Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "No brittleness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin self-repairing microcapsule and preparation method thereof

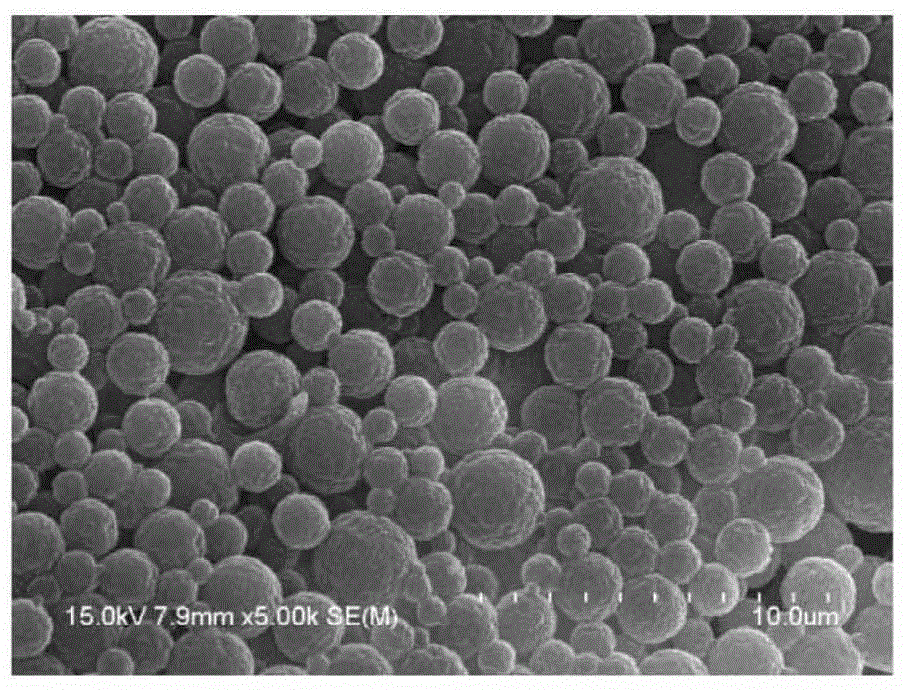

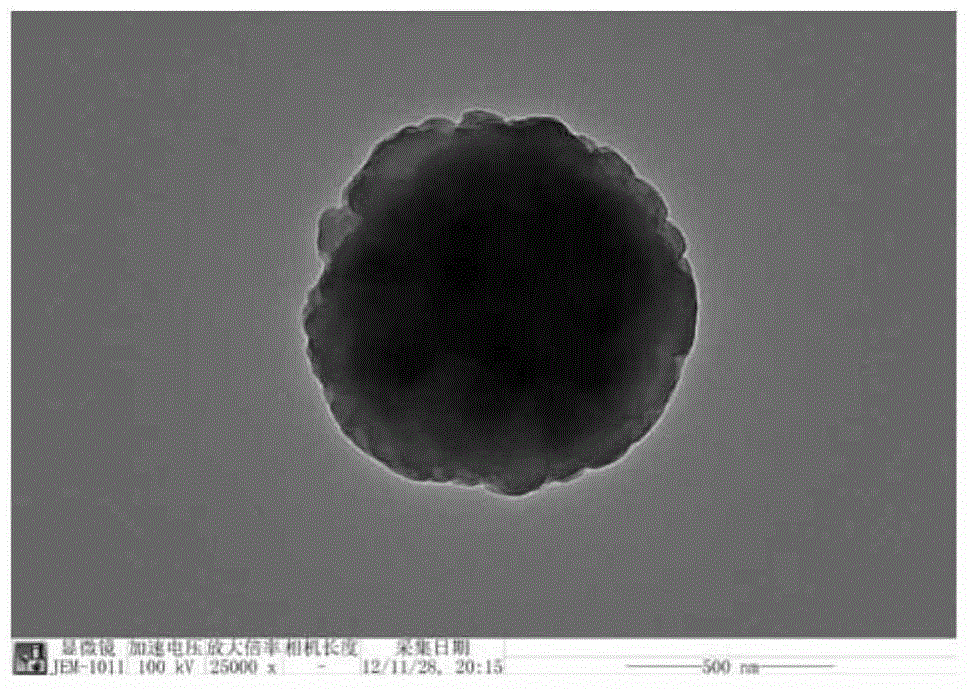

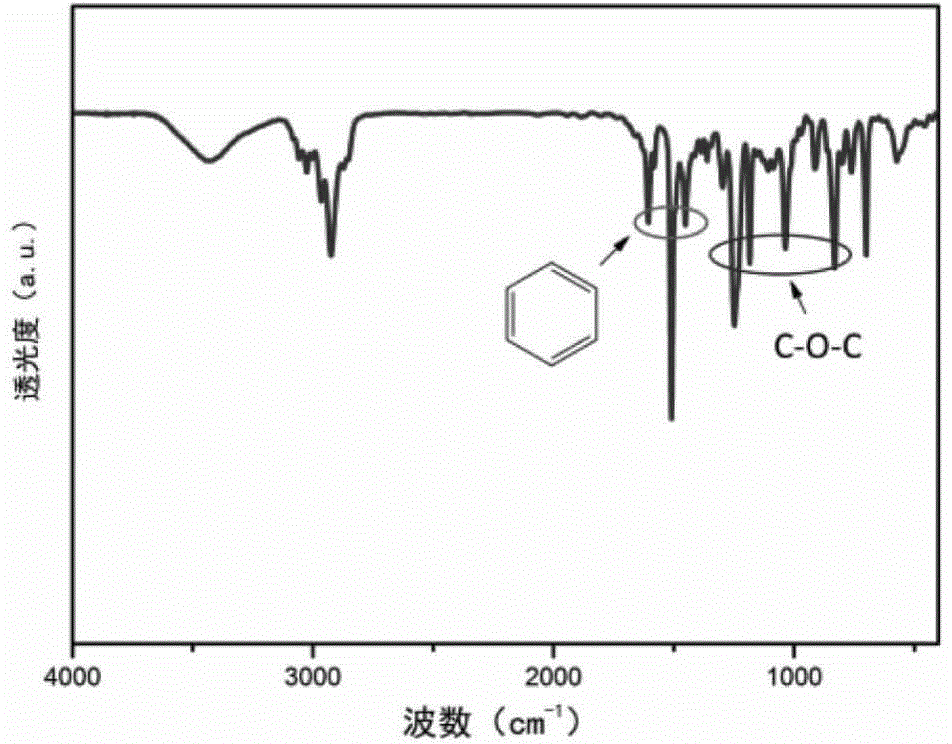

InactiveCN104624132AComposition is easy to controlImprove stabilityMicroballoon preparationMicrocapsule preparationEpoxyEmulsion polymerization

The invention provides an epoxy resin self-repairing microcapsule and a preparation method thereof. The method comprises the following steps: mixing a water phase containing inorganic nanoparticles and water with an oil phase containing epoxy resin, monoolefin monomer, a polyene cross-linking agent and an initiator to form a stable oil-in-water emulsion; and heating the emulsion to realize emulsion polymerization in order to form the epoxy resin self-repairing microcapsule. The epoxy resin self-repairing microcapsule is prepared by adopting the inorganic nanoparticles as an emulsifier through an emulsion polymerization process via the method; and compared with methods adopting molecular emulsifiers, the method provided by the invention has the advantages of no need of subsequent emulsifier removal, simple process, and no pollution to environment. The epoxy resin self-repairing microcapsule prepared in the invention has the advantages of excellent stability, excellent leakproofness and high cladding rate.

