Method for extracting ferroaluminum from chemical sludge for preparing polyaluminum ferric chloride flocculating agent

A technology of polyaluminum chloride and sludge, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as non-compliance with clean production, environmental secondary pollution, waste of resources, etc., and achieve the effect of controlling and treating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

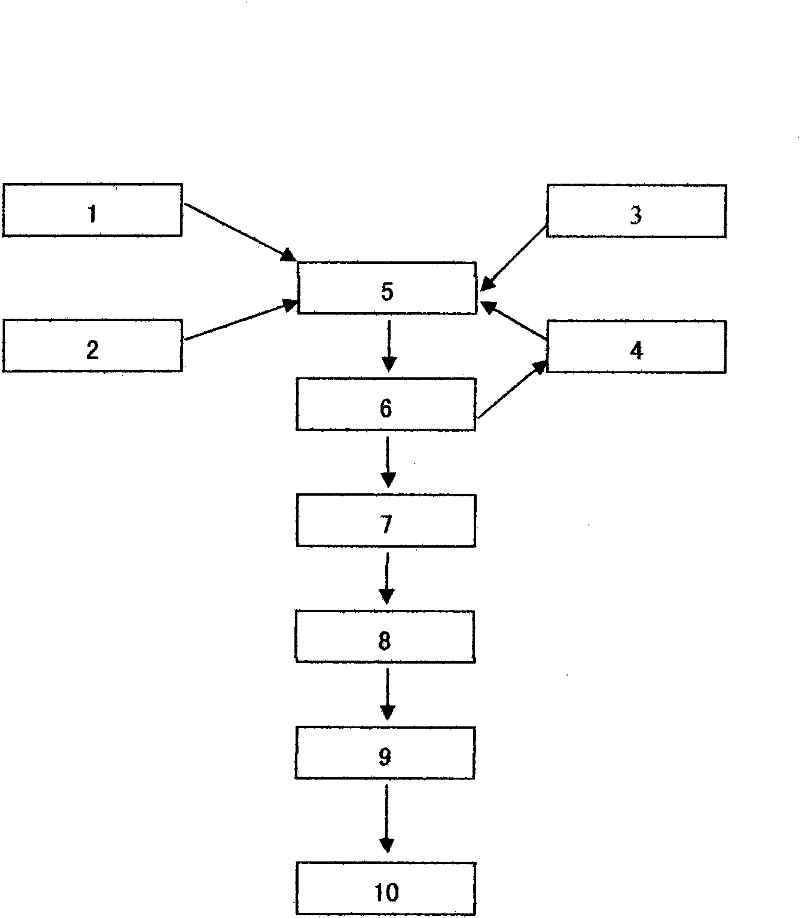

Method used

Image

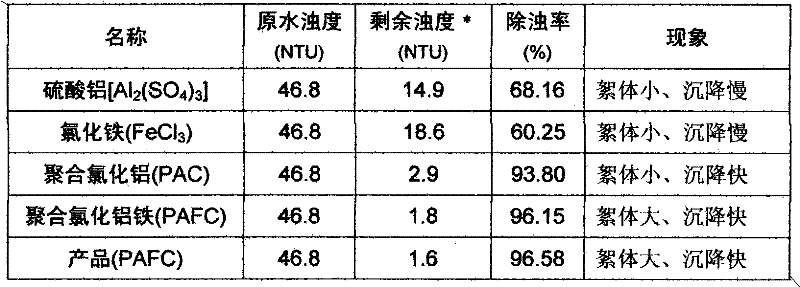

Examples

Embodiment

[0011] Take 10kg of chemical coagulation sludge with a water content of 85%, add 5L of water to dilute, heat to 75°C and stir for 10min, then add 1.5L of 31% concentrated hydrochloric acid until the pH value of the solution is 3.5, leave it at room temperature for 10min, and add a concentration of 0.20 mol / lH 2 o 2 800ml, continue stirring reaction 1.5h, obtain filter residue after conventional filtration, and put it in (the sodium hydroxide solution tail gas adsorption device of activated carbon adsorption+solid calcium chloride adsorption+10% is installed) constant temperature dry box, at temperature Under the condition of 120°C, dry at constant temperature for 36 hours, and then get dry sludge ash after cooling down to normal temperature;

[0012] 1 Take 100 g of dried sludge ash obtained after the above pretreatment and 2500 ml of hydrochloric acid with a mass concentration of 25%, 3 add it to a four-necked flask with a reflux condenser, 4 stir and react at 105° C. for 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com