Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "No blackening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PID resistance crystalline silicon battery and preparation method thereof

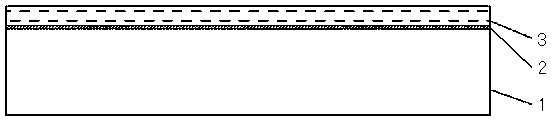

InactiveCN103928535ASimple structureStop erosionFinal product manufactureSemiconductor devicesEtchingSilicon oxide

The invention discloses a PID resistance crystalline silicon battery. The PID resistance crystalline silicon battery comprises a silicon dioxide layer and a silicon nitride antireflecting layer which sequentially cover a silicon substrate. A preparation method of the PID resistance crystalline silicon battery comprises the following steps that cleaning, texturing, diffusion, phosphorosilicate glass removing and edge etching are conducted on the silicon substrate; ozone is generated on the surface of the silicon substrate through an ozone generation device, then the silicon substrate is placed under a UV lamp to be irradiated, and a layer of silicon oxide is grown; PECVD equipment is used for growing the silicon nitride antireflecting layer on the silicon oxide, and then printing and sintering of electrodes on a front face and a back face are achieved. According to the PID resistance crystalline silicon battery, the structure of an antireflecting layer of the battery is mainly improved, the compact silicon dioxide layer is prepared between traditional single-layer or multi-layer silicon nitride and the crystalline silicon substrate by using the UV lamp for irradiating, the silicon dioxide layer can prevent erosion of positive ions to PN junctions, and therefore the influence of a PID effect is reduced.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

Light-emitting device

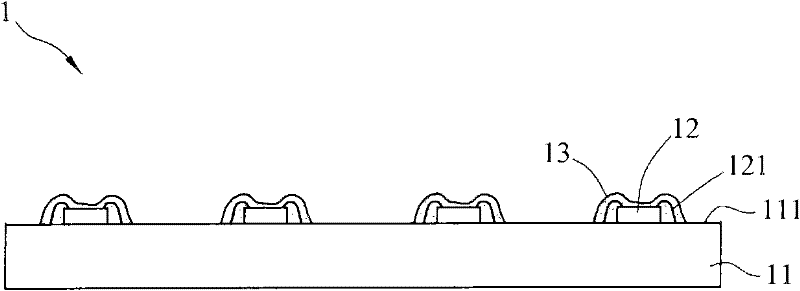

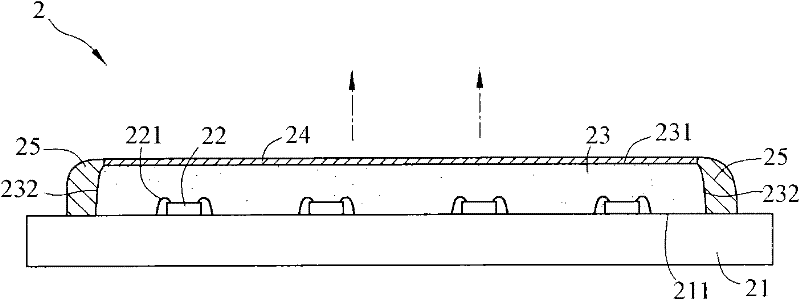

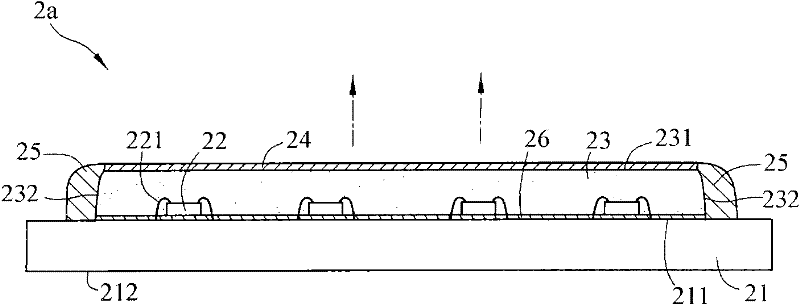

InactiveCN102412244AGuaranteed luminous efficiencyAvoid damageSolid-state devicesSemiconductor devicesColloidEngineering

A light-emitting device comprises a substrate, at least one light-emitting diode chip, a sealing colloid, a protective sheet and a protective material. The light-emitting diode chip is arranged on the substrate. The light-emitting diode chip is covered by the sealing colloid, which is provided with a top surface and a side surface. The protective sheet is arranged on the top surface of the sealing colloid. The protective material is arranged on the side surface, and is connected with the protective sheet and the substrate. The light-emitting device can prevent moisture or gas from affecting the luminous efficacy of the light-emitting device, and the service life of the light-emitting device is prolonged.

Owner:GIO OPTOELECTRONICS CORP

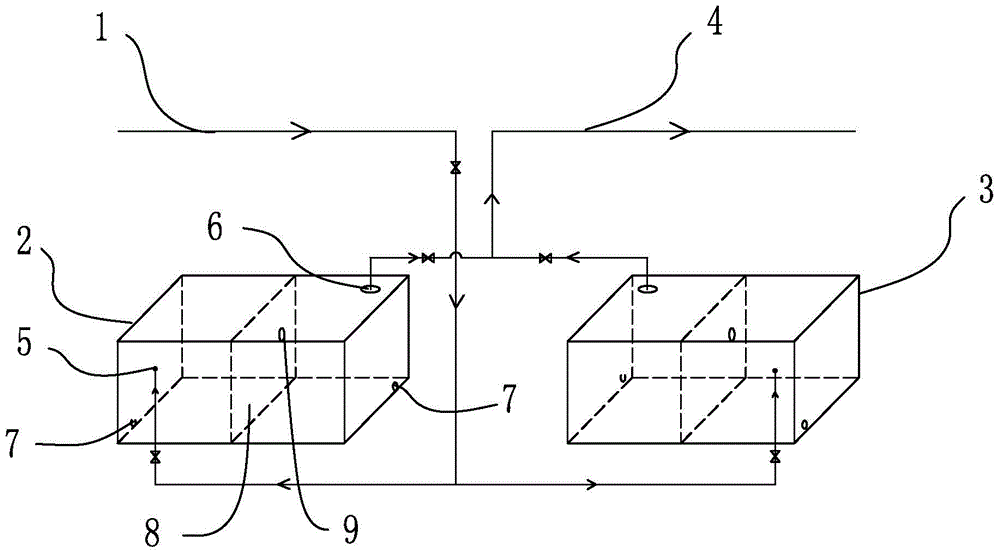

Double-light path CO2 laser processing device and method of alumina ceramics

InactiveCN106346130ASame design structureThe processing steps are completely consistentLaser beam welding apparatusBeam expanderLaser processing

The invention discloses a double-light path CO2 laser processing device and method of alumina ceramics. The double-light path CO2 laser processing device comprises two light path systems of the same structure; each light path system comprises a radio frequency CO2 laser, a circular polarizer, a beam expander, a laser cutting head and three reflecting mirrors, the circular polarizers are arranged on the light path output ends of the radio frequency CO2 lasers, one reflecting mirror, the corresponding beam expander, another reflecting mirror, the other reflecting mirror and the corresponding laser cutting head are arranged on an output light path of each circular polarizer in sequence, the light path output end of each laser cutting head is over against the surface of a to-be-processed workpiece, a CO2 laser focusing lens is arranged in each laser cutting head, a protective lens is installed below each CO2 laser focusing lens, a nozzle is installed on the lower part of each laser cutting head through a position adjustment mechanism, and the front and back position and the left and right position of each nozzle can be adjusted by adjusting the corresponding position adjustment mechanism. The processing efficiency and the processing quality of an alumina ceramic substrate are increased, and the cutting and scribing process effects of the alumina substrate are improved.

