Production method of carbide slag cement

A production method and technology of carbide slag, applied in cement production and other directions, can solve the problems of consuming large primary natural resources and pollution of carbide slag, and achieve the effects of controlling and controlling dust pollution, protecting the environment and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

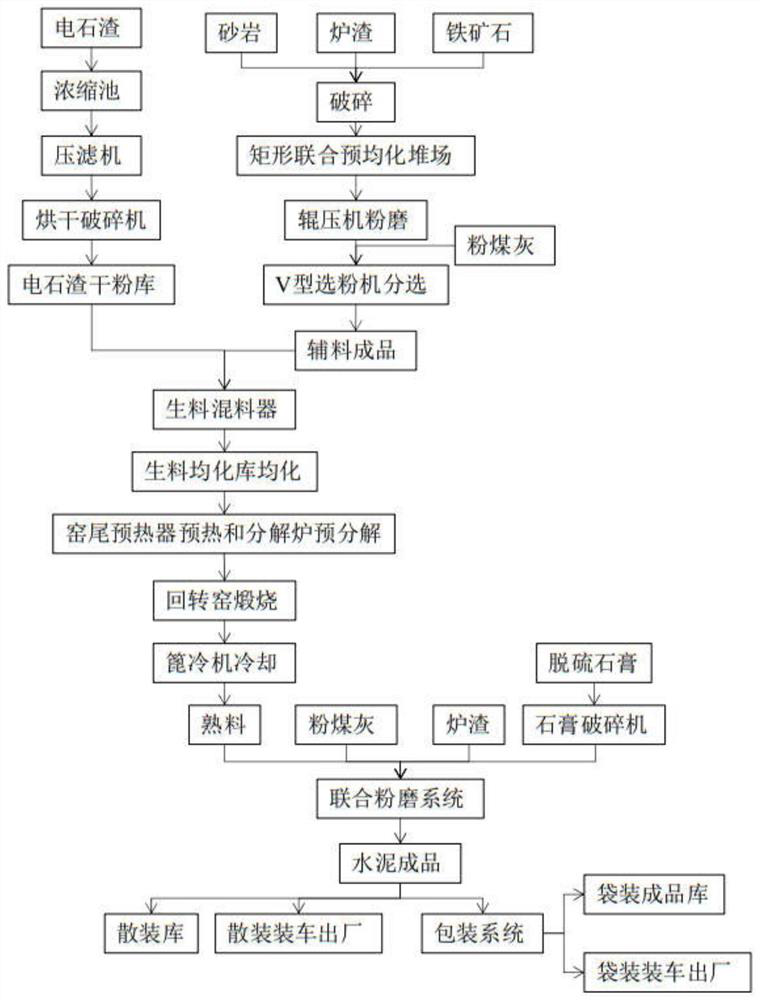

[0065] A kind of production method of calcium carbide slag cement, comprises the following steps:

[0066] 1) Raw material pretreatment: crush sandstone, slag, and iron ore and send them to the rectangular combined pre-homogenization yard for storage; desulfurized gypsum is crushed by a gypsum crusher and then sent to a round warehouse for storage. Send the fly ash to the garden warehouse for storage.

[0067] Concentrate the calcium carbide slag with a water content of more than 90% in the concentration tank, and reduce the water content to below 80%, then remove excess water through a filter press, press filter to form a filter cake with a water content of ≤38%, and finally send it to the oven After drying in the dry crusher, it is sent to the calcium carbide slag dry powder warehouse for storage.

[0068] Specifically, the chemical composition analysis table of raw materials used in carbide slag cement is as follows: (%)

[0069] L.O.I. SiO 2

Al 2 o ...

Embodiment 2

[0081] A kind of production method of calcium carbide slag cement, raw material and chemical composition thereof are consistent with embodiment 1, during production, differs from embodiment 1 in the following steps:

[0082] Step 2) In the batching and grinding of auxiliary materials, the extrusion pressure of the grinding treatment is 11 MPa, the number of grinding times is 4 times / rotation, the particle size of the feed is not higher than 55mm, and the comprehensive moisture is less than 3.5%. The particle size of the finished product of the above-mentioned auxiliary materials passes through a 0.08mm square hole sieve, and the sieve residue is ≤8%.

