Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

162results about How to "Guaranteed luminous efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

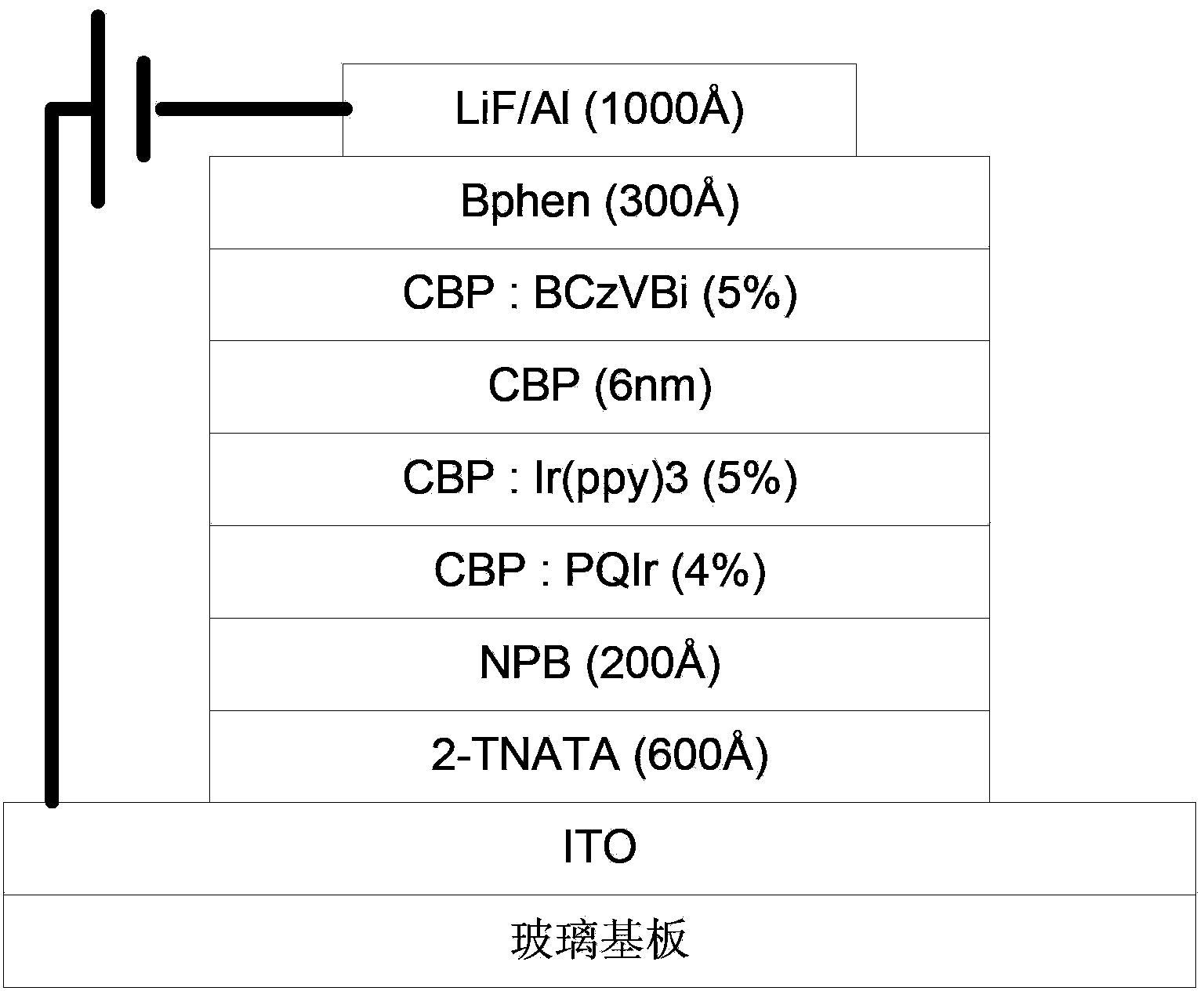

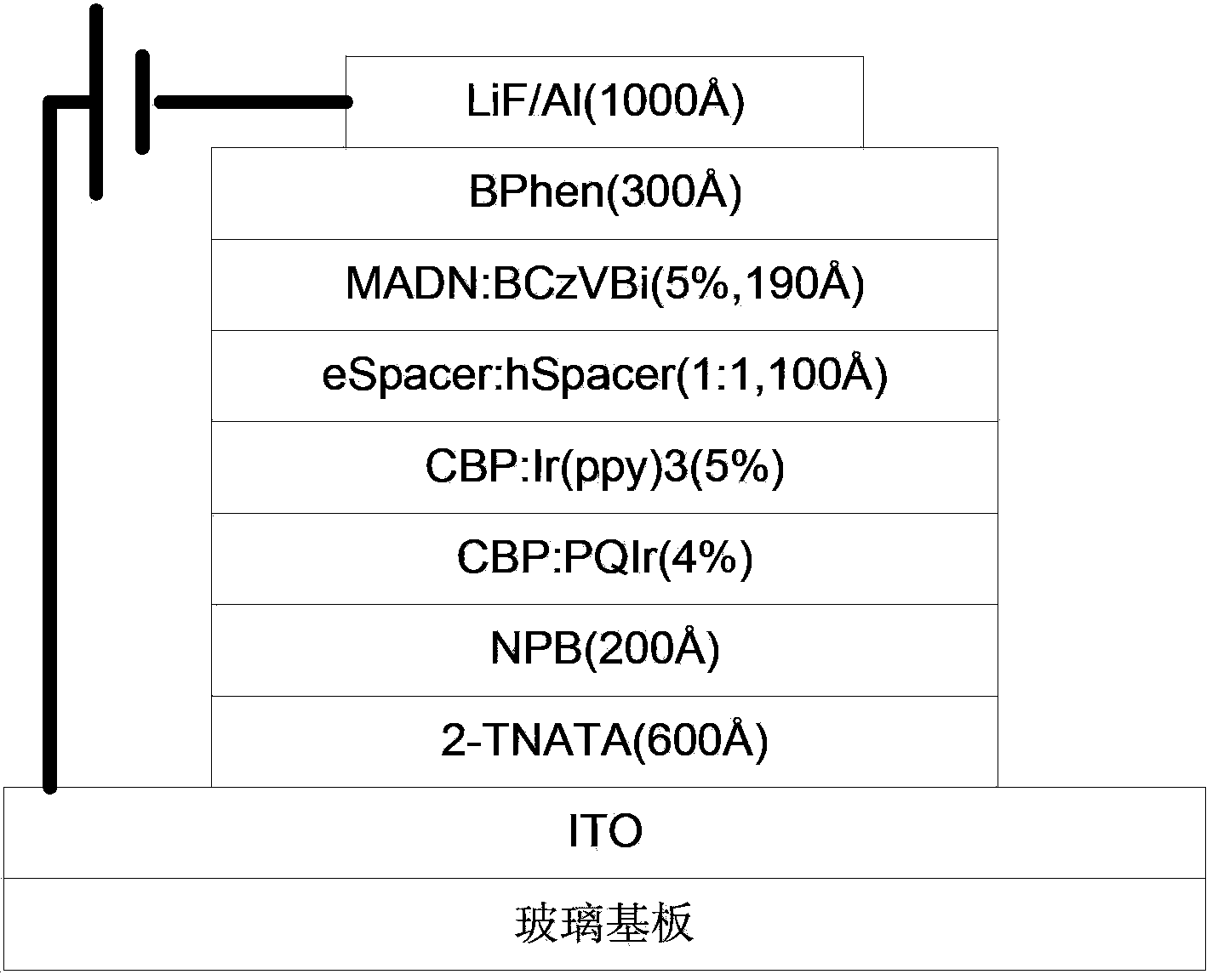

