Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

166results about How to "Process reaction conditions are mild" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of chitosan grafted copolymer flocculation-bactericide

InactiveCN103864991AHarm reductionSimplify the water purification processWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationSuspended particlesChemistry

The invention provides a chitosan grafted copolymer flocculation-bactericide for treating water bodies such as circulating cooling water, papermaking sewage, printing and dyeing sewage, domestic sewage, drilling fluid and the like. The bactericide is a compound agent which can kill the plankton such as viruses, bacteria, algae and the like in the water body and settles along with the colloid and suspended particles in the water body. The bactericide provided by the invention is prepared by graft copolymerization of chitosan and dimethyl diallyl ammonium salt and acrylamide triggered under the nitrogen protection.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

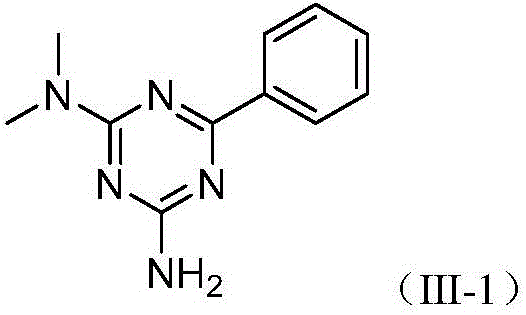

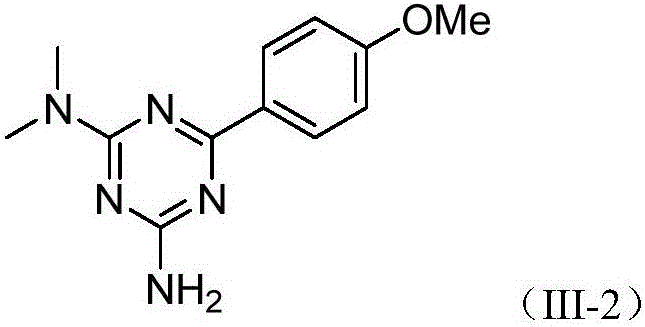

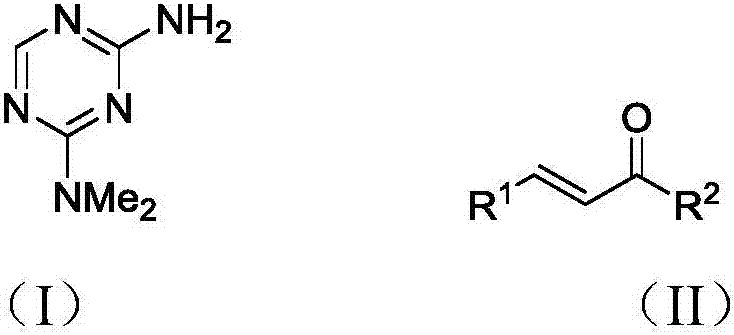

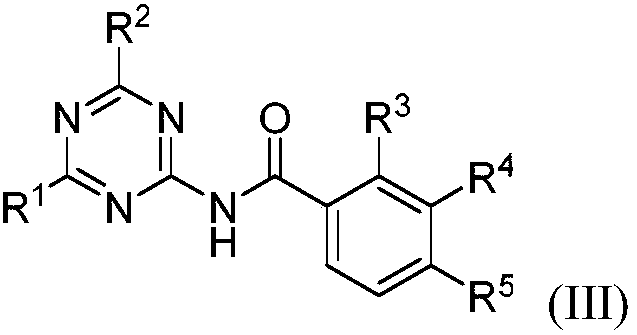

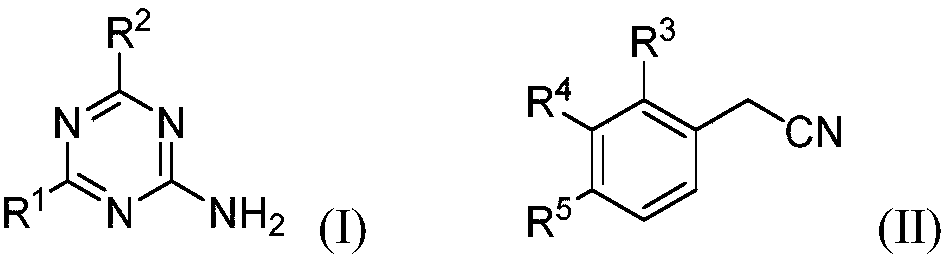

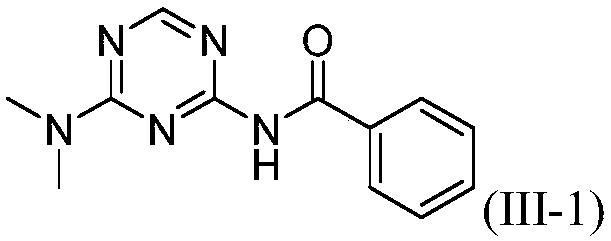

2,4-diamine-1,3,5-triazine compound, preparation method and application thereof

ActiveCN105837525AProcess reaction conditions are mildEasy to operateAntibacterial agentsOrganic chemistry1,3,5-TriazineAfter treatment

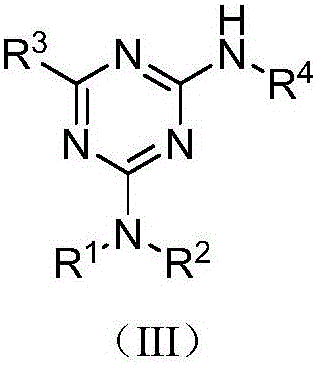

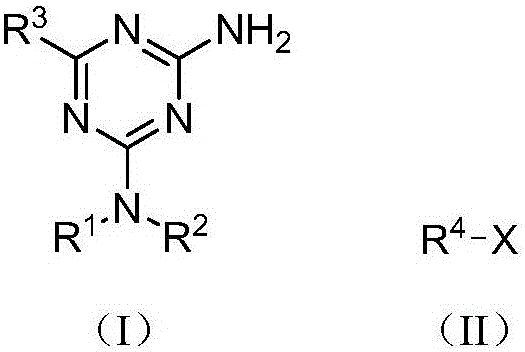

The invention provides a 2,4-diamine-1,3,5-triazine compound represented as the formula (III). A preparation method includes the following steps: adding compounds represented as the formulas (I) and (II), a metal copper catalyst, a ligand, an alkaline substance and a solvent into a reaction container, stirring the reactants to perform a reaction at 80-140 DEG C for 6-14 h and performing after treatment to the reaction liquid to obtain the compound (III). The preparation method has mild reaction conditions and convenient operations, is low in cost and has wide industrial application prospect. The 2,4-diamine-1,3,5-triazine compound has certain antibacterial activity and can be used for preparing antibacterial medicines and agents, lays fundament for screening and developing new medicines and has great practical value.

Owner:ZHEJIANG UNIV OF TECH

Method for producing alkylation gasoline by taking ionic liquid as accelerator of fluorosulphonic acid

InactiveCN101851526AEasy to separateLow costOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixtures productionChemical industryIonic liquid

The invention relates to a method for producing high-octane gasoline by accelerating catalytic conversion of fluorosulphonic acid into isobutene butylene with a novel ionic liquid in the field of chemical industry. The ionic liquid has an A+B- molecular structure, wherein the cation A+ has an imidazole, pyridine, quaternary ammonium salt, quaternary phosphorus salt cation structure or the like; the anion B- has a BF4-, PF6-, CF3SO3- structure or the like; and the ionic liquid can be a single ionic liquid or a mixed ionic liquid. By accelerating the catalytic conversion of the fluorosulphonic acid into the isobutene butylene with the ionic liquid, the alkylation gasoline can be produced at high selectivity under certain reaction conditions; and when the reaction is finished, the acidic ionic liquid catalyst can be conveniently separated from the alkylate by a simple process. Compared with the conventional sulfuric acid process and the conventional hydrogen fluoride process, the process has the advantages of mild reaction conditions, high selectivity of C8, low catalyst cost and high safety for use and is an environment-friendly new process.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of s-triazine compound

ActiveCN105753801AProcess reaction conditions are mildRaw materials are easy to getOrganic chemistryAlcoholTriazine

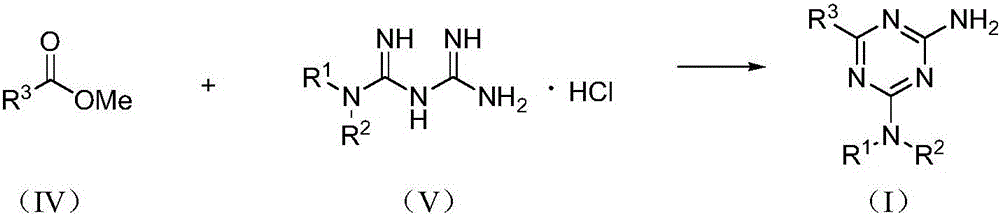

The invention provides a preparation method of an s-triazine compound shown in formula (III). The preparation method comprises steps as follows: an alcohol compound shown in formula (I), biguanide hydrochloride shown in formula (II), a metal ruthenium catalyst and an alkaline matter are added to a solvent and subjected to a stirring reaction at 80-130 DEG C for 10-18 h, and then the s-triazine compound shown in formula (III) is obtained after post-treatment of a reaction liquid. The preparation method is convenient to operate and low in cost and has wide industrial application prospect, the reaction condition is mild, and raw materials are easy to obtain.

