Method and equipment for hot dip of steel wire

A technology of hot-dip plating and steel wire, applied in hot-dip plating process, coating, metal material coating process, etc., which can solve the pollution of waste acid and pickling water acid gas, and the inability to use high-strength steel wire and chemical agents to discharge pollution and other issues, to achieve the effect of efficient production and environmental protection double benefits, huge economic significance and social benefits, and equipment investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

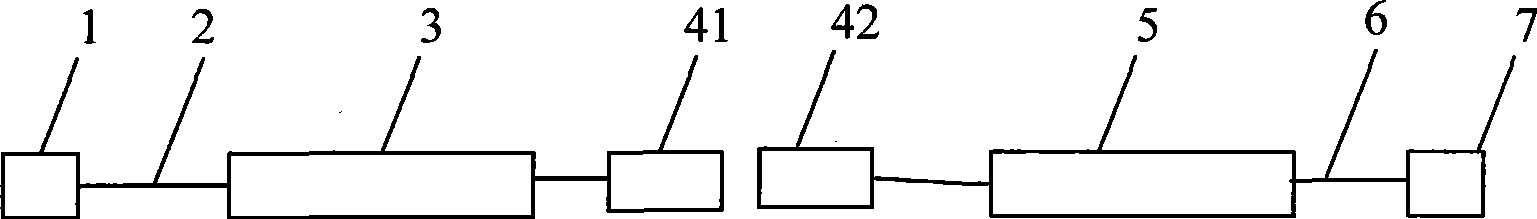

Image

Examples

Embodiment 1

[0051] Using the method and equipment of the present invention to implement hot-dip galvanizing of steel wire with a product diameter of 1.6mm, the zinc amount is required to be 100g / m 2 , Intensity 450-550Mpa. The process is:

[0052] After the wire rod with a diameter of 6.5mm is mechanically derusted and boron coated, it is drawn to a 1.6mm steel wire through 12 passes; ultrasonically cleaned by a composite cleaning tank to remove the lubricating grease in the drawing process, and the composite wave cleaning tank can Grade density 1.5w / cm 3 , The temperature of the cleaning water is 65℃, the cleaning time is 0.5 seconds, and the length of the cleaning tank is 8 meters; after the compound cleaning, it enters the chemical activation tank. This section is only immersed in the activator. The temperature of the chemical activation tank is normal temperature, and the length of the chemical activation tank is 2 meters. , Dip time 0.12 seconds; induction heating power frequency 20KHz, ...

Embodiment 2

[0055] Using the method and equipment of the present invention to implement hot-dip galvanizing of steel wire with a product diameter of 2.5mm, the zinc amount required is 250g / m 2 , The intensity is 1500-1800Mpa. The process is:

[0056] After the wire rod with a diameter of 6.5mm is mechanically derusted and boron-coated, it is drawn to a steel wire with a diameter of 2.5mm through 10 passes; then the lubricating grease in the drawing process is removed through the composite cleaning tank, and the energy level density of the ultrasonic cleaning tank 1.5w / cm 3 , The temperature of the cleaning water is 65℃, the cleaning time is 0.5 seconds, and the length of the cleaning tank is 8 meters; after the compound cleaning, it enters the chemical activation tank. This section is only immersed in the activator. The bath temperature is normal temperature. The length of the chemical activation tank is 2 meters. Dipping time 0.12 seconds; induction heating power frequency 20KHz, power 200KW...

Embodiment 3—6

[0059] Using the method and equipment of the present invention to perform hot-dip galvanizing of steel wires with diameters of 3.5mm, 4.0mm, 5.0mm and 6.0mm, respectively, the required zinc amount is 280g / m respectively 2 , 300g / m 2 , 300g / m 2 And 350g / m 2 , The intensity is 550, 550, 350 and 360Mpa respectively. The remaining process conditions are the same as in Example 1.

[0060] After testing, the zinc amount of the obtained galvanized steel wire corresponds to 295, 305, 300, 355g / m 2 , The intensity corresponds to 550, 558, 350, 384Mpa respectively.

[0061] The other parameters of Examples 1-6 are listed in Table 1 for easy reference.

[0062] Table 1: Partial parameter table of the embodiment

[0063] Example

[0064] The experiments of Examples 1 to 6 show that the hot-dipping method and equipment of the present invention have good adaptability and can be applied to hot-dipping steel wires of full specifications. In addition, although Examples 1 to 6 all take th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com