Owner:INST OF CHEM CHINESE ACAD OF SCI

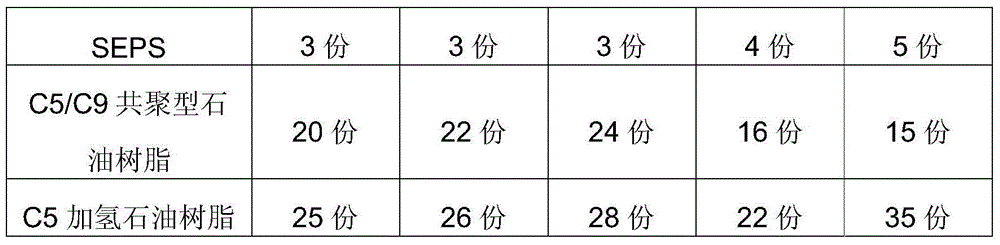

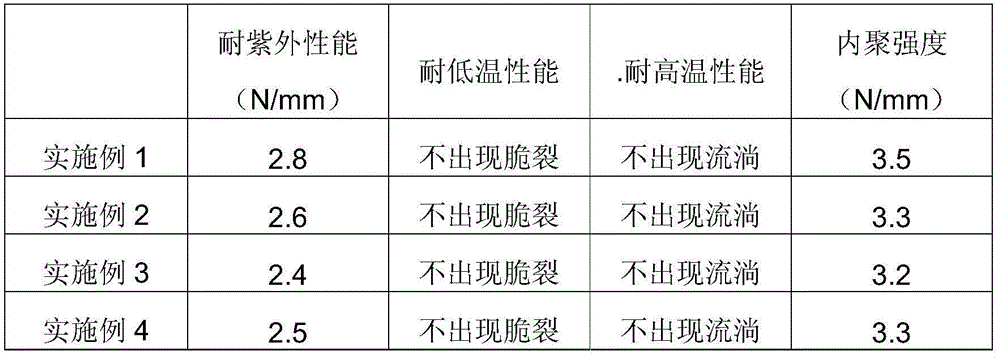

Hot melt adhesive for non-asphaltic base pre-laid polymeric waterproof rolls, and preparation method thereof

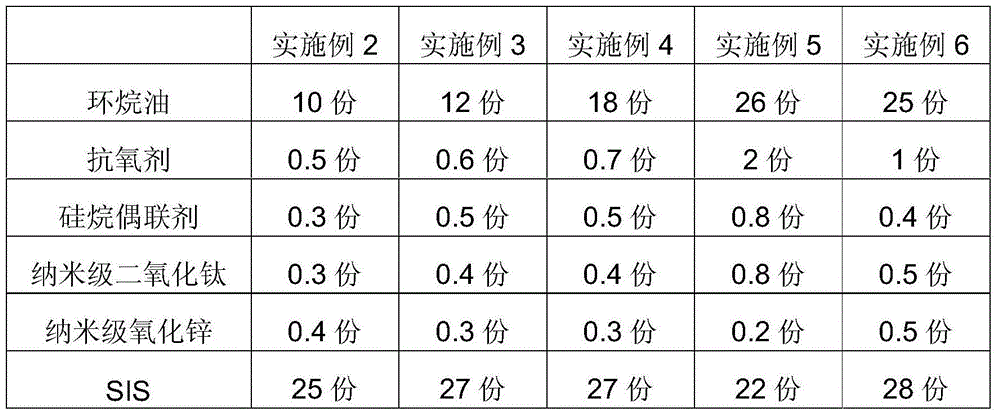

ActiveCN105086895AImproves UV resistanceImprove low temperature resistanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantTemperature resistance

The invention provides a hot melt adhesive for hot melt adhesive for non-asphaltic base pre-laid polymeric waterproof rolls. The The hot melt adhesive for non-asphaltic base pre-laid polymeric waterproof rolls comprises 10-30 parts of naphthenic oil, 0.1-3 parts of an antioxidant, 0.1-1 part of a silane coupling agent, 0.1-1 part of nanometer titanium dioxide, 0.1-1 part of nanometer zinc oxide, 20-32 parts of a styrene-isoprene-styrene copolymer, 1-5 parts of a styrene-hydrogenated isoprene-diblock copolymer, 15-30 parts of C5 / C9 copolymerized petroleum resin and 20-35 parts of C5 hydrogenated petroleum resin. The invention also provides a preparation method of the hot melt adhesive for non-asphaltic base pre-laid polymeric waterproof rolls. The hot melt adhesive has the advantages of excellent ultraviolet resistance, good low temperature resistance, good high temperature resistance, and appropriate cohesion strength, initial adhesion and peel strength, can be firmly pasted to a base material, can be firmly pasted to reaction sand particles spread on the surface of the base material, and has good weatherability.

Owner:HUIZHOU NENGHUI CHEM CO LTD

Tissue section cutting method for sea water left eye floundre and right eye founder fertilized egg

InactiveCN1749730ANo brittlenessNormal sliceWithdrawing sample devicesPreparing sample for investigationEmbryoPerivitelline space

The present invention relates to microscopic tissue section technology, and establishes one effective tissue section method for the fertilized egg of sea water left eyed founder and right-eyed founder based on the features of the fertilized egg of sea water left eyed founder and right-eyed founder. The fertilized egg is polylecithal pelagic egg with high egg membrane toughness and narrow perivitelline space. The tissue section method includes the following steps: 1. fixing the polylecithal pelagic egg with Bouiní»s fixing fluid and optimizing treatment period; 2. pricking the egg membrane with dissecting needle in the vegetative pole direction to peel off the egg membrane; and 3. directly embedded to fix embryo with hot agar. The method is simple and effective, and may be also applied in the tissue section of other sea water fish egg.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Iron and aluminum intermetallic compound and steel impulse fusion welding method

InactiveCN101195187AImprove welding efficiencyLow costArc welding apparatusWelding/soldering/cutting articlesArgon flowPulse duration

The invention discloses a method for fusion-welding iron-aluminum inter-metallic compounds and steel through pulses. The invention adopts Cr25Ni13Mo2Nb austenite steel welding wires as filling materials and inertia gas protection. The invention takes argon tungsten pulsed arc welding to weld the iron-aluminum inter-metallic compounds and carbon steel or stainless steel. The diameter of the austenite steel welding wires is 1.6-3.0 mm, the inertia gas protection is argon, the processing parameters of the argon tungsten pulsed arc welding are that base current is 70A-180A, pulse current is 100A-250A, pulse duration is 0.15s-0.60s, welding voltage is 12V-18V, argon flow is 10L / min-16L / min, the argon flow of back protecting gas is 2L / min-5L / min, and distance between a jet of a welding torch and a component is 6mm-12mm. The invention can weld the iron-aluminum inter-metallic compounds and the dissimilar materials of the steel to obtain welding connectors with non-cracks and non brittle phases under the condition of non-heating. The invention has the advantages of strong applicability, convenient operation, the invention is convenient for popularization and application, the invention is in particular suitable for welding the iron-aluminum inter-metallic compounds and the carbon steel or the stainless steel, and applied to weld the iron-aluminum inter-metallic compounds and other low-alloy structural steel and heat resistant steel.