[0083] Step 3) In raw meal batching and homogenization, the components and parts by weight in the raw meal are as follows: 80 parts by weight of carbide slag, 15 parts by weight of fly ash, 76 parts by weight of sandstone, 30 parts by weight of slag, and 20 parts by weight of iron ore share.

[0084] Step 4) In firing the clink...

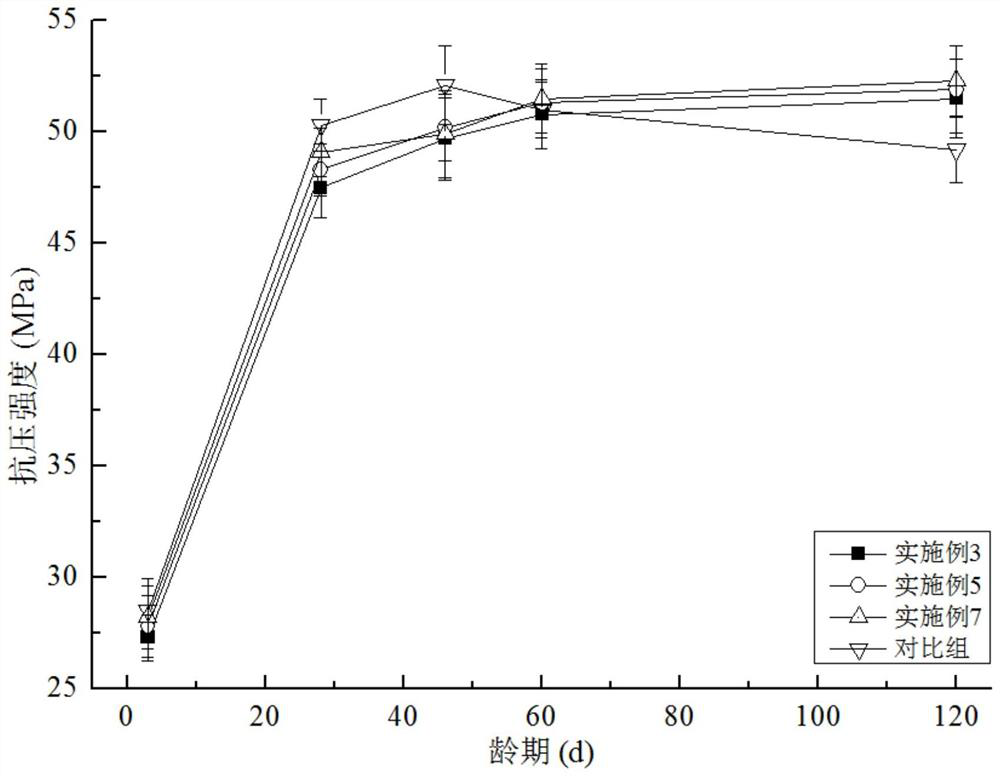

Embodiment 3

[0087] A kind of production method of calcium carbide slag cement, raw material and chemical composition thereof are consistent with embodiment 1, during production, differs from embodiment 1 in the following steps:

[0088] Step 2) In the batching and grinding of auxiliary materials, the extrusion pressure of the grinding treatment is 10 MPa, the grinding frequency is 3 times / rotation, the particle size of the feed is not higher than 55mm, and the comprehensive moisture is less than 3.5%. The particle size of the above-mentioned finished auxiliary materials passes through a 0.08mm square hole sieve, and the sieve residue is ≤5%.

[0089] Step 3) In raw meal batching and homogenization, the components and parts by weight in the raw meal are as follows: 77 parts by weight of carbide slag, 12 parts by weight of fly ash, 75 parts by weight of sandstone, 28 parts by weight of slag, and 19 parts by weight of iron ore share.

[0090] Step 4) In firing the clinker, the temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com