Owner:ZHEJIANG UNIV OF TECH

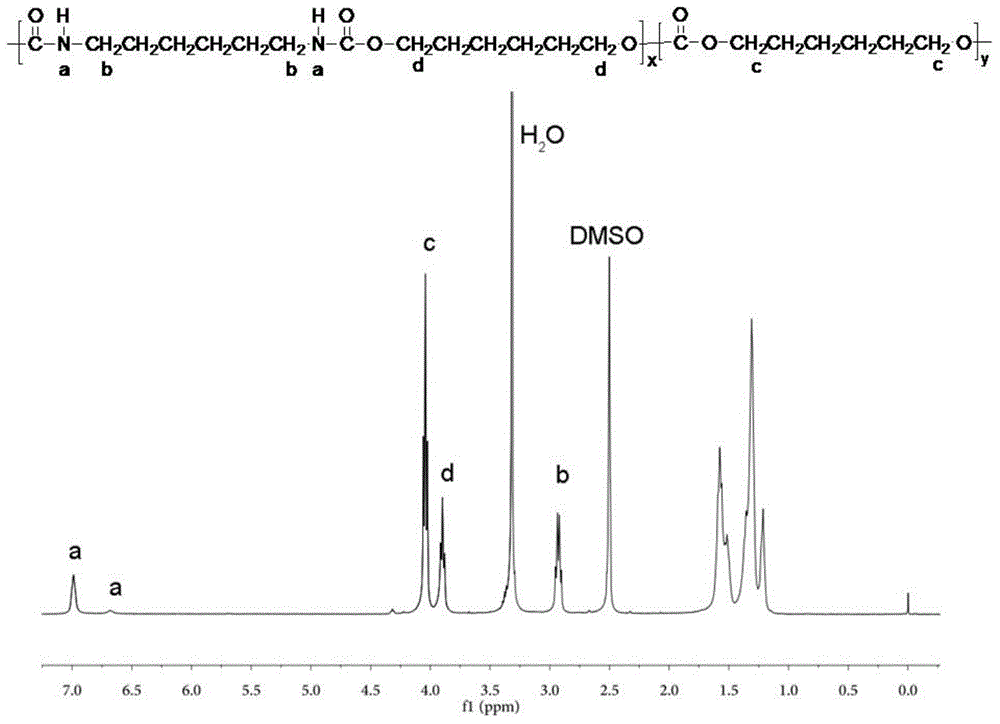

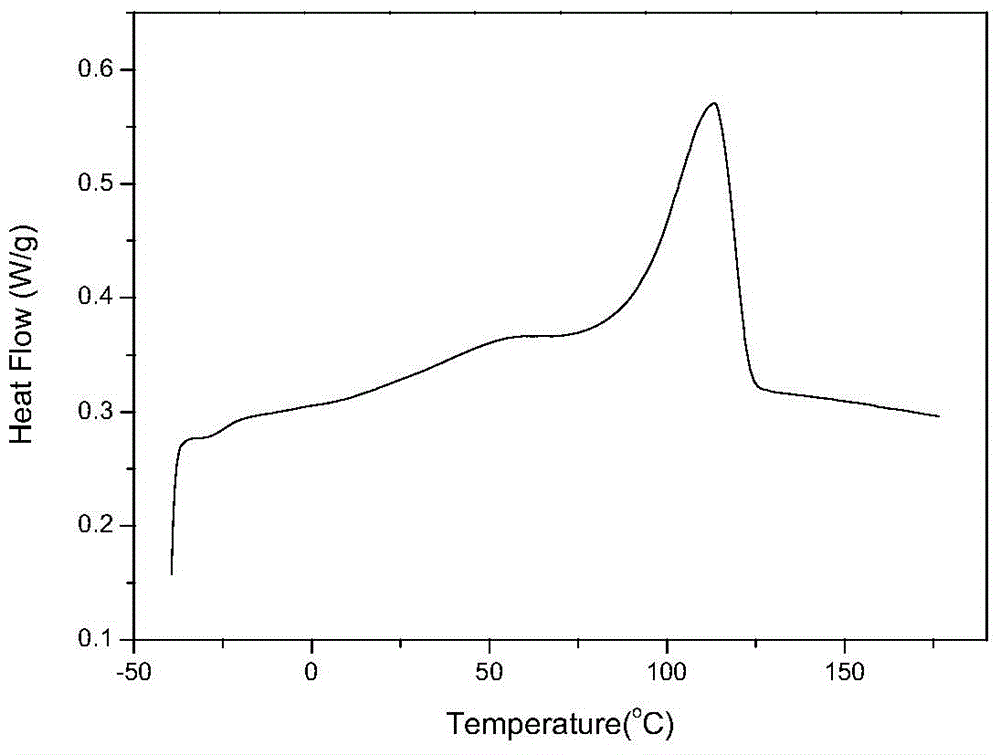

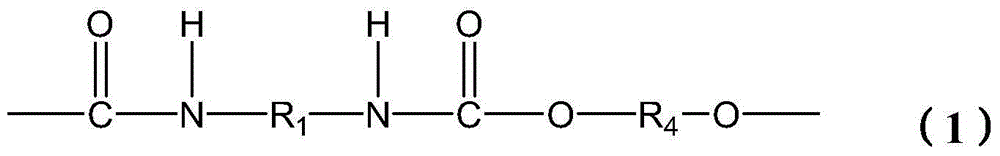

Polycarbonate polyurethane and green preparation method thereof

The invention relates to polycarbonate polyurethane and a green preparation method thereof. The polycarbonate polyurethane comprises polyurethane structural units and aliphatic polycarbonate structural units which are irregularly distributed. The polycarbonate polyurethane is successfully prepared by a nonisocyanate method, so that isocyanate and solvents are not used, and the development requirements of green chemical industry are met. In addition, the green preparation method of the polycarbonate polyurethane is relatively mild in reaction condition and low in requirement on devices; by selecting raw materials with different structures, the polycarbonate polyurethane having different linear structures and comprising two irregularly distributed structural units can be prepared, so that the structures are diverse and controllable; the prepared polycarbonate polyurethane is free of residue of isocyanate monomers, so that the application of polycarbonate polyurethane to the fields of foods and medicines is broadened.

Owner:INST OF CHEM CHINESE ACAD OF SCI

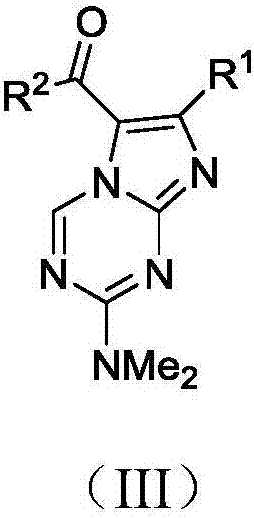

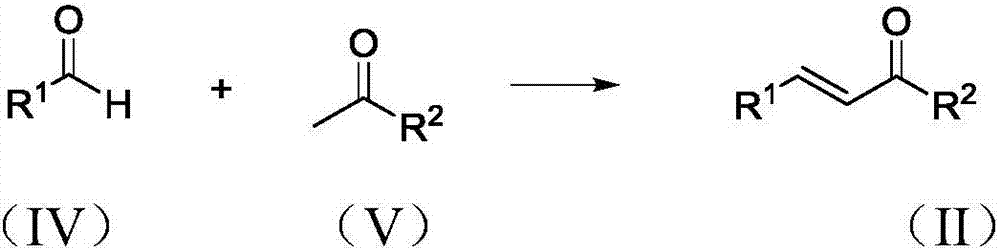

Imidazole-triazine type compound and preparation method and application thereof

ActiveCN107089983AMild reaction conditionsEasy to operateAntibacterial agentsOrganic chemistrySolventHalogen

The invention provides an imidazole-triazine type compound which is shown as the formula 3 in the description and a preparation method and application thereof. The method comprises the steps that a triazine compound and an alpha,beta-unsaturated ketone type compound are mixed and added into a solvent, under the existence of a metal copper catalyst and an oxidizing material, the mixed solution is stirred and reacts 5-20 hours under the temperature of 60-150 DEG C, after the reaction is finished, the reacted solution is subjected to post processing, and the imidazole-triazine type compound which is shown as the formula 3 is obtained; the metal copper catalyst is halogenide of the copper or a copper salt; the oxidizing material is a halogen elementary substance. The imidazole-triazine type compound can be applied to prepare antibacterial drugs or antibacterial agents, and the preferred antibacterial drugs are the drugs which inhibit activity of escherichia coli.

Owner:ZHEJIANG UNIV OF TECH

Environment-friendly method for metronidazole synthesis

The invention discloses an environment-friendly method for metronidazole synthesis. Formic acid is replaced with acetic acid, alcohol is added for esterification, neutralization is performed for three times, sodium sulfate and ethylene glycol are recovered, a nitration product is effectively recovered from a metronidazole mother solution, derivatives such as acetic ester, anhydrous sodium sulfate and the like are obtained, by-products such as ethylene glycol and the like are chemical raw materials with wide applications, resources are recycled, the raw materials are greatly saved, the production cost is reduced, and the whole novel process adopts simple steps and is convenient to operate.

Owner:WUHAN WUYAO PHARMA

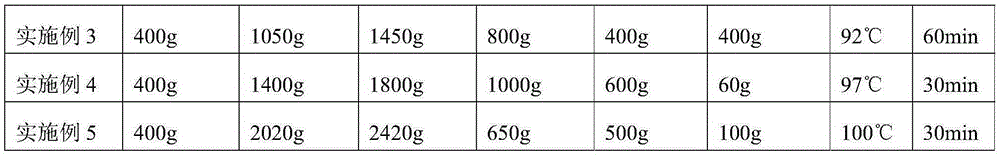

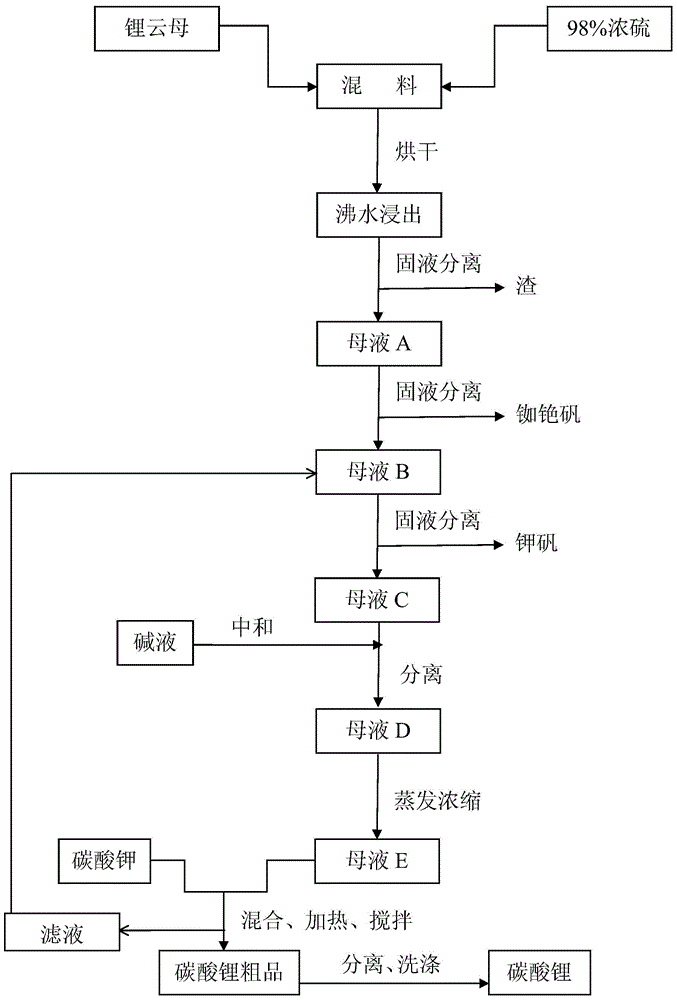

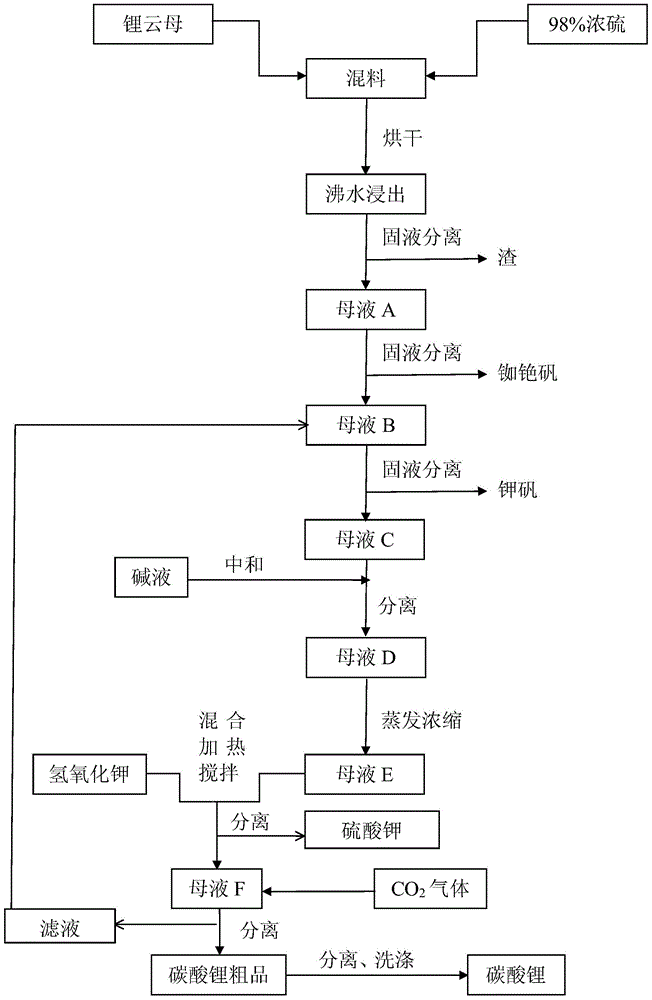

Method for preparing lithium carbonate from lepidolite

InactiveCN106145164AImprove leaching rateAdequate responseLithium carbonates/bicarbonatesFiltrationSlag

The method for preparing lithium carbonate from lepidolite comprises the following steps: take lepidolite (100-500 mesh), add 98% concentrated sulfuric acid in a mass ratio of 1: [0.8-3], stir, and dry step by step to obtain clinker , and crush the clinker into 100-500 mesh, add water to soak, stir, and boil to obtain a mixed solution; centrifuge the mixed solution while it is hot to obtain mother liquor A, cool the mother liquor A in a reaction vessel to 20-80°C, and crystallize Rubidium cesium alum is extracted, and then centrifuged to obtain mother liquor B; the mother liquor B is cooled to -30~20°C in the reaction vessel, potassium alum is crystallized, and then centrifuged to obtain mother liquor C; mother liquor C is neutralized with lye to the pH value After centrifugation, the mother liquor D is obtained, and then the mother liquor D is evaporated and concentrated, and then filtered to obtain the mother liquor E; the mother liquor E is mixed with potassium carbonate or sodium carbonate solution, heated to 80-100°C, and completed under stirring. That is, the crude product of lithium carbonate is prepared, and the crude product is centrifuged, washed and dried to obtain the finished battery grade lithium carbonate. The invention improves the leaching rate of lithium, saves raw materials, generates less slag, and lowers requirements on equipment.