Owner:SHANDONG UNIV

Antibacterial terpolycyantoamino-formaldehyde resin impregnated veneer

ActiveCN103978773AOvercome stratificationOvercome precipitation and other problemsLamination ancillary operationsNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to antibacterial terpolycyantoamino-formaldehyde resin impregnated veneer which is characterized in that the veneer is prepared by steps as follows: synthesis of terpolycyantoamino-formaldehyde resin, preparation of a terpolycyantoamino-formaldehyde resin veneer impregnation adhesive, preparation of a antibacterial terpolycyantoamino-formaldehyde resin veneer impregnation adhesive, manufacturing of antibacterial impregnated veneer and the like. The prepared veneer can be directly adhered, under a certain technological condition, to the surface of an artificial board, timber and the like which have antibacterial requirements. After adhesion, the surface of a product needs no finishing treatment, and the surface has good antibacterial performance, heat resistant, wear resistance and the like.

Owner:BEIHUA UNIV

Electronic component, semiconductor package and electronic device

InactiveCN101454887ANo brittlenessInhibitionSemiconductor/solid-state device detailsSolid-state devicesBond interfaceAlloy

In a conventional UBM made of, for example, Cu, Ni, or NiP, there has been a problem that when an electronic component is held in high-temperature conditions for an extended period, the barrier characteristic of the UBM is lost and the bonding strength decreases due to formation of a brittle alloy layer at a bonding interface. The present invention improves the problem of decrease in long-term connection reliability of a solder connection portion after storage at high temperatures. The electronic component comprises an electrode pad formed on a substrate or a semiconductor element and a barrier metal layer formed to cover the electrode pad and the barrier metal layer comprises a CuNi alloy layer on the side opposite the side in contact with the electrode pad, the CuNi alloy layer containing 15 to 60at% of Cu and 40 to 85at% of Ni.

Owner:RENESAS ELECTRONICS CORP

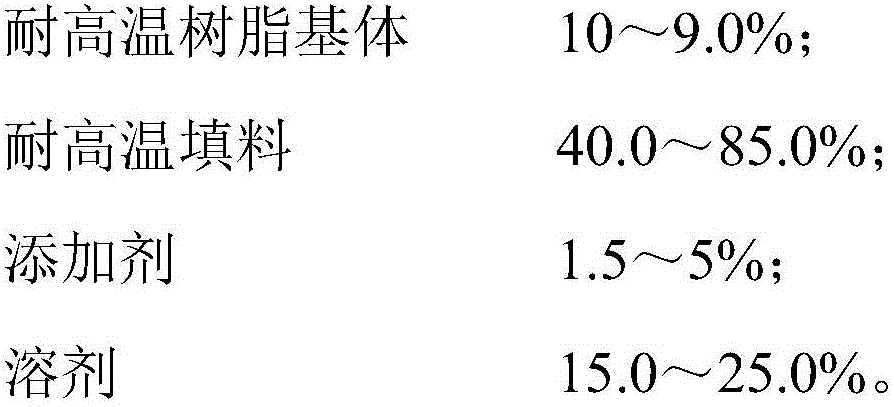

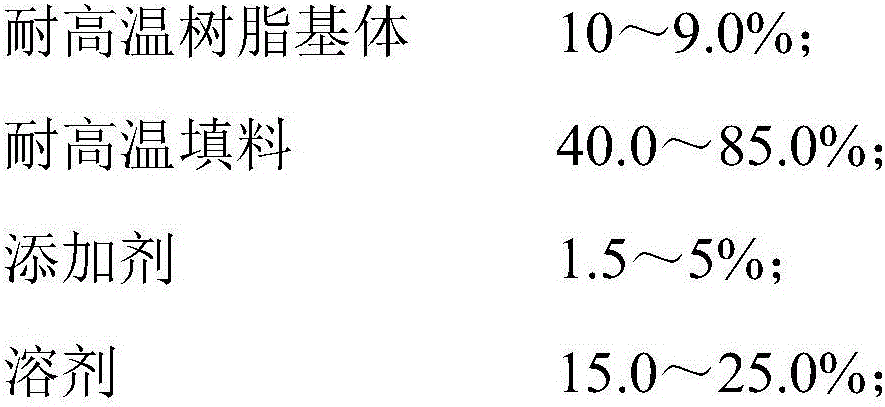

High-temperature-resistant shielding paint and preparation method thereof

The invention discloses high-temperature-resistant shielding paint and a preparation method thereof, and relates to the field of electromagnetic wave shielding paint. The high-temperature-resistant shielding paint is prepared from the following ingredients in percentage by mass: 10 to 9.0 percent of high-temperature-resistant resin matrix, 40.0 to 85.0 percent of high-temperature-resistant filling material, 1.5 to 5 percent of additive and 15.0 to 25.0 percent of solvents, wherein the high-temperature-resistant resin matrix is at least one of organic silicon resin, modified organic silicon resin and polyimide; the high-temperature-resistant filling material is a magnetic material with a cladding layer; the cladding layer is SiO2, Al2O3, BN or graphene; the magnetic material is at least one of ferrite, carbonyl iron powder, iron silicon aluminum or iron silicon chromium; the additive is at least one of a toughening agent, an anti-settling agent, an antioxygen, a defoaming agent, a dispersing agent and a flatting agent. The paint is still stable at high temperature for a long period; high-temperature-resistant and shielding effects are good.

