock shell sub assembly and an automatic open connecting sub assembly; the lock body sub assembly includes a lock body and a cover plate; the lock shell sub assembly includes a copper piece mounting plate, a copper piece and a shell cover; and the automatic open connecting sub assembly includes an electric door opening torsion spring shell, a gear A and an electric door opening motor. The integral front door lock body assembly adds a vehicle door electric opening function, an inner open double-pull function, a terrified lock function, a super lock function, a super lock mechanical wrong lock preventing function, an outer lock instant signal, a door lock half-open signal, a door lock full-open signal and a lock state signal, is compact in structure, prevents both dust and water, is high in transmission efficiency, and is higher in popularization and application values.

Owner:HAOYUE AUTOMOBILE SAFETY SYSTEM TECHNOLOGY LIMITED BY SHARE LTD

Catalytic cracking method for preparing N-(3-dimethylamino propyl) methacrylamide

InactiveCN101362706AStable working conditionHigh yieldOrganic compound preparationCarboxylic acid amides preparationHeat conductingCirculating pump

The invention discloses a catalytic cracking method for preparing N-(3-dimethylaminopropyl) methacrylamide, which comprises the steps that: an intermediate raw material of N-dimethylin-Beta-dipropylamino acrylamide and a catalyst of calcium nitrate are mixed and put into a reaction kettle, with the mixture ratio of the raw material to the catalyst to be 25:1 to 50:1; with the mixture ratio of the raw material to the catalyst to be 1000:0.5 to 1000:1, materials of certain quantity are sent to a high-post dripping tank by a storage-tank pump and dripped into a catalytic cracking reaction vessel at a stable speed when the pressure is reduced to the vacuum degree of 10mmHg and the temperature is raised to 220 DEG C, so that the concentration of the catalyst in the reaction vessel is kept basically stable in the reaction course; a hot water circulating pump is started to keep the returning temperature of the circulating hot water equal to or lower than 105 DEG C; a heat conducting oil heating system is started so that the temperature of the material in the reaction vessel increases to 220 DEG C; gaseous reacting materials are sent from the reaction vessel to a partial condenser; the cooled materials are sent out from the top of the partial condenser and enter into next process. With the same equipment parameters, the catalytic cracking method of the invention improves the production capacity of equipment and product yield rate and reduces energy consumption.

