A kind of thermotropic liquid crystal polyester and preparation method thereof

A liquid crystal polyester, thermotropic technology, applied in the field of materials, can solve the problems of poor exhaust, improper molding conditions, easy foaming of thermotropic liquid crystal polyester, etc., to achieve the effect of reducing clogging and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

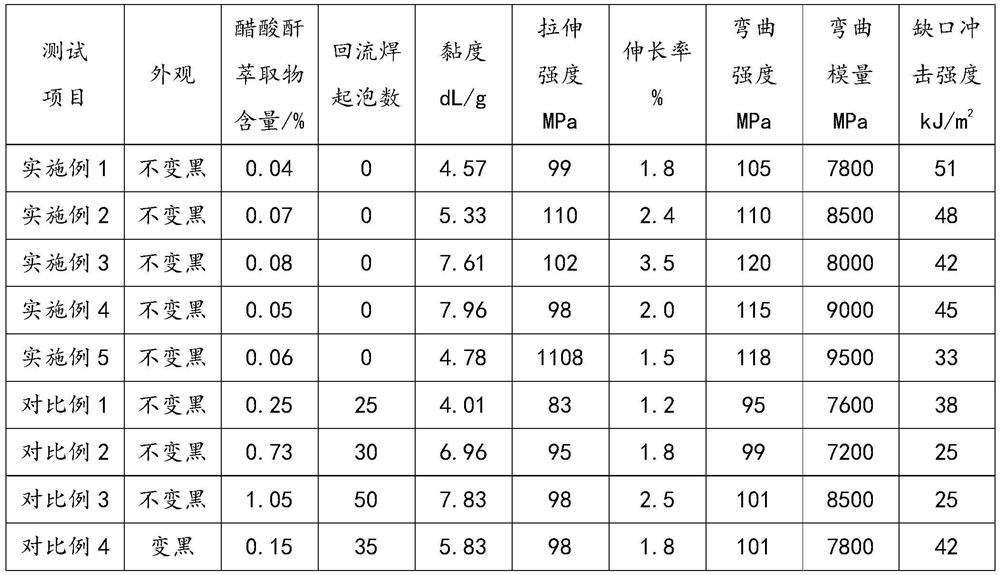

Examples

Embodiment 1

[0033] Add 2760g (20mol) p-hydroxybenzoic acid, 1860g (10mol) 4,4-diphenol, 415g (2.5mol) isophthalic acid, 1245g (7.5mol) terephthalic acid, 8160g ( 80mol) of acetic anhydride, 5g of potassium acetate, nitrogen purging to replace the air in the reaction kettle, then heat up to 140°C for acetylation reaction, while rectifying for 2 hours, during which the distillate gas with a boiling point lower than 120°C is discharged, and then after condensation Afterwards, collect and weigh to obtain 2550 g of by-product acetic acid, and keep the amount of acetic anhydride in the reaction system to be about 50% of the total amount of acetic anhydride and acetic acid. Keep the temperature in the kettle at 150°C, slowly evacuate to 100pa, drain and condense the remaining acetic anhydride in the system, and the collected acetic anhydride can be reused. Continue to heat up to 340°C, during which the by-product acetic acid produced by the polymerization is discharged in time, and finally vacuu...

Embodiment 2

[0035] Add 3450g (25mol) p-hydroxybenzoic acid to 20 liters of reactor, 940g (5mol) 2-hydroxy-6-naphthoic acid, 550g (5mol) hydroquinone, 830g (5mol) terephthalic acid, 8160g (80mol) Acetic anhydride, 5g N-methylimidazole, after purging and displacing the air in the reactor with nitrogen, the temperature was raised to 150°C for acetylation reaction, while rectification was carried out for 2.5 hours, during which the distillate gas with a boiling point lower than 120°C was discharged, and then after condensation Afterwards, collect and weigh to obtain 1800 g of by-product acetic acid, and keep the amount of acetic anhydride in the reaction system to be about 80% of the total amount of acetic anhydride and acetic acid. Keep the temperature in the kettle at 150°C, slowly evacuate to 50pa, discharge and condense the remaining acetic anhydride in the system, and the collected acetic anhydride can be reused. Continue to heat up to 340°C, during which the by-product acetic acid produ...

Embodiment 3

[0037]Add 4140g (30mol) p-hydroxybenzoic acid, 1880g (10mol) 2-hydroxyl-6-naphthoic acid, 6120g (60mol) acetic anhydride, 5gN-methylimidazole to the 20 liter reactor, after nitrogen purging replaces the air in the reactor , heated up to 150°C, carried out acetylation reaction, and rectified for 2.5 hours at the same time, during which the fraction gas with a boiling point lower than 120°C was discharged, and then collected and weighed after condensation to obtain 1820g of by-product acetic acid, keeping the content of acetic anhydride in the reaction system The amount is about 80% of the total amount of acetic anhydride and acetic acid. Keep the temperature in the kettle at 150°C, slowly evacuate to 100pa, drain and condense the remaining acetic anhydride in the system, and the collected acetic anhydride can be reused. Continue to raise the temperature to 320°C, during which the by-product acetic acid produced by the polymerization is discharged in time, and finally vacuumize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com