Owner:AEROSPACE SCI & IND WUHAN MAGNETISM ELECTRON

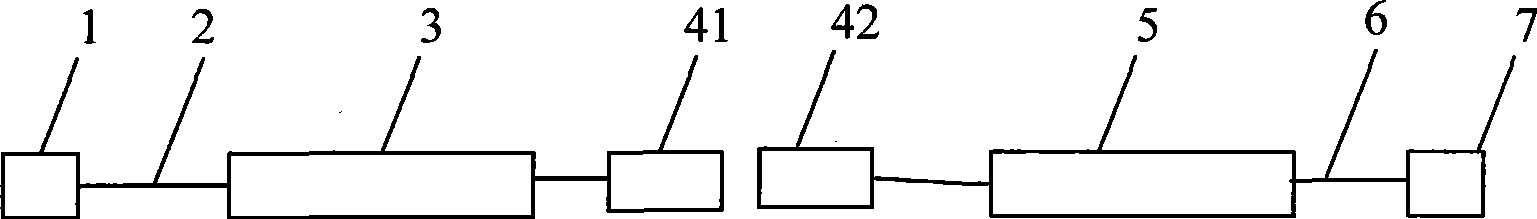

Method and equipment for hot dip of steel wire

ActiveCN101463457AHuge economic significance and social benefitsIncrease productivityHot-dipping/immersion processesOrganic acidActivation technique

The invention relates to a steel wire hot-dip coating method and equipment thereof. The method is characterized in that a single wire rod is sequentially processed by the following techniques of paying off, mechanical derusting, boron smearing, drawing, combined ultrasonic cleaning, chemical activation, compound annealing and deacidizing, hot-dip coating and wire collection; steel wire hot-dip coating is continuously completed; the ultrasonic frequency of the combined ultrasonic cleaning technique is 25-40KHz, the energy level density is 50-100w / l, the cleaning temperature is 40-70 DEG C, and the time is 0.5-1s; the chemical activation technique adopts weak organic acid activate fluid to treat, the activate fluid is manufactured by activating agent diluted by mass ratio of 10-20%, and the mass components of the activating agent are 3-6% of sodium nitrite, 10-15% of propane diacid and the rest of aminosulfonic acid, the activation temperature is 20-60 DEG C, and the time is 0.5-2s; the compound annealing and deacidizing technique is continuously carried out by high frequency induction heating and tubular heating, and annealing and deacidizing are simultaneously completed. The equipment are characterized by comprising a wire rod paying out machine, a mechanical derusting device, a boron smearing treatment facility, a steel wire drawing machine, a ultrasonic wave cleaner, a chemical activation groove, a compound annealing and reducing furnace, a hot-dip pan and a wire-rewinding machine which are sequentially connected with each other.

Owner:TIANJIN GONGDA GALVANIZING EQUIP CO LTD

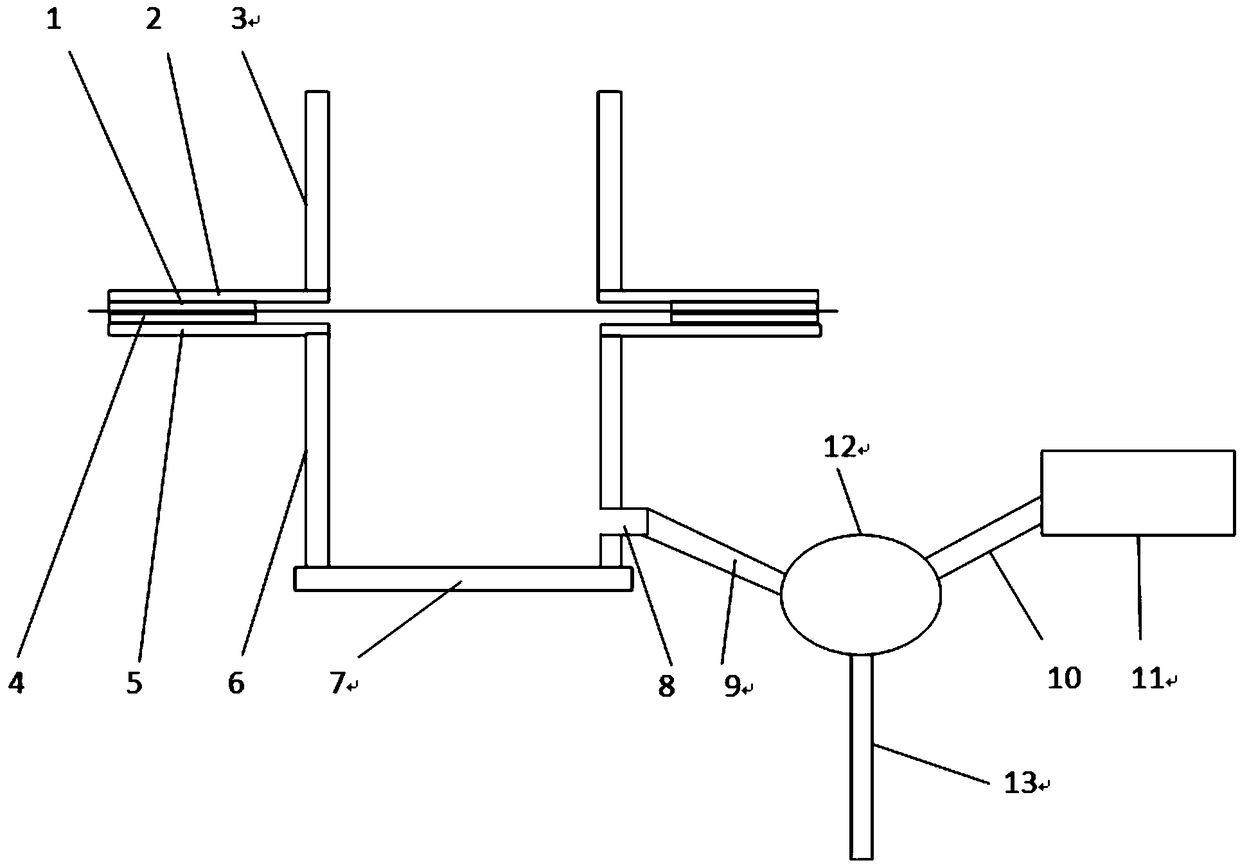

Flexible pressure sensor using graphene as electrode material and preparation method thereof

ActiveCN109341902AStrong bending resistanceNo brittle fractureFluid pressure measurement by electric/magnetic elementsForce measurementFiberNanofiber

Provided is a flexible pressure sensor using graphene as the electrode material. Two outer flexible film layers are doped PCL electrospun films with graphene micro-sheets of which the average radial size is higher than 5-10 microns. Two electrode layers are conductive ink containing graphene micro-sheets with large radial size and nano-silver particles with minimal agglomeration. A dielectric layer is electrospun from nano-fibers. A preparation method for preparing the flexible pressure sensor and a special preparation device are further provided.

Owner:国宏中晶集团有限公司

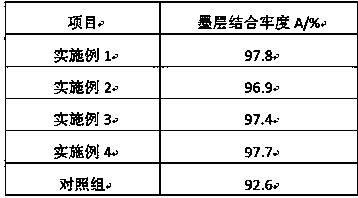

Alkaline chloride galvanizing additive and preparation method thereof

The invention discloses an alkaline chloride zinking primer, wherein the primer comprises following components based on mass percent: 9.6% to 14.5% sodium hydroxide, 5.0% to 7.0% potassium chloride, 0.6% to 0.9% zinc oxide, 0.35% to 0.45% DPE-3 adjuvant, 0.35% to 0.45% ZB-80 lustre-coating agent and 76% to 84% water. The preparation method of the alkaline chloride zinking primer is provided. The invention has advantages that the plating layer has high combination ratio, high depositing speed, bright and fined plated products without brittleness, coarse skin and color change when baking temperature is at 250 deg. C, great anti-impurity capacity, without fogging and bubbling phenomena. The salt spray test uses 150 hours to 200 hours with low cost. The invention saves energy and is easy to processes waste.