Owner:深圳前海南锂新材料有限公司

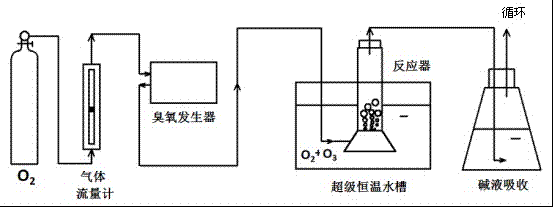

Method for purifying chlorine-containing wastewater discharged during zinc hydrometallurgy

InactiveCN107140727AProcess reaction conditions are mildIncrease profitElectrolysis componentsWater contaminantsChemistryOxide

The invention discloses a method for purifying chlorine-containing wastewater discharged during zinc hydrometallurgy. The process comprises the following steps: controlling flow of oxygen or air by a mass flow meter; feeding into an ozone generator after measurement; converting some oxygen into ozone under action of a high-pressure and high-frequency electric field by a discharge tube in the ozone generator; combining the generated ozone with unionized gas to form a mixed gas; uniformly dispersing the mixed gas by a gas distributor, then performing contact reaction on the mixed gas and chlorine-containing wastewater having a certain temperature so as to complete dechlorination; and feeding a tail gas into the ozone generator again after absorbing chlorine by lye so as to realize circulation. The method provided by the invention is mild in reaction condition, high in dechlorination rate, and low in cost due to the regenerated manganese oxide can be returned to a zinc hydrometallurgy system.

Owner:SICHUAN UNIV

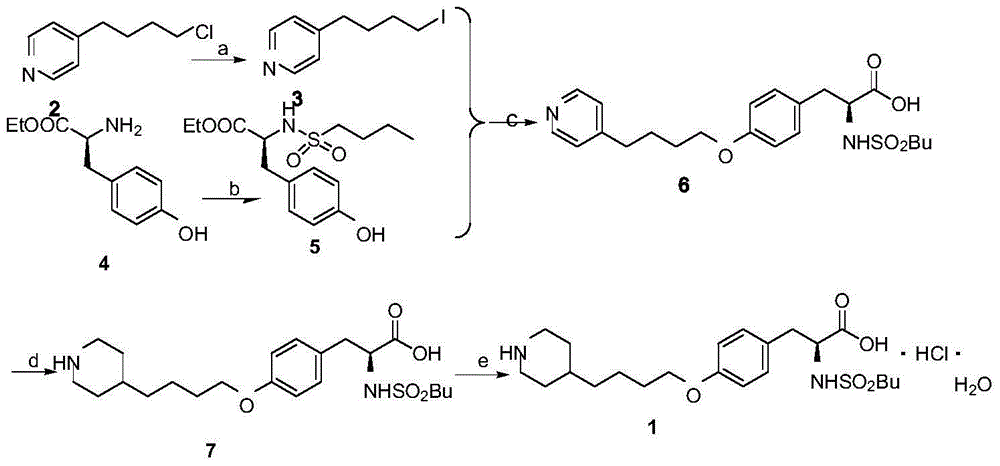

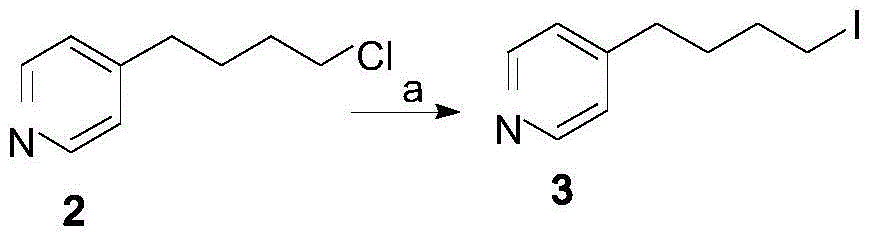

Preparation method of high-purity vortioxetine hydrobromide

ActiveCN104725335ARaw materials are easy to getProcess reaction conditions are mildOrganic chemistryChlorobenzene2-Chlorophenol

The invention discloses a preparation method of high-purity vortioxetine hydrobromide. The method comprises the following steps: firstly, synthesizing 2-(2,4-dimethyl phenyl sulfanyl) chlorobenzene from 2-chlorophenol and 2,4-dimethylbenzenethiol; then, adding di(dibenzylideneacetone)palladium, 1,1'-binaphthyl-2,2'-bis(diphenyl phosphine), sodium tert-butoxide, and methylbenzene into a reaction bottle to mix, and adding other materials so as to prepare vortioxetine; and dissolving the prepared vortioxetine by using 14-16 times of ethyl acetate, so that a vortioxetine hydrobromide coarse product is obtained; and finally, purifying the coarse product so as to obtain a vortioxetine hydrobromide fine-product. The method disclosed by the invention is easily-obtained in raw materials, mild in process reaction conditions, high in product yield, high in product purity, and convenient for industrial production. Prepared vortioxetine hydrobromide is white crystalline powder, and the purity is more than 99.5%.

Owner:郑州大明药物科技有限公司

Bisphenol fluorene synthesizing process catalyzed with solid supported heteropolyacid

InactiveCN1986509AEasy to recycleThe synthesis process is reasonable and feasibleCatalyst carriersOrganic chemistryHeteropoly acidCarboxylic acid

The bisphenol fluorine synthesizing process includes mixing phenol, 9-fluorenone, solid supported heteropoly acid and mercapto carboxylic acid, with phenol / 9-fluorenone molar ratio of 6-14 to 1, solid supported heteropoly acid accounting for 5.0-20.0 % of total reactant weight, heteropoly acid / solid carrier weight ratio of 0.3-1 to 1 and mercapto carboxylic acid / 9-fluorenone weight ratio of 0.02-0.50 to 1, to react at 60-130 deg.c via stirring for 6-14 hr; filtering the reacted product while it is still hot, and recovering the catalyst; washing the catalyst, merging the washed liquid with the filtrate, crystallizing, filtering, drying, recrystallizing in organic solvent and vacuum drying to obtain bisphenol fluorine crystal. The present invention has product purity as high as 99.8 %, simple post-treatment, less metal corrosion and environmental pollution and recovery of catalyst, and may be used widely in the phenol and 9-fluorenone condensation reaction.

Owner:HARBIN ENG UNIV

Copper-based catalyst, preparation method thereof and application of copper-based catalyst to furfural hydrogenation catalysis

InactiveCN109569604ALow costEasy to separateOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsProduct systemReaction rate

The invention discloses a copper-based catalyst taking zirconia as a carrier, a preparation method of the copper-based catalyst and an application of the copper-based catalyst to furfuryl alcohol preparation by furfural hydrogenation. The copper-based catalyst taking the zirconia as the carrier is expressed by a formula Cu / ZrO2-M, wherein Cu is an active component, active metal Cu accounts for 0.05-40% of the total weight of the catalyst, and the carrier ZrO2-M is mesoporous zirconia and accounts for 99.95-60% of the total weight of the catalyst. According to the copper-based catalyst with thezirconia carrier, precious metal is not used as an active component, the copper-based catalyst is low in cost, only contains Cu and the zirconia carrier and is free from other components and simple in preparation process, and furfural conversion rate and furfuryl alcohol selectivity can be effectively improved. Besides, a process for preparing furfuryl alcohol by furfural is mild in reaction condition and high in reaction rate. A product system is simple in separation, and the catalyst is reusable and low in corrosion to equipment. Water serves as a reaction medium, any inorganic acid and alkali are omitted in reaction, and the problem of environmental pollution in the furfural hydrogenation process is avoided.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Method for extracting nickel from laterite-nickel ore and mineralizing CO2 simultaneously