Owner:SUZHOU DELPHI LASER

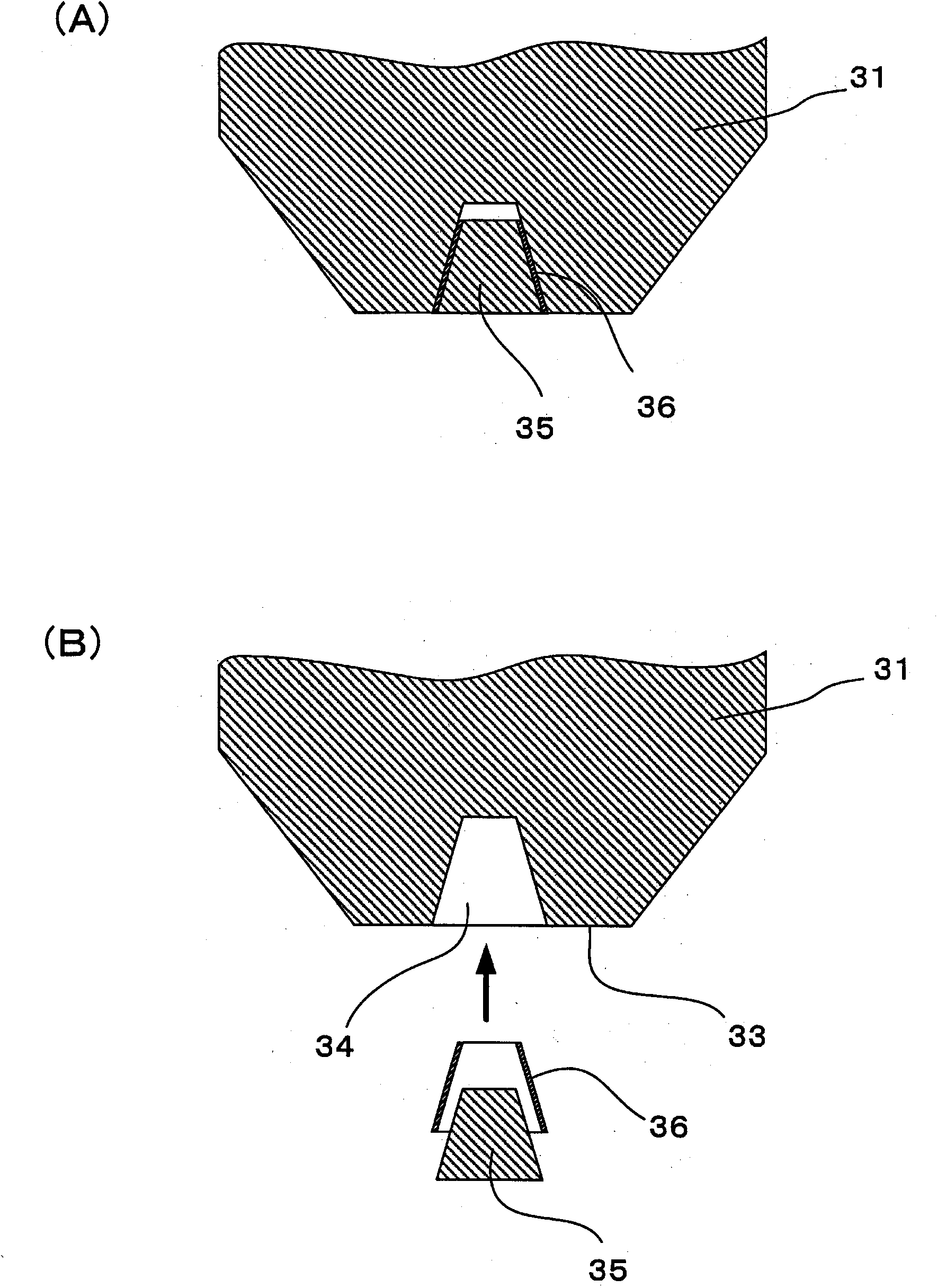

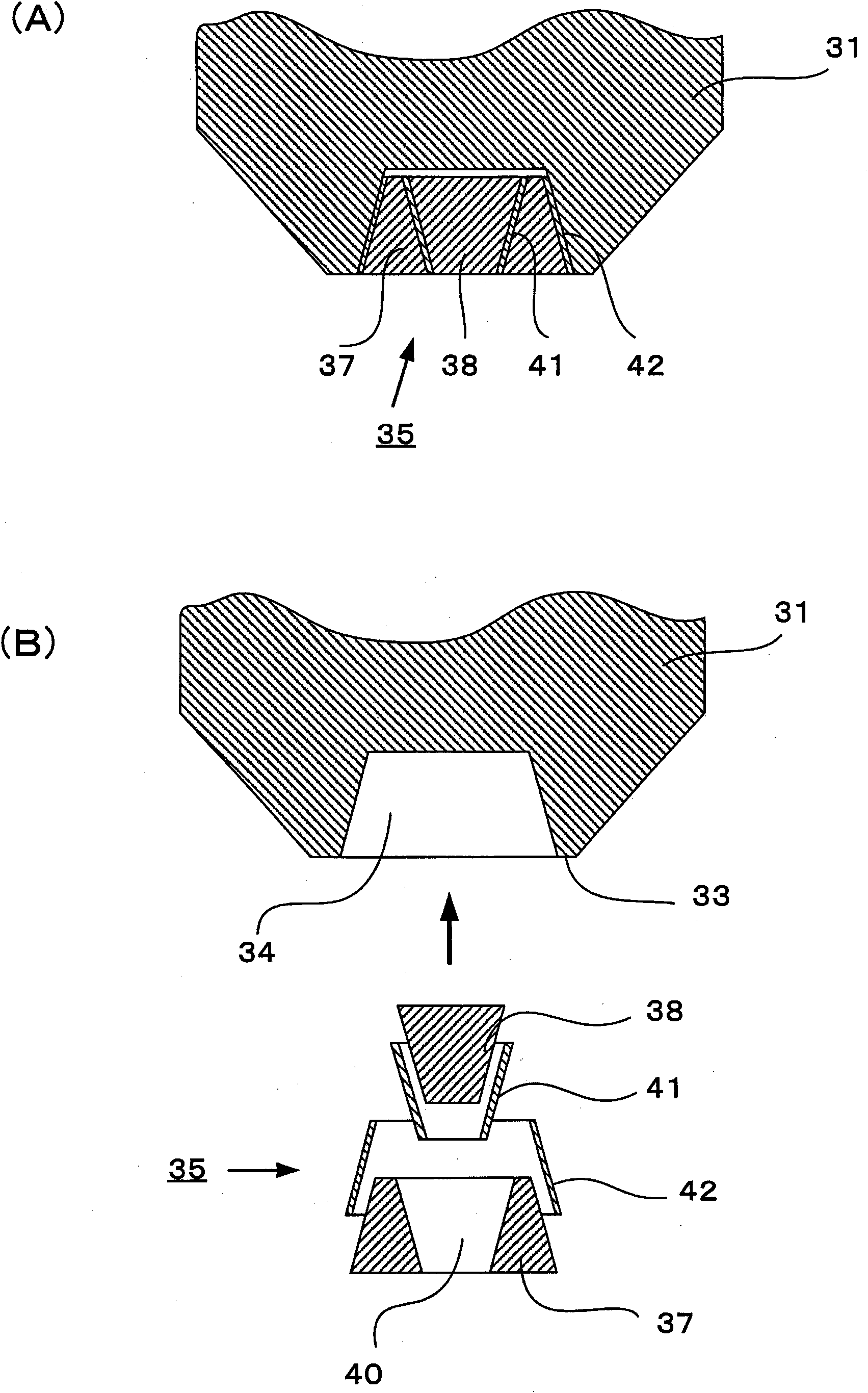

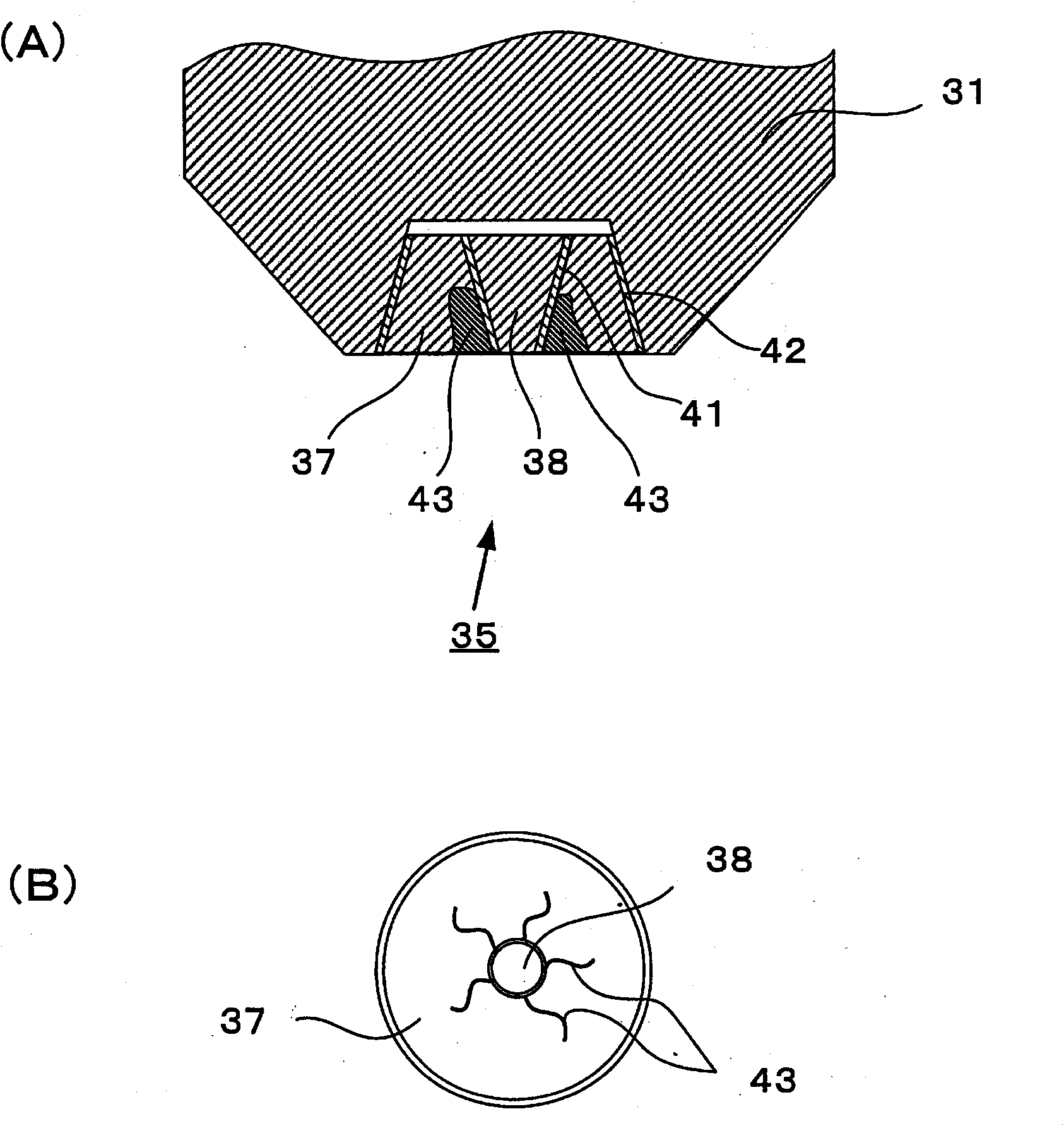

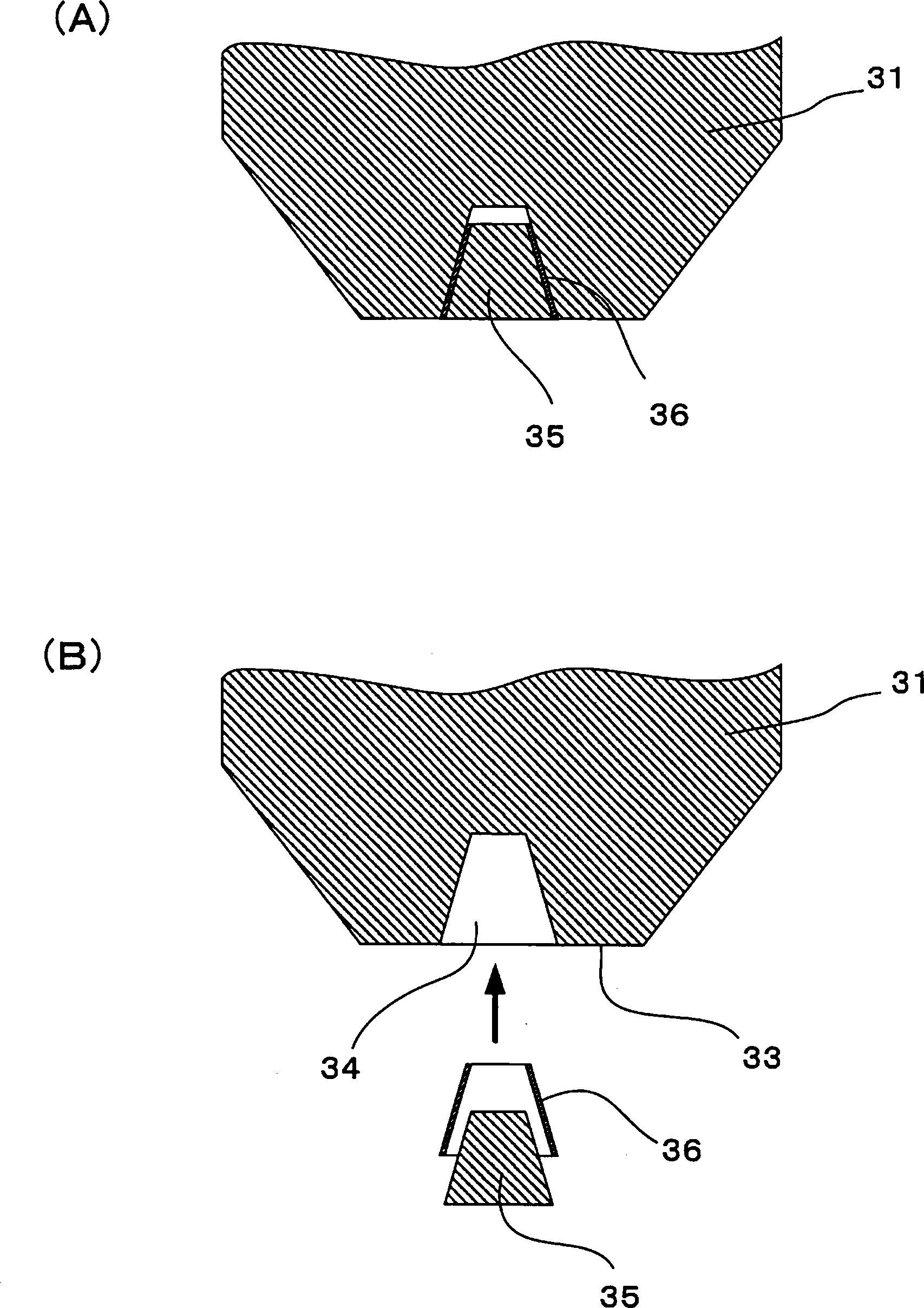

Short arc type discharge lamp

InactiveCN101958221AWon't turn blackNo deformation and protruding phenomenonHigh-pressure discharge lampsGas discharge lamp detailsEngineeringElectrode material

The invention provides a short arc type discharge lamp. A pair of anode and cathode is relatively configured within a light-emitting tube. An electrode structure is configured so that the middle part in the front end of the anode cannot be much farther than a surrounding annular part, and the lamp does not become black due to evaporation of an electrode material particularly when the lamp is lighted regularly at rated power and the lamp is lighted in full load / standby mode at the power less than the rated power. The short arc type discharge lamp is characterized in that a buffer component consisting of a material with yield stress smaller than the electrode material is sandwiched between the middle part in the front end of the anode and the surrounding annular part. The thermal stress of the middle part in the front end is relaxed through the buffer component.

Owner:USHIO DENKI KK

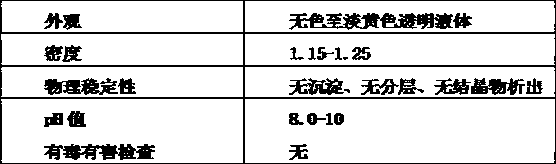

Preparation method of photoresist stripping liquid

ActiveCN104330959AGood emulsifying effectWon't corrodePhotosensitive material processingSolubilityEthylene diamine

The invention relates to a preparation method of photoresist stripping liquid. The preparation method is characterized by comprising the following steps: adding methylbenzene or dimethylbenzene, taken as a solvent, into a batching tank, introducing phenol into the batching tank and mixing; diluting an emulsifying agent with water, then adding a complexing agent into the diluted emulsifying agent, mixing uniformly, filtering, and adding the filtered mixture into the batching tank; and after mixing, filtering, thereby obtaining a finished product, wherein the emulsifying agent is prepared by mixing OP-10 and TX-100 according to a ratio of 0.5-2 to 1, the mass of the added emulsifying agent accounts for 0.1%-0.6% of that of phenol, the complexing agent is prepared by mixing diethylenetriamine pentaacetic acid and hydroxyethyl ethylene diamine triacetic acid according to a mass ratio of 1 to 0.5-2, and the mass of the added complexing agent accounts for 3%-8% of that of the emulsifying agent. The photoresist stripping liquid produced by the preparation method has the advantages of good oil solubility, good water solubility and no erosion to aluminium-silver materials.

Owner:江阴市化学试剂厂有限公司 +1

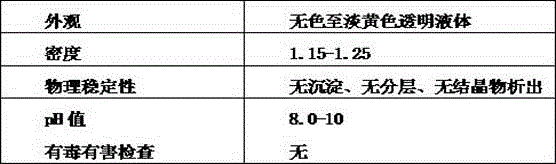

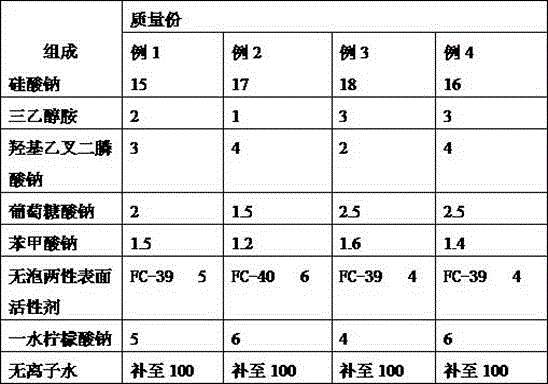

Whitening agent for aluminum cell phone battery cover and preparation method of whitening agent

ActiveCN106757094AOvercome the complex process shortcomings of separate cleaning treatmentImprove bindingWhitening AgentsCitric Acid Monohydrate

The invention provides a whitening agent for an aluminum cell phone battery cover and a preparation method of the whitening agent. The preparation method comprises the following steps that firstly, under the normal temperature, the solid raw materials of sodium silicate, sodium gluconate, sodium citrate monohydrate, sodium benzoate and 1-hydroxyethanediphosphonic acid sodium salt are sequentially stirred and dissolved in deionized water, then liquid raw materials of triethanolamine and a bubble-free ampholytic surfactant are added and stirred uniformly, and transparent liquid is obtained; the die-cast aluminum cell phone battery cover can be cleaned through the transparent liquid, and the good cleaning effect is achieved; and the raw materials used in the product formula are all environmental-friendly raw materials, no environment controlled matter components exist, and the product is gentle in performance, environmentally-friendly, free of toxin, simple in manufacturing process, low in cost, free of flavor and good in effect, and discharge is free of pollution to the environment.