Owner:唐军

Photosensitive resin composition

InactiveUS20070112106A1Improve heat resistanceGood dimensional stabilityPhotosensitive materialsPhotomechanical apparatusHeat resistanceDouble bond

To provide a photosensitive resin composition satisfying both of the sensitivity at the time of exposure and alkali developability as well as giving a cured material excellent in dimensions stability and scarcely exhibiting brittleness while keeping good heat resistance. The photosensitive resin composition contains a polymer (A) having an N-substituted maleimide group, a carboxyl group, and an ethylenic unsaturated double bond at a ratio less than 0.05 moles per 100 parts by mass of the polymer.

Owner:NIPPON SHOKUBAI CO LTD

Copper electroplate liquid and preparation method thereof

The invention relates to a copper electroplate liquid and a preparation method thereof. The formula of the electroplate liquid comprises the following raw materials: 80-150g / L of copper sulfate, 50-90g / L of copper chloride, 40-70g / L of sodium sulfate, 60-120g / L of potassium sulphate, 5-30g / L of a brightener, 5-20g / L of a wetting agent, 25-55g / L of a buffer agent and deionized water added to 1,000ml. The method comprises the following steps: putting the deionized water into a container; weighing a proper amount of brightener and a proper amount of wetting agent, stirring and dissolving; weighing a proper amount of copper sulfate and a proper amount of sulfur copper chloride to a solution, stirring and dissolving at room temperature; adding sodium sulfate and potassium sulphate to the solution; and heating the solution to 55-65 DEG C, heating and stirring, and then adjusting the pH value of the solution by adopting the buffer agent. A clad layer formed by the method is good in ductility, free of brittleness, bright in surface, high in flatness, strong in throwing power and covering power, and high in current efficiency; the electroplate liquid is non-toxic; and a high-density zone of the clad layer is not scorched.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Processing for piston ring embedded chrome plating impregnated porcelain

InactiveCN1924334AHigh bonding strengthPrevent peelingMachines/enginesPistonsFurnace temperaturePiston ring

This invention discloses one piston imbedded chroming imbibitions ceramics process method, which comprises the following steps: putting the processed tank on piston outside circle into chromium acid for etching then into coating liquid mixed with chroming acid, hydric sulphate, trivalent chromium and JPRX addictive with chromium layer deposited with cracks; putting the chroming piston ring into thermal process vacuum furnace ceramics for vacuum voltage for 0.1 to 1 MPa for one to eight hours.

Owner:江苏仪征金派内燃机配件有限公司

Glue with high negative oxygen ion and low formaldehyde release quantity for impregnated paper and preparation method thereof

InactiveCN107793999ANo brittlenessImprove toughnessNon-macromolecular adhesive additivesPaper coatingOxygen ionsToughness

The invention provides glue with high negative oxygen ion and low formaldehyde release quantity for impregnated paper and a preparation method thereof. The glue is prepared from the ingredients: 100 weight parts of low-formaldehyde-emission glue, 0.2 to 0.3 weight part of anti-sticking agents, 0.3 to 0.4 weight part of release agents, 0.08 to 0.1 weight part of dustproof agents, 0.1 to 0.15 weightpart of curing agents, 8 to 19 weight parts of negative ion powder, neutral dispersants for regulating 0.5 to 0.8 weight part of dispersing agents to the neutral state by a sodium hydroxide solution,wherein the concentration of the sodium hydroxide solution is 0.625 to 0.65mol / L. When the glue is applied to impregnated glue film paper, a large number of negative ions can be generated; the formaldehyde release quantity of the glue is very low, so that the quality of air in environment is effectively improved; meanwhile, the addition of negative oxygen powder does not influence the toughness and the later-period pressing and attaching performance of the impregnated paper; the attractive appearance and the use of the product are also not influenced.

Owner:ZHEJIANG SHENGLONG DECORATION MATERIAL

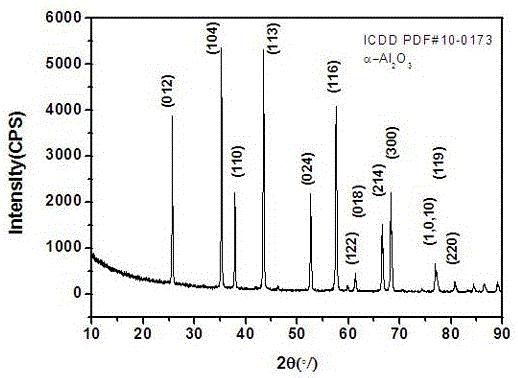

High-flexibility 95 ceramic and preparation method thereof

A kind of high-toughness 95 porcelain and preparation method thereof, the raw material of preparing 95 porcelain is made of MgO nanocrystal, α-Al 2 o 3 Nanocrystalline, Suzhou soil, silicon dioxide and calcium carbonate are composed according to weight ratio (0~5): (89.78~94.50): (1.36~1.43): (1.42~1.50): (2.99~3.15); 95 preparation methods include The steps of preparing raw meal, ball milling the raw meal into powder, making slurry, removing iron, granulating, particle grading, molding and firing. The present invention uses magnesium hydroxide nanocrystals and boehmite nano-whiskers for calcination, and then rapid cooling to obtain dispersed nanoparticles, which can reduce the sintering temperature, promote crystal transformation, and generate ternary or more complex eutectic material, so that the made 95 porcelain is easy to deform without brittle cracks when it is stressed, and has high toughness.

Owner:洛阳三睿宝纳米科技有限公司

Production technology of polypropylene building template

InactiveCN103012958AExcellent impact resistanceExcellent deformation resistanceForming/stuttering elementsConstruction engineeringProcess engineering

The invention provides a production technology of a polypropylene building template, which is the technology for producing the building template by adopting waste plastics as the raw materials. The production technology comprises the steps of pretreating the raw materials, mixing the materials, and carrying out extrusion molding. The raw materials are treated based on a certain ratio and prepared into the product building template under a certain condition. The product building template has the characteristics that the construction quality is high, the building template can be recycled for a plurality of times, the cost is reduced, the benefit is increased, the energy conservation and environment protection are realized, and the residues can be recycled; and the product building template has a large market demand and wide prospect, and is an excellent substitute for steel templates, bamboo plywood and wood plywood.

