A Method of Improving the Surface Quality of 8mm Diameter Hypoxic Bright Copper Rod

A surface quality, bright copper technology, applied in workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve the problems of high cost, improved surface quality of copper rods, high energy consumption, etc., to reduce production energy consumption, reduce Number of surface defects, effect of reducing copper powder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

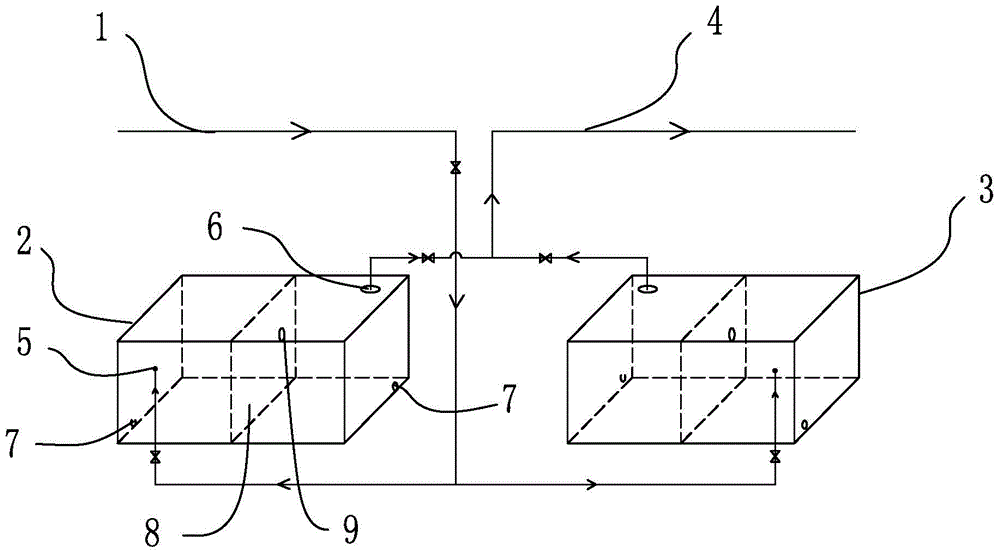

[0022] A method for improving the surface quality of 8mm-diameter low-oxygen bright copper rods is improved on the basis of the traditional 8mm-diameter low-oxygen bright copper rod production process, which mainly includes batching, smelting, casting, rolling, cleaning, drying, coating Wax and packaging processes, wherein the following processes are improved:

[0023] a. Rolling: The electrolytic copper raw material is smelted into molten copper and then cast. After casting, a slab is obtained. Before the edge milling machine, a scoring machine with four corners of the slab is installed, and the slab passes through the four corners of the slab. After the initial edge milling of the scoring machine, the edge milling machine is officially milled, and then the rough rolling and the finishing rolling are respectively carried out on the rough rolling mill and the finishing mill. During the rolling process, a high-pressure dephosphorization pump is set to pump out the emulsion and ...

Embodiment 2

[0028] The difference between embodiment 2 and embodiment 1 is:

[0029] In the sedimentation system, there are three sedimentation tanks, and each sedimentation tank is provided with three sedimentation chambers.

[0030] In the rough rolling process, the mass fraction of alcohol in the rough rolling emulsion is 0.5%, the oil mass fraction is 1.0%, and the pH value of the rough rolling emulsion is 8.0-9.0; The alcohol mass fraction in the rolling emulsion is 1.5%, the oil mass fraction is 2.0%, the pH value of the finishing rolling emulsion is 8.9-9.0, and the temperature of the rough rolling emulsion and the finishing rolling emulsion are both controlled at 45-47°C. The mass fraction of alcohol in the cleaning solution in the cleaning process is 2.5%, the pH value of the cleaning solution is between 8.5-9.0, and the temperature of the cleaning solution is controlled at 32-34°C; in the drying process, the compressed The pressure of the air is 0.6MPa; the concentration of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com