Owner:江西瑞思博新材料有限公司

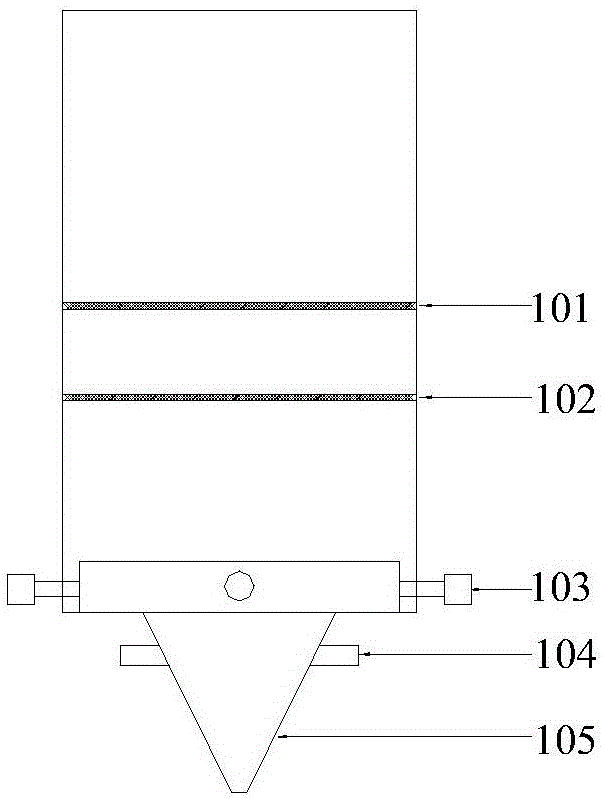

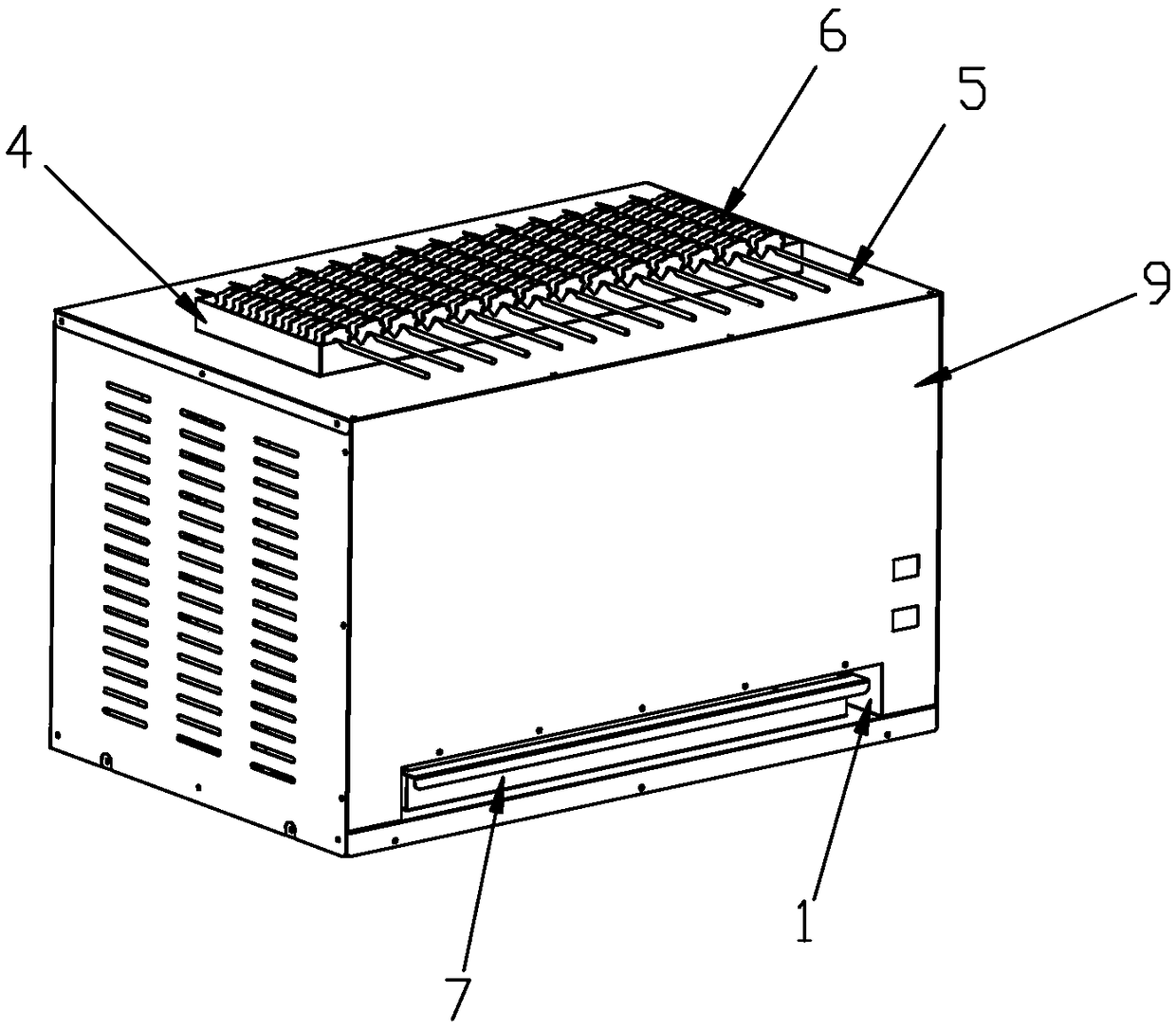

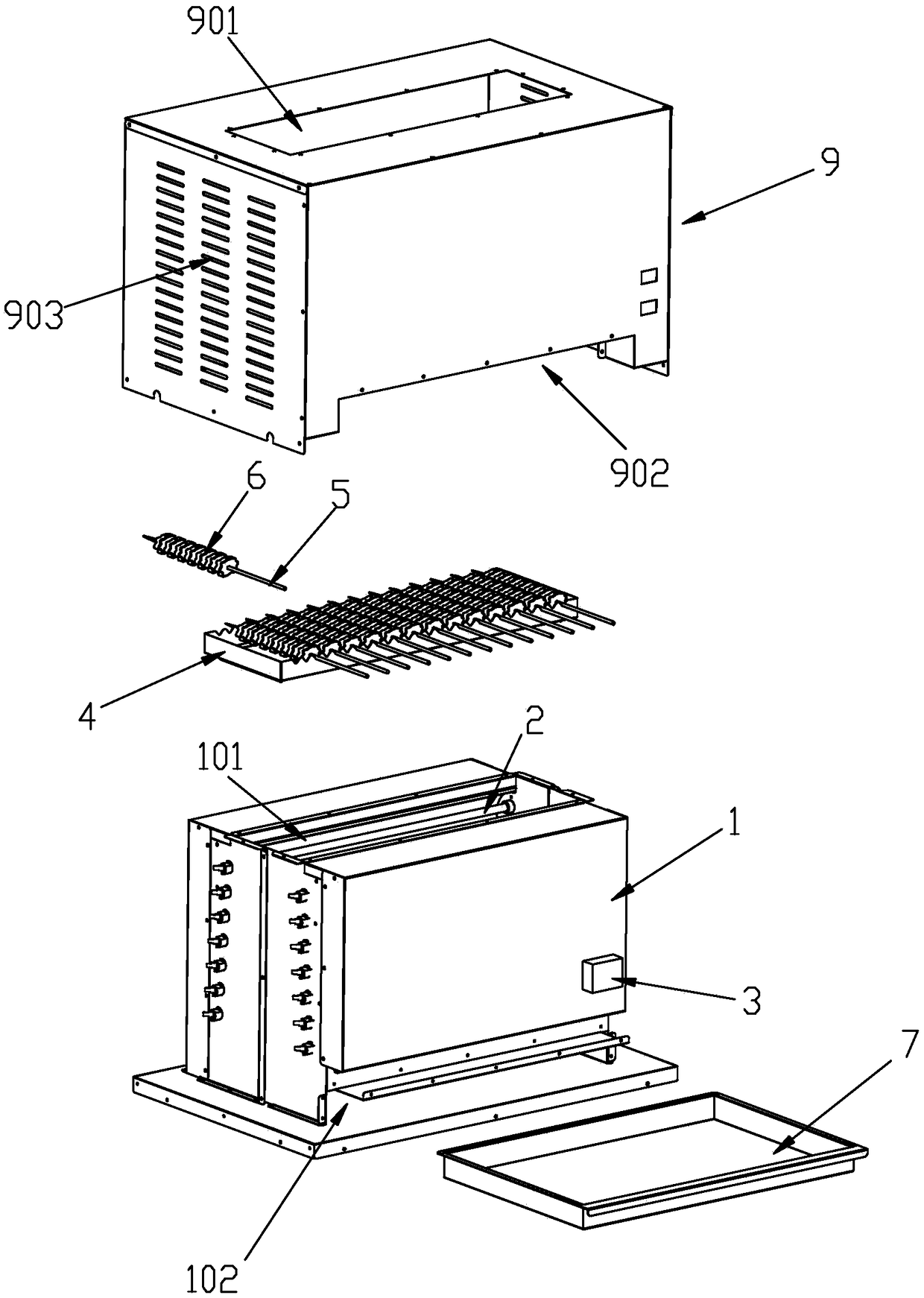

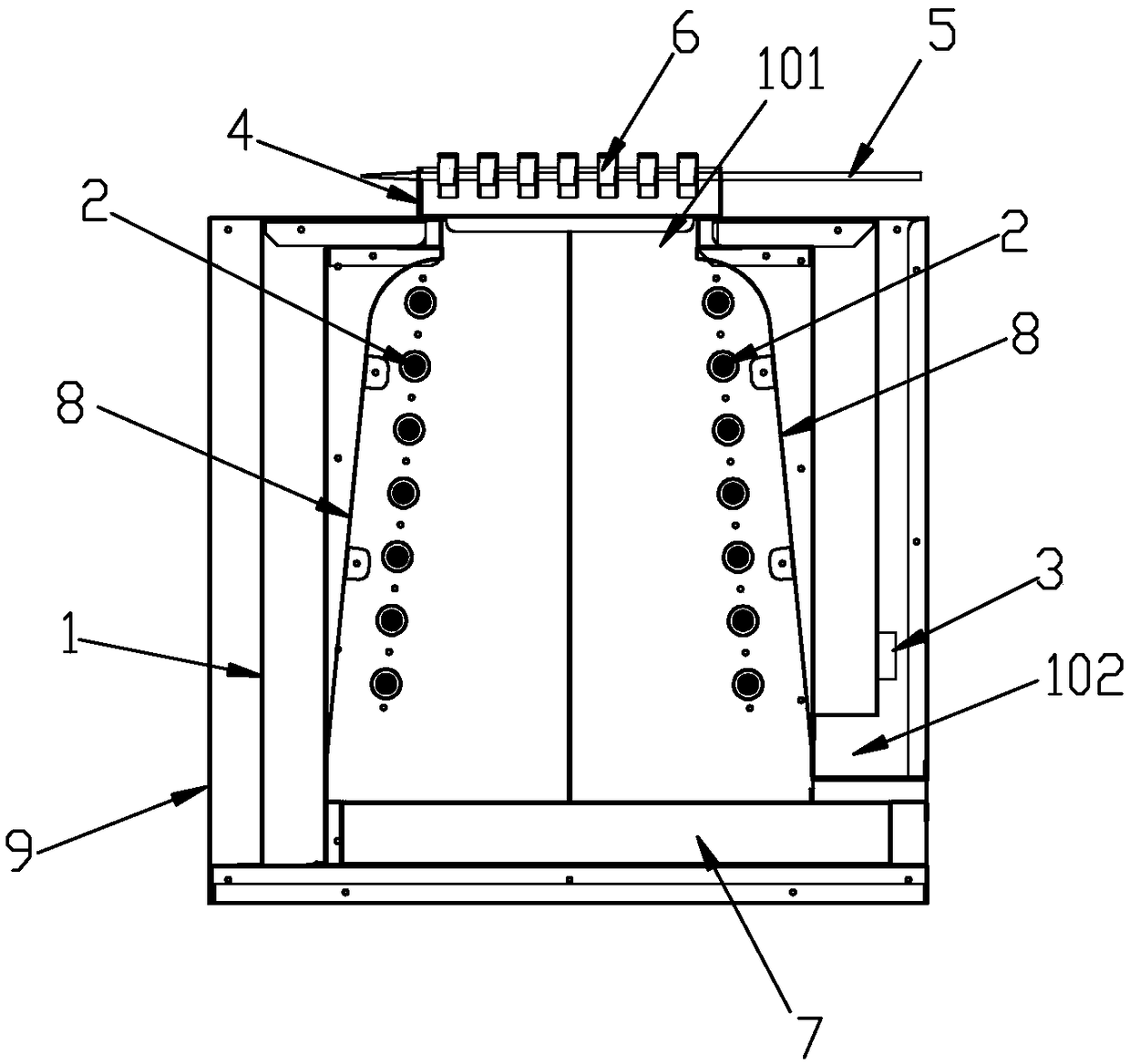

Electric heating barbecue oven

The invention relates to an electric heating barbecue oven which comprises an oven tank. A plurality of electric heating bars are arranged in the oven tank and are electrically connected with an external power source by the same power switch; an oven opening for leading heat radiation energy of the electric heating bars out of the oven tank from the inside of the oven tank is formed in the top ofthe oven tank, a skewer frame in the shape of a rectangular frame is arranged at the oven opening, a frame opening of the skewer frame is butted to the oven opening, the bottom of the skewer frame isfixed to the outer top surface of the oven tank, skewer grooves for laying skewers are symmetrically formed in the tops of two corresponding sides of the skewer frame, and kebabs on the skewers can bealigned with the oven opening by the aid of the skewer grooves; an oil collecting tray is arranged at the bottom of the oven tank, is opposite to the oven opening in the up-down directions, is used for collecting oil stain which drips from the kebabs, and is movably inserted in the oven tank from a tray opening formed in a side wall of the bottom of the oven tank. The electric heating barbecue oven has the advantages that the kebabs can be barbecued by the electric heating bars in a heat radiation manner, and accordingly the kebabs barbecued by the electric heating barbecue oven are healthfuland hygienic; soot can be prevented from being exhausted to the external, oil and juice which are generated when the kebabs are roasted can be prevented from dripping on the electric heating bars tobe combusted to generate smoke, and accordingly the electric heating barbecue oven is favorable for environmental protection.

