New deep purification process of organic waste gas, and applications of new deep purification process in treatment of industrial organic waste gas

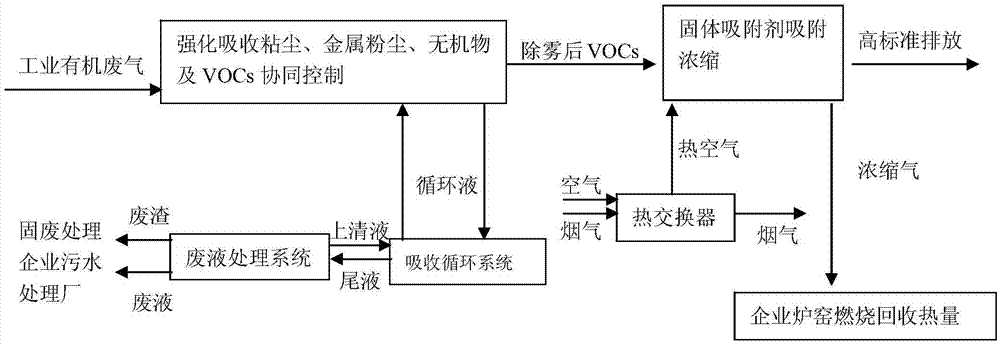

A technology for deep purification of organic waste gas, applied in gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problems that the treatment effect cannot meet the emission requirements, the regeneration and recovery device is not equipped, and the treatment facilities are difficult to play a role, etc. , to achieve the effect of overcoming low VOCs removal efficiency, low load, and preventing sticking and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Organic waste gas in the spraying workshop of an aluminum profile factory, with an air volume of 5000m 3 / h, the exhaust gas temperature is 45°C, the main component is benzene, and the average concentration is 35mg / m 3 ;The average concentration of toluene is 125mg / m 3 ;The average concentration of xylene is 150mg / m 3;The average concentration of n-hexane is 100mg / m 3 ;The average concentration of n-heptane is 75mg / m 3 , the average particle concentration is 158mg / m 3 .

[0040] Process 1 was used to treat it. The composition of the absorption liquid and the purification effect of pollutants are shown in Table 1.

[0041] Table 1 Absorption liquid composition and pollutant purification effect in Example 1

[0042]

[0043] It can be seen from Table 1 that process 1 and its series of absorbing liquids described in Example 1 have a good removal effect on spraying organic waste gas.

Embodiment 2

[0045] A furniture factory emits organic waste gas with an air volume of 7000m 3 / h, the exhaust gas temperature is 40°C, the main component is butanone, and the average concentration is 30mg / m 3 ;The average concentration of benzene is 153mg / m 3 ;The average concentration of toluene is 50mg / m 3 ;The average concentration of xylene is 250mg / m 3 ; The average concentration of ethyl acetate is 130mg / m 3 , the average concentration of butyl acetate is 180mg / m 3 , the average particle concentration is 236mg / m 3 .

[0046] Process 2 was used to treat it. The composition of the absorption liquid and the purification effect of pollutants are shown in Table 2.

[0047] Table 2 Absorption liquid composition, adsorbent type and pollutant purification effect in Example 2

[0048] It can be seen from Table 2 that the process 2 and its series of absorbing solutions described in Example 2 all have good removal effects on furniture organic waste gas.

Embodiment 3

[0050] A circuit board factory discharges organic waste gas with an air volume of 10,000m 3 / h, the exhaust gas temperature is 40°C, the main component is toluene, and the average concentration is 85mg / m 3 ; The average concentration of butyl acetate is 74mg / m 3 ;The average concentration of xylene is 76mg / m 3 , the average concentration of particulate matter is 534mg / m 3 .

[0051] Process 1 and process 2 were used to treat them respectively. The composition of absorption liquid and adsorbent and the purification effect of pollutants are shown in Table 3.

[0052] Table 3 Absorption liquid composition, adsorbent type and pollutant purification effect in Example 2

[0053]

[0054] It can be seen from Table 3 that the process 1 and its series of absorbing liquids described in Example 3 have a good removal effect on the organic waste gas of the circuit board factory, and the process 2 is adopted on the basis of process 1, and the removal rate of each pollutant is further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com