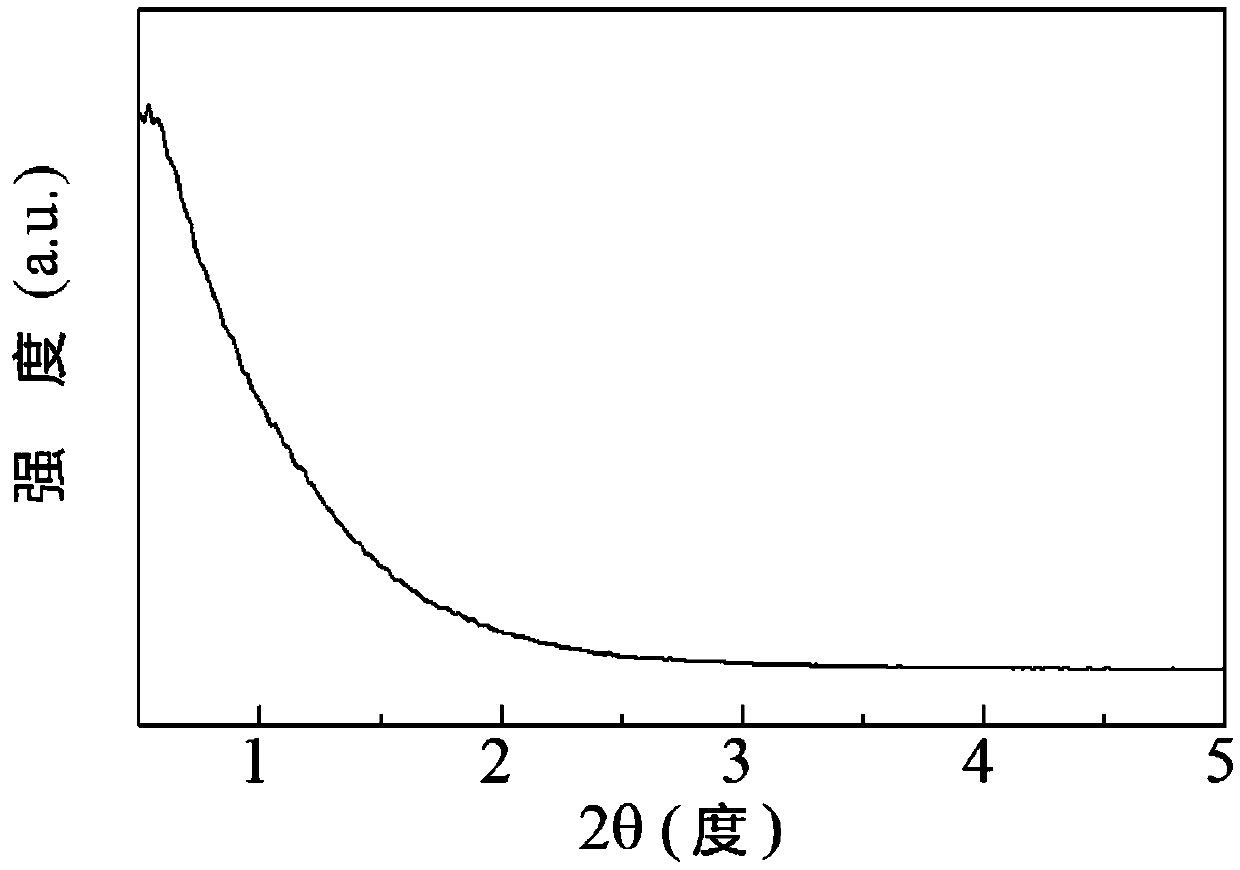

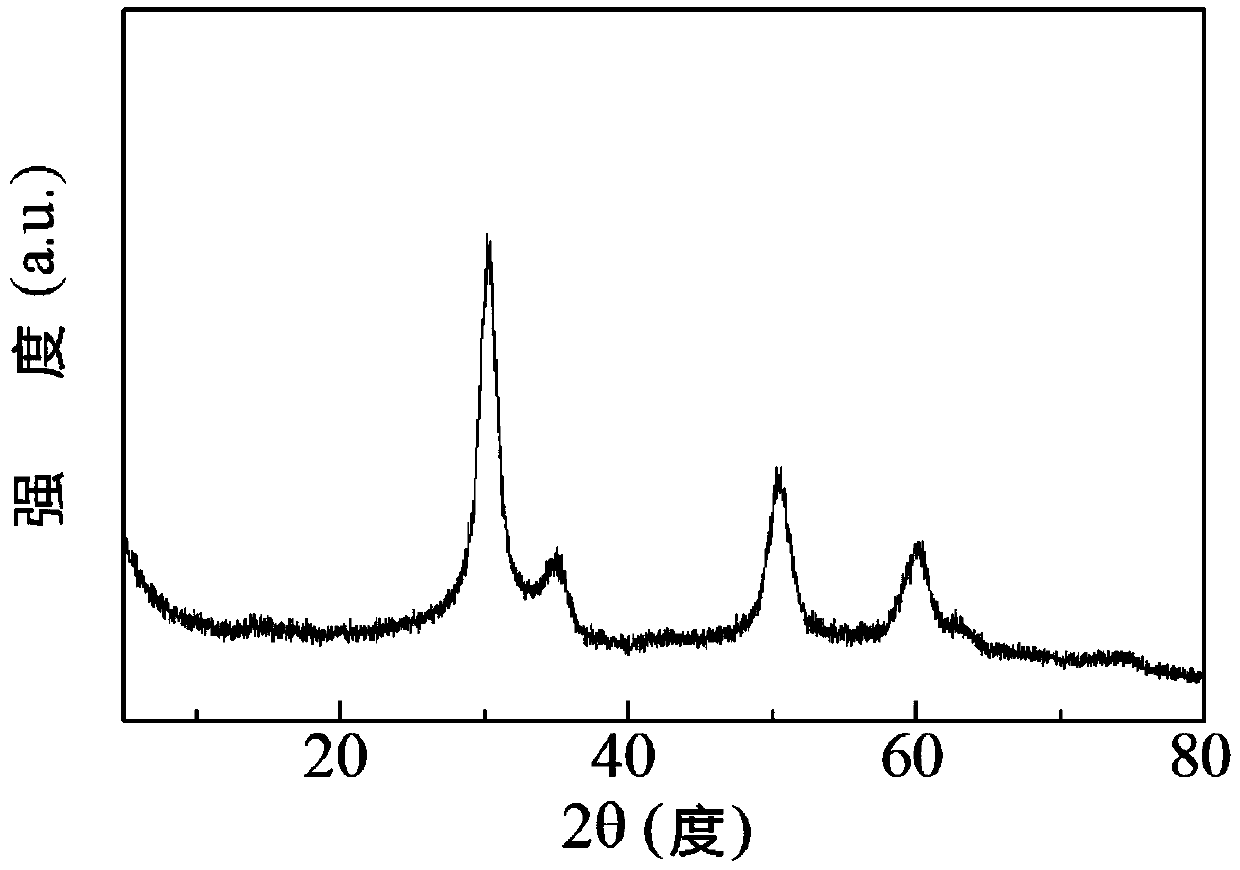

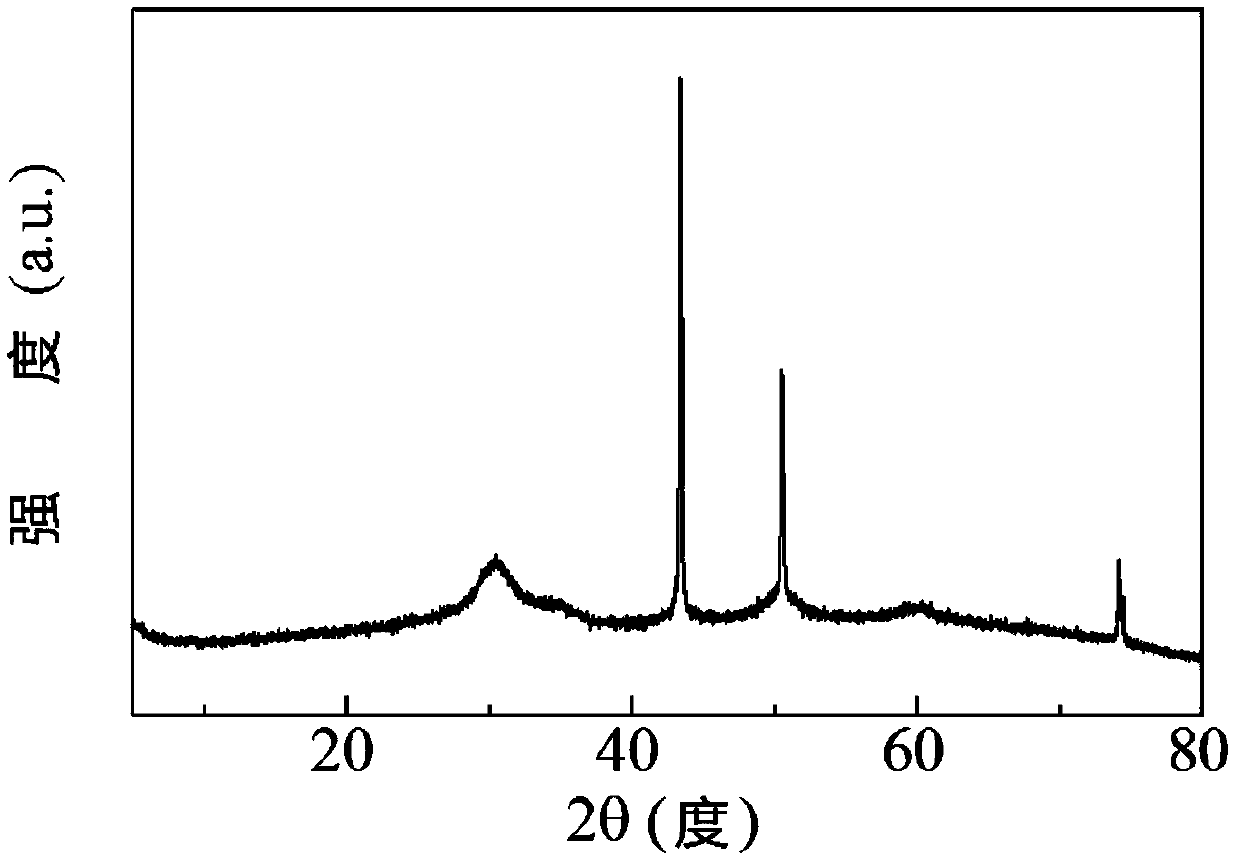

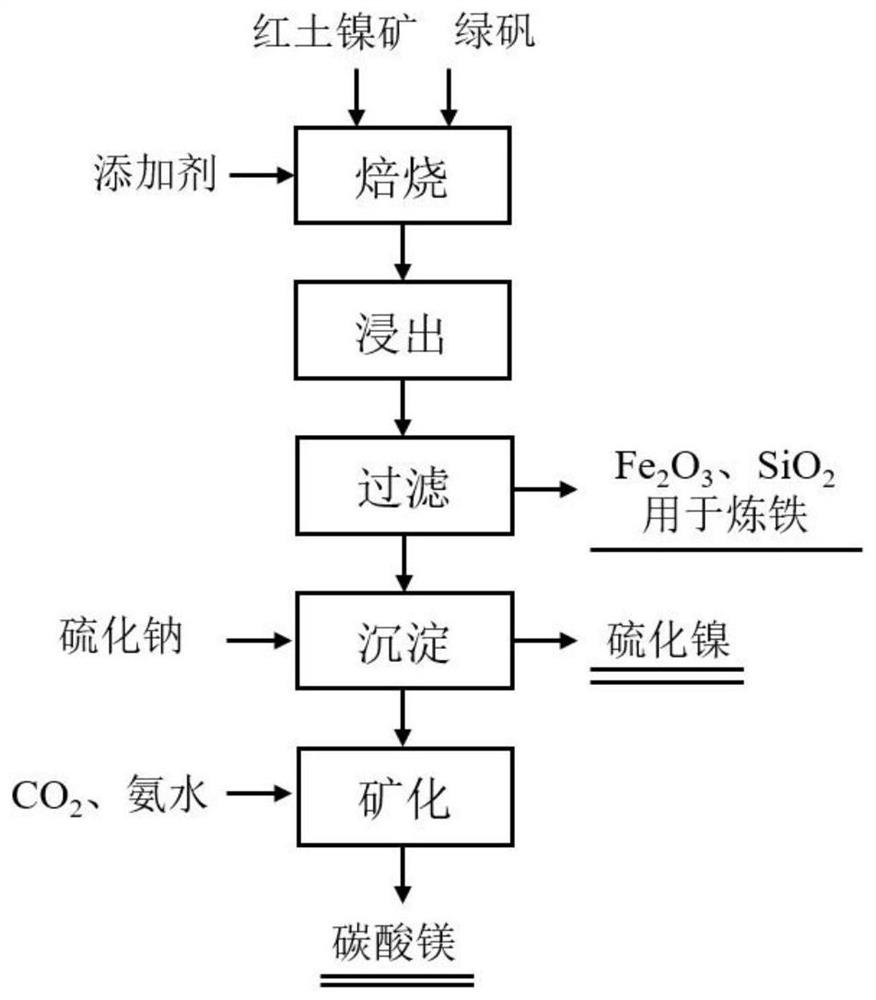

ActiveCN113025832AReduce pollutionNo emissionsMagnesium carbonatesNickel sulfatesPregnant leach solutionMining engineering

The invention discloses a method for extracting nickel from laterite-nickel ore and mineralizing CO2 simultaneously. The method comprises the following steps that (1) the crushed laterite-nickel ore is mixed with copperas and an additive at a certain temperature to be roasted, so that nickel and magnesium elements in the laterite-nickel ore are converted into corresponding sulfate; (2) the roasted product obtained in the first step is leached out with water to obtain a sulfate leaching solution and leaching residues rich in SiO2 and Fe2O3; (3) sodium sulfide is added into the leaching solution to obtain a nickel sulfide product and a precipitation mother solution; and (4) ammonia water is added into the mother solution obtained in the third step, and CO2 is further connected in to generate magnesium carbonate so as to realize CO2 mineralization.