Owner:佛山市集智智能科技有限公司

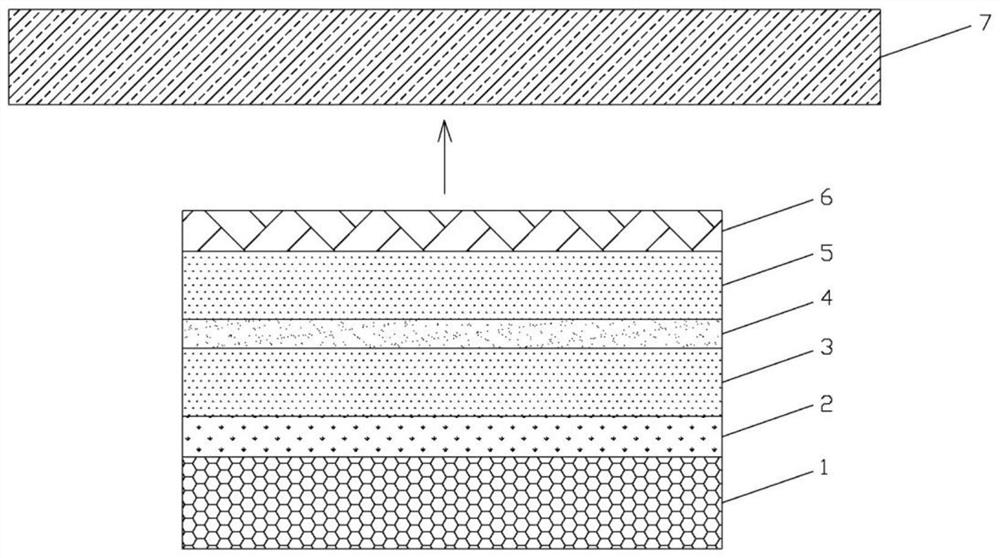

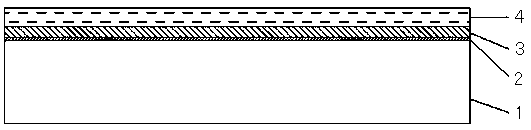

Imitation golden decoration film capable of replacing gold foil and preparation method

InactiveCN111605350AGolden color brightImprove antioxidant capacityDecorative surface effectsVacuum evaporation coatingParaffin waxAntioxidant capacity

The invention discloses an imitation golden decoration film capable of replacing gold foil and a preparation method of the imitation gold decoration film. The imitation golden decoration film comprises a base film, and a mold release agent layer, a first coating layer, an aluminum coating layer, a second coating layer and a gelatinous layer which are sequentially arranged on the base film, whereinthe first coating layer and the second layer are formed by mixing and coating of golden paints and an antioxidant. The imitation golden decoration film disclosed by the invention can replace gold foils, the color and luster are the same as those of the gold foils, and are golden bright, so that the same effect can be achieved; graphene oxide is added to the paint, so that the antioxidant abilityof the imitation golden decoration film is improved, and blackening phenomenon cannot generate after the imitation golden decoration film is used for a long time, and the imitation golden decoration film has favourable anticorrosion performance and waterproof performance; paraffine emulsion is adopted as a material of the mold release layer, the wax capacity coated onto the base film is uniform, the film forming is uniform, and the stripping effect is good; the preparation method is simple and convenient, environmentally-friendly and economic; the material costs are greatly reduced; the usingmethod is convenient; and the imitation golden decoration film is applied to decoration construction of all kinds of occasions.

