Production technology for bakelite powder and pre-thermoplastic machine thereof

A production process and technology of bakelite powder, applied in the field of bakelite powder production process and its preheating equipment, can solve the problems of harsh working environment of workers, serious environmental pollution, high production energy consumption, and achieve convenient temperature control, large heat transfer area, The effect of reducing energy consumption in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

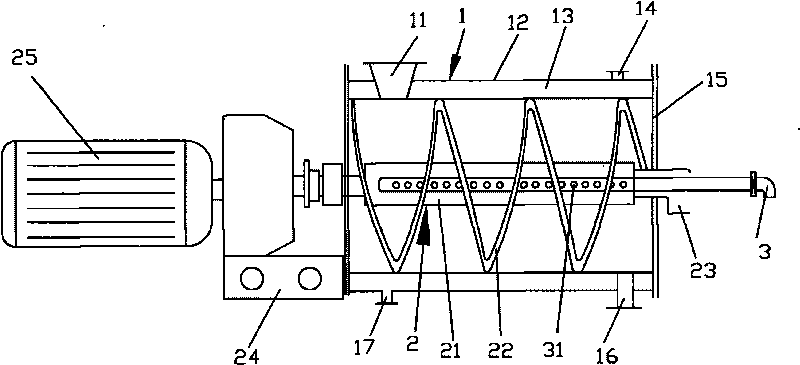

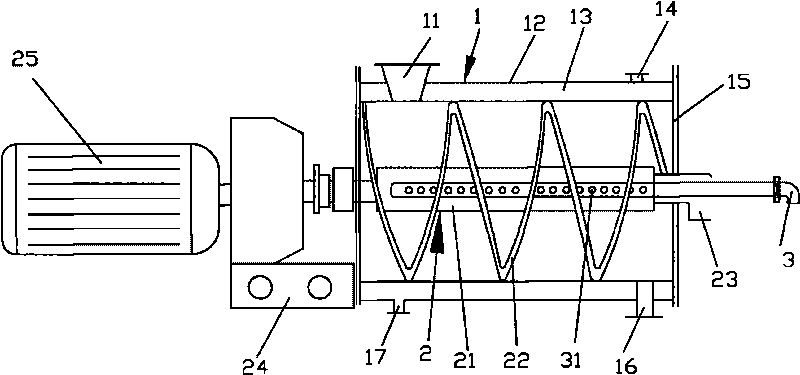

[0012] The present invention will be further described below with reference to the accompanying drawings.

[0013] The preheating molding machine is composed of a casing 1 and a screw pusher 2 installed in the casing 1. The casing 1 is a cylinder 12 with a heating jacket 13, and the two ends of the cylinder 12 are provided with a cover 15. One end of the cylinder 12 is provided with a feed interface 11, and the other end is provided with a discharge interface 16. The screw pusher 2 is a rotating shaft 21 with a spiral piece 22 on the surface, and the rotating shaft 21 is connected with the belt reducer 24 outside the cylinder. The motor 25 is connected. The heating method of the preheating molding machine can be electric heating or steam heating. In this embodiment, steam heating is used. The heating jacket 13 of the cylinder body 12 is directly provided with a steam inlet connecting pipe 14 and a condensed water outlet connecting pipe 17; The rotating shaft 21 of the device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com