Owner:CHONGQING UNIV

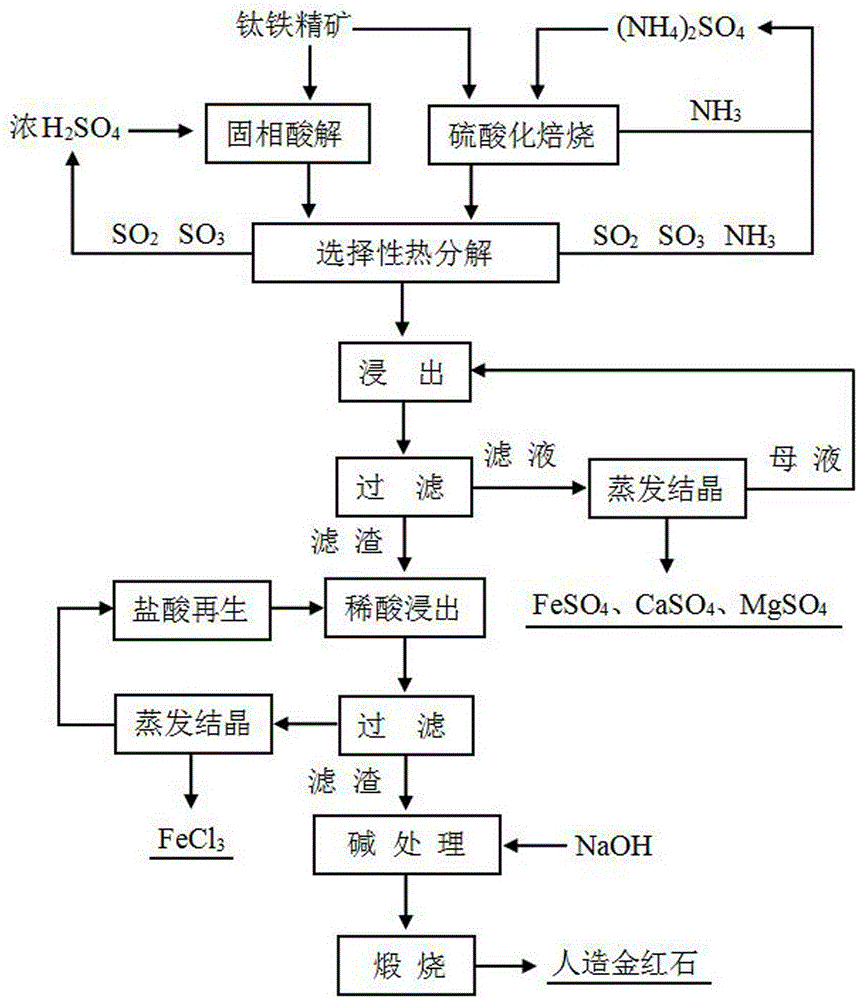

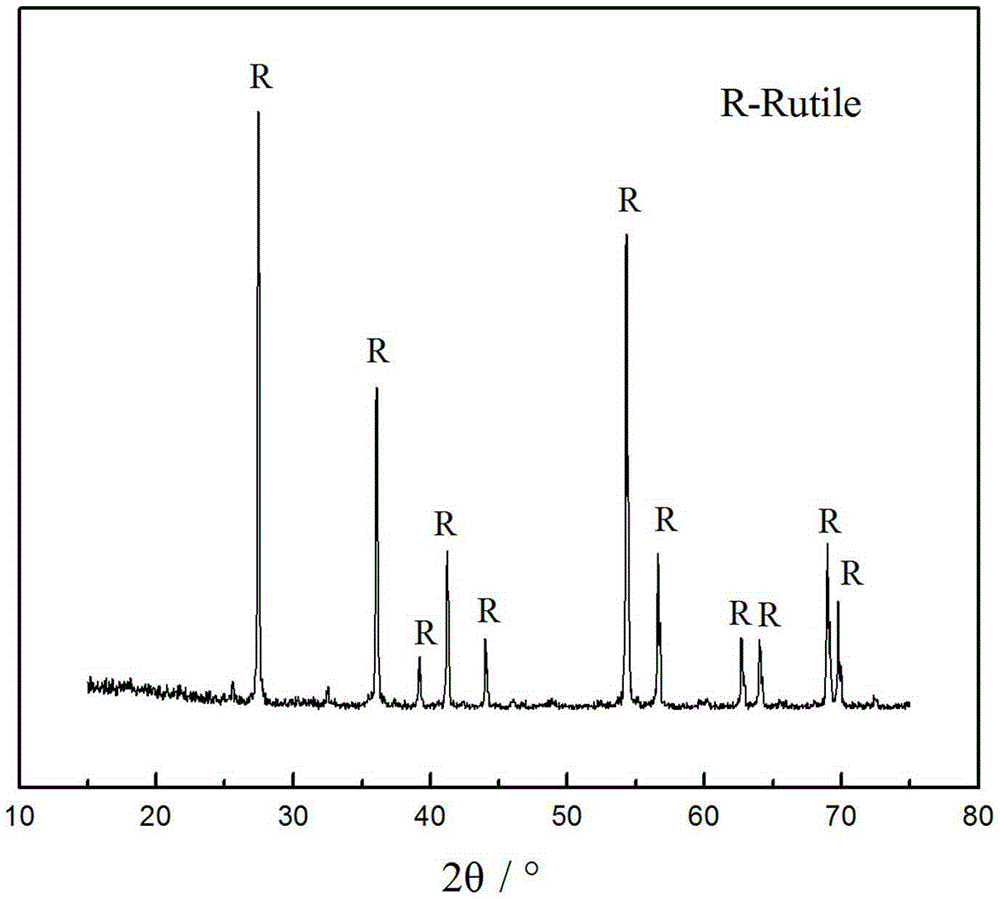

Method for preparing high-grade artificial rutile from high-calcium and high-magnesium rock-mineral ilmenite

InactiveCN105293576AMild reaction conditionsProcess reaction conditions are mildTitanium dioxideChemistryIron oxide

The invention discloses a method for preparing high-grade artificial rutile from high-calcium and high-magnesium rock-mineral ilmenite. The method comprises the following steps: step 1, sulfating and decomposing ilmenite at low temperature and converting titanium, iron, calcium, magnesium and other metal components into corresponding sulfates; step 2, selectively decomposing solid products obtained in the step 1 at moderate temperature to enable TiOSO4 to be resolved into water-insoluble TiO2, (NH4)2Fe(SO4)2 to be resolved into soluble FeSO4 and Fe2(SO4)3 and CaSO4, MgSO4, FeSO4, Fe2(SO4)3 and the like to be not resolved or almost not resolved; step 3, immersing a roasted product obtained in the step 2 with water to enable sulfates of soluble iron, calcium and magnesium to be dissolved so as to effectively separate TiO2 from other metal components to obtain titanium slag; step 4, adopting diluted hydrochloric acid to leach titanium slag in the step III so as to remove insoluble iron oxides generated by decomposition of a small quantity of FeSO2 and Fe2(SO4)3 in the moderate-temperature roasting process; step 5, performing alkaline treatment on the titanium slag obtained in the step 4 to remove acid-insoluble SiO2 in titanium slag; step 6, calcining and transforming the titanium slag obtained in the step 5 to obtain rutile titanium dioxide slag (artificial rutile).

Owner:SICHUAN UNIV

Tirofiban hydrochloride preparation process

ActiveCN104447509AProcess reaction conditions are mildHigh yieldOrganic chemistryChemical industryTirofiban Hydrochloride

The invention belongs to the field of medicine and chemical industry. According to the present invention, the tirofiban hydrochloride prepared through substitution, condensation, reduction, salification and other reactions has characteristics of high yield, good quality and good stability, and the preparation process of the present invention provides a synthesis process suitable for the practical industrial mass production.

Owner:HARVEST PHARMA HUNAN CO LTD

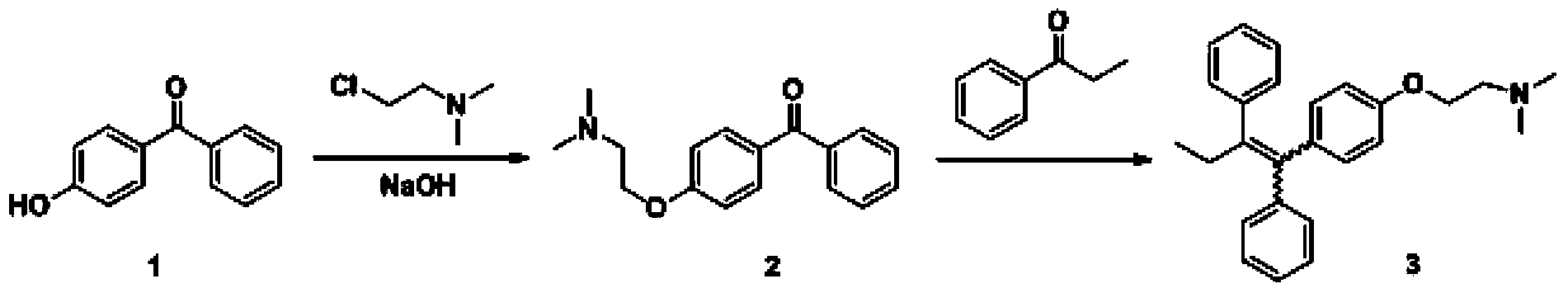

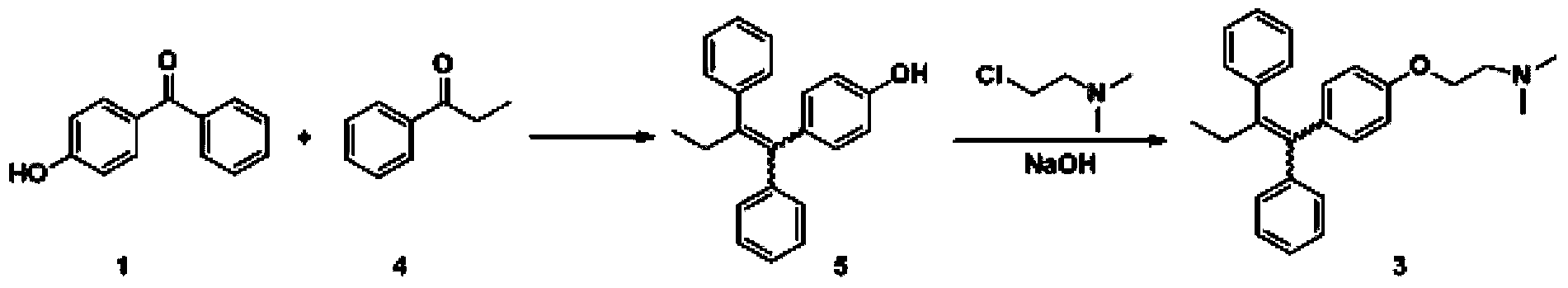

Preparation method of high-purity tamoxifen citrate

InactiveCN103450036ASave operating timeHigh yieldOrganic compound preparationCarboxylic acid salt preparationAlkyl transferIsomerization

The invention discloses a preparation method of high-purity tamoxifen citrate. By improving the problems in the existing route, the invention discloses a novel synthesis method of high-purity low-E-isomer-content tamoxifen citrate. The method comprises the following steps: by using simple and accessible 4-hydroxybenzophenone as a raw material, carrying out coupling reaction and alkylation reaction to obtain a crude product 2-[4-(1,2-diphenyl1-butenyl)-phenoxy]-N,N-dimethylethylamine; directly carrying out isomerization reaction on the crude product, carrying out simple purification, and salifying with citric acid to conveniently obtain the high-purity tamoxifen citrate of which the E isomer content does not exceed 0.05%. The technique adopts a continuous feed mode, and only needs one-step purification, thereby solving the problems of high cost and difficulty in preparing high-purity tamoxifen citrate in pharmaceutical industry. The technique has the advantages of mild reaction conditions, high stability, high purity and high yield, is simple to operate, and provides an option for large-scale production.

Owner:ASYMCHEM LAB TIANJIN +4

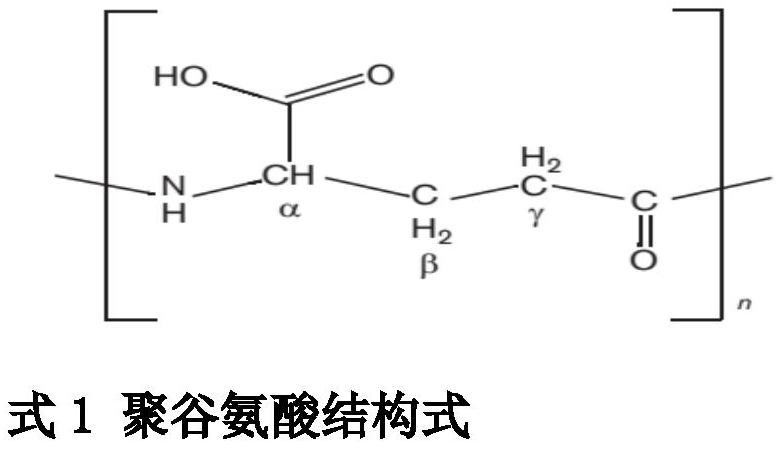

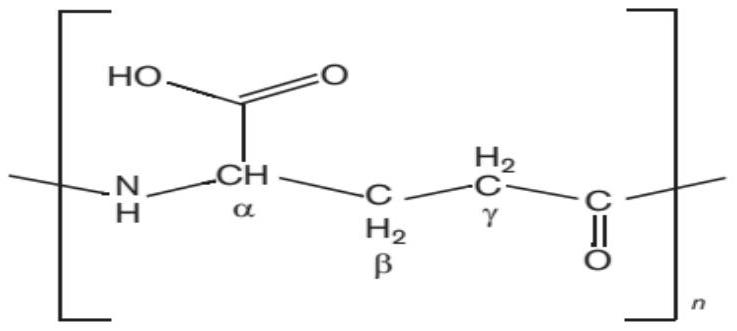

Synergistic stable nitrogenous fertilizer and preparation method thereof

InactiveCN112321361APromote absorptionEffective lockingSuperphosphatesCalcareous fertilisersSoil scienceUrease enzyme

The invention relates to a synergistic stable nitrogen fertilizer and a preparation method thereof. The fertilizer comprises the following components: a nitrogen fertilizer, medium trace elements, a nitrogen regulating synergist (urease inhibitor and / or nitrification inhibitor) and a carbon source synergist, wherein the nitrogen fertilizer is urea, and the medium trace elements comprise calcium, magnesium, sulfur, boron, silicon, iron and zinc. The weight part ratio of the nitrogen fertilizer to the medium trace elements to the nitrogen regulating synergist to the carbon synergist is 1: 0.05-0.1: 0.001-0.1: 0.1-0.3. By adding a certain amount of the carbon synergist and the nitrogen regulating synergist into the fertilizer, the release time and rate of the nitrogen fertilizer can be regulated, the fertilizer efficiency is slow and stable, the fertilizer meets various nutritional requirements of crops in different growth periods, solves the contradiction between crop fertilizer requirement and soil fertilizer supply, reduces greenhouse gas emission and nitrogen leaching loss, and is a novel synergistic stable nitrogen fertilizer.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

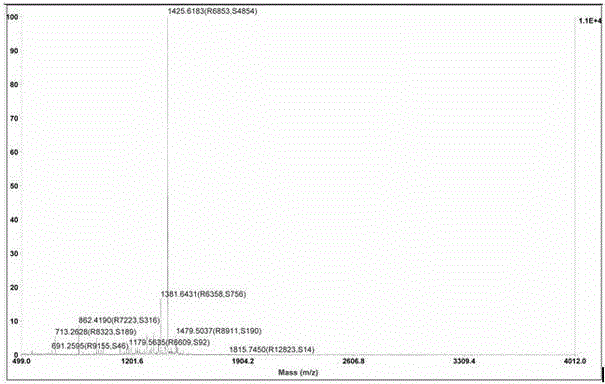

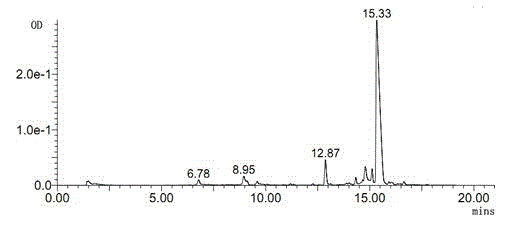

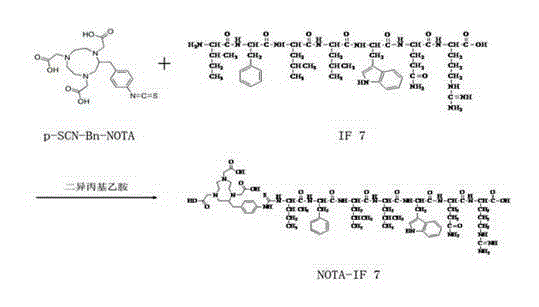

Preparation method of targeting tumor vasculature Anxa1 marked precursor NOTA-IF7

InactiveCN103936830AConveniently preparedTargetedPeptide preparation methodsIn-vivo testing preparationsIsotopic labelingArginine

The invention relates to a preparation method of targeting tumor vasculature Anxa1 marked precursor NOTA-IF7, which belongs to the fields of organic chemistry and medicines. According to the invention, a double-function chelating agent 1,4,7-triazacyclononane-1,4,7- triaceticacid (1,4,7-triazacyclononane-1,4,7- triaceticacid, p-SCN-Bn-NOTA, NOTA for short) is coupled with specifically combined tumor vasculature 7 peptide amino acid (isoleucine-phenylalanine-leucine-leucine-tryptophan-glutamine-arginine, IF7), and a HPLC one-step method is used for purifying to obtain NOTA-IF7. THE preparation method of NOTA-IF7 is simple, the reaction condition of the technology is mild, the yield is high, the product can be used for isotope mark of fluorine-18, copper-64 and gallium-68, and is conveniently prepared to a positron photographic developer for tumor.