Owner:HUNAN FENGSHUO TECH

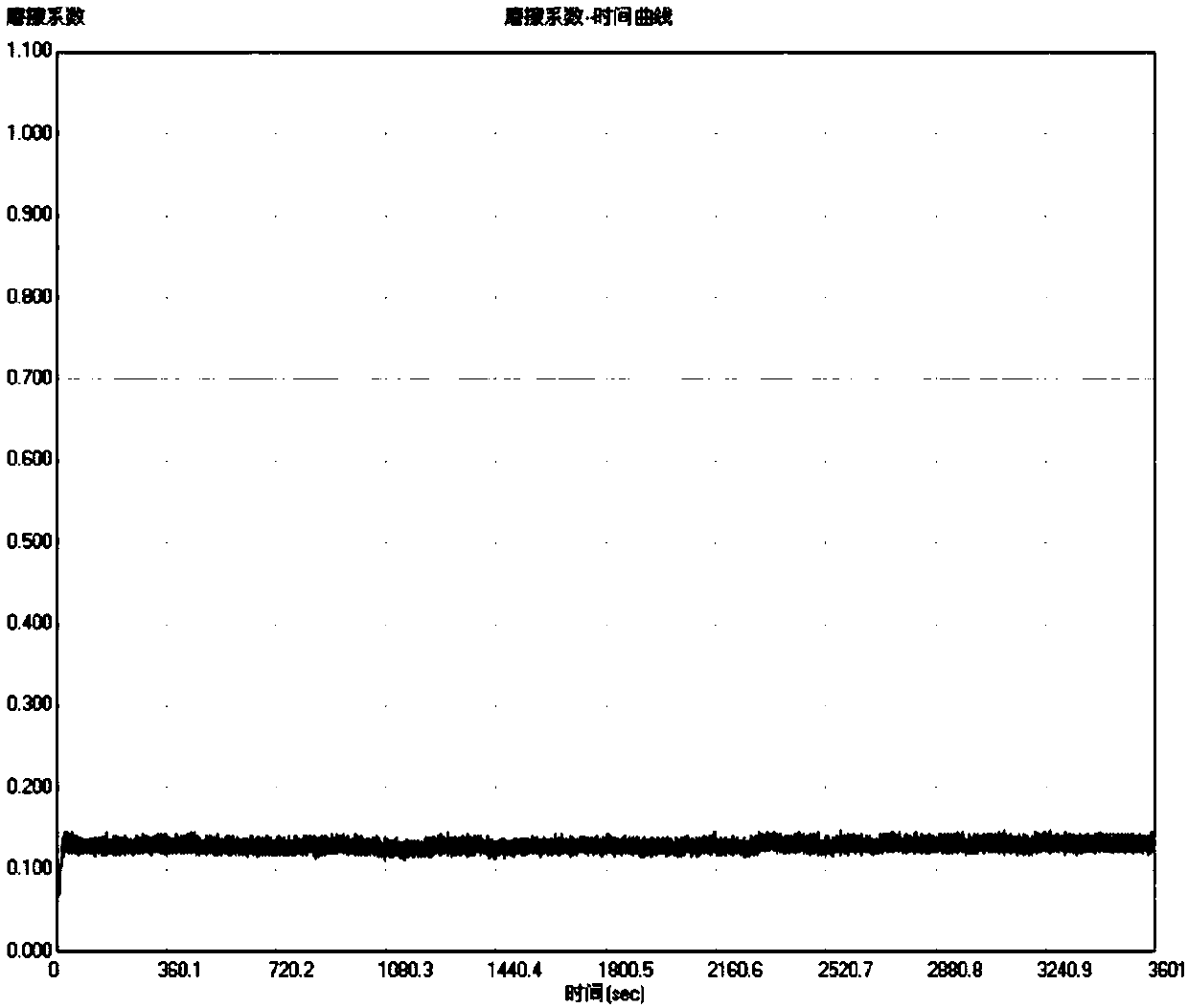

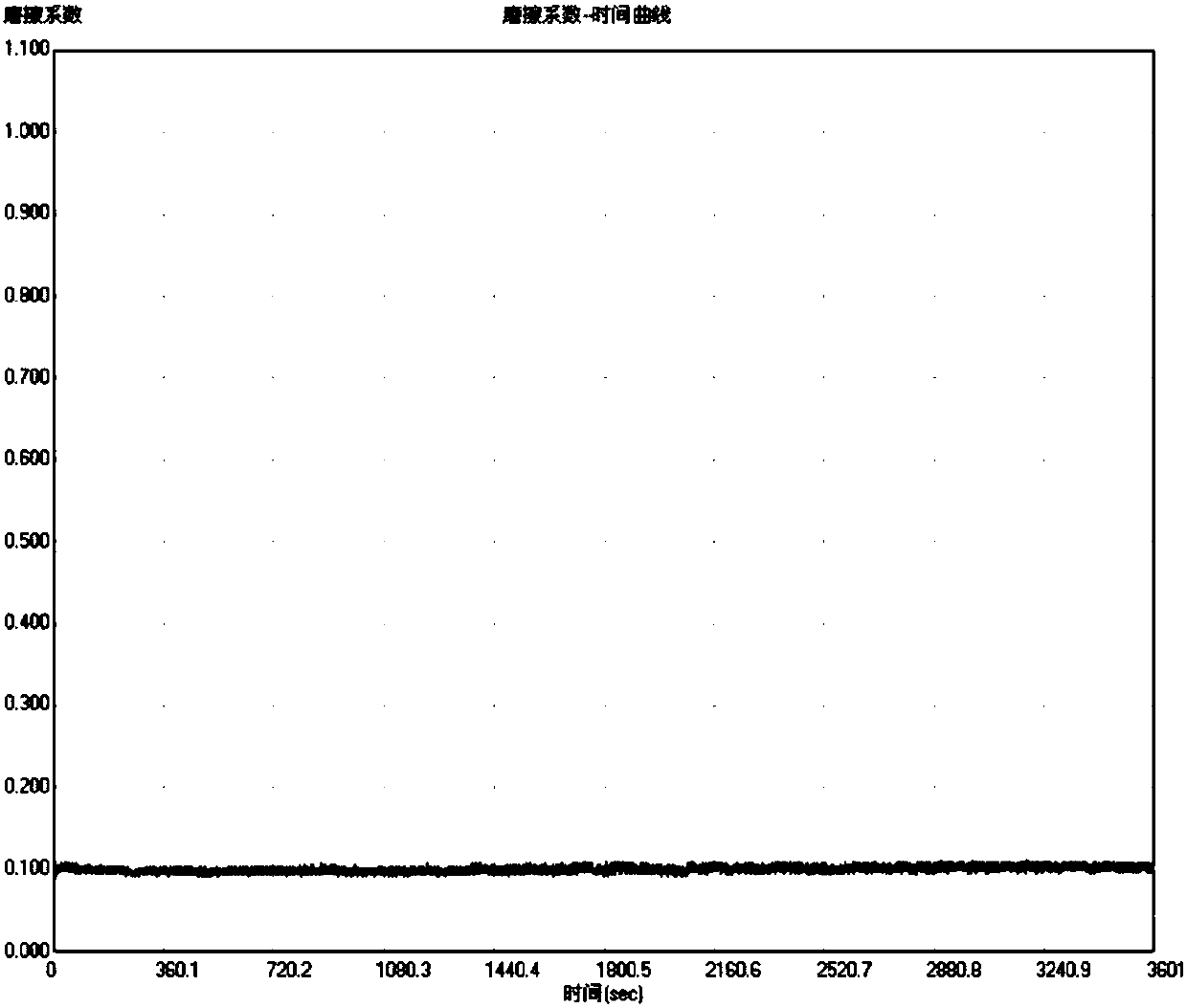

Corrugated paper printing process for fruit packaging boxes

InactiveCN110792000ASolve the problem of airtightnessSolve moisture resistanceMechanical working/deformationCoated paper substratePolymer scienceCarton

