Ammonia-cooled ammonia reclamation method and mating device thereof

A kind of ammonia recovery and self-cooling technology, applied in the direction of ammonia preparation/separation, etc., can solve the problems of high impurity content in the inlet gas, large construction investment, high steam consumption, etc., to improve the utilization rate of raw materials, solve the expansion of ammonia water, reduce the The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

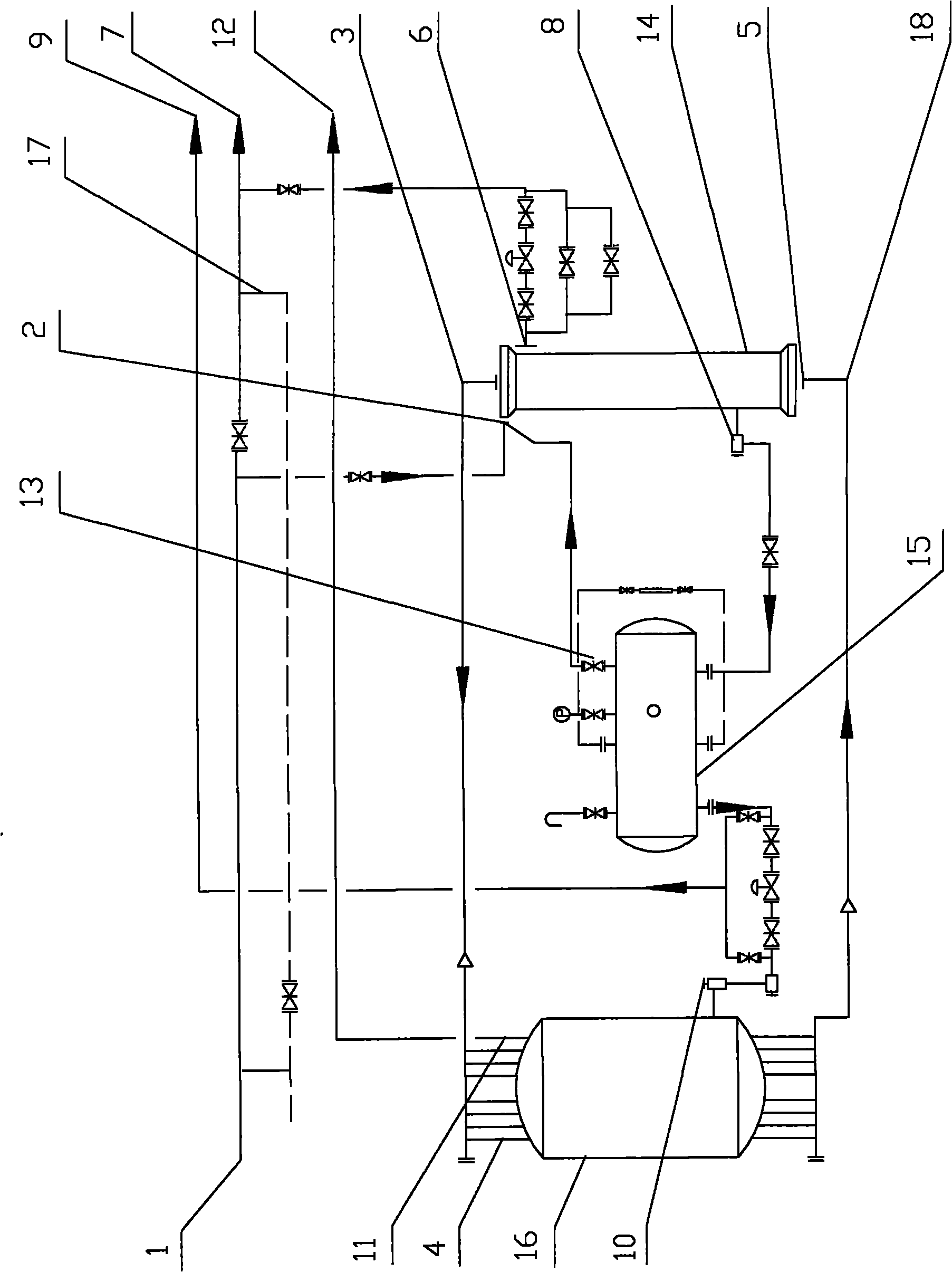

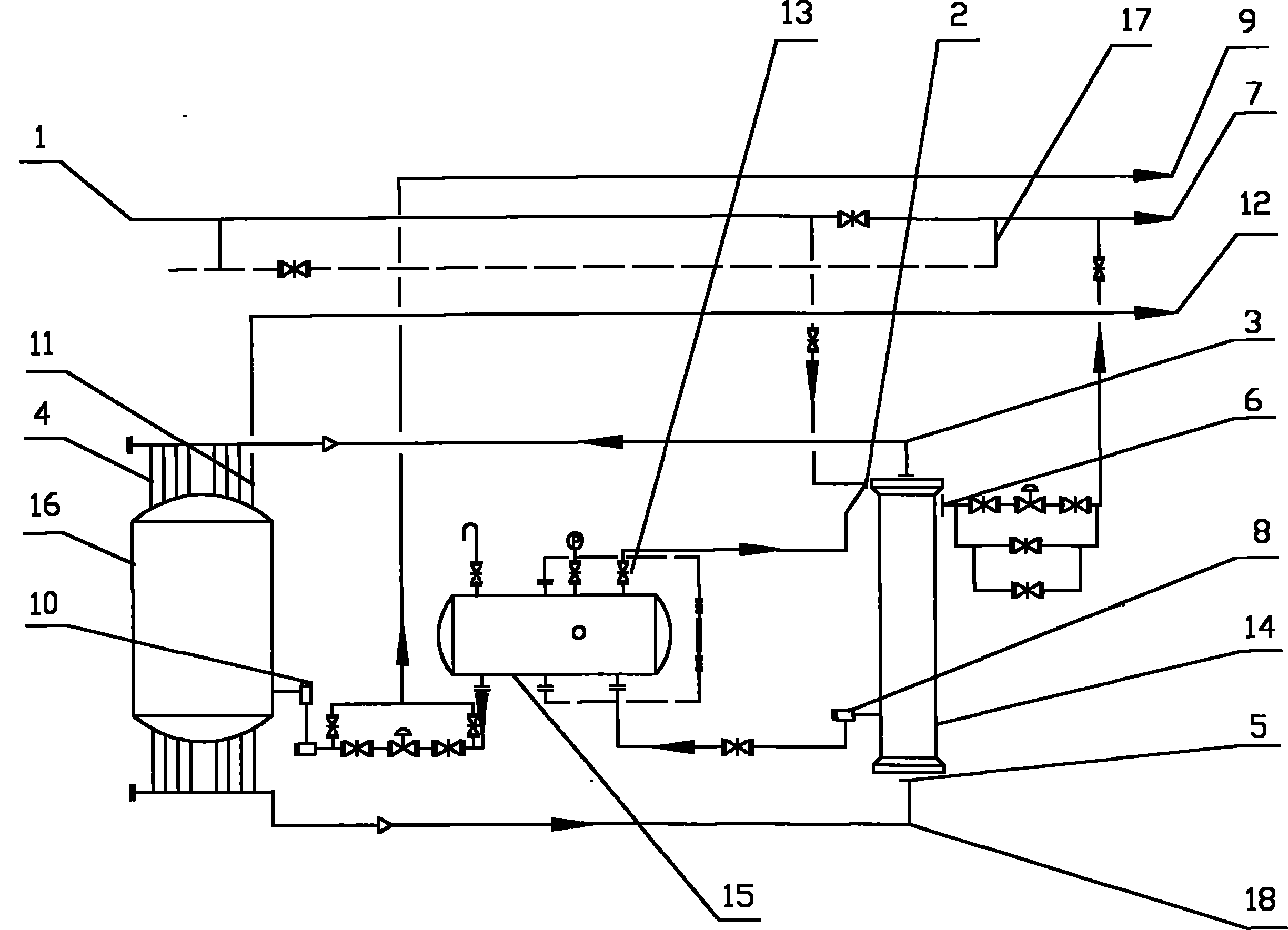

[0018] 1. The relaxation gas from the liquid ammonia storage tank, containing 45% ammonia, enters the cold heat exchanger tube at a temperature of 15 °C, exchanges heat with the cold relaxation gas between the tubes, and comes out of the cold heat exchanger tube after cooling down to 5 °C. Then enter the ammonia evaporation condenser tube, in the ammonia evaporation condenser, the gaseous ammonia is greatly cooled to -10°C and condensed into liquid ammonia;

[0019] 2. After the ammonia is condensed, the release gas entrains the liquid ammonia mist and comes out from the bottom of the ammonia evaporator condenser, and then enters between the cold and heat exchanger tubes again. The release gas undergoes gas-liquid separation between the cold and heat exchanger tubes and absorbs the heat of the gas in the tubes , the liquid ammonia is separated and accumulated at the bottom of the cold heat exchanger; the temperature of the released gas after separation of ammonia is raised to 5...

Embodiment 2

[0024] 1. The release gas from the liquid ammonia storage tank, containing 42% ammonia, enters the cold heat exchanger tube at a temperature of 15°C, exchanges heat with the cold release gas between the tubes, and comes out of the cold heat exchanger tube after cooling down to 5°C. Then enter the ammonia evaporation condenser tube, in the ammonia evaporation condenser, the gaseous ammonia is greatly cooled to -10°C and condensed into liquid ammonia;