Owner:蒋孟军 +4

Lithium hexafluorophosphate synthesis technology with high reaction efficiency

ActiveCN106186004AImprove reaction efficiencyStable temperatureLithium compoundsReaction temperaturePhysical chemistry

The invention discloses a lithium hexafluorophosphate synthesis technology with high reaction efficiency. The technology is characterized by: letting lithium fluoride anhydrous hydrogen fluoride solution from a blending tank pass through an intermediate tank and transferring the solution to a constant temperature mixing cooling kettle by a lithium fluoride anhydrous hydrogen fluoride solution intermediate pump, pumping the feed liquid in the mixing cooling kettle into a reaction tower feed inlet by a circulating absorption pump, performing atomization by an atomizing nozzle, then subjecting the processed feed liquid to full heat transfer and mass transfer with phosphorus pentafluoride gas from a phosphorus pentafluoride purification section, and carrying out synthetic reaction at a temperature at 0-10DEG C and under ordinary pressure, subjecting a little unreacted phosphorus pentafluoride gas to further reactive absorption by the lithium fluoride anhydrous hydrogen fluoride solution in a tail gas balance absorber, making the reacted solution enter the mixing cooling kettle to further participate in circulating absorption reaction. And the reaction tower, the tail gas balance absorber and the constant temperature mixing cooling kettle compose an airtight reaction system. The technology provided by the invention can realize continuous and automatic production, the production cost is low and the product consistency is good.

Owner:JIANGSU JIUJIUJIU TECH

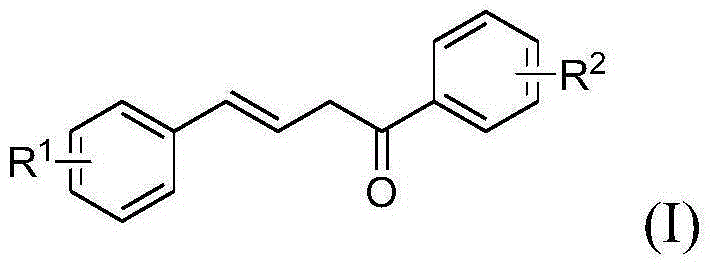

Terphenyl compound and preparation method therefor and application thereof

ActiveCN105175241ASingle structureProcess reaction conditions are mildOrganic compound preparationCarbonyl compound preparationAntitumor activityPhotochemistry

The invention discloses a terphenyl compound represented by a formula (II) and discloses a preparation method for the terphenyl compound and an application of the terphenyl compound in preparing anti-tumor drugs. The preparation method for the terphenyl compound disclosed by the invention is simple in process, mild in reaction condition, convenient to operate and low in cost and has a wide industrial application prospect. The product is single in structure, generates no isomers and has anti-tumor activity. The formula (II) is as shown in the description.

Owner:邳州市润宏实业有限公司

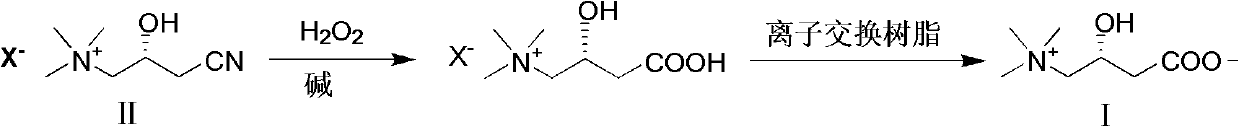

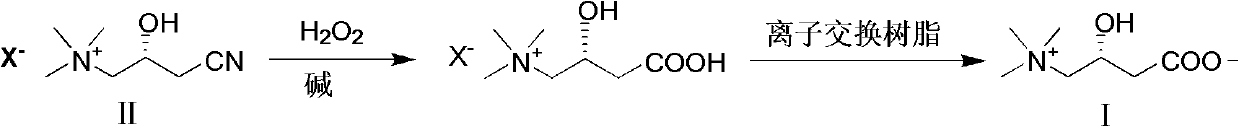

Synthesis method of L-carnitine

InactiveCN102020575AProcess reaction conditions are mildShort reaction timeOrganic compound preparationAmino-carboxyl compound preparationSynthesis methodsIon exchange

The invention discloses a synthesis method of L-carnitine with a structure shown in a formula (1), which adopts L-(-)-3-cyan-2-hydroxyl propyl trimethylamine halide as a raw material and is prepared by hydrolysis and ion exchange; the hydrolysis is carried out in the following steps: in alkaline solution, hydrogen peroxide is used for hydrolyzing the L-(-)-3-cyan-2-hydroxyl propyl trimethylamine halide, and after full reaction, the hydrolysis reaction liquid is obtained. In the technique disclosed in the invention, the reaction condition is mild, the reaction time is short, the reaction yield is high, three wastes are less, and the implementation value and social and economic benefits are larger.

Owner:ZHEJIANG UNIV OF TECH +1

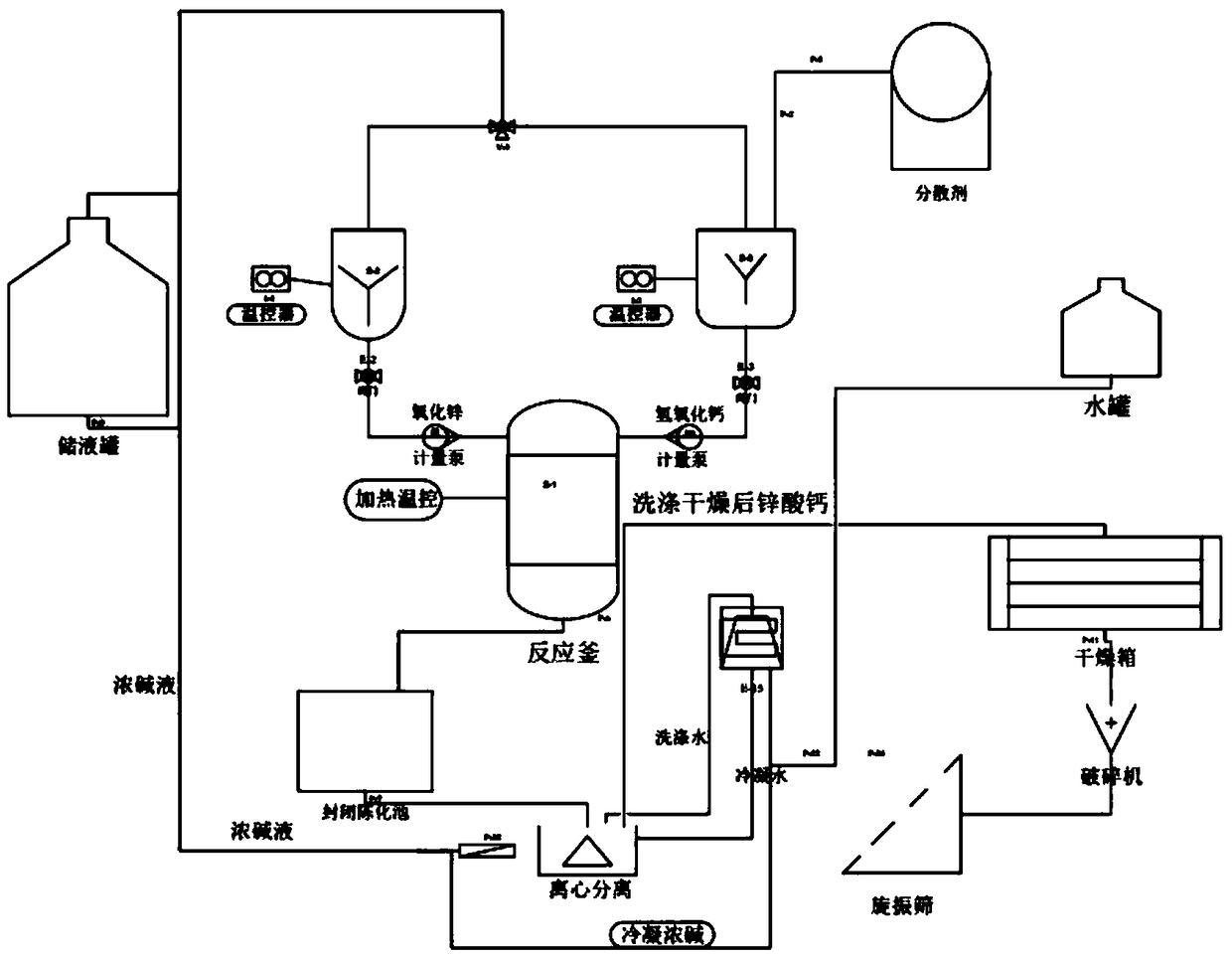

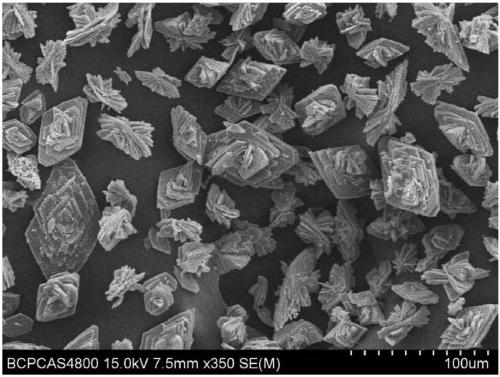

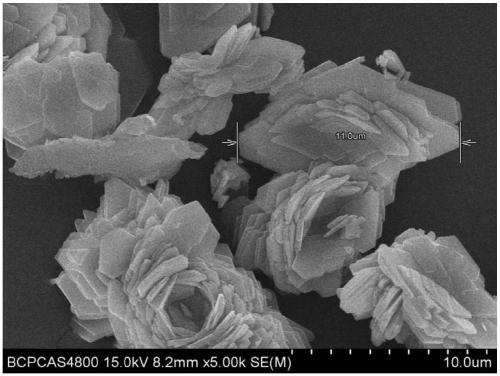

Synthetic process and equipment for calcium zincate as zinc-nickel battery negative electrode material

ActiveCN109455754AHigh purityAvoid the phenomenon of different shapes and uneven particle sizesCell electrodesZinc compoundsCalcium hydroxideOrganic acid

The invention relates to the technical field of calcium zincate synthesis and discloses a synthetic process for calcium zincate as a zinc-nickel battery negative electrode material. The synthetic process comprises the following steps of 1, mixing zinc oxide with organic acid, performing full reaction, performing filtering to remove impurities, then adding a certain quantity of strong alkaline solution, and performing mixing reaction to form a zincate solution; 2, (1) performing reaction on the organic acid and calcium hydroxide to produce an organic acid calcium solution, then dropwise addinga dispersant to form a mixed solution; or (2) adding the calcium hydroxide in a certain quantity of water, then dropwise adding the dispersant to form suspension liquid; 3, mixing products prepared instep 1 and step 2; 4, transferring reaction liquid obtained in step 3 into an ageing groove, performing still standing for 2-48 h, then performing centrifugal treatment, washing and drying filter residues, and performing crushing and sieving to obtain a product; and 5, recovering filtrate obtained in step 4 as a reaction medium for recycling use. The process realizes recycling of alkaline liquorand reduces pollution.