Owner:SHENYANG WANHATE CHEM

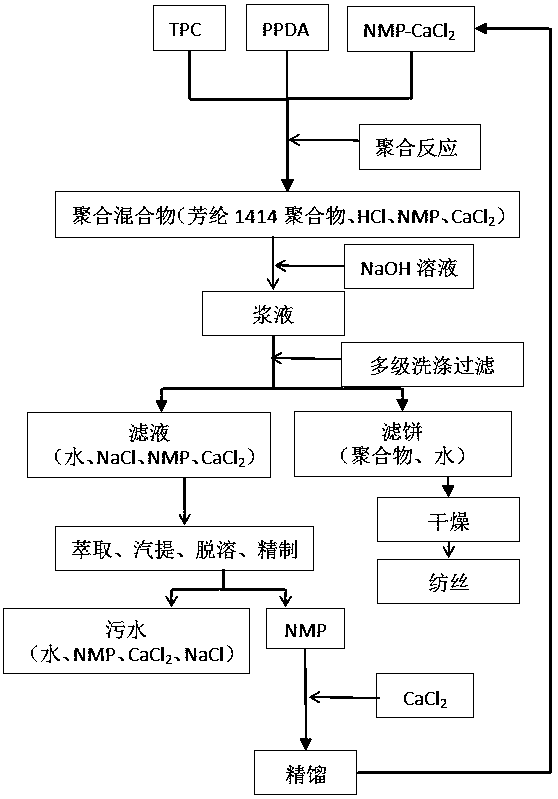

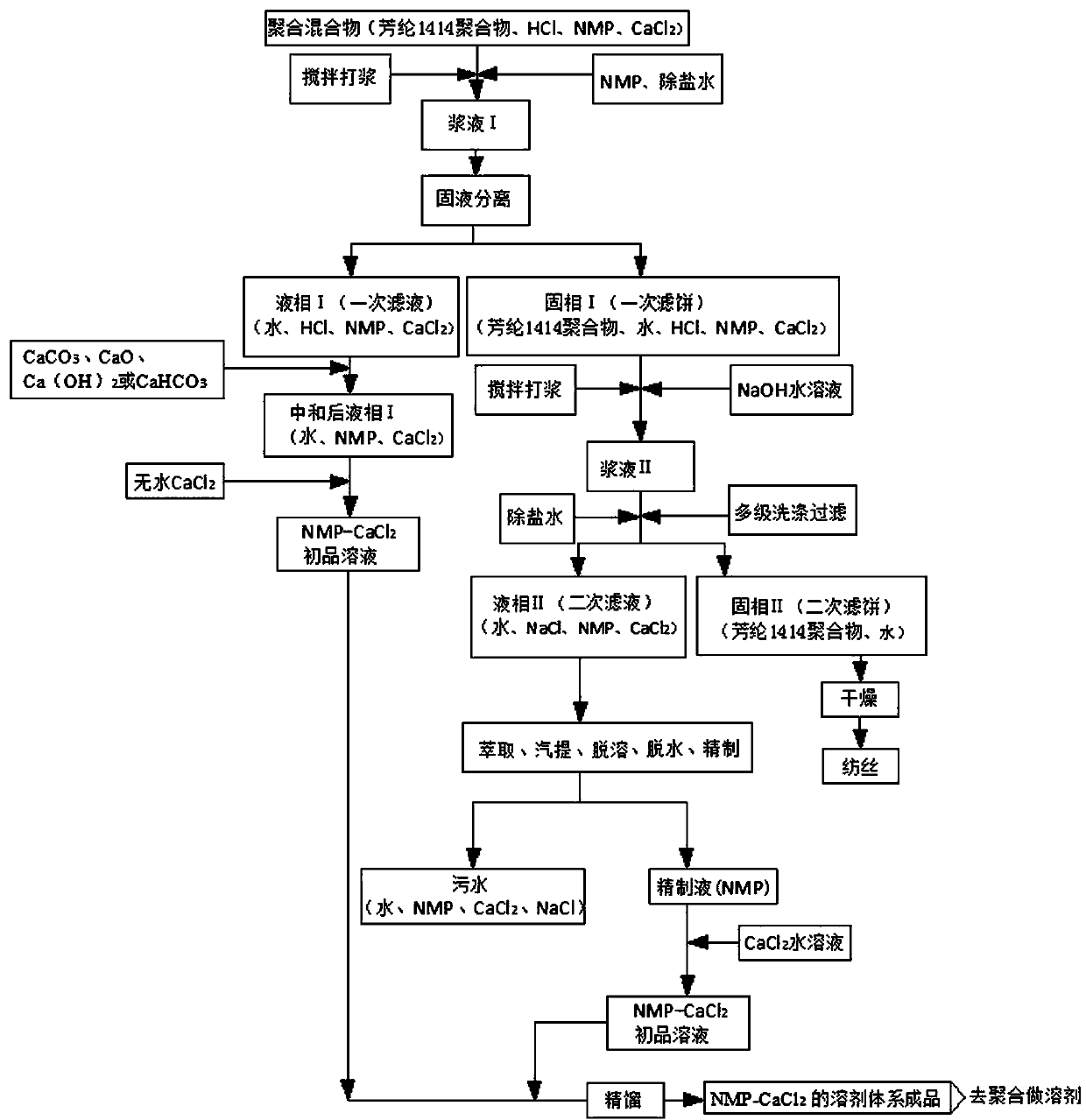

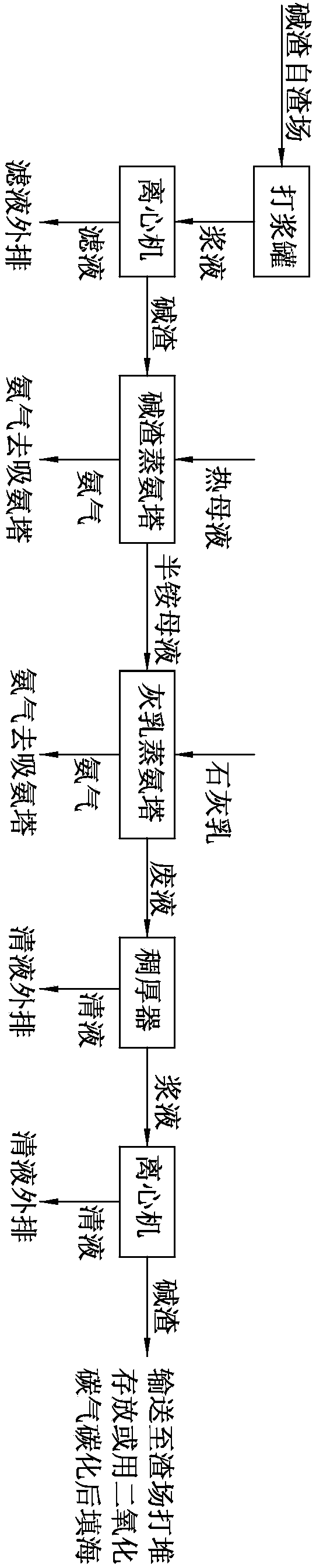

Polymerization solvent system recovery process in aramid fiber 1414 production

ActiveCN111534891AReduce chloride ionCalcium ion decreasedArtificial filament recoveryTextile/flexible product manufacturePyrrolidinonesAramid

The invention discloses a polymerization solvent system recovery process in aramid fiber 1414 production, and belongs to the technical field of high-molecular polymer production. In the technical scheme, through the work procedures of twice neutralization, twice pulping, extraction, steam stripping, refining and the like, para-aramid polymers are washed and purified; in addition, auxiliary agentsof calcium chloride and solvents of N-methyl pyrrolidone used in the production are recovered and are repeatedly utilized; the cyclic economy is formed; meanwhile, the chloride ion content in the discharged sewage is effectively reduced; the environment-friendly requirements are better met; and the environment-friendly and economic effects are achieved.

Owner:BLUESTAR CHENGDU NEW MATERIALS

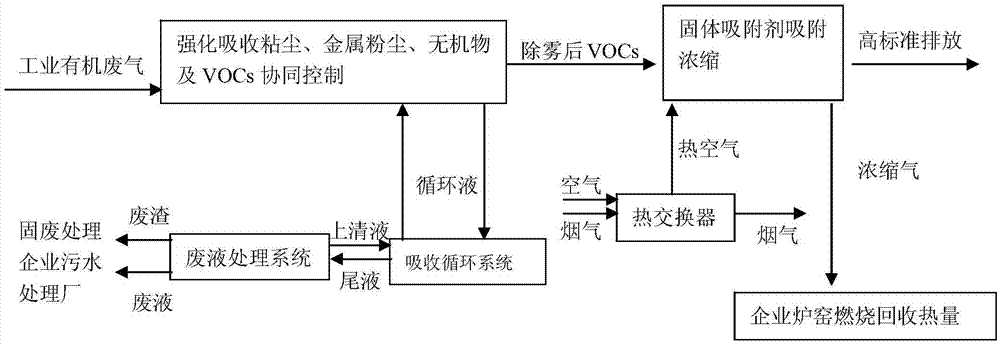

New deep purification process of organic waste gas, and applications of new deep purification process in treatment of industrial organic waste gas

InactiveCN106975334APollution Control and TreatmentLarge specific surface areaGas treatmentDispersed particle separationParticulatesTime efficient

The invention discloses a new deep purification process of organic waste gas, and applications of the new deep purification process in treatment of industrial organic waste gas. According to the present invention, through the integrated innovation of an efficient liquid absorption method and a solid adsorption method, the efficient synergistic purification of particulate matters, VOCs and multiple pollutants is achieved; the concrete principle is that most of the VOCs in waste gas are subjected to absorption removal by using an efficient liquid absorbent through a like dissolves like principle and other principles while the vast majority of particulate matters are removed through washing, most of water is removed from the purified waste gas through a demister, the water removed waste gas enters an adsorption section, and the VOCs in the waste gas is subjected to adsorption removal so as to achieve the standard discharging; and with the previous section absorption process, the bonding and the clogging of the subsequent section adsorption equipment can be prevented, the production load can be reduced, the long-time efficient and stable running can be ensured, and the double efficient synergistic control of the multiple pollutants in the method and between the methods can be achieved; and the new deep purification process has advantages of high VOCs removal efficiency and flexible process selection, and is suitable for the treatment of industrial organic waste gas.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Method for microwave pre-roasting and submerged arc furnace combined production of manganese-iron alloy

Belonging to the technical field of microwave metallurgy and manganese-iron alloy smelting, the invention relates to a method for microwave pre-roasting and submerged arc furnace combined production of manganese-iron alloy. The method includes: crushing manganese ore and a carbonaceous reducing agent, then mixing them evenly to obtain a mixed material; pre-roasting the mixed material under microwave condition to obtain a hot material; and then placing the obtained hot material into a submerged arc furnace, adding coke and conducting heating in the submerged arc furnace to 1450-1550DEG C to perform smelting, thus obtaining the manganese-iron alloy. In the microwave pre-roasting process, microwave heating can be carried out in a microwave shaft furnace. The method has short production cycle and low energy consumption, and can properly solve various harmful phenomena caused by charging of cold materials into the furnace.