The invention relates to the technical field of carton printing, in particular to a corrugated paper printing process for fruit packaging boxes. The corrugated paper printing process comprises seven steps of corrugated paper pretreatment, flexographic plate making, corrugated paper surface treatment, corrugated paper PE lamination, outer layer PE lamination surface treatment, flexographic plate printing and polishing and calendaring treatment. The adhesive force between PE lamination and corrugated paper is enhanced through corona treatment, and then a water-based ink and the PE lamination areeffectively combined through low-temperature plasma treatment, so that the combination fastness of an ink layer is improved, and the sealing performance and the moisture resistance of the corrugatedpaper are better through PE lamination; compared with solvent-based ink, the water-based ink does not generate harmful gas, is higher in safety performance, and is cheaper than UV ink, the toughness of a film formed by the water-based ink adapts to that of PE lamination, the brittle fracture phenomenon is avoided, and the defect that the film formed by the UV ink is prone to brittle fracture is overcome.

Owner:邵帅

Thermoplastic polyolefin TPO waterproof coiled material and preparation method thereof

InactiveCN107933034AImprove physical performanceGood oil resistanceRoof covering using flexible materialsSynthetic resin layered productsThermoplasticPolypropylene

The invention discloses a thermoplastic polyolefin TPO waterproof coiled material. The waterproof coiled material has a three-layer structure, the upper surface and the lower surface are separately aTPO coiled material layer, and the middle is a polyester fiber mesh grid fabric reinforcement layer, wherein the TPO coiled material layer of the upper surface is white, and the TPO coiled material layer is prepared by taking a thermoplastic polyolefin synthetic resin material formed by binding of ethylene propylene rubber and polypropylene as a base material, taking modified nano calcium carbonate as a filler, and adding an anti-aging agent, a tackifier, a bridging agent, a dispersant, a softener and a toner. The TPO waterproof coiled material provided by the invention has excellent weather resistance and durability of the ethylene propylene rubber and weldability of the polypropylene, and the weather resistance and stability of the product are further guaranteed through screening of themodified nano calcium carbonate which has better filling performance and better dispersibility and is suitable for a TPO coiled material system, and cooperative use of the anti-aging agent, the tackifier, the bridging agent, the dispersant, the softener and the toner.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

Powder metallurgy preparation method of graphene reinforced aluminum-based composite material

InactiveCN112725660AEvenly dispersedImproves Structural IntegrityTransportation and packagingMetal-working apparatusHigh energyGraphite

The invention provides a powder metallurgy preparation method of a graphene reinforced aluminum-based composite material, which comprises the following steps: preparing graphene-aluminum composite powder by long-time low-energy ball milling in advance, annealing, and carrying out short-time high-energy ball milling, densification processing and heat treatment to finally obtain the composite material. Uniform compounding of matrix powder and graphene is achieved through long-time low-energy ball milling, meanwhile, interface reaction can be avoided, and the structural integrity of graphene is protected; the annealed composite powder can improve the plastic deformation capacity of the composite powder while improving the quality of the graphene; short-time high-energy ball milling is performed, so that composite powder is welded into particles, and the quality of graphene is not damaged; and in addition, for the composite material of a aluminum alloy matrix, the uniformly dispersed graphene promotes the precipitation of fine dispersed precipitated phases in the matrix, and the mechanical properties of the composite material are further improved. The method is beneficial to protecting the integrity of the graphene structure to the maximum extent, exerts the graphene strengthening potential, saves energy and time, and is suitable for batch preparation and production.

Owner:SHANGHAI JIAO TONG UNIV

Heat treatment process of rocker

InactiveCN101994119APrevent brittle fractureEasily brokenSolid state diffusion coatingPass rateBrittle fracture

The invention discloses a heat treatment process of a rocker, belonging to the workpiece heat treatment processes for general machinery. The heat treatment process for the rocker workpiece can guarantee stable quality and prevent workpiece from brittle fracture, and has reduced requirement on carburization equipment and the product pass rate reaching 100%. The heat treatment process comprises the processes of impact molding, carburization, quenching, high-temperature tempering, preheating and malcomising for the rockers.

Owner:徐鹤铭

A non-seam liner glass steel pipe and assembling method

InactiveCN1773153AShort repair cycleNo brittlenessLaminationLamination apparatusUltimate tensile strengthSteel tube

The present invention discloses a kind of jointless steel pipe with glass inside liner and its production method. It includes the following several portions: jointless inside lining glass pipe, seamless steel pipe, positioning ring pipe head, pipe hoop, pipe tail, draw hook, pipe head rubber cap and air nozzle. Said invention adopts a í‹pressure adsorptioníŒ method to make the external surface of glass pipe be stuck to the internal surface of seamless steel pipe so as to obtain the invented product. Said invention also provides the concrete steps of the í‹pressure adsorptioníŒ method. Said invented product can be used for making oil field ground oil transmission pipline, so that it has extensive application range.

Owner:孙英久

Heat-resistant high-strength mould material

The invention discloses a heat-resistant high-strength mould material. The mould material comprises 1.4%-5.2% of C, 1.2%-5.0% of Si, 0.4%-1.2% of Mn, 0.01%-0.02% of S, 0.4%-1.0% of Cu, 0.6%-5.0% of Cr, 0.4%-4.8% of Ti, 1%-6% of Mg, 0.5%-3.0% of Al and 80%-96% of Fe in proportion. According to the heat-resistant high-strength mould material, the heat-conducting property is superior to that of steel, and the wetting property can be significantly improved through the Mg and the Ti which are added to the material; in addition, the material is free of brittleness, and the mechanical strength is close to that of the steel; graphite is a good solid lubricant, and hence the surface abrasion of aluminum and alloy of the aluminum can be reduced.

Owner:TAICANG JIEGONG PRECISION METAL MATERIALS CO LTD

Material for piston rod in ultra-low temperature reciprocating compressor and surface reinforcing method of material

ActiveCN107828945AGuaranteed room temperatureGuaranteed Low Temperature PerformanceMolten spray coatingEngineeringQuenching

The invention discloses a material for a piston rod in an ultra-low temperature reciprocating compressor and a surface reinforcing method of the material and belongs to the technical filed of materials of ultra-low temperature moving parts and surface reinforcing in equipment manufacturing industries. The material of the piston is obtained by means of the method that 1Ni9 steel forge pieces serveas a raw material and are sequentially subjected to performance heat treatment, finishing and stable treatment, wherein as for the performance heat treatment process, normalizing treatment is conducted at the temperature of 890-910 DEG C, primary quenching is conducted at the temperature of 810-830 DEG C, secondary quenching is conducted at the temperature of 660-680 DEG C, and tempering treatmentis conducted at the temperature of 570-590 DEG C. The surface of the material of the piston is sprayed with a WC-Co coating through a supersonic flame spraying technology. The material of the pistonrod and the coating quality meet the performance requirements of the parts under the ultra-low temperature, the difficult problem of selecting of the materials of the main parts such as the piston rodof the ultra-low temperature reciprocating compressor equipment and the surface reinforcing method is solved, and the foundation is laid for future better and quicker development of natural gas and hydrocarbon liquefaction, storage and conveying device equipment in China.