Owner:JIANGSU KINGHENG PACKAGE MATERIAL CO LTD

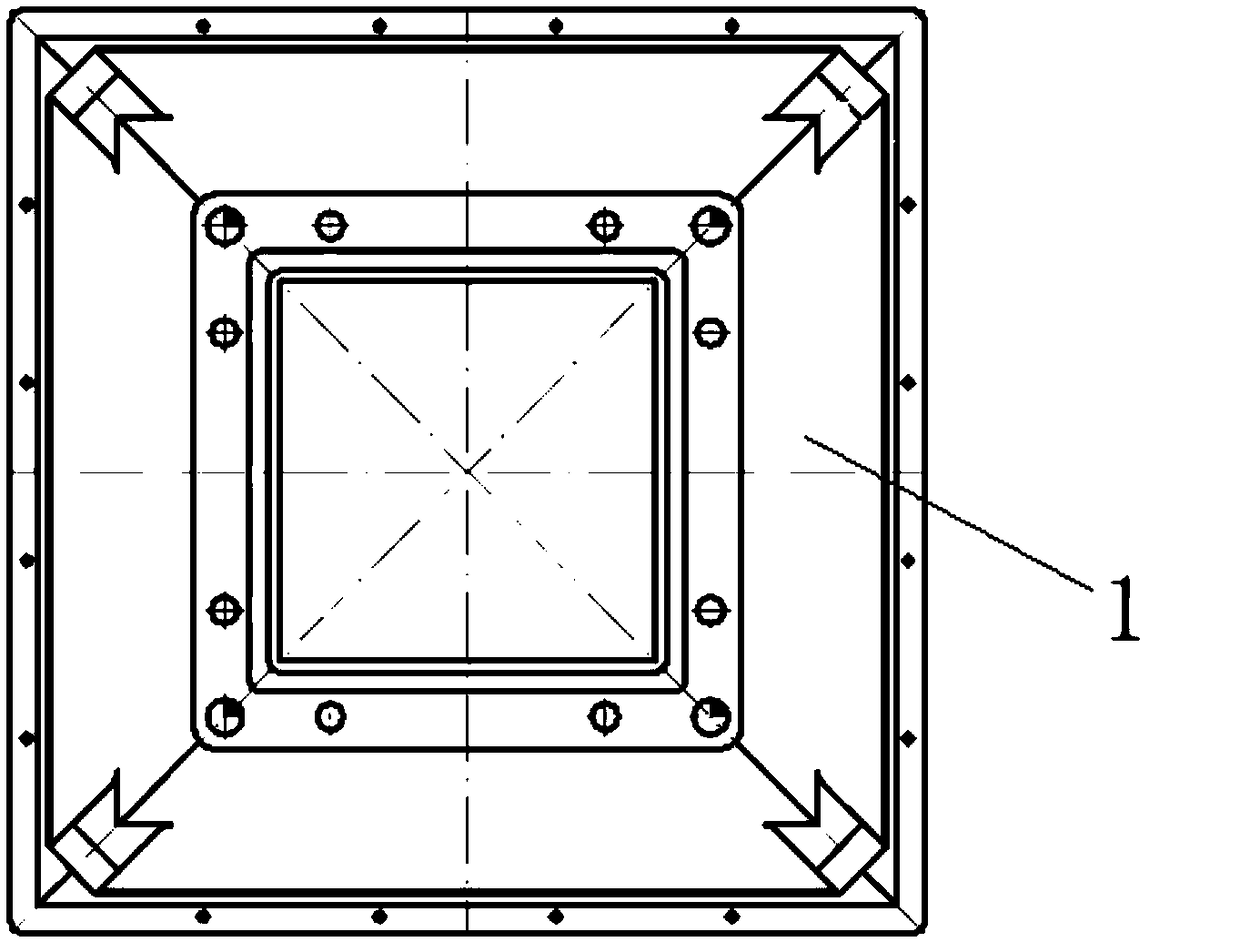

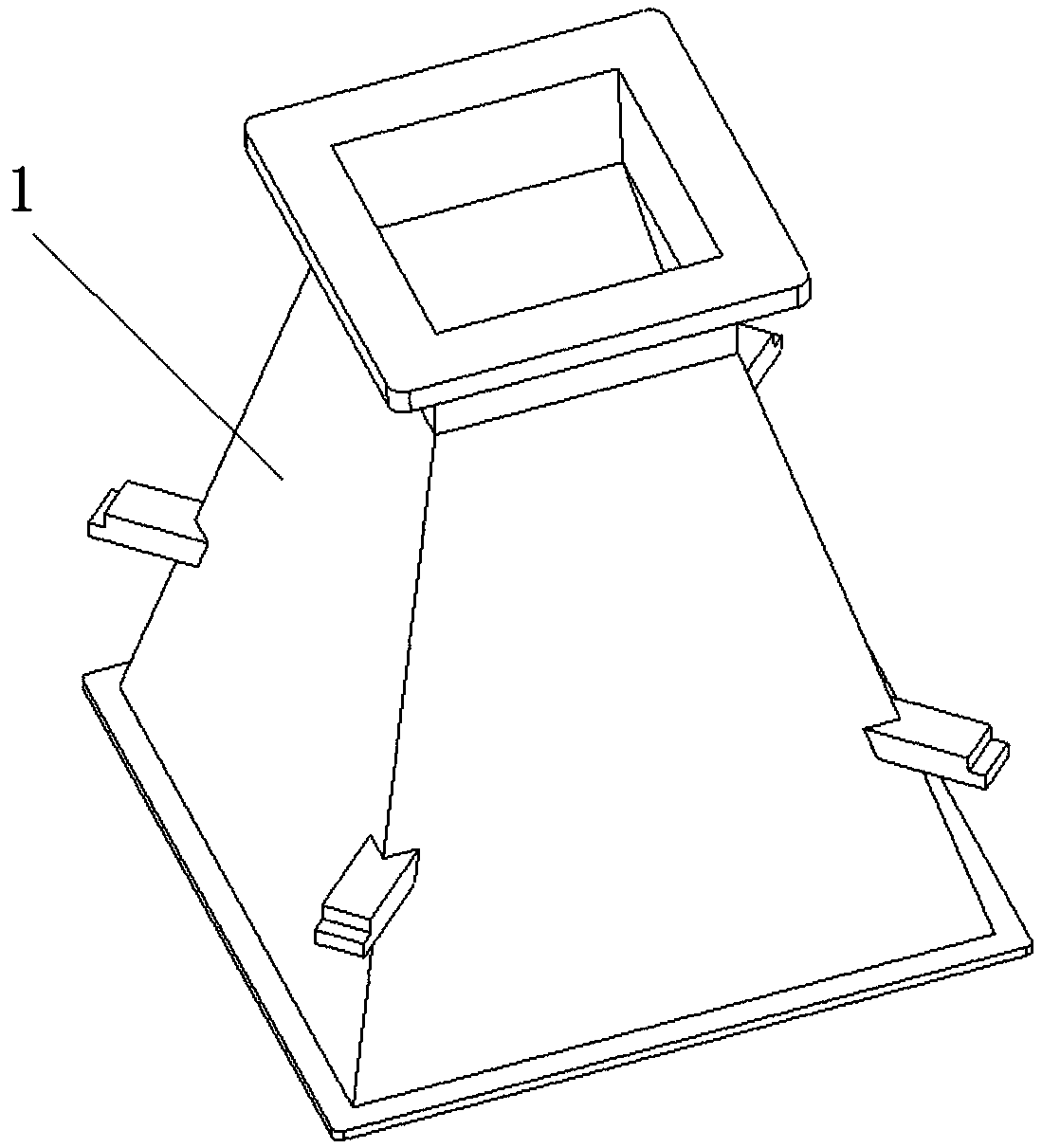

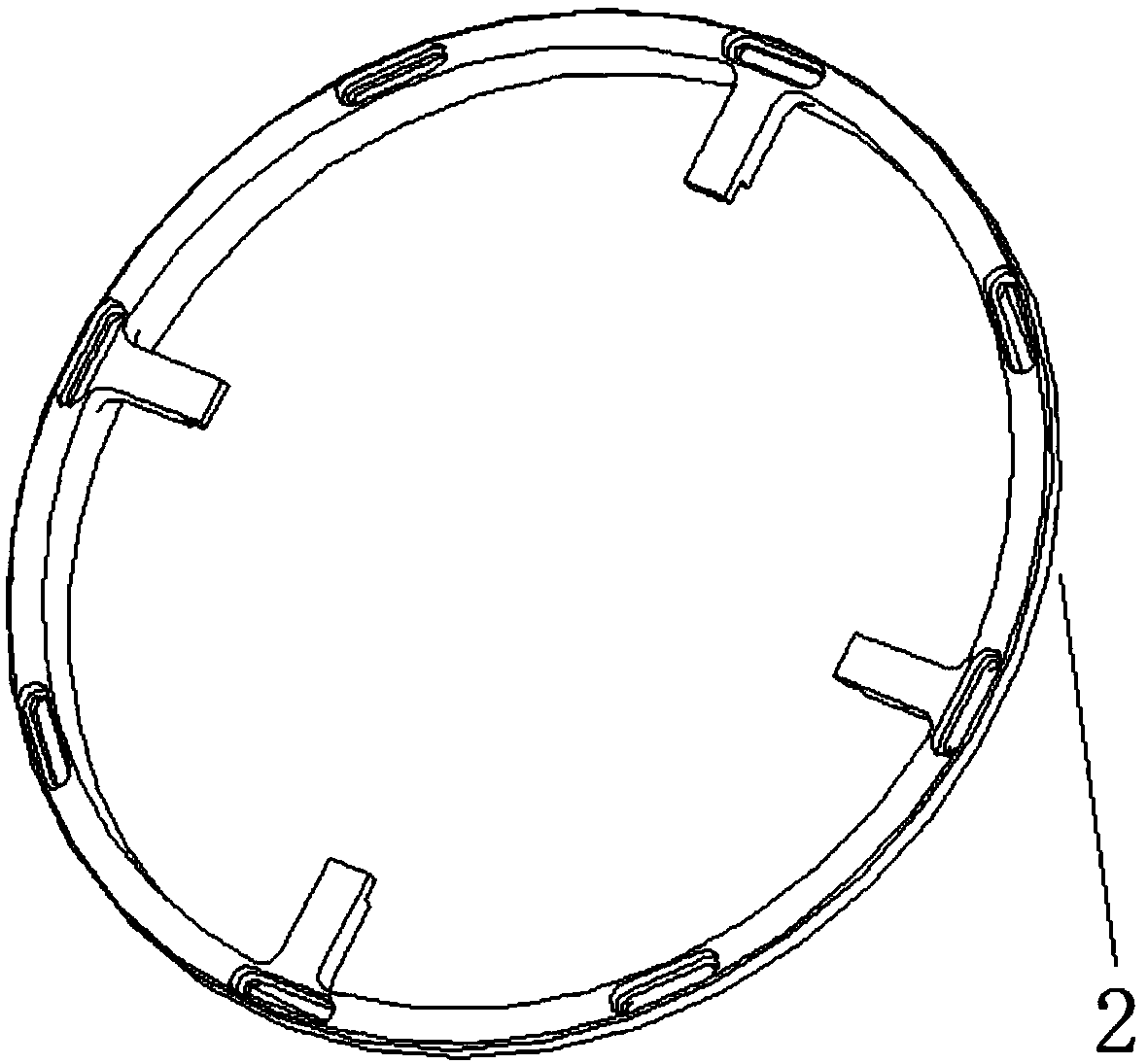

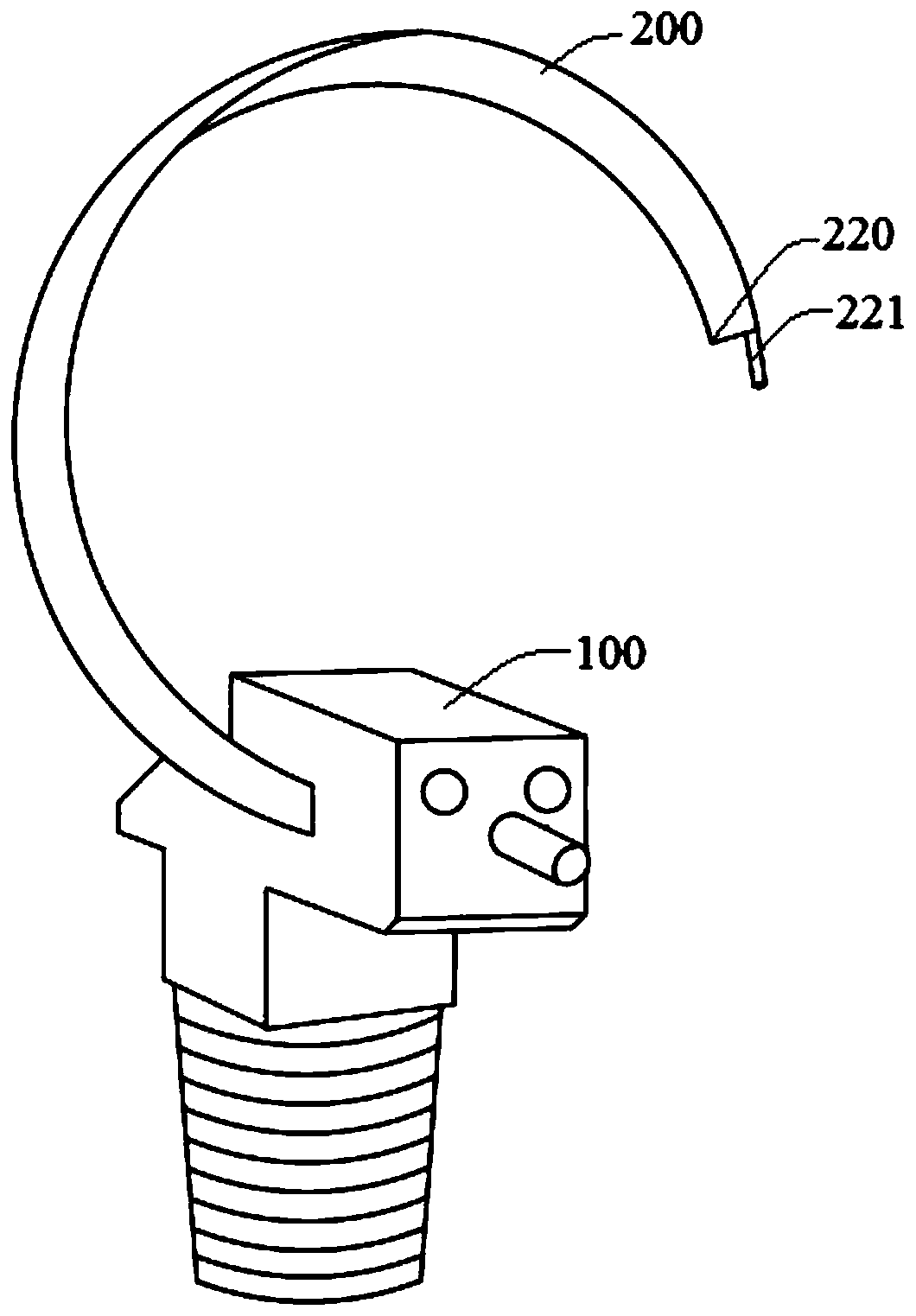

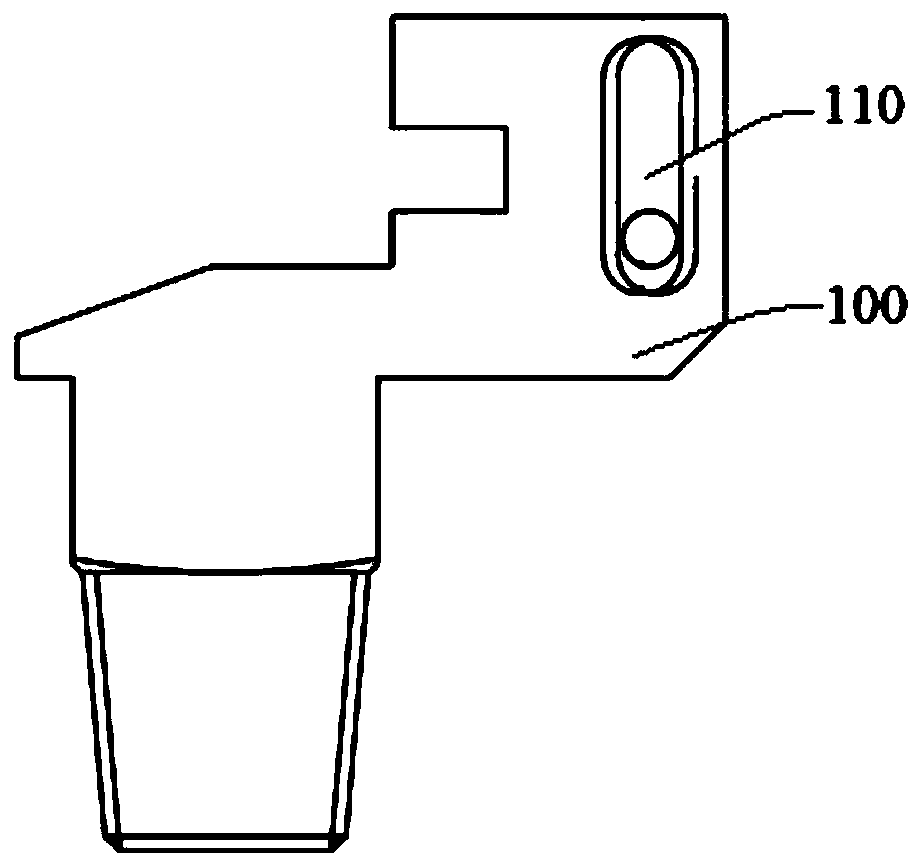

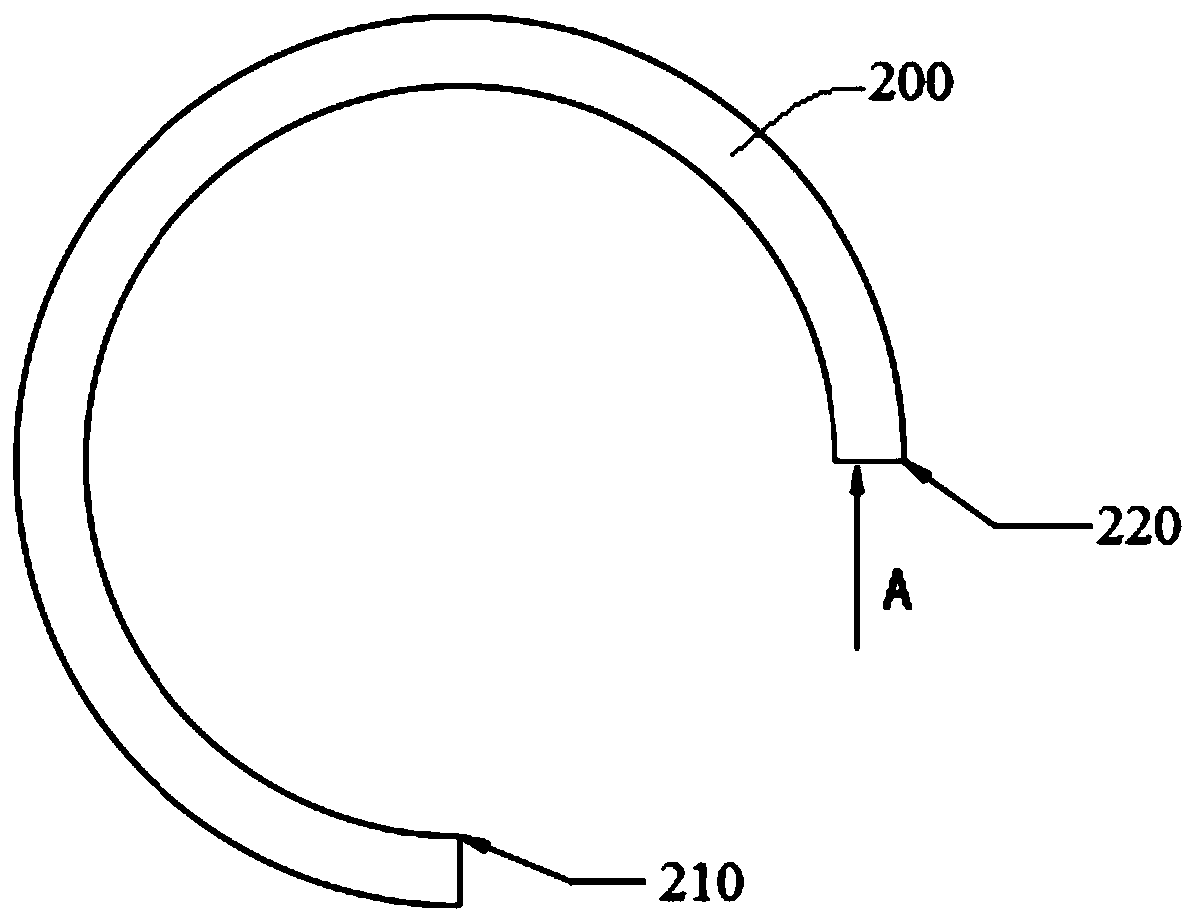

High-frequency induction brazing method and high-frequency inductor for a new type of feed horn

ActiveCN107042347BAccurate temperature controlImprove heating efficiencyHeating appliancesMetal working apparatusEngineeringFiller metal

The invention discloses a novel feed horn high frequency induction brazing method and a high frequency inductor. The novel feed horn high frequency induction brazing method comprises the following steps: firstly designing a horn structure, and enabling the assembling clearance of the connector between each of horns and the corresponding flange to be smaller than 0.1 mm; after processing horns and flanges, performing preassembling; cleaning qualified horns and flanges, and removing surface impurities; fixing the horns and the flanges on a working table, pre-coating with a brazing flux, and setting the distance between the high frequency inductor and the connectors; limiting the distance as 1-4 mm, re-calibrating the welding gap between each of the horns and the corresponding flange; arranging high frequency induction heating equipment, adjusting the output power and the welding technological parameters; adopting a high frequency induction brazing method, heating the connectors, and adding brazing filler metal after the brazing flux is molten; welding the connectors in sequence in a symmetric manner, performing post-welding cleaning after the workpieces are cooled so as to remove the residual brazing flux; one end of the connecting frame of the high frequency inductor is connected with one end part of an induction coil, and the other end is connected with an electrode; the induction coil is M-shaped, or a magnetizer is embedded in the lower part of the induction coil.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

Preparation method of coprinus comatus cultivation matrix

InactiveCN106518331ANo blackeningSubstrate has good air permeabilityCalcareous fertilisersBioloigcal waste fertilisersDiseaseCorn flour

The invention discloses a preparation method of a coprinus comatus cultivation matrix. The preparation method comprises the following steps that (1) palm fiber, straw, wheat bran, gypsum, corn flour and water are stirred and uniformly mixed; and (2) the mixture obtained in the step (1) is heated to 30-35 DEG C, baking soda is sprinkled into the mixture, the constant temperature is maintained for 3-6 min, then, the mixture is cooled to the normal temperature, and the coprinus comatus cultivation matrix is obtained. The coprinus comatus cultivation matrix obtained through the preparation method is good in air permeability, whole stems of cultivated coprinus comatus are pure white, and the lower ends of the cultivated coprinus comatus stems are free of the blackening phenomenon; compared with the growth cycle of common coprinus comatus, the growth cycle of the coprinus comatus cultivation matrix is shortened by 50% or more; and diseases and insect pests are avoided in the growth process.

Owner:CHENGDU TIANLU FUNGI

Preparation method of culture substrate

InactiveCN106495866ANo blackeningNo pestsCalcareous fertilisersBioloigcal waste fertilisersSodium bicarbonateCarrageenan

The invention discloses a preparation method of a culture substrate, which comprises the following steps of: (1) agitating and uniformly mixing palm threads, straws, wheat bran, gypsum, maize meal and water, (2) heating a mixture obtained in step (1) to 35-40 DEG C, spilling into sodium bicarbonate, adding carrageenan for uniform agitation, keeping a constant temperature for 3-6min, cooling to the room temperature and obtaining the culture substrate. The culture substrate prepared with the method is particularly applicable to culture of coprinus comatus; a whole stem of the cultured coprinus comatus is white and has no blackening at the lower end; a growth cycle of the cultured coprinus comatus is less than that of the common coprinus comatus by above 50%; and the coprinus comatus is free from diseases and insect pests in a growing process and is brittle and hard in taste.

Owner:CHENGDU TIANLU FUNGI

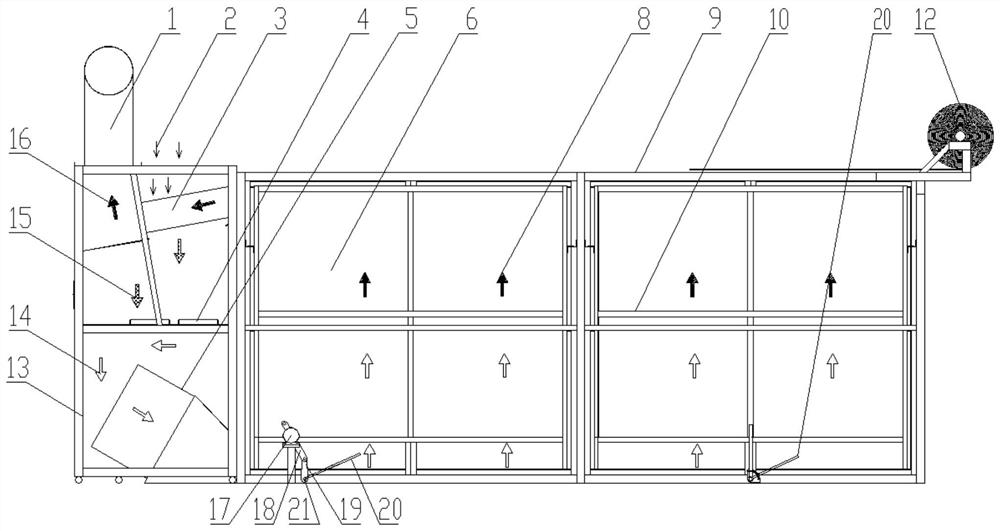

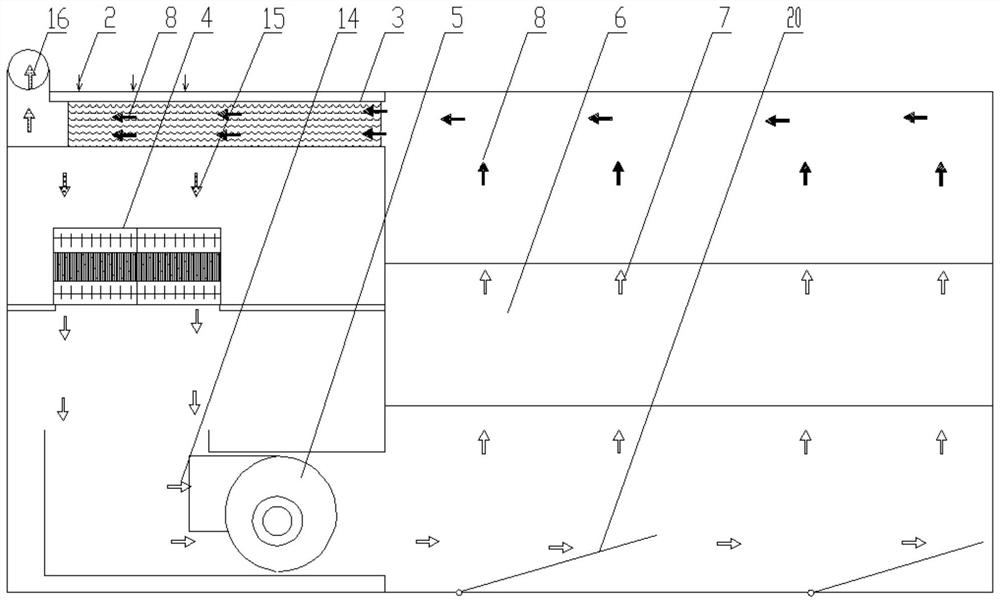

Preparation method of dried zanthoxylum bungeanum maxim

ActiveCN112344675ALow costGood conditionFood processingDrying gas arrangementsCold airZanthoxylum bungeanum

