Imitation golden decoration film capable of replacing gold foil and preparation method

A decorative film and gold technology, which is applied in the field of imitation gold decorative film and its preparation, can solve the problems that imitation gold foil is easy to oxidize and blacken, affect the appearance of products, etc., and achieve the effects of improving anti-oxidation ability, uniform wax content, and strong barrier ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

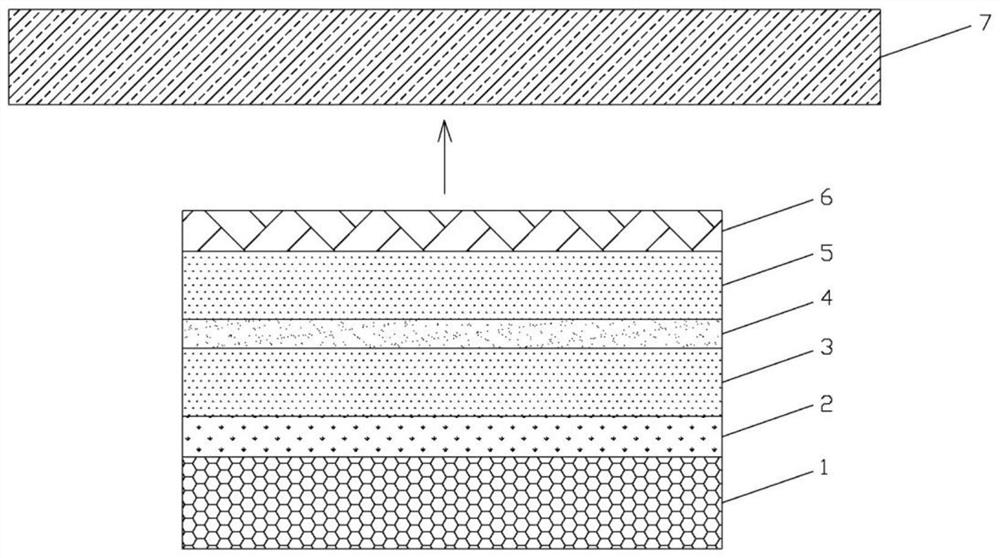

[0034] A gold imitation decorative film that can replace gold foil, the preparation method of which comprises the following steps:

[0035] (1) the golden paint and graphene oxide are mixed uniformly in a ratio of 600:1 by weight to obtain an anti-oxidation golden paint;

[0036] (2) In parts by weight, mix and stir 10 parts of paraffin wax and 50 parts of ethanol evenly, add a mixed solution of 4 parts of sodium lauryl sulfate and 30 parts of water, and emulsify for 50 minutes at a stirring speed of 200 rpm. Paraffin emulsion;

[0037] (3) Print paraffin emulsion on the front side of the base film, dry at 120°C for 10 seconds and solidify to form a film to obtain a release agent layer;

[0038] (4) print anti-oxidation golden paint on the upper surface of the release agent layer, and dry the paint after printing so that the paint is cured to obtain the first coating layer;

[0039] (5) The base film is put into a vacuum coating machine, and an aluminum layer is plated on th...

Embodiment 2

[0045] A gold imitation decorative film that can replace gold foil, the preparation method of which comprises the following steps:

[0046] (1) the golden paint and graphene oxide are mixed uniformly in a ratio of 400:1 by weight to obtain an anti-oxidation golden paint;

[0047] (2) In parts by weight, mix and stir 1 part of paraffin wax and 35 parts of ethanol evenly, add a mixed solution of 8 parts of sodium lauryl sulfate and 60 parts of water, and emulsify for 30 minutes at a stirring speed of 300 rpm. Paraffin emulsion;

[0048] (3) Print paraffin wax emulsion on the front side of the base film, dry at 100°C for 20 seconds and solidify to form a film to obtain a release agent layer;

[0049] (4) print anti-oxidation golden paint on the upper surface of the release agent layer, and dry the paint after printing so that the paint is cured to obtain the first coating layer;

[0050] (5) The base film is put into a vacuum coating machine, and an aluminum layer is plated on ...

Embodiment 3

[0055] A gold imitation decorative film that can replace gold foil, the preparation method of which comprises the following steps:

[0056] (1) the golden paint and graphene oxide are mixed uniformly in a ratio of 500:1 by weight to obtain an anti-oxidation golden paint;

[0057] (2) In parts by weight, mix and stir 4 parts of paraffin wax and 60 parts of ethanol evenly, add a mixed solution of 2 parts of sodium lauryl sulfate and 20 parts of water, and emulsify for 60 minutes at a stirring speed of 300 rpm. Paraffin emulsion;

[0058] (3) Print paraffin emulsion on the front of the base film, dry at 120°C for 20s and solidify to form a film to obtain a release agent layer;

[0059] (4) print anti-oxidation golden paint on the upper surface of the release agent layer, and dry the paint after printing so that the paint is cured to obtain the first coating layer;

[0060] (5) the base film is put into a vacuum coating machine, and an aluminum layer is plated on the upper surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com