Owner:KUNMING UNIV OF SCI & TECH

Recovery and treatment method for alkali residues produced in soda ash production

ActiveCN108483461AReduce the amount of solidsReduce production loadSilicaTransportation and packagingLiquid wasteChemical reaction

The invention discloses a recovery and treatment method for alkali residues produced in soda ash production. The recovery and treatment method comprises the following steps: (1) subjecting alkali residues to separation and dehydration, then subjecting the alkali residues and hot mother liquor to an ammonia distilling reaction in an ammonia distilling tower, controlling the pH value of liquid in the ammonia distilling tower to be 9.0 or below, and maintaining excess ammonium chloride in the mother liquor; (2) conveying semi-ammonium mother liquor obtained after ammonia distillation of the mother liquor in the step (1) to another ammonia distilling tower, and adding lime milk for ammonia distillation, wherein 0.13-0.19 m<3> of the lime milk is added into each cubic meter of the semi-ammoniummother liquor, and ammonia distillation is continued until the ammonia index of waste liquid in the tower is less than 50 mg / l; and (3) subjecting the waste liquid of secondary ammonia distillation to solid-liquid separation, dehydrating the alkali residues and conveying ammonia gas distilled from the tops of the ammonia distilling towers in two ammonia distillation operations to an ammonia absorption tower for recovery. According to the treatment method for the alkali residues in the invention, after the alkali residues are subjected to the secondary ammonia distillation reaction, about 80-85% of the solid has been involved in the chemical reaction; and after dehydration, the amount of the solid (wet basis) is reduced to less than 12.3% of the amount of the solid before ammonia distillation.

Owner:山东海天生物化工有限公司

Bromelain production method

The invention discloses a bromelain production method which includes the steps: firstly, cleaning; secondly, crushing; thirdly, squeezing juice; fourthly, performing two-stage centrifugation; fifthly, performing ceramic membrane microfiltration; sixthly, performing ultrafiltration and concentration; seventhly, drying. According to the bromelain production method, two-stage centrifugation of the squeezed pineapple juice is achieved, purity of clarification pineapple juice is improved, microfiltration pressure is reduced, ceramic membrane microfiltration is performed, high rejection of living bacteria under the physical state is achieved, downstream enzyme clear solution with high clarity is separated, production load of a downstream concentration process is reduced, part of pigment and impure protein are removed by the aid of ultrafiltration and concentration, quality and stability of products are improved, ultrafiltration and concentration are performed at normal temperature, enzyme activity is not lost, and bromelain yield is improved.

Owner:HEFEI XINDA MEMBRANE TECH

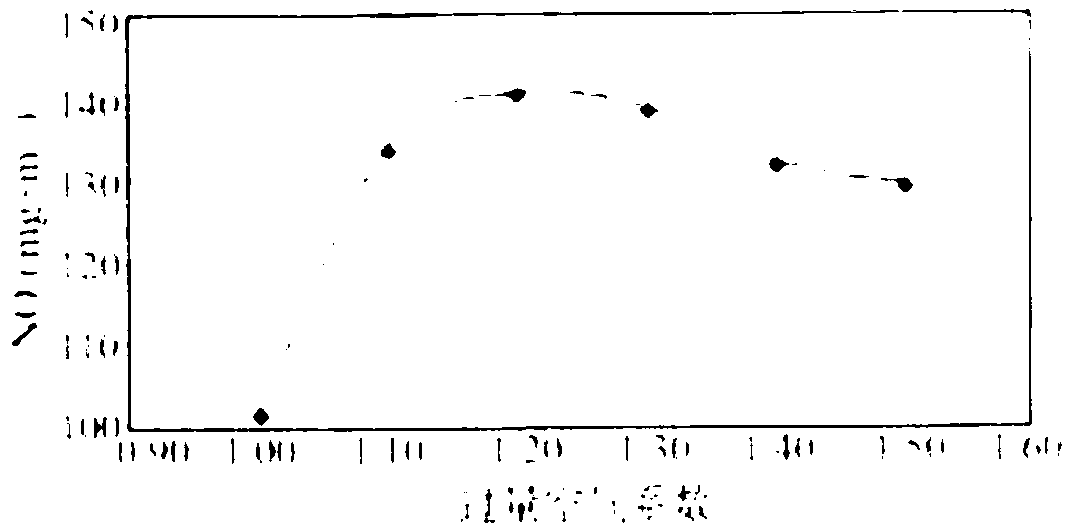

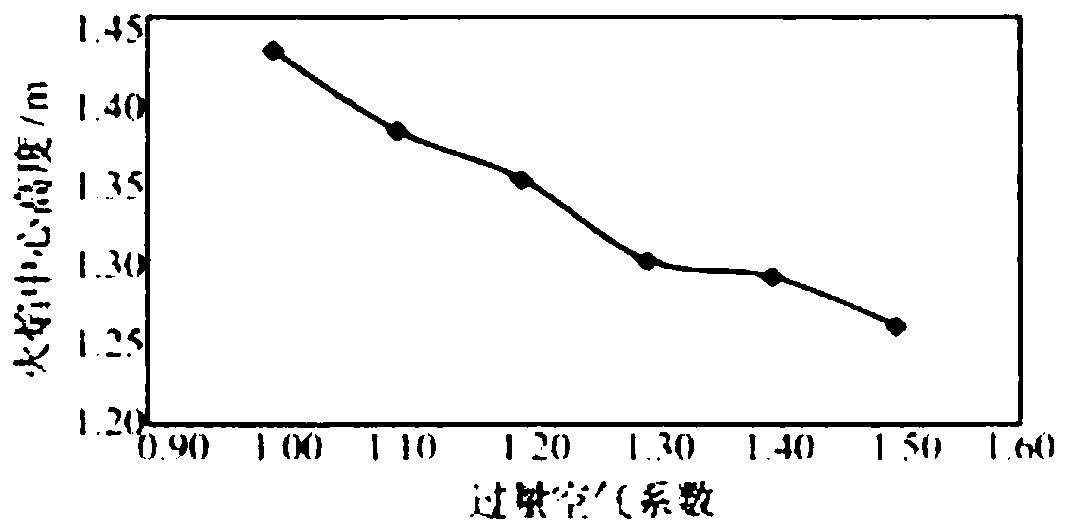

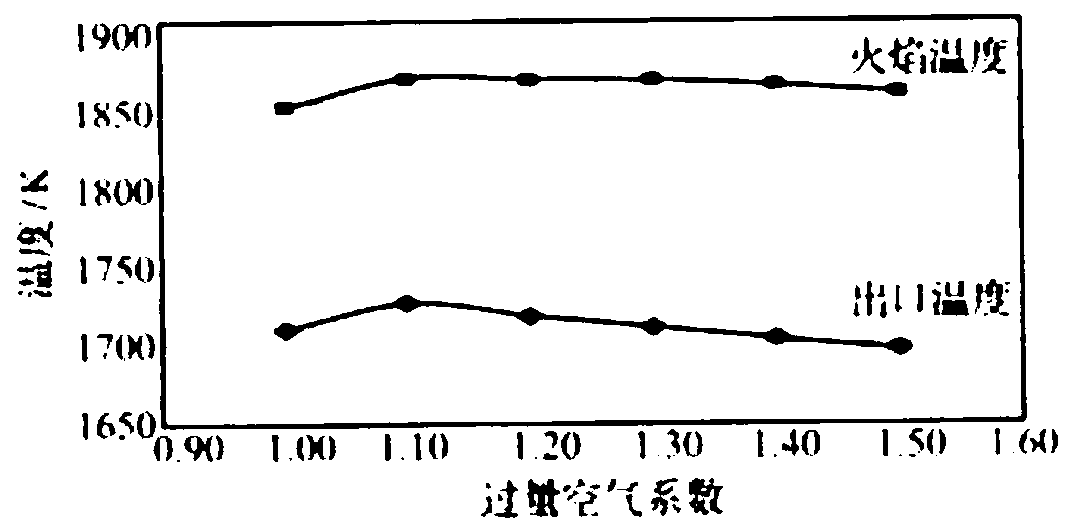

Optimized coke oven heating management method

InactiveCN109266366AQuality improvementStable emissionsCombustible gas coke oven heatingSuction forceWorking environment