Owner:沈阳鼓风机集团往复机有限公司

Rhizoma coptidis piece processing and comprehensive utilizing method

The invention belongs to the technical field of traditional Chinese medicine processing and particularly relates to a rhizoma coptidis piece processing method. Mainly a new choice is provided for rhizoma coptidis piece processing. The method includes the following steps of harvesting, crude cleansing, dewatering, refined cleansing, slicing, drying and screening, and rhizoma coptidis decoction pieces are obtained, and leftovers obtained during cutting of the rhizoma coptidis pieces are comprehensively utilized. The method can be used for processing rhizoma coptidis pieces and rhizoma coptidis on the producing area, the method is high in industrialization degree, energy is saved, and the content of total alkaloids in the obtained rhizoma coptidis decoction pieces is higher than that of total alkaloids in rhizoma coptidis decoction pieces obtained through a traditional method by 10% or above.

Owner:SOUTHWEST UNIVERSITY

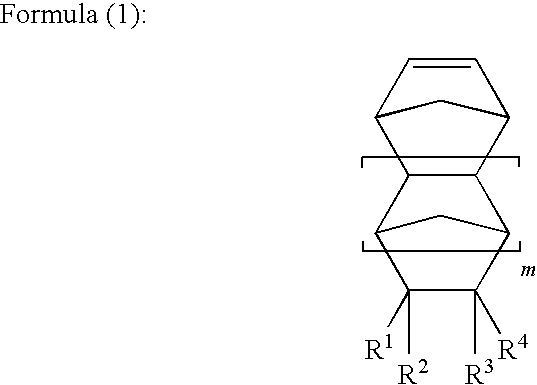

Cyclic olefin-based copolymer, film, and polarizing plate and liquid crystal display device including the same

ActiveUS7662445B2Reduce penetrationLow in propertyLiquid crystal compositionsThin material handlingCarbon numberPolymer science

A copolymer contains 10 to 69 mol % of a structural unit derived from propylene, 1 to 50 mol % of a structural unit derived from at least one α-olefin having a carbon number of from 4 to 20 and 30 to 89 mol % of a structural unit derived from at least one cyclic olefin represented by the formula (1) as defined herein, and has a weight average molecular weight of from 50,000 to 1,000,000.

Owner:FUJIFILM CORP

Water-proof paint

InactiveCN1511900AQuality improvementAdvanced technical indicatorsAntifouling/underwater paintsUnspecified rubber coatingsAdhesiveNeoprene

The waterproof paint consists of adhesive, reflecting material, additive, etc., the adhesive is chloroprene rubber and the reflecting material is aluminum paste. The waterproof paint has excellent waterproof function and obvious high and low temperature resistance. The present invention is used for the surface of building and other matters and has the advantages of simple construction, no need of curing and no gas pollution.

Owner:赵振威

Air purifier and decorative picture with formaldehyde removing function

ActiveCN108129963AIncrease contact areaImprove purification efficiencyGas treatmentDispersed particle separationEngineeringAir purifier

The invention discloses an air purifier with a formaldehyde removing function. The air purifier comprises a shell. The invention further discloses a decorative picture with the formaldehyde removing function. The decorative picture comprises a picture frame, a back plate and a picture plate, wherein the picture frame, the back plate and the picture plate form a shell of the decorative picture; anair inlet and an air outlet are formed in the shells of the air purifier and the decorative picture respectively; multiple layers of catalyst membranes are tightly arranged inside the shells at intervals; air passages are formed in gaps between the catalyst membranes; a preparation method of the catalyst membranes comprises the following steps: (1), coating a base film with UV-curable coating containing catalyst particles, and preheating coating by using infrared light, wherein the preheating temperature is 50-130 DEG C and the preheating time is 5s to 5min; (2), after preheating, curing by using UV light. The air purifier is small in volume and high in formaldehyde removing efficiency.

Owner:杭州玻美文化艺术有限公司

Glue used for plastic

The invention discloses a glue used for plastic, comprising 50-70 weight parts of alpha-cyanoacrylate, 2-8 weight parts of methyl methacrylate graft latex, 4-9 weight parts of vinyl acetate emulsion, 5-10 weight parts of zinc oxide, 2-6 weight parts of casein, 1-4 weight parts of glycerin, 2-5 weight parts of natural rubber, 10-15 weight parts of phenolic resin, 3-7 weight parts of curing agent, and 2-7 weight parts of toluene. The glue disclosed herein can be used for rapid bonding of various plastic products, especially for small area bonding between plastics and small area bonding between plastic and other material. The glue disclosed herein has the advantages of strong bonding force, no whitening, short curing time, and no brittleness, etc.

Owner:HUBEI FOR LONG PIPE TECH CO LTD

Surface pretreatment method for improving abrasion resistance of automobile brake pad

InactiveCN109182956AImprove wear resistanceExtended service lifeSolid state diffusion coatingFurnace typesPretreatment methodHeat treated

The invention provides a surface pretreatment method for improving the abrasion resistance of an automobile brake pad and relates to the technical field of processing and treatment of brake pads. Thesurface pretreatment method for improving the abrasion resistance of the automobile brake pad comprises the processes that a brake pad blank is subjected to heat treatment and cutting machining and then subjected to sanding treatment, cleaning treatment, carbon and nitrogen infiltration treatment, sand blasting treatment, secondary cleaning treatment and the like; and finally, a layer of treatmentliquid is smeared, and gluing is conducted after drying. After a series of treatment, the internal stress of the brake pad can be effectively lowered, the surface hardness of the brake pad can be improved, the brake pad has the quite high abrasion resistance, corrosion resistance, thermal fatigue resistance and adhesion prevention, and the service life of the brake pad is greatly prolonged.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

Ceramic metallic halogen lamp electrode

InactiveCN101425446AGuaranteed low current requirementsAvoid shockGas discharge lamp detailsNiobiumCeramic metal

The invention discloses a ceramic metal halogen lamp electrode which comprises a main rod made of thorium-tungsten alloy materials; a yttrium-molybdenum alloy-wire spiral body is wound on one end of the main rod, and a high-purity tungsten wire spiral body is wound on the other end of the main rod; and the main rod end part on which the yttrium-molybdenum alloy-wire spiral body is wound is connected with an outer-lead niobium rod. The invention is a high-effective and environment-friendly ceramic metal halogen lamp electrode and has the advantages of high efficiency, safety, environment protection, even electrode spring, and the like.

Owner:佛山宁宇科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com