The invention provides a preparation method of dried zanthoxylum bungeanum maxim. The preparation method of the dried zanthoxylum bungeanum maxim comprises the following steps of naturally air-dryingpicked fresh zanthoxylum bungeanum maxim; dehumidifying with hot air: sequentially drying the naturally air-dried zanthoxylum bungeanum maxim in a drying chamber at 32 + / -0.5 DEG C for 2 + / -1 hours, in a drying chamber at 35 + / -0.5 DEG C for 3 + / -1 hours, and in a drying chamber at 37 + / -0.5 DEG C for 3 + / -1 hours; drying in a drying chamber at 39 + / -0.5 DEG C for 8 + / -1 hours to enable zanthoxylum oil to overflow out of the surface; drying in a drying chamber at 41 + / -0.5 DEG C for 9 + / -1 hours; drying the zanthoxylum bungeanum maxim subjected to the previous step in a drying chamber at 43 + / -0.5 DEG C for 5 + / -1 hours, and then drying the zanthoxylum bungeanum maxim in a drying chamber at 45 + / -0.5 DEG C for 3 + / -1 hours; and in the drying process, heating cold air by a heater and introducing into the drying chamber, and introducing generated damp-hot air into a heat exchanger as a heat source for preheating cold air. According to the preparation method of the dried zanthoxylum bungeanum maxim provided by the invention, waste heat recovery is achieved, power consumption is greatly reduced, emission of air containing pollutants is fundamentally eradicated, and energy conservationand emission reduction of pepper drying are achieved.

Owner:重庆蔓极科节能环保科技有限公司

Coprinus comatus cultivation matrix

InactiveCN106495867ANo blackeningNo pestsCalcareous fertilisersBioloigcal waste fertilisersGypsumSodium bicarbonate

The invention discloses a coprinus comatus cultivation matrix. The cultivation matrix is prepared from the following components: straws, wheat bran, gypsum, corn flour, palm threads and sodium bicarbonate. According to coprinus comatus cultivated by the cultivation matrix, the stem of the whole coprinus comatus is pure white, the blackening phenomenon of the lower end of the stem is avoided, the growth cycle is 50 percent or above less than that of common coprinus comatus, and diseases and insect pests are avoided in a growth process.

Owner:CHENGDU TIANLU FUNGI

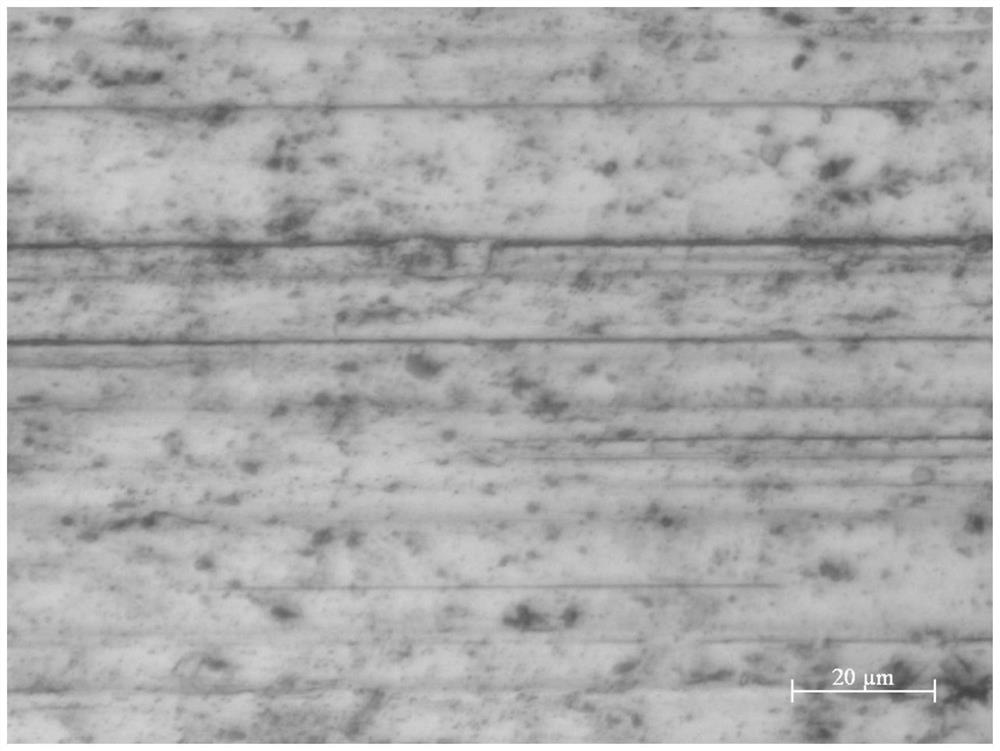

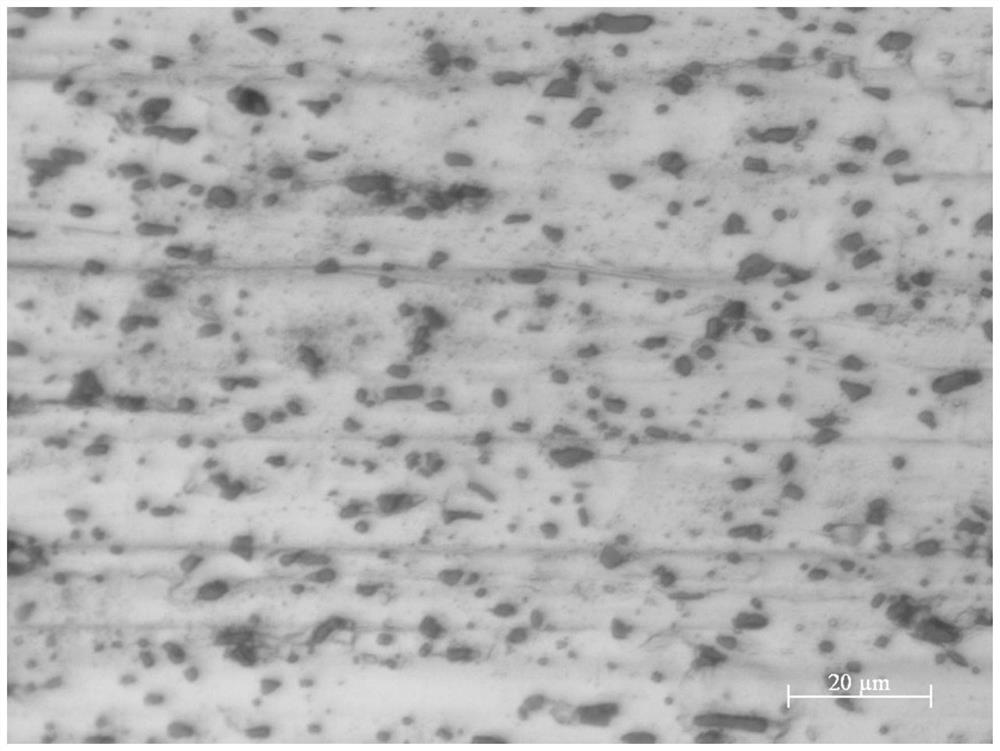

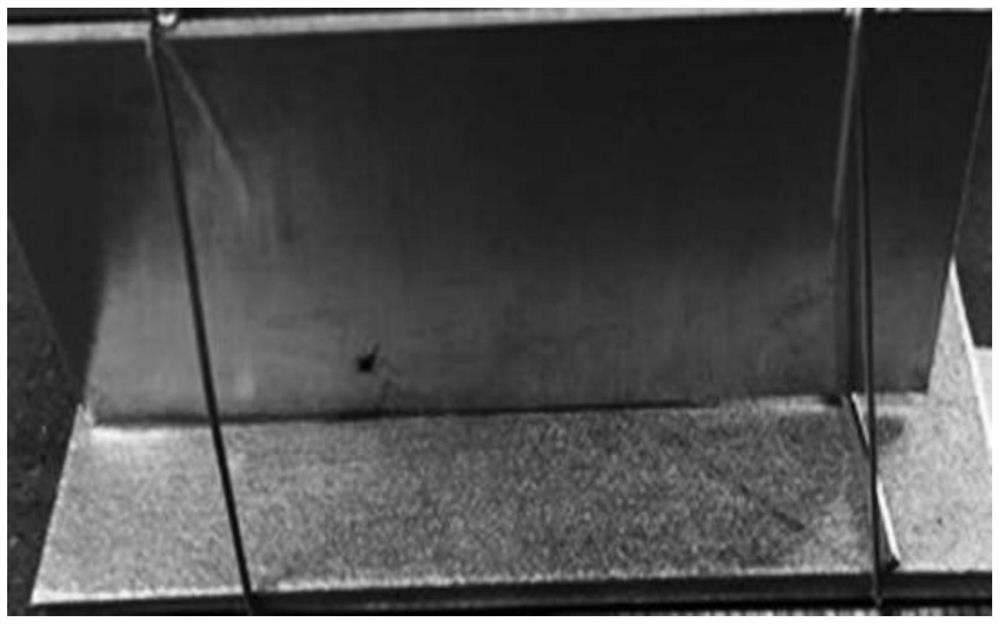

Alkali cleaning fluxless or vacuum brazing sheet preparing method

ActiveCN108247233AUniform surface reactionEven parts clearanceWelding/cutting media/materialsHeat exchange apparatusSodium silicateSurface finishing

The invention discloses an alkali cleaning fluxless or vacuum brazing sheet preparing method. The method comprises following steps that an alloy casting device is adopted, a casting ingot is casted, acore layer and a brazing layer are each subject to annealing, and then are hot rolled into thin sheets, all layers are welded together, hot rolling and cold rolling are carried out, finally, annealing is carried out, before welding, and a surface treatment method is executed. The surface treatment method comprises following steps that firstly, an organic solvent is used for cleaning the surface of an alkali cleaning fluxless or vacuum brazing sheet; secondly, alkali liquor is used for cleaning a product in the first step, and the product comprises one or multiple of 0 to 5wt% of sodium gluconate, 0 to 5wt% of sodium pyrophosphate, 0 to 10wt% of sodium carbonate, 0 to 3% of sodium phosphate and 1 to 10wt% of sodium bicarbonate, 0 to 1wt% of NaOH and 0 to 5wt% of sodium silicate; thirdly, asaturated EDTA solution or saturated isopropanol solution is used for cleaning the product in the second step; fourthly, a salpeter solution is adopted to carry out acid pickling on the product obtained in the third step; fifthly, washing is carried out. The corrosion to silicon particles is small, the pollution is small, good brazing gaps are ensured, and the good effect is obtained.

Owner:HUAFON NIKKEI ALUMINUM

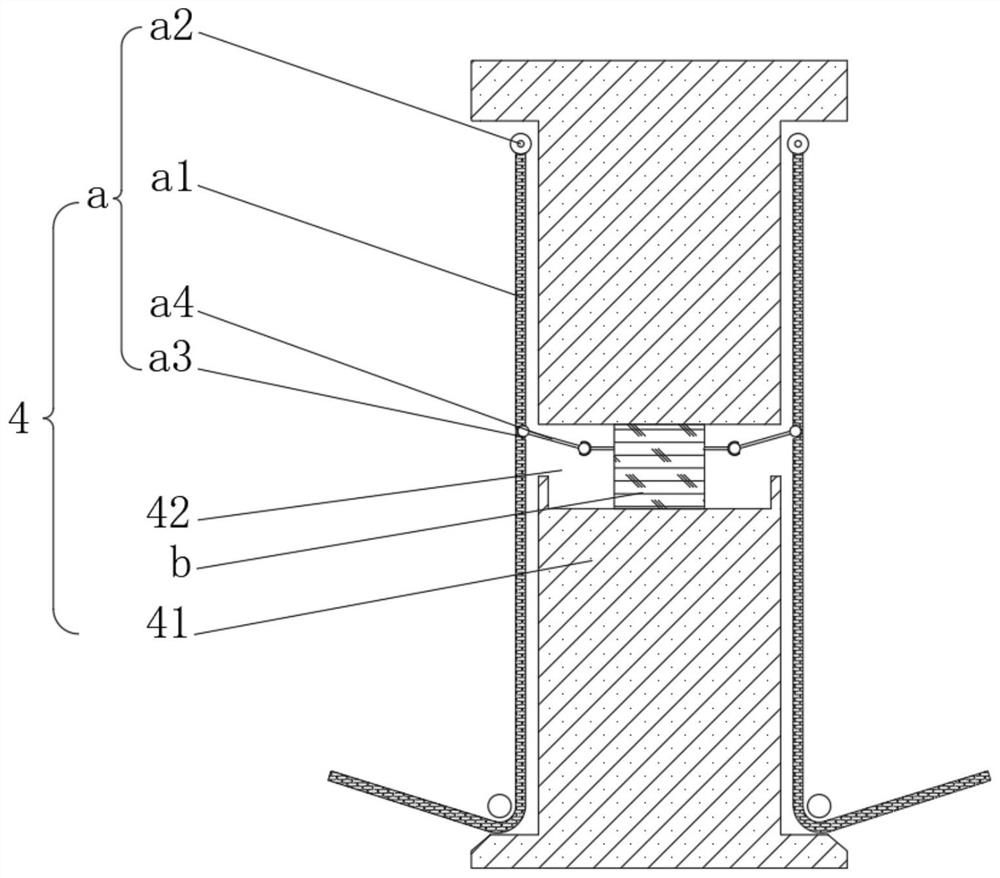

Welding fixing device

PendingCN112355429AEliminate inner wall crushReinforced outer surface elasticWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWeld seam

The invention discloses a welding fixing device. The welding fixing device comprises a welding fixing device body composed of a tray, a base and a supporting rod, wherein the top of the tray is fixedly connected with the bottom of the base; a groove is formed in the top of the base; the bottom of the inner wall of the groove is fixedly connected with the bottom of the supporting rod; the supporting rod is sleeved with a first welding piece; a second welding piece is connected into the first welding piece in a sliding manner; the supporting rod comprises a rod body; a fixing mechanism and a correcting mechanism are arranged in the rod body; the fixing mechanism comprises a rotating rod; and a sliding mechanism is arranged on the top of the rotating rod. The invention relates to the technical field of welding. The welding fixing device solves the problems that due to transverse welding, welding defects such as unsmooth welding seams on the surface of a welding part, uneven and full fillet filling, base metal corrosion, over-burning blackening, undercut (pipe opening burning), overlap height, cracks, air holes and impurities are caused.

