Pretreatment process of livestock and poultry breeding wastewater

A livestock and poultry breeding wastewater pretreatment technology, applied in the field of livestock and poultry breeding wastewater pretreatment process, can solve the problems of ineffective removal of ammonia nitrogen, unfavorable growth of related bacteria, large dosage of chemicals, etc., to achieve enhanced removal of suspended solids , reduce the dosage of chemicals, and reduce the effect of treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

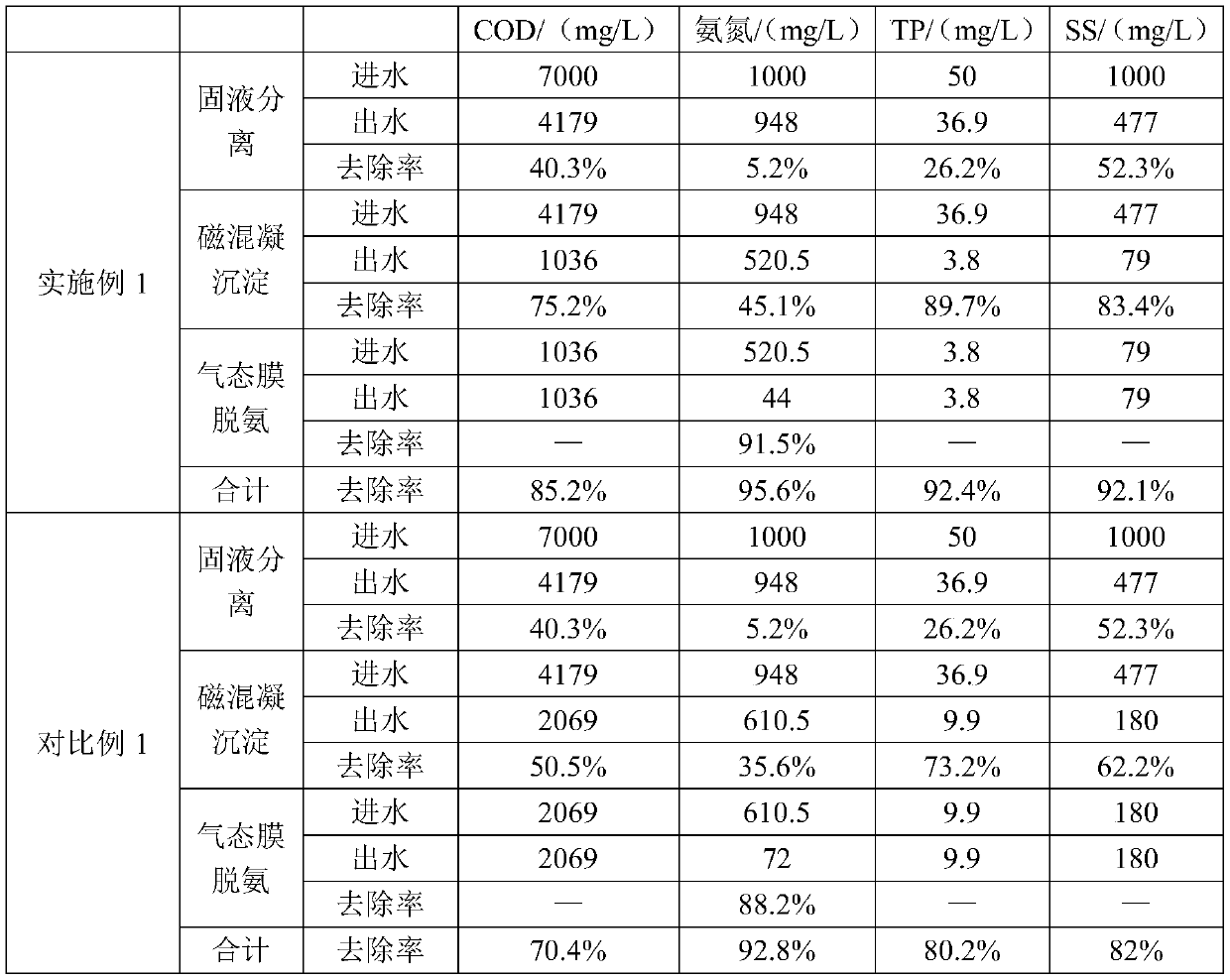

Embodiment 1

[0033] A pretreatment process for livestock and poultry breeding wastewater, comprising the steps of:

[0034] (1) Solid-liquid separation: Take 1000mL of livestock and poultry breeding wastewater with a COD concentration of 7000mg / L, an ammonia nitrogen concentration of 1000mg / L, a TP concentration of 50mg / L, and a SS concentration of 1000mg / L, and carry out solid-liquid separation through a solid-liquid separator. Separation and removal of suspended solids of large particles, the solids after solid-liquid separation are used for composting to produce organic fertilizers, and the waste water after solid-liquid separation goes to the next process;

[0035] (2) Magnetic coagulation sedimentation: a) Add 8g / L ferric oxide and 500mg / L PAC to the wastewater after solid-liquid separation, and stir at 210r / min for 4min to react with ferric oxide and PAC Adsorb colloids and small particle suspensions to form tiny flocs; b) add 10mg / L of PAM, stir at 120r / min for 6min to make PAM even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com