The invention discloses an optimized coke oven heating management method. The method comprises the following steps: S1, additionally arranging 1-3 CO online analyzers in a smoke distribution channel at the coke side, and additionally arranging 1-3 CO online analyzers on the top of a furnace; S2, additionally arranging one online air surplus coefficient analyzer in a smoke distribution channel at the machine side; S3, gradually adjusting the suction force of the smoke distribution channels, the suction force of the top of a regenerative chamber and the pressure of a fire observation hole, adjusting accordingly based on the oxygen content of the exhaust gas, the air surplus coefficient and the like, and taking the change of SO2 content in the exhaust gas into account. Under the premise of guaranteeing stable coke quality, the method reduces the standard temperature of a coke oven by 18 DEG C on average, and reduces the temperature of the furnace top space to 825 DEG C or below, so thatthe working environment of workers in the top of the furnace is greatly improved.

Owner:HUAIBEI MINING IND

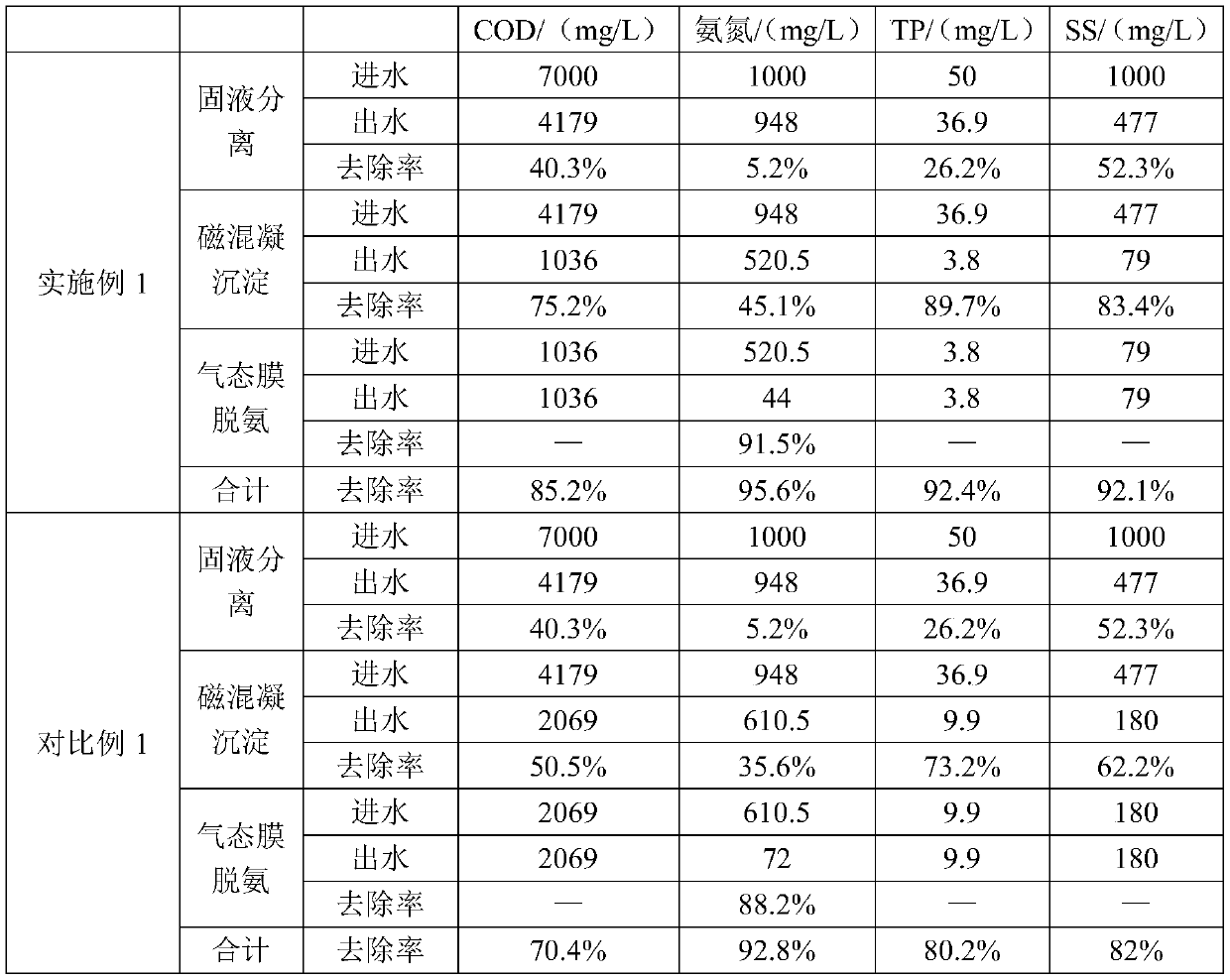

Pretreatment process of livestock and poultry breeding wastewater

PendingCN111573954ARealize resource utilizationReduce dosageAmmonium nitratesWater treatment parameter controlPretreatment methodSludge

The invention discloses a pretreatment process of livestock and poultry breeding wastewater. The pretreatment process comprises the following steps: 1) solid-liquid separation: carrying out solid-liquid separation on the livestock and poultry breeding wastewater to remove large-particle suspended matters; 2) magnetic coagulation sedimentation: treating the wastewater having undergone solid-liquidseparation to obtain magnetic powder-containing sludge and magnetically coagulated liquid; 3) pH value adjustment: adjusting the pH value of the magnetically coagulated liquid to 10.5-12; 4) gaseous membrane deamination: allowing ammonia nitrogen in the magnetically coagulated liquid to pass through a gaseous membrane in a gaseous form so as to allow the ammonia nitrogen to be absorbed by an ammonia absorption liquid; and 5) separation and reuse of magnetic powder: carrying out magnetic separation on the magnetic powder-containing sludge to obtain the magnetic powder and sludge. According to the invention, pollutants such as CODs, suspended solids, ammonia nitrogen, TP and the like in the wastewater can be synchronously removed, so subsequent biochemical treatment is facilitated; accordingto the pretreatment process, added chemicals are low in cost and toxicity and basically free of secondary pollution, a high-concentration ammonium salt solution is generated, resourceful treatment ofthe livestock and poultry breeding wastewater is achieved, the magnetic powder can be recycled after magnetic separation, and a sludge amount is reduced.