[0025] 2. After the ammonia is condensed, the release gas entrains the liquid ammonia mist and comes out from the bottom of the ammonia evaporator condenser, and then enters between the cold and heat exchanger tubes again. The release gas undergoes gas-liquid separation between the cold and heat exchanger tubes and absorbs the heat of the gas in the tubes , the liquid ammonia is separated and accumulated at the bottom of the cold heat exchanger; the temperature of the released gas after separation of ammonia is raised to 5°C, and ...

Embodiment 3

[0030] 1. The release gas from the liquid ammonia storage tank, containing 48% ammonia, enters the cold heat exchanger tube at a temperature of 15°C, exchanges heat with the cold release gas between the tubes, and comes out of the cold heat exchanger tube after cooling down to 5°C. Then enter the ammonia evaporation condenser tube, in the ammonia evaporation condenser, the gaseous ammonia is greatly cooled to -10°C and condensed into liquid ammonia;

[0031] 2. After the ammonia is condensed, the release gas entrains the liquid ammonia mist and comes out from the bottom of the ammonia evaporator condenser, and then enters between the cold and heat exchanger tubes again. The release gas undergoes gas-liquid separation between the cold and heat exchanger tubes and absorbs the heat of the gas in the tube , the liquid ammonia is separated and accumulated at the bottom of the cold heat exchanger; the temperature of the released gas after separation of ammonia is raised to 5°C, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com