Owner:森克创能(天津)新能源科技有限公司

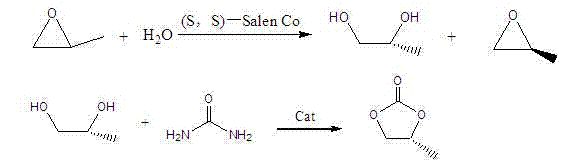

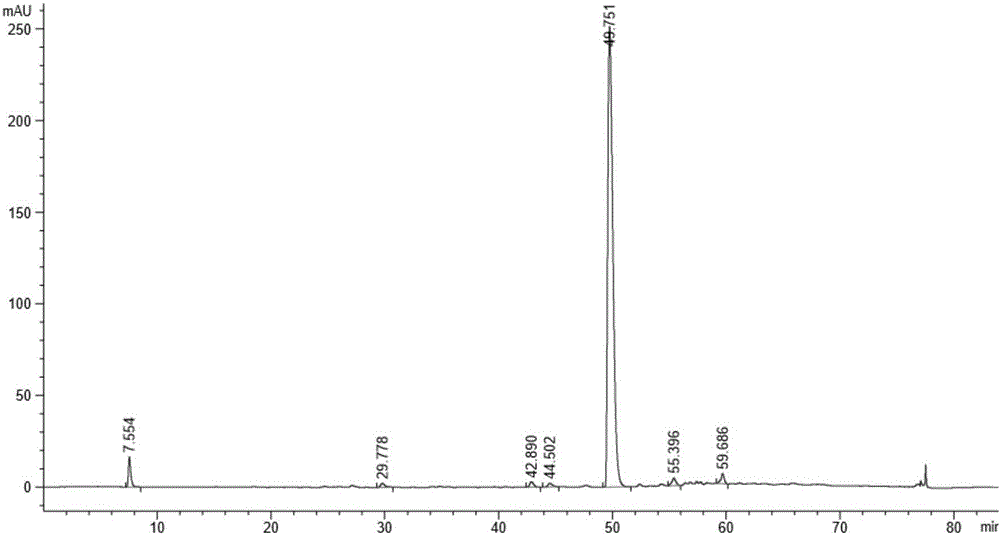

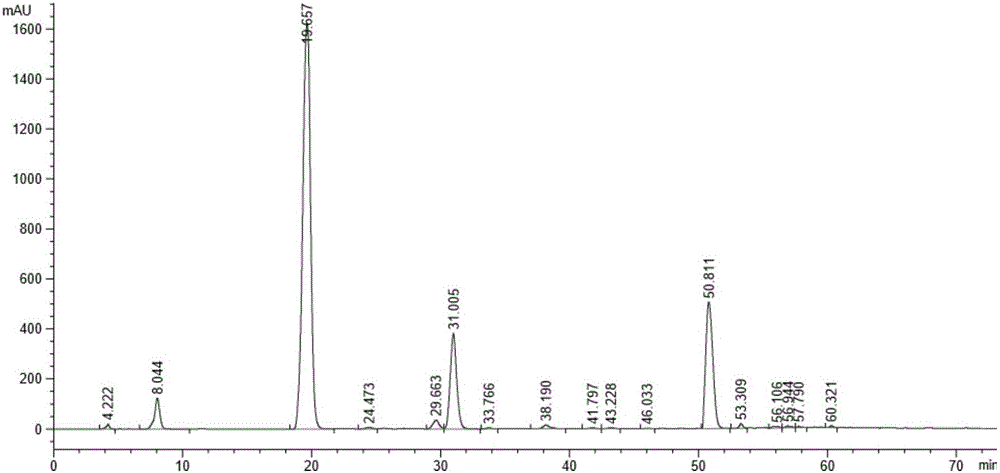

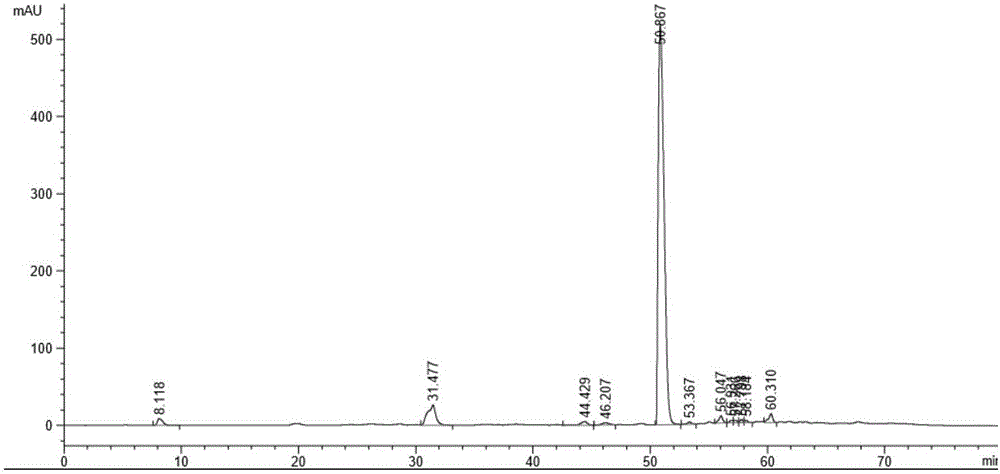

Preparation method of (R)-propylene carbonate

The invention relates to a preparation method of (R)-propylene carbonate and belongs to the technical field of medicine production and the technical field of preparation of a tenofovir intermediate particularly. The preparation method comprises the following steps of: activating a catalyst by adopting methylbenzene and acetic acid in air; mixing epoxy propane and the activated catalyst, then dropwise adding water, then stirring to react under the condition of normal temperature, then distilling out (S)-epoxy propane, and then carrying out reduced pressure distillation to obtain (R)-1,2-propanediol; mixing (R)-1,2-propanediol, carbamide and zinc oxide, reacting till the end under the condition of environmental temperature of 100-120 DEG C, then carrying out the reduced pressure distillation to remove (R)-1,2-propanediol, and then continuously distilling to obtain the (R)-propylene carbonate. The preparation method disclosed by the invention is low in production cost. According to the preparation method, the excessive (R)-1,2-propanediol is recovered to be continuously used, and the used raw material urea is more favorable to clean production in comparison with diethyl carbonate.

Owner:扬州三友合成化工有限公司

Synthetic method for 1,2-di-O-isopropylidene-3,5,6-tri-O-benzyl-D-glucofuranose

InactiveCN106046067AEasy feedingEffective controlSugar derivativesSugar derivatives preparationDistillationTribenoside

The invention discloses a synthetic method for a key tribenoside intermediate 1,2-di-O-isopropylidene-3,5,6-tri-O-benzyl-D-glucofuranose. The method comprises the following steps: adding 1,2-di-O-isopropylidene-D-glucofuranose as shown in a formula (I) which is described in the specification into benzyl chloride, controlling temperature, carrying out stirring and adding inorganic base; carrying out a nucleophilic substitution reaction under alkaline conditions; and then carrying out molecular distillation and purification so as to obtain high-purity high-content 1,2-di-O-isopropylidene-3,5,6-tri-O-benzyl-D-glucofuranose (II). The method provided by the invention has the advantages of mild reaction conditions, capacity of controlling generation of impurities, usage of a small amount of solvents, simple and convenient operation, no pollution and suitability for large-scale production; the manner of molecular distillation and purification can remove impurities which cannot be removed by using a common high temperature reduced-pressure distillation manner, product purity can reach 92.3%, and product content reaches 95%; and the high-content intermediate 1,2-di-O-isopropylidene-3,5,6-tri-O-benzyl-D-glucofuranose is beneficial for preparation of tribenoside (III).

Owner:山东康曼生物科技有限公司

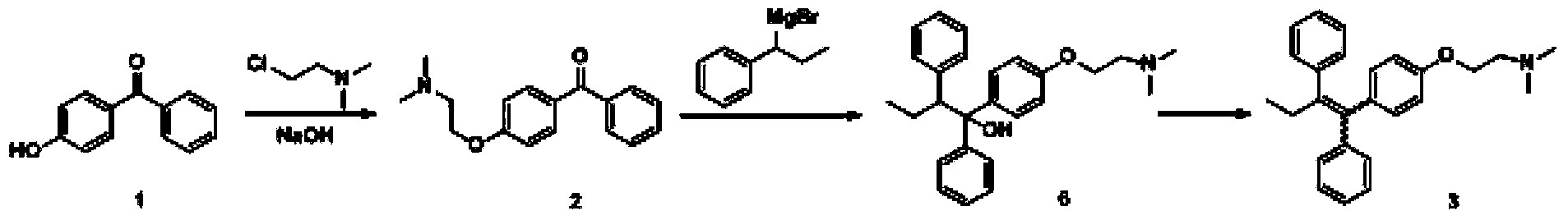

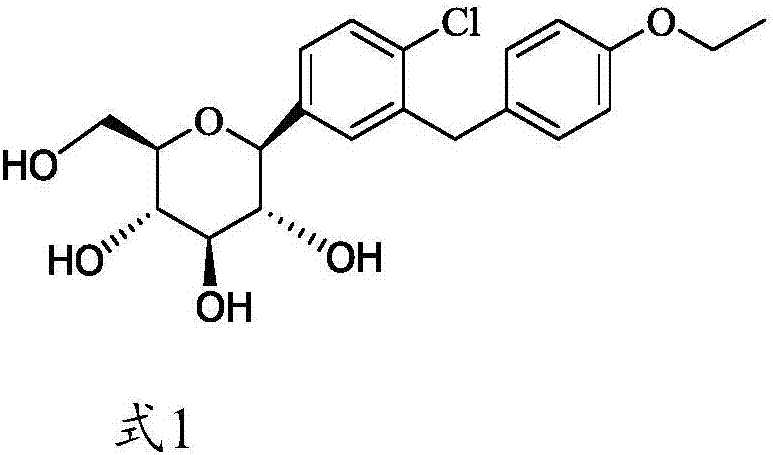

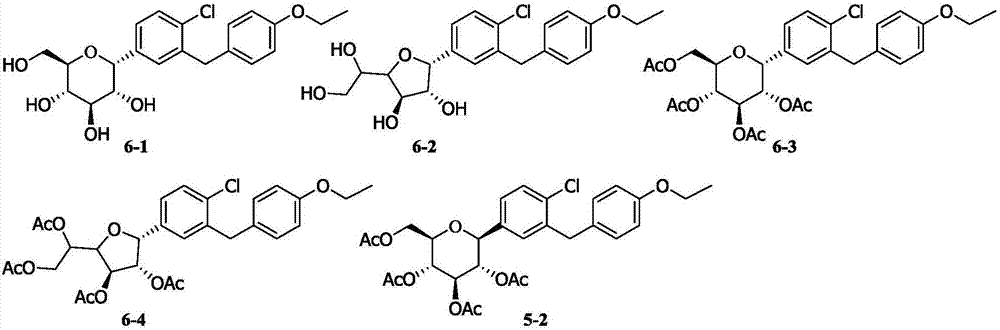

Method for synthesizing irregular glucitol

The invention relates to a method for synthesizing irregular glucitol (1S)-1,5-dehydration-1-[4-chlorine-3-[(4-ethyoxyl phenyl) methyl] phenyl]-D-glucitol. The reaction formula of the compound is as shown in the specification. The method is gentle in process reaction condition, simple and convenient to operate, applicable to industrial production and relatively high in total product yield, that is, the total product yield is 43-53%, and medicine-grade irregular glucitol 6 is easily prepared.

Owner:SHANGHAI SHYNDEC PHARMA CO LTD

Production technique of tenofovir disoproxil fumarate

InactiveCN105566394AHigh purityProcess reaction conditions are mildOrganic compound preparationGroup 5/15 element organic compoundsIce waterOrganic solvent

The invention provides a production technique of tenofovir disoproxil fumarate. The production technique comprises the following steps: directly adding an ice-water mixture into a reaction solution in the tenofovir disoproxil fumarate preparation process, and crystallizing by physical cooling to obtain the tenofovir disoproxil fumarate, wherein excessive chloromethyl isopropyl carbonate and other organic solvents, the catalyst and impurities can completely enter the water layer; and dissolving in dichloromethane, and washing with water to remove a small amount of impurities entrained by the tenofovir disoproxil fumarate to obtain the tenofovir disoproxil fumarate with the purity of 95% or above, wherein the purity of the product after direct salification is up to 99% or above.