Owner:长沙工研院环保有限公司

Method for pre-calcining carbon-containing manganese ore through microwave heating

The invention relates to a method for pre-calcining carbon-containing manganese ore through microwave heating, and belongs to the technical field of microwave metallurgy and manganese-iron alloy smelting. The method comprises: crushing carbon-containing manganese ore to 5-80 mm, crushing a carbonaceous reducing agent to 50-200 mesh, and then uniformly mixing carbon-containing manganese ore and the carbonaceous reducing agent to obtain a mixed material; keeping warm at 750-950 DEG C under a microwave condition for 20-50 min, so as to obtain a water-eliminated thermal-state material possessing a certain carbonate decomposition rate and obtained after high-valent manganese oxides are reduced. According to the method, a microwave heating precalcination process is firstly employed for reducing high-valent manganese oxides in carbon-containing manganese ore, and then a manganese-iron alloy melting furnace (blast furnace or submerged arc furnace) reducing reaction in the prior art is combined for preparing manganese-iron alloy.

Owner:KUNMING UNIV OF SCI & TECH

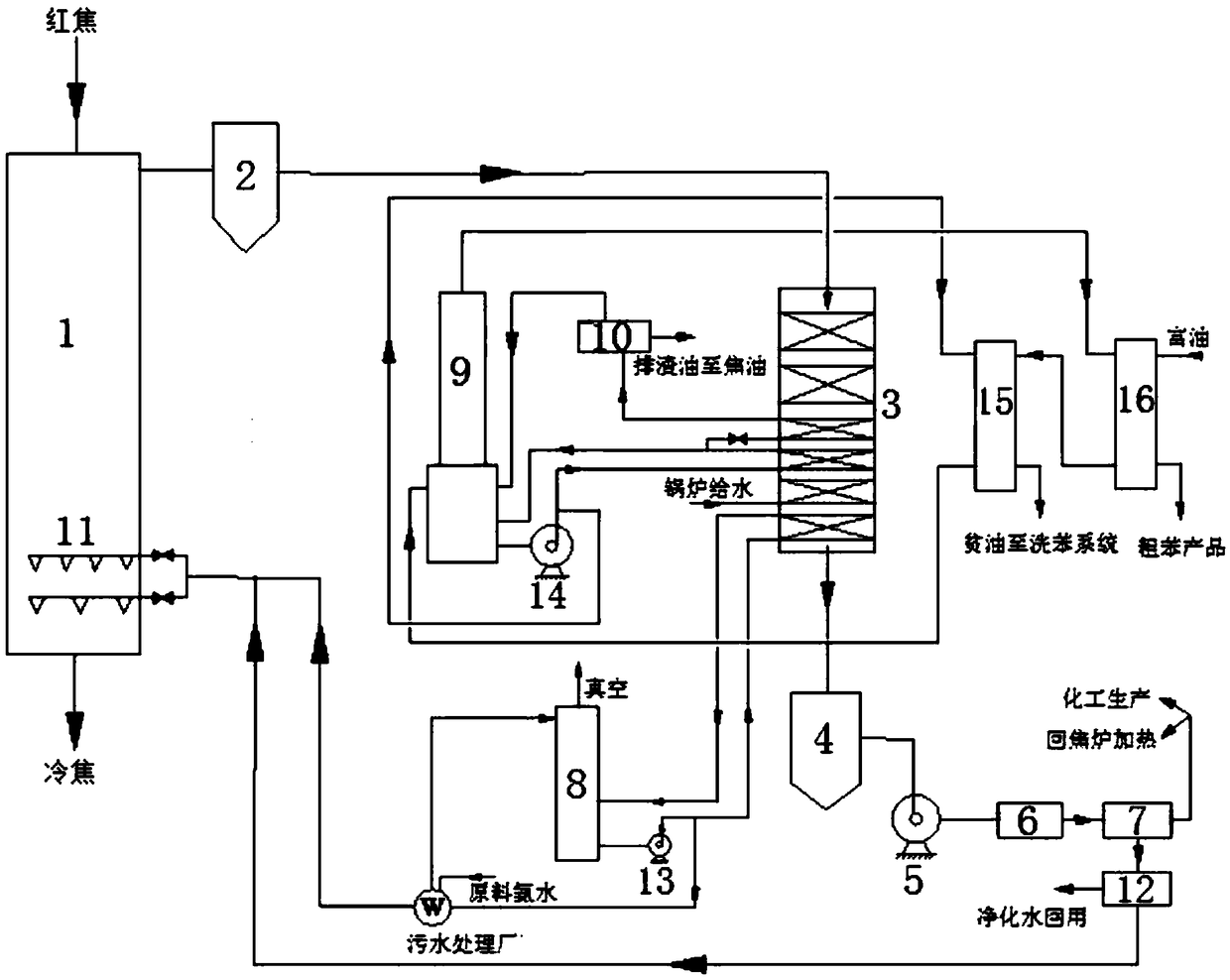

Dry coke quenching residual heat energy recycling and coking wastewater treatment combined technology

InactiveCN109231329AChange loss on ignitionHigh loss on ignitionWater contaminantsEnergy inputChemical reactionEvaporation

The invention provides a dry coke quenching residual heat energy recycling and coking wastewater treatment combined technology. Ammonia evaporation wastewater is upward sprayed out from the bottom ofa cooling section of a dry coke quenching furnace (1) to absorb sensible heat of red coke; the ammonia evaporation wastewater is in direct contact with the red coke and is gasified to generate steam;the steam and the red coke are subjected to heat absorption chemical reaction to generate water gas; meanwhile, organic matter pyrolysis gas in the ammonia evaporation wastewater, the water gas and the steam form mixed gas; the mixed gas is exhausted from an annular channel in the middle of the dry coke quenching furnace; after the mixed gas is subjected to dust removal, the mixed gas is conveyedinto a dry coke quenching residual heat boiler (3); and the mixed gas sequentially passes through a steam overheating section, upper and lower sections of a tower-bottom circulating oil heater of a benzene removal tower, an evaporation section of the dry coke quenching residual heat boiler and a tower-bottom circulating ammonia water heating section of an ammonia evaporation tower from top to bottom and is subjected to gradient heat exchange, and the mixed gas is output from the bottom of the dry coke quenching residual heat boiler. According to the technology provided by the invention, dry coke quenching residual heat energy is used for replacing negative-pressure evaporated ammonia and a negative-pressure benzene removal heat source; the coking wastewater also can be treated to obtain the water gas; and the technology can be used for effectively recycling and utilizing the dry coke quenching residual heat energy, and energy saving and environment protection are realized.

