Method for desalination and concentration of medical intermediate

An intermediate and desalination technology, applied in the field of desalination and concentration of pharmaceutical intermediates, can solve the problems of cumbersome operation of ion exchange method, high operating cost of resin replacement, and great occupational hazards of operators, achieving a high degree of automation control and increasing the number of enterprises Economic benefits, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

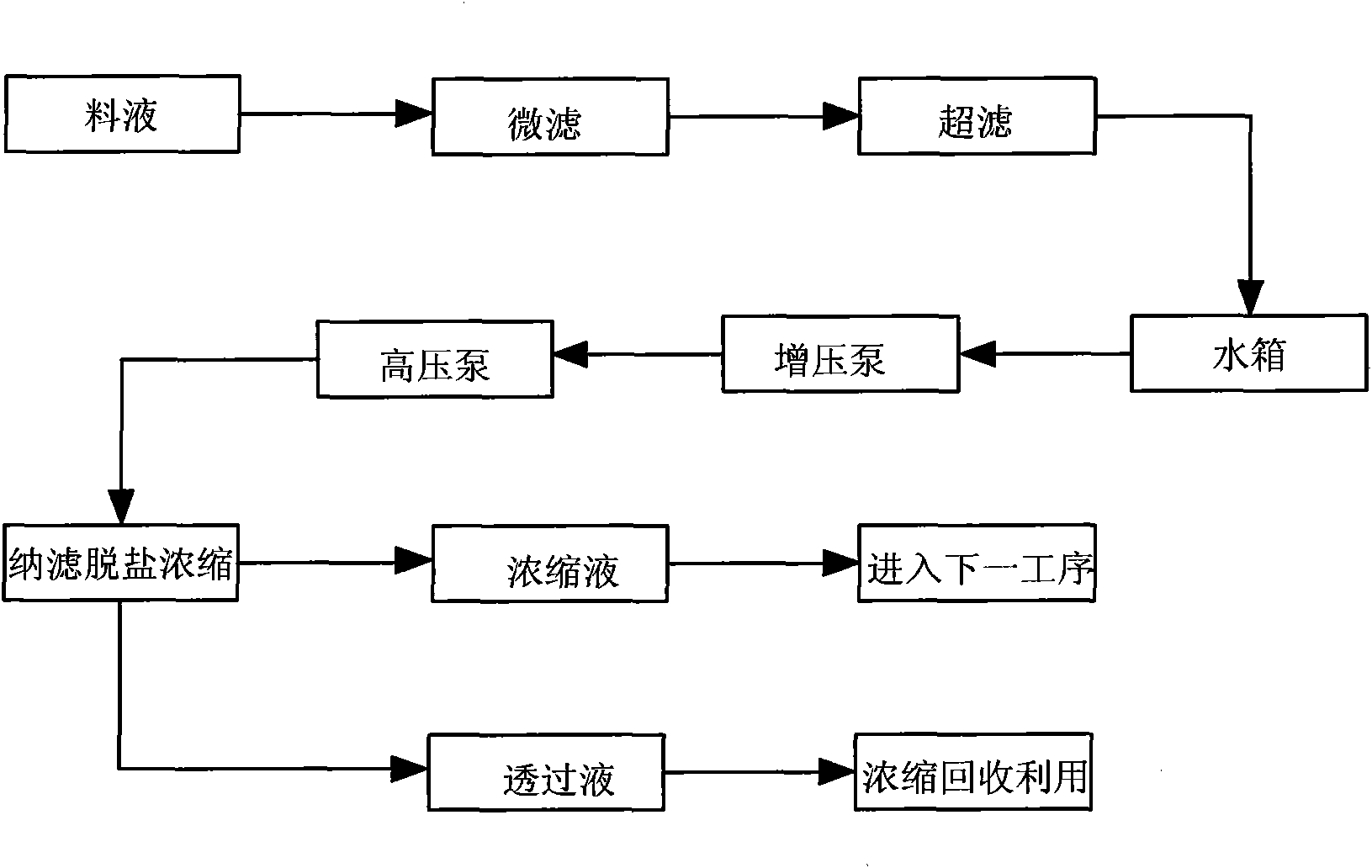

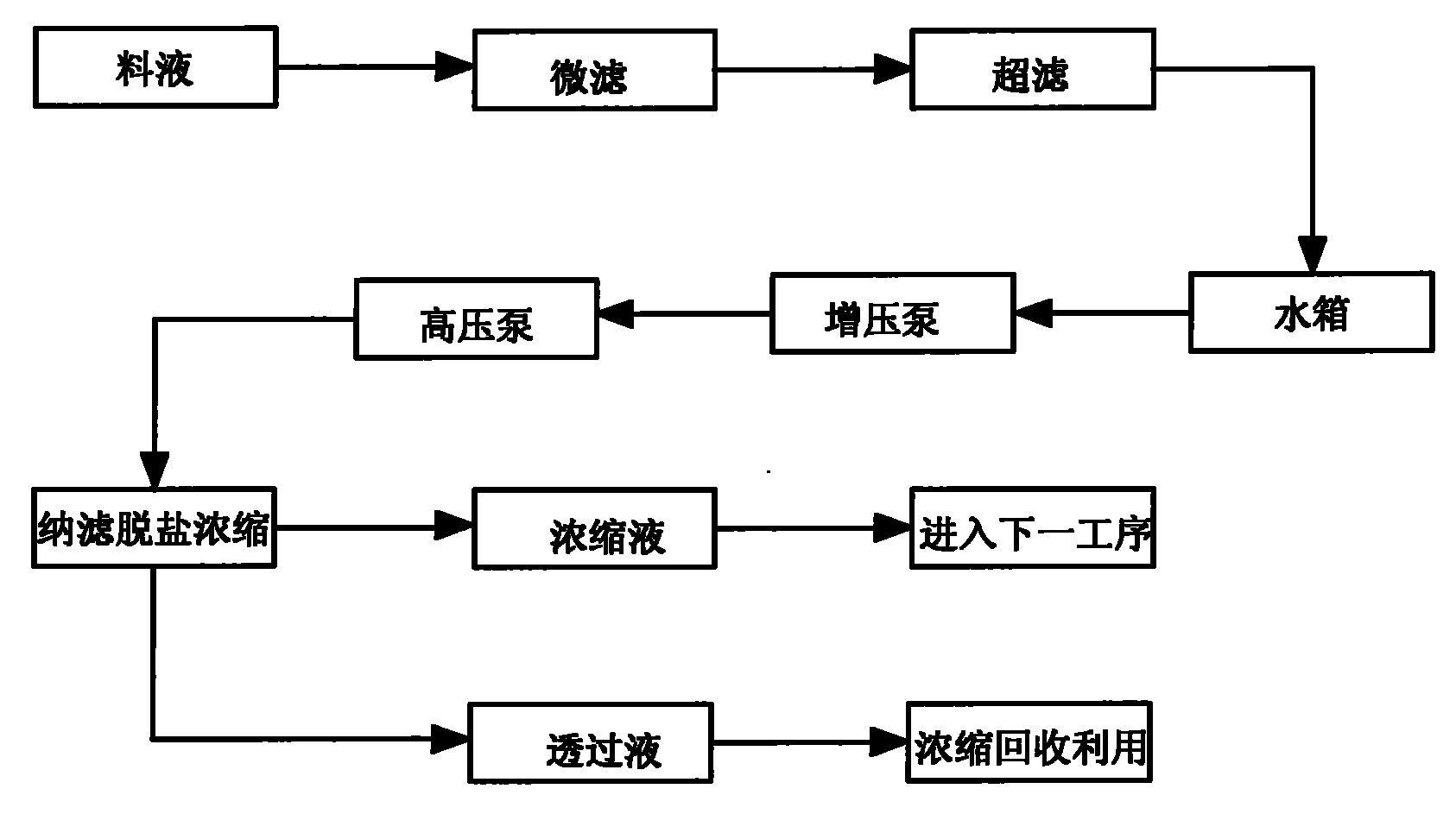

[0014] Embodiment 1: with reference to attached figure 1 with 2 . The desalination and concentration method of pharmaceutical intermediates uses nanofiltration constant volume desalination technology to desalt and concentrate pharmaceutical intermediates. The specific steps: 1) pass the raw materials of pharmaceutical intermediates containing 1% to 25% salt through microfiltration membrane and ultrafiltration The filter membrane removes macromolecular particles, organic matter and colloidal substances in the solution; 2) the raw material solution after removing macromolecular particles, organic matter and colloidal substances enters the water tank and cools down to 10°C to 25°C through cooling water; 3) the cooled The raw material liquid is pressurized by the booster pump and the high-pressure pump in turn, and the nanofiltration constant-capacity desalination technology is used to wash and concentrate the pharmaceutical intermediates, and the rate of adding leachate during t...

Embodiment 2

[0020] Embodiment 2: with reference to attached figure 2. A system for desalting and concentrating pharmaceutical intermediates, the raw material liquid supply pipeline is connected to the inlet of water tank 1, the outlet of water tank 1 is connected to the inlet of primary nanofiltration membrane module 2 through booster pump 7 and high-pressure pump 8, and the primary nanofiltration membrane module 2 is connected to the outlet of water tank 1. The filter membrane module 2 is provided with a concentrated liquid outlet and a permeate outlet, wherein the permeate outlet is connected to the inlet of the water tank 9 through a pipeline, and the outlet of the water tank 9 is connected to the inlet of the secondary nanofiltration membrane module 3 through a booster pump 10 and a high-pressure pump 11 , the concentrate outlet is provided with two outlets, one of which is connected to the inlet of the water tank 1 through a valve and a pipeline, and the other outlet is connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com