Optimized coke oven heating management method

A management method and coke oven technology, applied in the field of coking and coking, can solve problems such as high coke energy of coke ovens, careless management of coke oven temperature, accelerated formation of nitrogen oxides, etc., and achieve the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for optimizing coke oven heating management in this implementation includes the following steps:

[0031] Step 1: Add 1-3 CO on-line analyzers to the side flue of the machine coke, and add 1-3 CO on-line analyzers to the top of the furnace;

[0032] Step 2, add an online analyzer for excess air coefficient in the side flue of the machine;

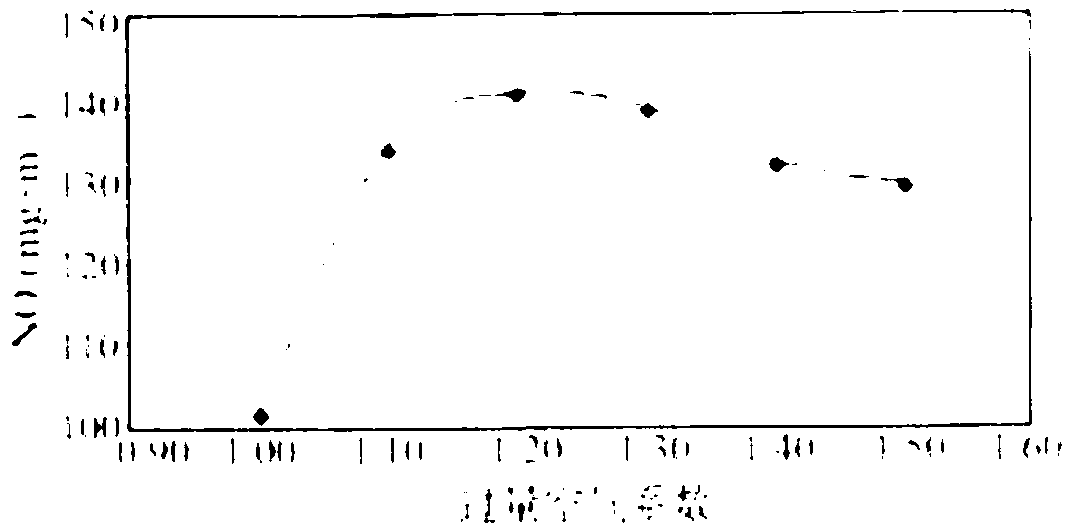

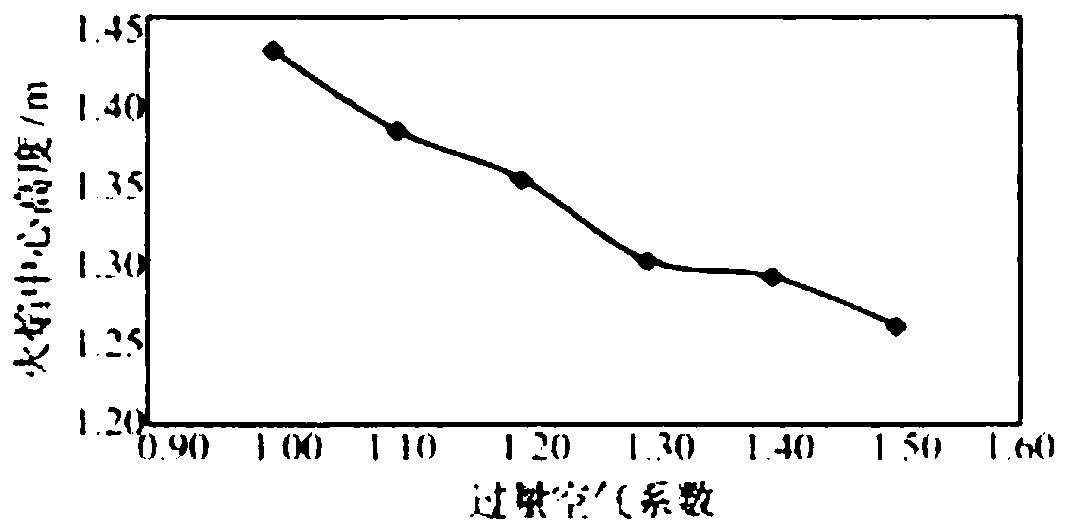

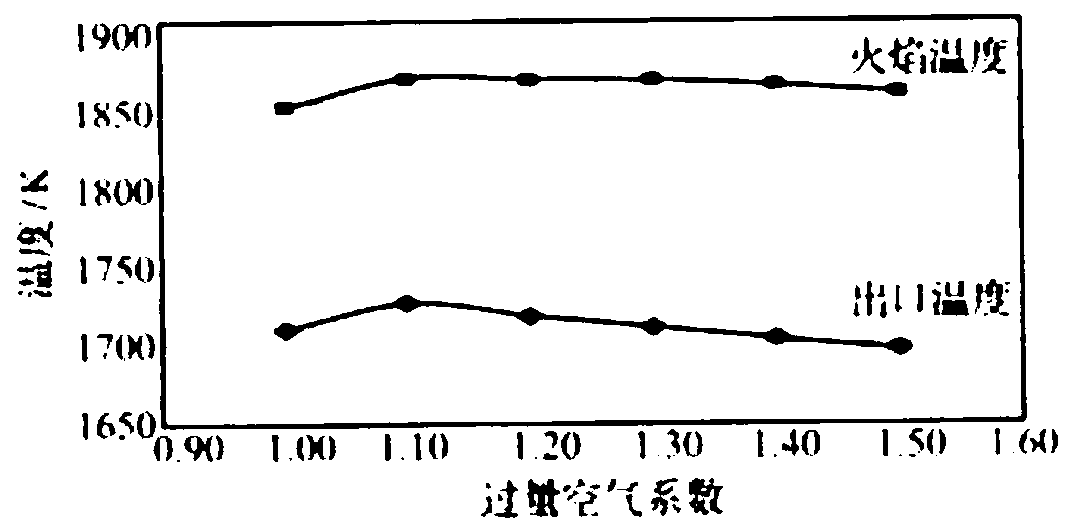

[0033] Step 3: gradually adjust the suction of the sub-flue, the top suction of the regenerator and the pressure of the fire hole, and make corresponding adjustments according to the oxygen content of the exhaust gas and the excess air coefficient, while taking into account the SO in the exhaust gas 2 Content changes;

[0034] Step 4: Increase the horizontal row coefficient to above 0.93, the furnace head temperature coefficient to above 0.89, the straight line uniformity coefficient to above 0.92, the stability coefficient to above 0.89, and adjust the standard temperature according to the coke pushing current and coke mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com