Owner:XUZHOU WEITIAN CHEM CO LTD

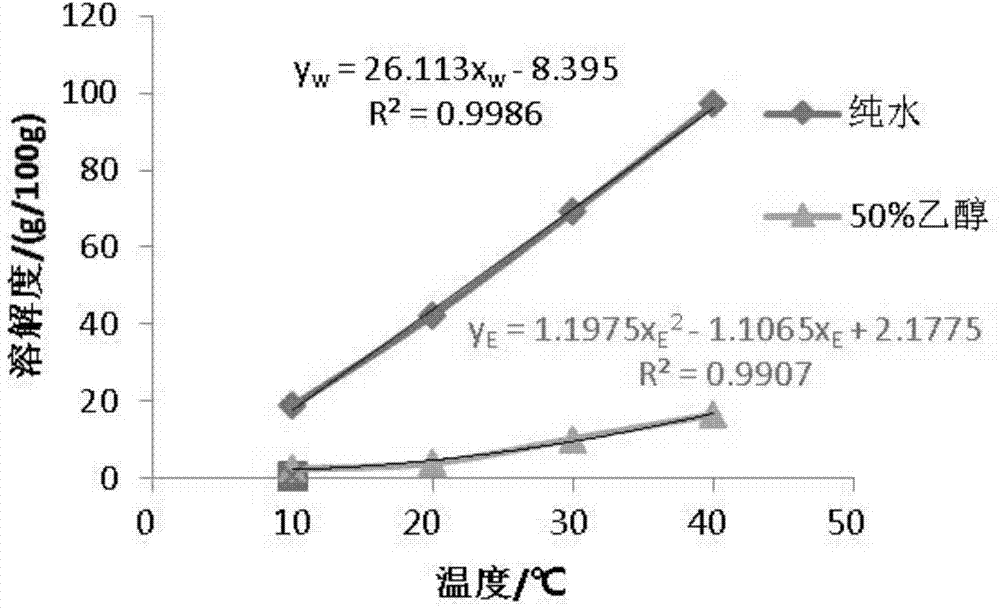

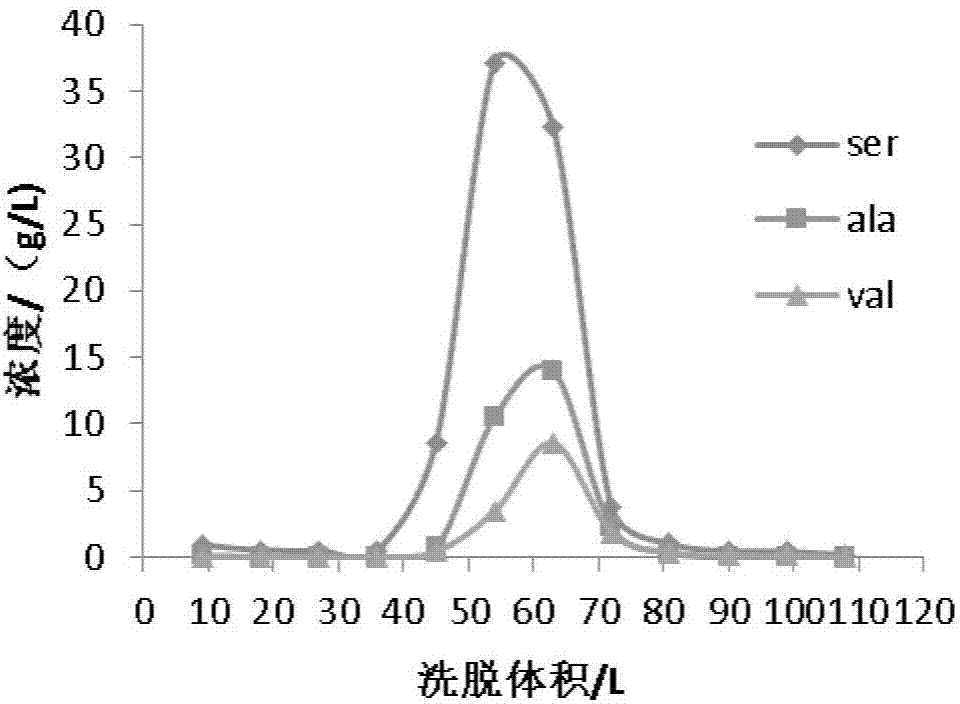

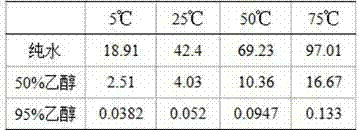

A method for separating and extracting L-serine from Corynebacterium glutamicum fermentation broth

InactiveCN103539688BHigh purityEfficient use ofOrganic compound preparationAmino-carboxyl compound preparationActivated carbonUltrafiltration

The invention discloses a method for separating and extracting L-serine from Corynebacterium glutamicum fermentation liquid, which comprises the following steps: flocculating the fermentation liquid, decolorizing the extract after solid-liquid separation through active carbon adsorption, and decolorizing by ultrafiltration. In addition to macromolecules, cationic resin is used to adsorb amino acids, and ammonia water is used for elution. The eluate was concentrated in vacuo, and ethanol was added for cooling crystallization to obtain L-serine crystals. The method of the invention has high extraction efficiency, and the single-pass extraction rate can reach more than 56%, and the comprehensive extraction rate can reach more than 80% through recovery and reprocessing of the mother liquor. The method of the invention is easy to implement industrially, the extraction cost is relatively low, and it can be processed in large batches.

Owner:GUANGDONG HUANXI BIOLOGICAL TECH

Aldehyde removal method of pentaerythritol

InactiveCN102603480AReduce unit consumptionReduce work intensityOrganic compound preparationHydroxy compound preparationPentaerythritolTower

The invention discloses an aldehyde removal method of pentaerythritol. Pentaerythritol condensation liquid is delivered into an aldehyde removal tower through an inlet located at the upper part of the aldehyde removal tower for aldehyde removal, after aldehyde is removed, formaldehyde is discharged from the top of the aldehyde removal tower, and liquid with aldehyde removed is extracted from the bottom of the aldehyde removal tower. Through the method provided by the invention, the best effect of removal formaldehyde can be achieved, so that the aldehyde content of the liquid with aldehyde removed is decreased to below 0.5g / l, and the unit formaldehyde consumption is decreased. A production environment of pentaerythritol is effectively protected, the operation is stable, the quality of pentaerythritol products and a recovery rate of formaldehyde are improved, 4525 tons of formaldehyde can be recycled calculated based on 30000 tons of annual output of pentaerythritol, and the saved formaldehyde can create benefit of about 5200000 yuan every year. The control pressure of the aldehyde removal tower is decreased to 198kPa from 220kPa, the production load of equipment is reduced, the service life of the equipment is prolonged, the maintenance to production equipment and the working strength of workers are reduced, and the work efficiency of workers is improved.