Owner:雒明伟

Waterproof intermediate cross cable

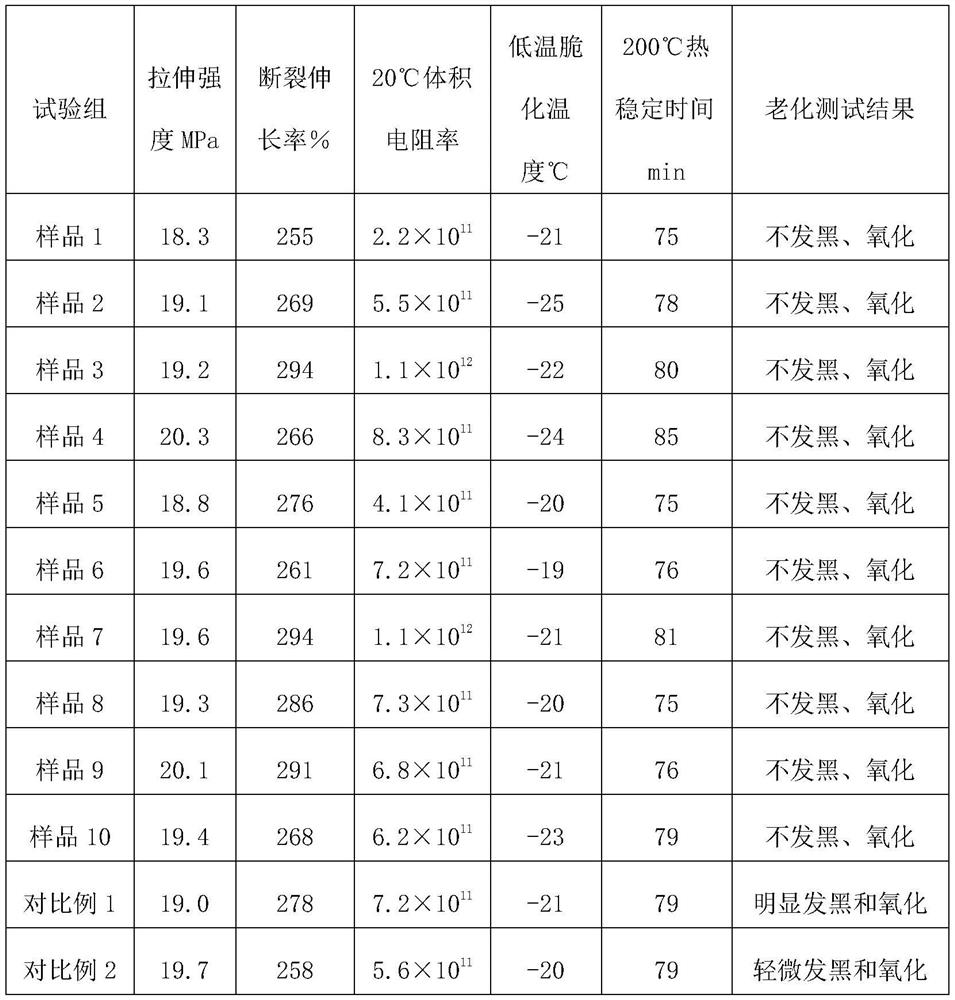

PendingCN114566307ASolve the problem of safety and long service lifePrevent oxidation of conductor surfacePlastic/resin/waxes insulatorsClimate change adaptationPOLYETHYLENE WAXPoly ethylene

A waterproof intermediate alternating current cable is provided with a cable core body and an anti-aerugo PVC insulating layer wrapping the outer surface of the cable core body. And the anti-aerugo PVC insulating layer contains polyvinyl chloride with the polymerization degree of 1000-1300, diisononyl phthalate, epoxidized soybean oil, polyethylene wax and an anti-aerugo compatilizer. The anti-aerugo PVC insulating layer is further provided with a waterproof layer and an outer sheath layer, the waterproof layer wraps the outer surface of the cable core body, and the outer sheath layer wraps the outer surface of the waterproof layer. The anti-aerugo PVC insulating layer of the waterproof intermediate alternating current cable contains the anti-aerugo compatilizer, so that the conductor surface of the cable core body can be prevented from being oxidized, the blackening phenomenon is avoided, the problems of safety and long service life of a cable product are solved, and the cost is reduced.

Owner:GUANGDONG SHINE CABLES

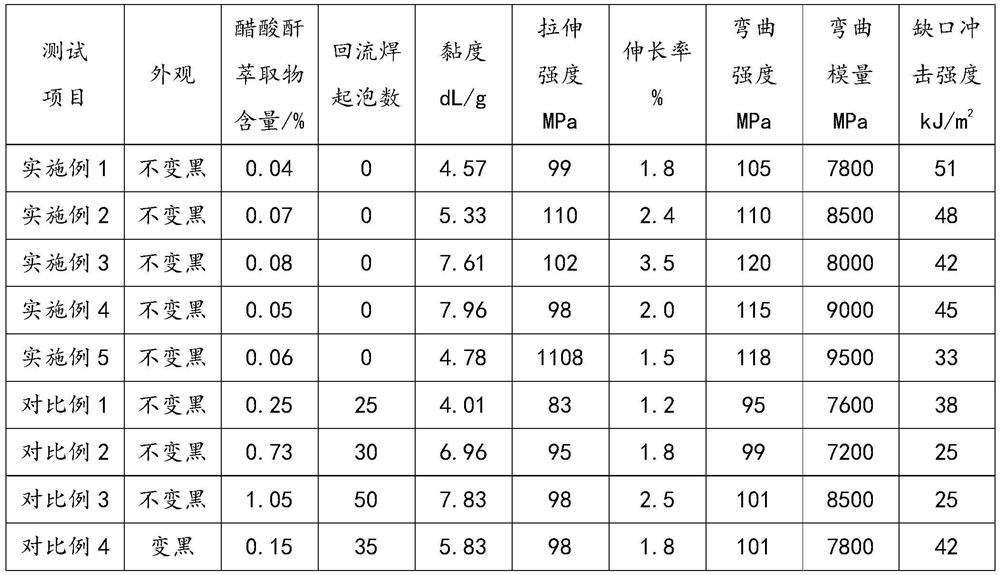

A kind of thermotropic liquid crystal polyester and preparation method thereof

ActiveCN110982050BNo blackeningThe acetylation reaction is completeLiquid crystal compositionsPolyesterPolymer science

The invention belongs to the field of materials, and discloses a thermotropic liquid crystal polyester obtained by reacting monomers, aliphatic acid anhydrides and catalysts. The monomers include: HO-Ar-COOH (I), HO-Ar-OH ( II), at least one of HOOC-Ar-COOH (III), wherein, Ar is wherein, Ar is at least one of phenyl, biphenyl, naphthyl, anthracenyl or phenanthrenyl; the aliphatic The amount of substance of acid anhydride is 1.3-3 times of the amount of substance of hydroxyl group in the monomer. The present invention eliminates the by-product fatty acids and strictly controls the amount of aliphatic acid anhydrides during the acetylation reaction process, so that the acetylation reaction is more complete, and the clogging caused by monomer volatilization is reduced, and the thermotropic liquid crystal polyester prepared is not There will be blackening, no blistering during reflow, and excellent mechanical properties.

Owner:JIANGMEN DENGZHONGTAI ENG PLASTICS CO LTD

Electric potential induced attenuation prevention crystalline silicon battery and preparation method thereof

InactiveCN103928536AGood anti-PID effectExcellent anti-PIDFinal product manufactureSemiconductor devicesIonSilicon nitride

The invention discloses an electric potential induced attenuation prevention crystalline silicon battery. The electric potential induced attenuation prevention crystalline silicon battery comprises an amorphous silicon layer, a silicon-rich silicon nitride layer which has a passivation effect and a nitrogen-rich silicon nitride layer which has an antireflection effect, wherein the amorphous silicon layer, the silicon-rich silicon nitride layer and the nitrogen-rich silicon nitride layer sequentially cover a silicon substrate. According to the electric potential induced attenuation prevention crystalline silicon battery, an antireflecting layer structure of the battery is mainly improved, a layer of compact amorphous silicon is deposited between traditional single-layer or multi-layer silicon nitride and the crystalline silicon substrate by a PECVD method, the compact amorphous silicon layer can prevent erosion of positive ions to PN junctions, and therefore the influence of a PID effect is lowered. The electric potential induced attenuation prevention crystalline silicon battery can be achieved by only making simple modification on a process on existing equipment, and is compatible with an existing process, simple in method and low in cost.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

Chinese red glaze water as well as preparation method and application thereof

ActiveCN108249761AImprove physical performanceImprove crack resistanceCobalt(II,III) oxideZinc nitrate

The invention relates to Chinese red glaze water as well as a preparation method and application thereof. The Chinese red glaze water contains the following components in parts by weight: 1 to 5 partsof glaze soil, 0.2 to 0.6 part of bryozoatum, 0.7 to 1.4 parts of medical stone, 0.8 to 1.5 parts of quartz, 20 to 40 parts of red lead, 0.3 to 0.7 part of limestone, 0.3 to 0.7 part of stannic oxide, 0.2 to 0.6 part of kaoline, 18 to 30 parts of coal ash, 0.4 to 1 part of copper flower, 2.5 to 6.5 parts of cobaltosic oxide, 0.5 to 1.2 parts of fluorite, 0.3 to 1.2 parts of zinc nitrate, 0.5 to 1.5 parts of zinc fluosilicate and 50 to 80 parts of water. Through a special formula, a preparation method and a coloring method, ceramics after glazing have advantages of antibacterial performance, high glossiness, high mechanical strength and the like.

Owner:福建省德化县中国白陶瓷有限责任公司

Processing method of nickel electroplated pressure gauge

The invention discloses a processing method of a nickel electroplated pressure gauge, and belongs to the technical field of pressure gauges. The processing method sequentially comprises an nickel electroplating process and a welding process, wherein a gauge connector of the pressure gauge is electroplated with a nickel layer through nickel electroplating process, the gauge connector, a spring tubeand a sealing piece are welded sequentially through the welding process, wherein a soldering flux with an effective component as rosin is adopted in the welding process, after each welding is finished, the welded part is put into hot water for being soaked for 4-7 minutes, and then is washed with flowing clean water for 30-60 minutes; and the mass part of the rosin in the rosin soldering flux ispreferably 20 parts, and the rosin soldering flux is located inside a tin welding wire. According to the processing method, the total process time is shortened, blackening of the nickel plated gauge connector in the welding process is avoided, the cost is reduced, and the production efficiency is improved.

Owner:MAANSHAN NAITE INSTR TECH

Aluminum-based circuit board laser cutting process and equipment thereof

PendingCN114101929AImprove cutting accuracyImprove cutting efficiencyPrinted circuitsWelding/soldering/cutting articlesCarbon dioxide laser lightCopper foil

The invention discloses an aluminum-based circuit board laser cutting process and equipment thereof. An aluminum-based circuit board comprises an aluminum substrate, an insulating layer is arranged on the aluminum substrate, a copper foil circuit formed by etching a copper foil and a sunken position are arranged on the insulating layer, a paint layer is arranged on the copper foil circuit and the sunken position, and a groove is formed in the sunken position by the paint layer; a joint cutting mode of carbon dioxide laser and optical fiber laser is adopted, the energy density of the carbon dioxide laser is relatively low, the cutting effect on a paint layer and an insulating layer in the aluminum-based circuit board is good, after the paint layer and the insulating layer are cut, the edges are free of dust, burrs and deformation, and a copper foil circuit is free of damage, blackening and oxidation; and the energy density of the optical fiber laser is relatively high, the cutting effect on the aluminum substrate is relatively high, and the edge of the cut aluminum substrate is smooth and neat.