Owner:JINGMEN SHUAIBANG CHEM SCI & TECHCO

Aromatic amido replaced s-triazine compound and preparation and application

ActiveCN108794414AMild reaction conditionsRaw materials are easy to getOrganic chemistryAntineoplastic agentsDrugSolvent

The invention provides an aromatic amido replaced s-triazine compound. A 2-amino-1,3,5-triazine compound and a cyanogen compound are mixed and then a solvent is added, reaction is performed under theeffect of a copper catalyst, and reaction liquid posttreatment is performed to obtain the compound. According to the preparation method of the compound, reaction conditions are mild, raw materials areeasy to obtain, operation is convenient, the cost is low, and the compound has a wide industrial application prospect. The aromatic amido replaced s-triazine compound has certain anti-human osteogenic sarcoma cell activity and can be applied to preparation of an antitumor drug, especially to preparation of drugs for treating osteogenic sarcoma. A structural general formula of the compound is shown in the description.

Owner:ZHEJIANG UNIV

Preparation method of isophorone diamidoformate

ActiveCN103012210AReduce usageProcess reaction conditions are mildCarbamic acid derivatives preparationOrganic compound preparationIsophoroneDistilled water

The invention relates to a preparation method of isophorone diamidoformate. The method comprises the following steps: getting dimethyl carbonate and isophorone diamine as the raw materials; and catalyzing the raw materials to react by virtue of a loaded solid catalyst; and then separating by distilled water so as to obtain the product that is the isophorone diamidoformate. The method is free from hypertoxic phosgene, environmentally-friendly, and mild in reaction condition, can be carried out at medium and low temperature, and brings simple requirements to equipment; the catalyst can be conveniently separated and recycled; and the product is separated by adding the distilled water, and the rectification is saved, so that the operation is simple and convenient, and the purity of the product is higher.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

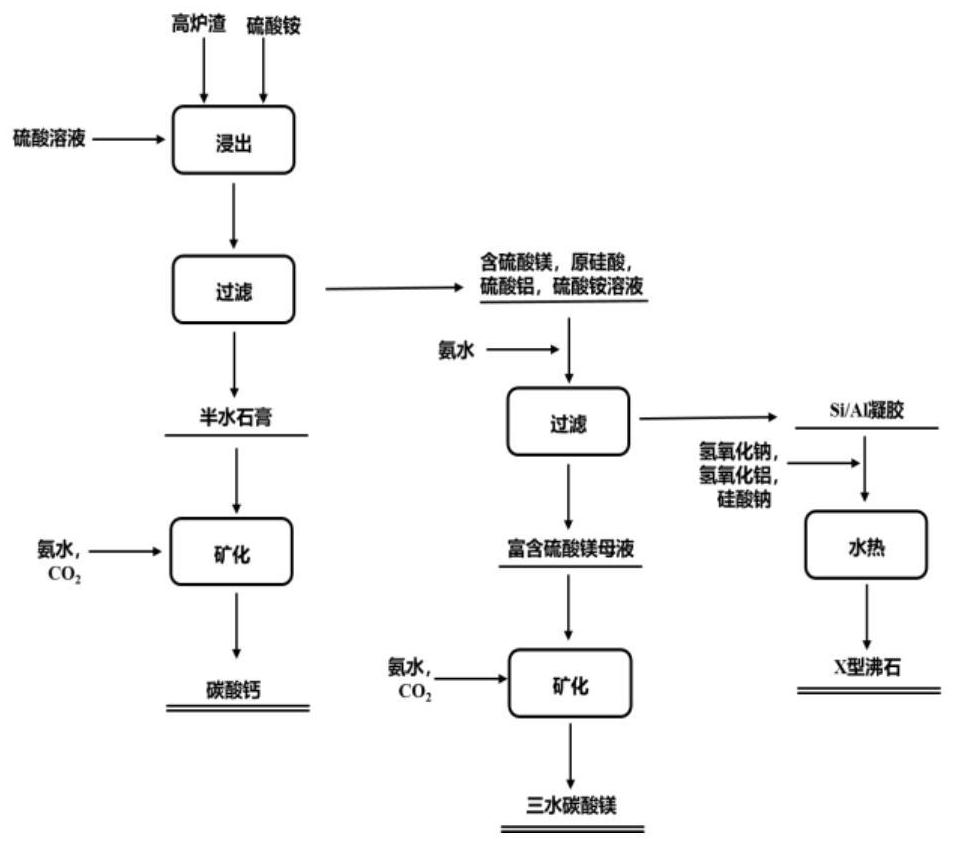

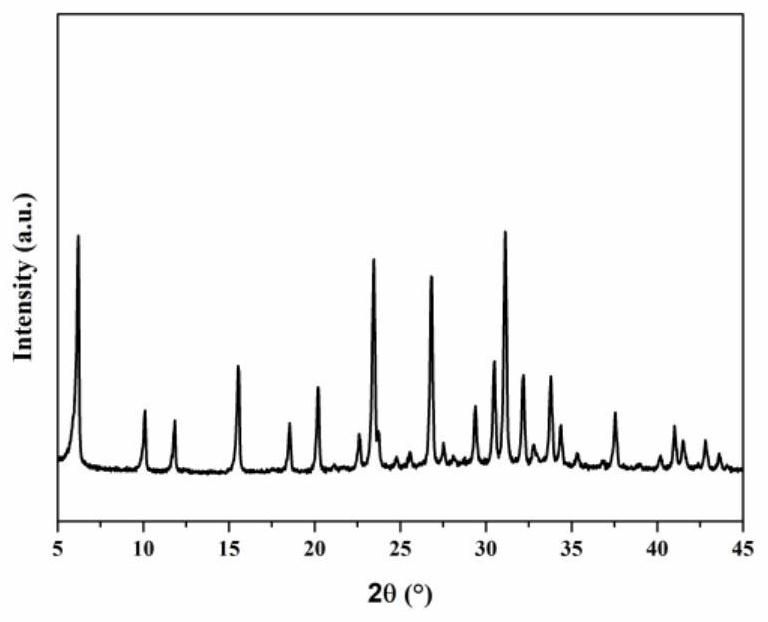

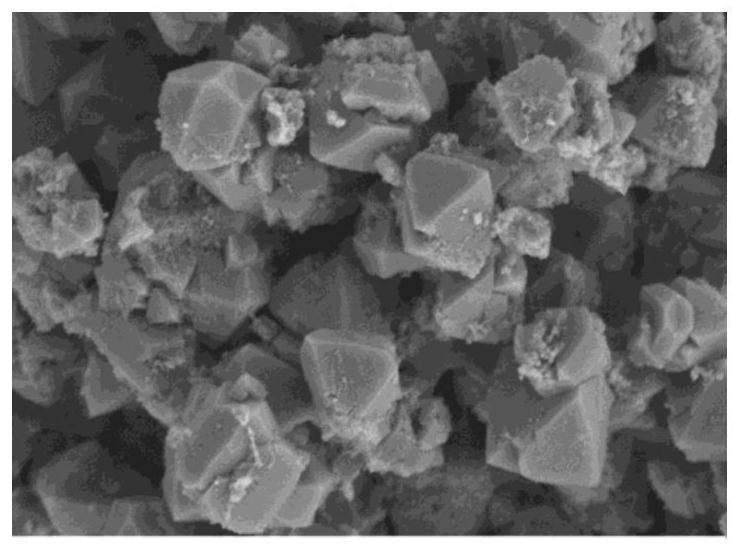

Method for co-producing X-type zeolite by mineralizing CO2 with blast furnace slag

PendingCN113860307AHigh purityRealize resource utilizationCalcium/strontium/barium carbonatesCarbon compoundsAluminium hydroxideSlag

The invention discloses a method for co-producing X-type zeolite by mineralizing CO2 with blast furnace slag, which comprises the following steps: (1) mixing blast furnace slag and ammonium sulfate, and conducting leaching with a sulfuric acid solution to obtain a sulfate leaching solution and semi-hydrated gypsum leaching slag; (2) adding ammonia water into the leachate obtained in the first step, adjusting the pH value, precipitating silicon and aluminum to form silica-alumina gel, and conducting filtering to obtain silica-alumina gel and magnesium sulfate mother liquor; (3) dissolving aluminum hydroxide, sodium hydroxide and sodium silicate in water according to a certain proportion, and fully conducting stirring to obtain white sol (guiding agent) for later use; (4) adding a proper amount of a guiding agent into the silica-alumina gel obtained in the step (2), fully conducting mixing with sodium hydroxide, putting the mixture into a reaction kettle, carrying out hydrothermal reaction for a period of time, and washing a solid product with deionized water to obtain X-type zeolite; and (5) adding ammonia water into the semi-hydrated gypsum leaching residues obtained in the first step and the second step and the magnesium sulfate mother liquor, introducing CO2 to generate calcium carbonate and magnesium carbonate trihydrate respectively, so as to achieve CO2 mineralization.

Owner:CHONGQING UNIV

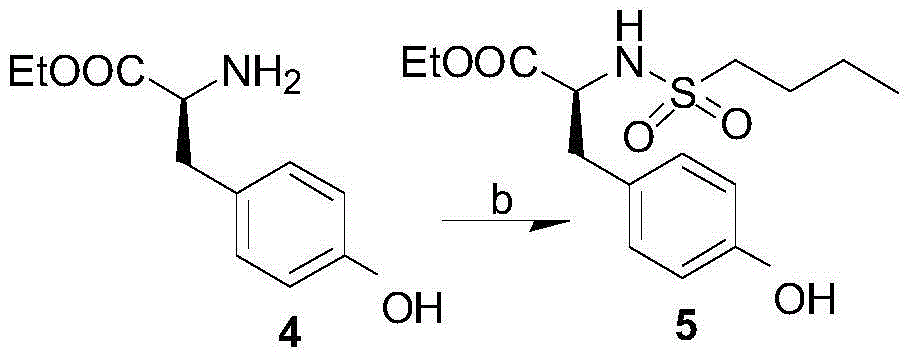

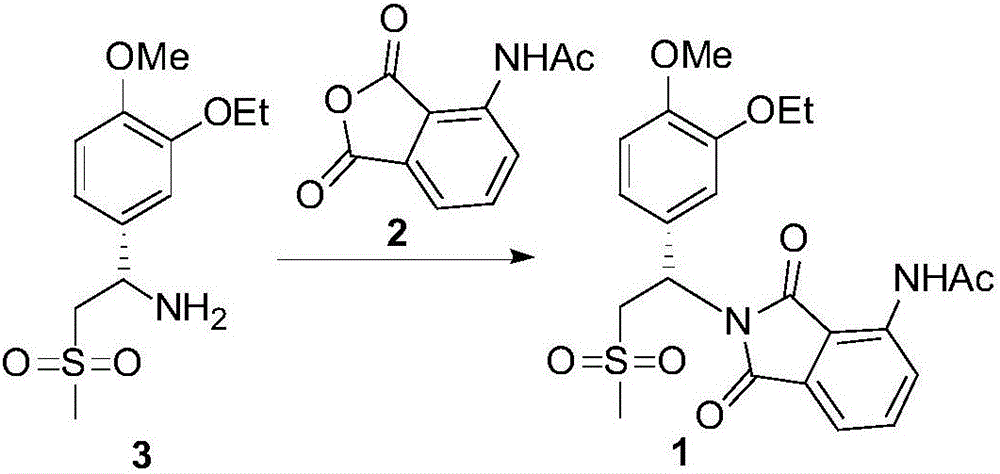

Synthesis process of apremilast intermediate

ActiveCN106543050AProcess reaction conditions are mildShort stepsOrganic compound preparationOptically-active compound separationMethoxystemofolineAlcohol

The invention discloses a synthesis process of an apremilast intermediate. The synthesis process comprises the following steps: (a) carrying out reaction on 3-ethoxyl-4-methoxystyrene and methanesulfonyl chloride under the action of a ruthenium catalyst to generate 4-[(1-chloro-2-methylsulfonyl)-ethyl]-2-ethoxyl-1-methoxybenzene; and (b) carrying out reaction on 4-[(1-chloro-2-methylsulfonyl)-ethyl]-2-ethoxyl-1-methoxybenzene and an alcohol liquid of ammonia, so as to obtain 1-(3-ethoxyl-4-methoxyl)phenyl-2-methylsulfonylethylamine. The synthesis process is simple and convenient to operate, and special reaction conditions are not needed, so that the synthesis process is more suitable for industrial production.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com