Owner:贵州金江化工有限公司

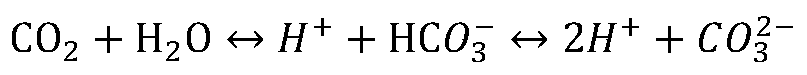

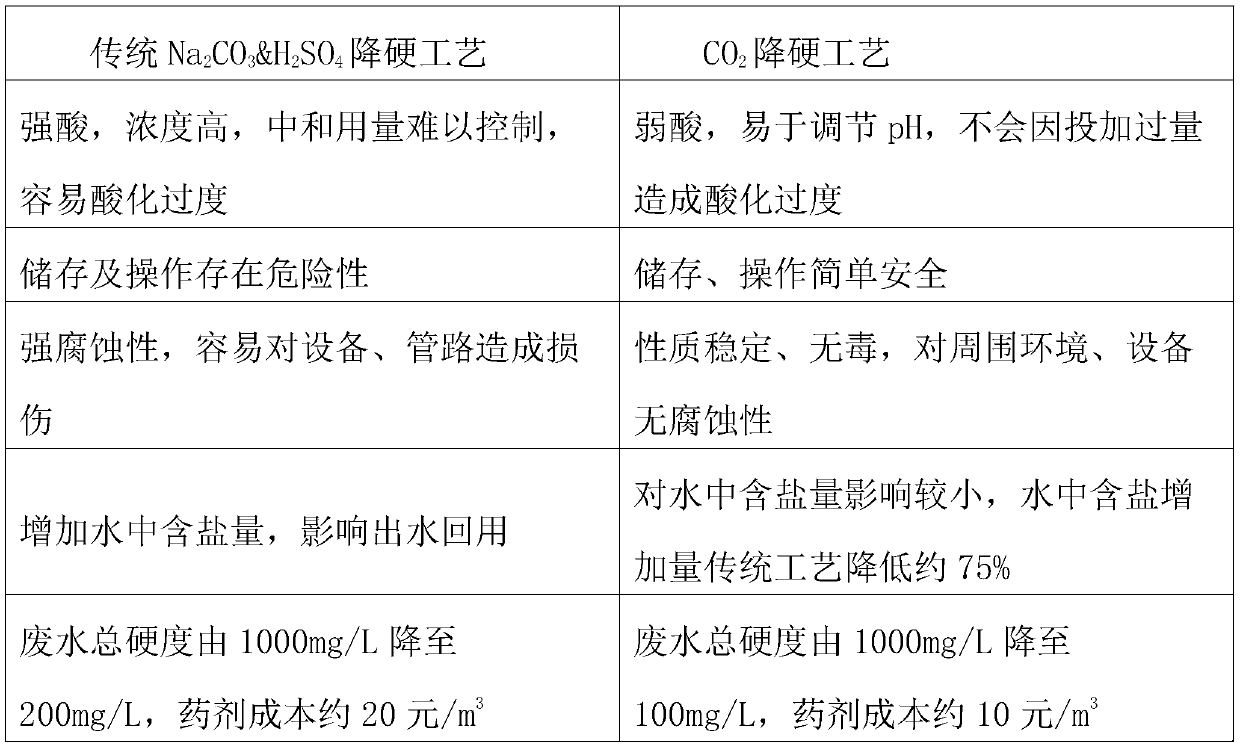

Hardness reduction treatment method for lead-zinc smelting industrial wastewater subjected to up-to-standard treatment

InactiveCN111547879AReduce hardnessReduce production loadTreatment involving filtrationWater softeningIndustrial waste waterEngineering

The invention relates to a hardness reduction treatment method for lead-zinc smelting industrial wastewater subjected to up-to-standard treatment, and belongs to the technical field of lead-zinc smelting industrial wastewater treatment and zero discharge. The treatment method comprises the specific steps: storing liquid carbon dioxide in a storage tank, converting the liquid carbon dioxide into gaseous carbon dioxide through an air temperature vaporizer, and conveying the gaseous carbon dioxide to a dissolved gas reactor; pumping the high-hardness reclaimed water subjected to up-to-standard treatment into the dissolved gas reactor, and carrying out a reaction with the gaseous carbon dioxide; adding a sodium hydroxide solution into the reacted liquid, and enabling the liquid to sequentiallyenter a 1# reaction tank, a 2# reaction tank, a 3# reaction tank and a 4# reaction tank for reaction; enabling the liquid after the reaction is finished to enter an inclined plate sedimentation tankfor solid-liquid separation, and filtering slag water by a filter. According to the method, a carbon dioxide and sodium hydroxide hardness reduction process is utilized, so that the hardness of raw water is continuously, stably and efficiently reduced, the salt content of the raw water is not greatly increased, the production load of subsequent high-power concentration and evaporation salting-outis reduced, and the initial investment and the operation cost of zero-emission treatment of the reclaimed water reaching the standard are effectively reduced.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

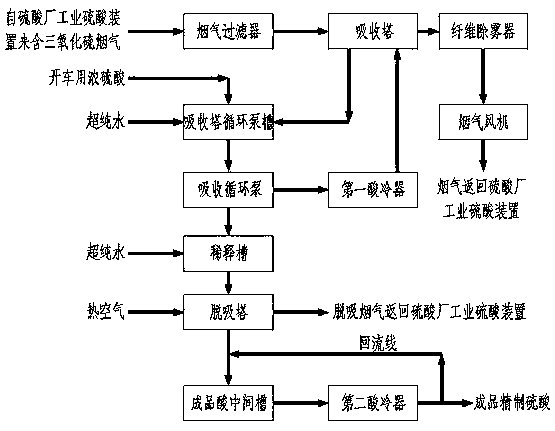

Process for producing refined sulfuric acid by sulphuric acid plant

ActiveCN108793089AReduce energy consumptionReduce manufacturing costSulfur compoundsSulfurSulfur trioxide

The invention relates to a process for producing a refined sulfuric acid by a sulphuric acid plant, specifically, the sulfur trioxide containing exhaust gas of the sulphuric acid plant is taken as theraw material, is filtered by an exhaust gas filter to remove the impurity, is then conveyed to an absorption tower, and is absorbed by concentrated sulfuric acid, the concentration of the sulfuric acid is regulated by using the ultrapure water, the dilution heat and the heat of the sulfuric acid are used to desorb the sulfuric acid at the high temperature, the nitric oxide and the sulfur dioxidein the sulfuric acid are removed, and the refined sulfuric acid is prepared. A refined sulfuric acid product is a reagent sulfuric acid or a sulfuric acid for a storage battery according to the condition of the exhaust gas. The process of the method is simple, the energy consumption is low, the investment is saved, and the process is suitable for the transformation of the newly built sulphuric acid plant and the old sulphuric acid plant.