Owner:广东洛克智能科技设备有限公司

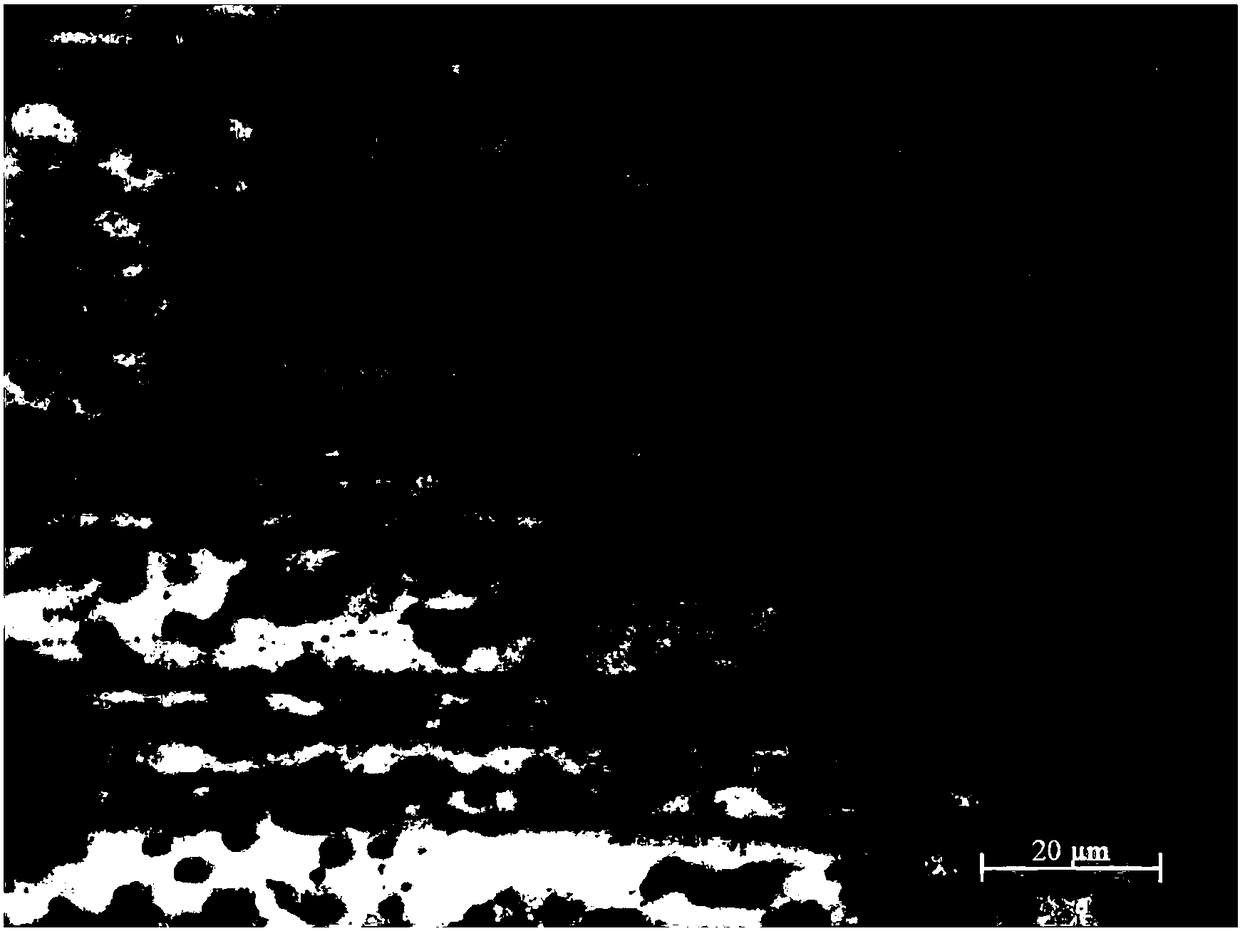

Preparation method of alkali-cleaned flux-free or vacuum brazing sheet

ActiveCN108247233BReduce corrosionNo blackeningWelding/cutting media/materialsHeat exchange apparatusSodium bicarbonateSodium phosphates

The invention discloses an alkali cleaning fluxless or vacuum brazing sheet preparing method. The method comprises following steps that an alloy casting device is adopted, a casting ingot is casted, acore layer and a brazing layer are each subject to annealing, and then are hot rolled into thin sheets, all layers are welded together, hot rolling and cold rolling are carried out, finally, annealing is carried out, before welding, and a surface treatment method is executed. The surface treatment method comprises following steps that firstly, an organic solvent is used for cleaning the surface of an alkali cleaning fluxless or vacuum brazing sheet; secondly, alkali liquor is used for cleaning a product in the first step, and the product comprises one or multiple of 0 to 5wt% of sodium gluconate, 0 to 5wt% of sodium pyrophosphate, 0 to 10wt% of sodium carbonate, 0 to 3% of sodium phosphate and 1 to 10wt% of sodium bicarbonate, 0 to 1wt% of NaOH and 0 to 5wt% of sodium silicate; thirdly, asaturated EDTA solution or saturated isopropanol solution is used for cleaning the product in the second step; fourthly, a salpeter solution is adopted to carry out acid pickling on the product obtained in the third step; fifthly, washing is carried out. The corrosion to silicon particles is small, the pollution is small, good brazing gaps are ensured, and the good effect is obtained.

Owner:HUAFON NIKKEI ALUMINUM

Whitening agent for aluminum mobile phone battery cover and preparation method thereof

ActiveCN106757094BOvercome the complex process shortcomings of separate cleaning treatmentImprove bindingWhitening AgentsElectrical battery

The invention provides an aluminum mobile phone battery cover whitening agent and a preparation method thereof, which is prepared as follows: at room temperature, the above-mentioned solid raw materials: sodium silicate, sodium gluconate, sodium citrate monohydrate, sodium benzoate The raw materials of sodium hydroxyethylidene diphosphonate are stirred and dissolved in ion-free water, and then the liquid raw materials triethanolamine and non-foaming amphoteric surfactant are added and stirred evenly to obtain a transparent liquid. It can clean the die-casting aluminum mobile phone battery cover and has a good cleaning effect. The raw materials used in the product formula are all environmentally friendly raw materials, and there are no environmentally controlled substances. The product performance is mild, environmentally friendly and non-toxic, and the production process is simple. Low cost, no smell, good effect, no pollution to the environment.

Owner:江西瑞思博新材料有限公司

A Method of Improving the Surface Quality of 8mm Diameter Hypoxic Bright Copper Rod

InactiveCN104646412BReduce the number of surface defectsReduce copper powder contentWork cooling devicesWork cleaning devicesWaxEmulsion

The invention discloses a method for improving the surface quality of a low-oxygen light copper rod with the diameter of 8mm. The method is improved on the basis of a traditional production process of the low-oxygen light copper rod with the diameter of 8mm. The method comprises the following procedures of preparing materials, smelting, casting, rolling, washing, drying by blowing, coating wax and packaging, and is characterized in that the procedures of rolling, washing, drying by blowing, coating the wax are improved; a primary edge milling and emulsion circulating system is additionally arranged in the rolling procedure, and formulas of emulsion, washing liquid and wax liquid are optimized. The surface quality of finished products is improved, the effect is remarkable, energy and consumption are saved and the production cost is reduced. The method relates to the field of machining of metal copper.

Owner:XINXING PIPES ZHEJIANG COPPER

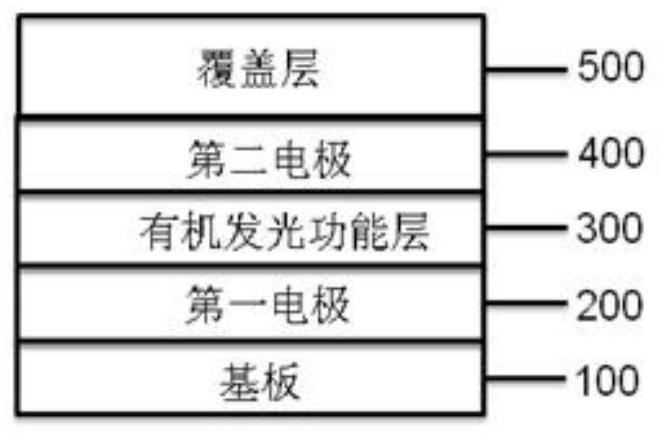

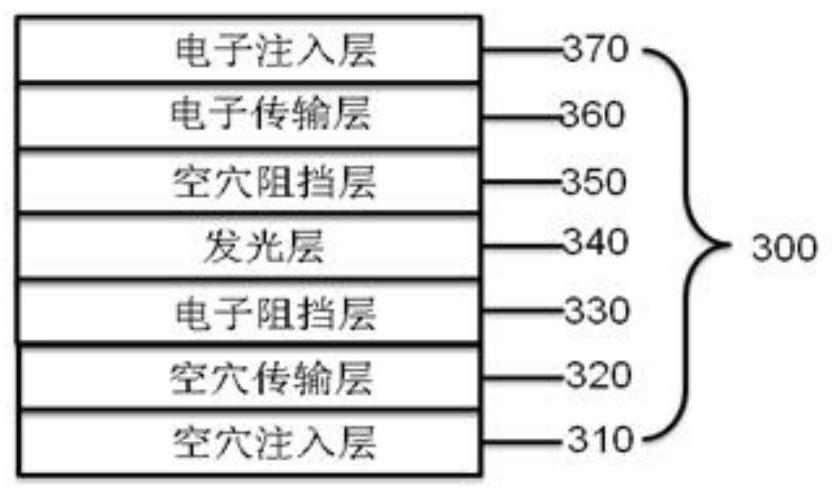

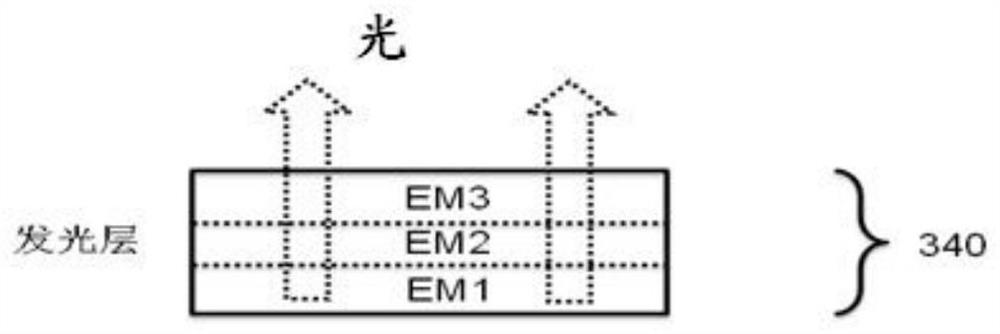

Monoamine organic compound simultaneously containing pyrenyl and benzoxazolyl or benzothiazolyl and application thereof

PendingCN114133358ANo crystallizationImprove light extraction efficiencyOrganic chemistrySolid-state devicesSimple Organic CompoundsThiazole

The invention discloses a monoamine organic compound containing pyrenyl and benzoxazolyl or benzothiazolyl at the same time and application of the monoamine organic compound. The compound is an amine compound containing pyrenyl and benzoxazolyl or benzothiazolyl at the same time, has a shallow LUMO energy level and thermal stability, is low in evaporation temperature, has a decomposition temperature higher than the evaporation temperature, and has a low extinction coefficient and a high refractive index in the field of visible light. After the compound is applied to the OLED device as a covering layer, the light extraction efficiency of the OLED device can be effectively improved, and the angle dependence is reduced, so that the luminous efficiency of the device is improved, and the visual polarization performance is optimized.

Owner:JIANGSU SUNERA TECH CO LTD

Breeding matrix for coprinus comatus cultivation

InactiveCN106542895ANo blackeningNo pestsCalcareous fertilisersBioloigcal waste fertilisersBiotechnologyPalm fiber

The present invention discloses a breeding matrix for coprinus comatus cultivation, wherein the breeding matrix comprises straw, wheat bran, gypsum, corn powder, palm fiber, baking soda and zeolite. According to the present invention, the whole fungus stem of the bred coprinus comatus is white, the lower end of the fungus stem does not produce the darkening phenomenon, the growth period is shortened by more than 50% compared to the general coprinus comatus growth period, plant diseases and insect pests are not generated during the growth process, and at least two batches of the coprinus comatus can be bred with the same breeding matrix.

Owner:CHENGDU TIANLU FUNGI

short arc discharge lamp

InactiveCN101958221BWon't turn blackNo deformation and protruding phenomenonHigh-pressure discharge lampsGas discharge lamp detailsMetalElectrode material

The lamp has an anode (31) and a cathode, which are arranged opposite to each other in a fluorescent tube. The anode comprises a middle region at a pointed end, and an edge region, which radially surrounds the middle region. The pointed end lies opposite to the cathode. A buffer material (36) made of metal with reduced yield stress than anode material is arranged between the middle region and the edge region. The buffer material consists of an insert body (35), which is separated from the anode. The insert body is inserted into an opening by the buffer material.

Owner:USHIO DENKI KK

Preparation method of white peppers

InactiveCN108719884ARetain nutrientsNo blackeningFood ingredient functionsHazardous substancePre treatment

The invention relates to a preparation method of white peppers. The method comprises the following steps: 1) raw material preparation; 2) raw material pretreatment; 3) spreading and drying in the sun;4) mixing; and 5) pickling. The method strictly controls the addition amount of salt so as to control the generation of harmful substances and to reserve nutrient components of the raw materials to amaximum extent. Meanwhile, a proper amount of vinegar is added, so that the prepared peppers do not appear to be black. The method carries out pickling by using a mud jar replacing ceramic or glass jars in the prior art, so that the prepared peppers have a white, light and transparent color, are free from water and free from melting no matter how long the peppers stay in the jar, and have a delicious, crisp and refreshing mouth feel.

Owner:湖南外婆家绿色环保食品有限公司

Alumino earth-alkali silicate glasses with high thermal capacity for light bulbs

InactiveCN1224584CProduction economyImprove energy savingGas discharge lamp detailsIncadescent envelopes/vesselsAlkaline earth metalHalogen

The invention relates to alumino earth-alkali silicate glasses for molybdenum glass fusions in the form of light bulbs, as the outer shell for lamps, in particular for lamps with regenerative halogen cycles at bulb temperatures of from over 550° C. up to 700° C. Surprisingly and contrary to the current expectation it was found that alumino earth-alkali silicate glasses with a water content of 0.025 to 0.042 wt. % meet the requirements for halogen lamp glass and do not display any disadvantages due to the presence of the above impurity for the halogen cycle process at bulb temperatures of between 550 and 700° C. In glasses with a water content of from 0.025 to 0.042 wt. % the water present does not act as an impurity in the sense that it does not disturb the equilibrium between formation and decomposition of tungsten halides. A blackening of the inner surface of the bulb does not occur, or not a greater degree when compared with bulb glasses with a considerably lower water content.

Owner:TELUKS SHPETSIALGLAS GMBKH

Method for making dried lime loach

InactiveCN109156756AEasy to cookDeliciousFood ingredient as taste affecting agentCooking & bakingChemical preservatives

The invention discloses a method for making dried lime loach and relates to the technical field of foods. The dried lime loach is made by steps of raw material pretreatment, baking, roasting and baking. Compared with the prior art, the method has the advantages that original nutrient components of loach are easily absorbed by human bodies when being maintained, the loach is free of chemical preservative and is safe to eat, and the problem that the loach is single in eating function is solved.

Owner:冯术奇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com