Owner:CHINA NERIN ENG

System optimization process capable of improving compression effect of synthesis gas compressor and equipment thereof

ActiveCN112499583AReduce stressReduce energy consumptionChemical industryHydrogen productionSyngasGas compressor

The invention discloses a system optimization process capable of improving the compression effect of a synthesis gas compressor. The system optimization process mainly comprises the following steps: S1, preparing feed gas; S2, compressing the synthesis gas; S3, converting the synthesis gas into ammonia, connecting a synthesis tower outlet water cooler in parallel on the basis of an original synthesis tower outlet water cooler in the process steps, changing an existing combined NH3 condenser into two same NH3 condensers which are connected in parallel, additionally arranging a rubber ball cleaning device, and connecting two intermittent coolers in parallel. Under the condition that normal production is guaranteed, the energy consumption of the unit is reduced, the steam consumption of the unit is reduced, the rubber ball cleaning device is used for cleaning the inner wall pipe of the heat exchange equipment, the influence of scale resistance on the total heat transfer coefficient is reduced, the heat exchange efficiency is higher under the same energy consumption, and the process is suitable for wide popularization.

Owner:灵谷化工集团有限公司

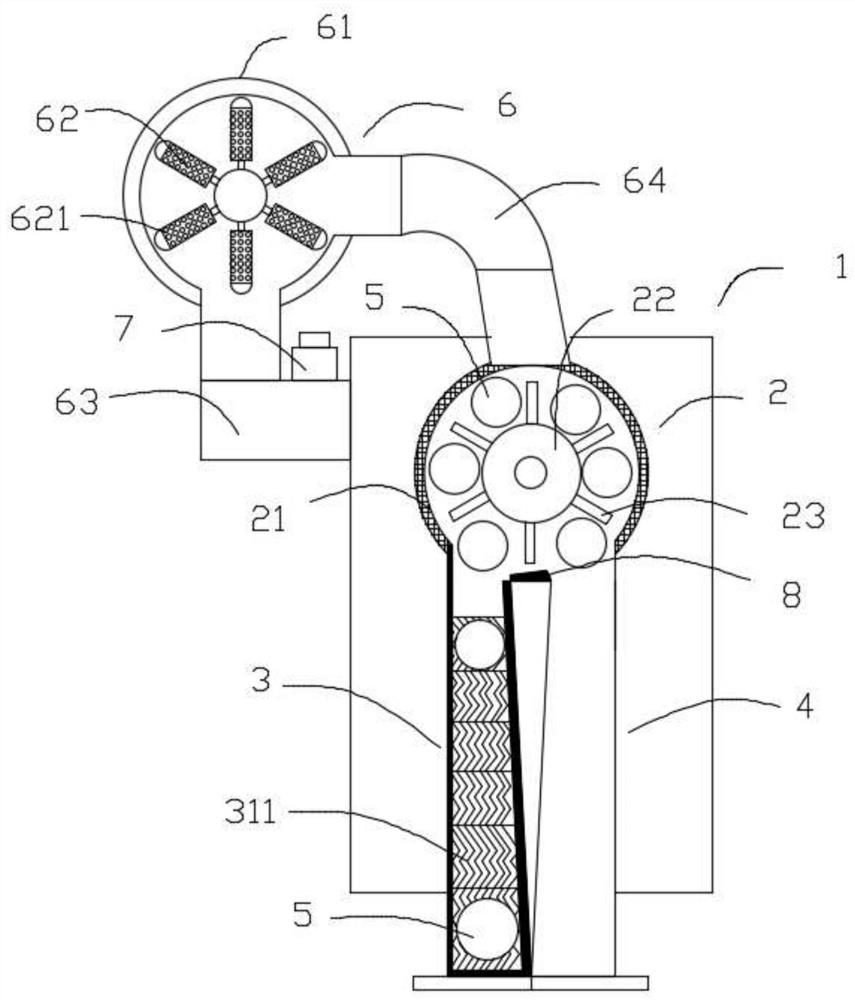

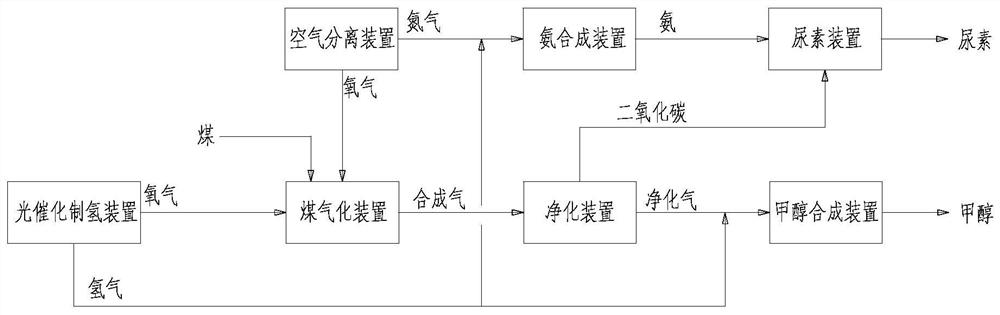

Ammonia-alcohol co-production method capable of realizing low carbon emission through combination of photocatalysis and coal gas

PendingCN113860991AEmission reductionIncrease profitUrea derivatives preparationProductsGlycol synthesisLow-carbon emission

The invention relates to the field of carbon neutralization energy conservation and emission reduction, and particularly discloses an ammonia-alcohol co-production method for realizing low-carbon emission through combination of photocatalysis and coal gas. A process device for implementing the method comprises a photocatalytic hydrogen production device, an air separation device, a coal gasification device, a purification device, a methanol synthesis device, an ammonia synthesis device and a urea device. According to the invention, through comprehensive utilization of photocatalytic hydrogen production, green production of hydrogen is realized. The method is coupled with the traditional coal chemical industry production process, and a conversion device is canceled, so that a large amount of carbon emission caused by hydrogen production is avoided, the utilization rate of carbon elements in coal is improved, and low-carbon production of the coal chemical industry is realized.

Owner:HUALU ENG & TECH

Preparation method for Huangjinya osmanthus-scented Congou black tea

PendingCN110583815AGuaranteed standardizationGuaranteed industrial productionPre-extraction tea treatmentTea flavoringFlavorFreeze-drying

The invention discloses a preparation method for Huangjinya osmanthus-scented Congou black tea, and relates to the technical field of black tea preparation. The preparation method comprises the following steps of S1, collection of fresh leaves, wherein pekoe fresh leaves are selected as raw materials, and the picking standard includes selection of single buds, early development of a bud and a leaf, completeness and tidiness of the buds and leaves, exclusion of no fish leaf or damaged leaf and the like; and S2, withering, the picked fresh leaves of the same level are conveyed to a factory, andspread and withered in time. According to the preparation method for the Huangjinya osmanthus-scented Congou black tea, the osmanthus-scented Congou black tea can be subjected to standard, precise andsanitary treatment, and standardized and industrialized production of products can be ensured; the products can be produced on a large scale in a centralized mode, and it is ensured that the productsare stable in quality and consistent in flavor; according to the preparation method, by adopting a cryogenic freezing-drying technology, the flavor of spring bud tea is ensured, and the fragrance ofosmanthus is further ensured effectively; and the high-quality spring tea and the osmanthus tragrans with best flavor are combined, and the product quality of the osmanthus-scented black tea is improved greatly.

Owner:成都巧匠农业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com