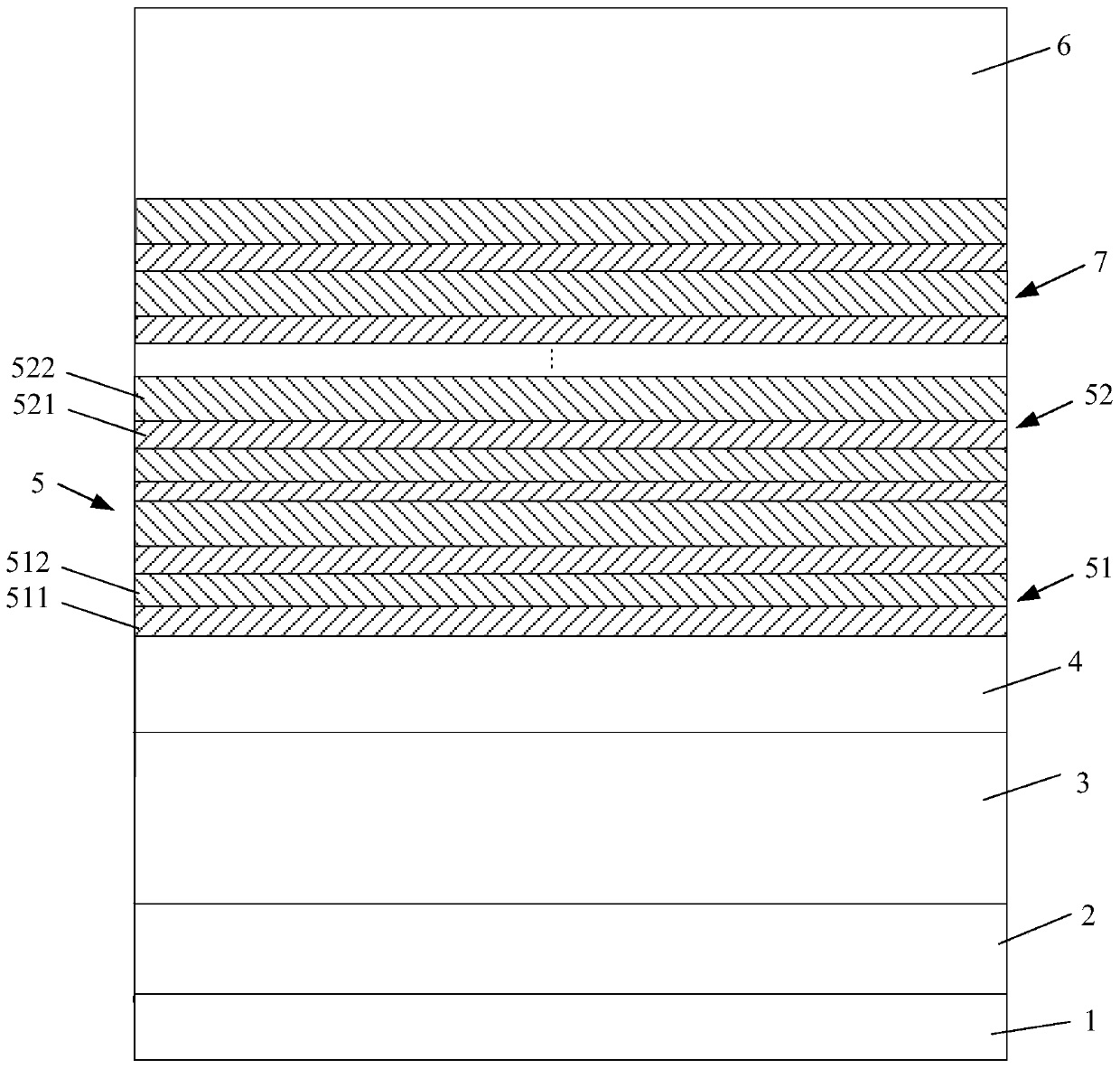

High-efficient white-light organic electroluminescence device

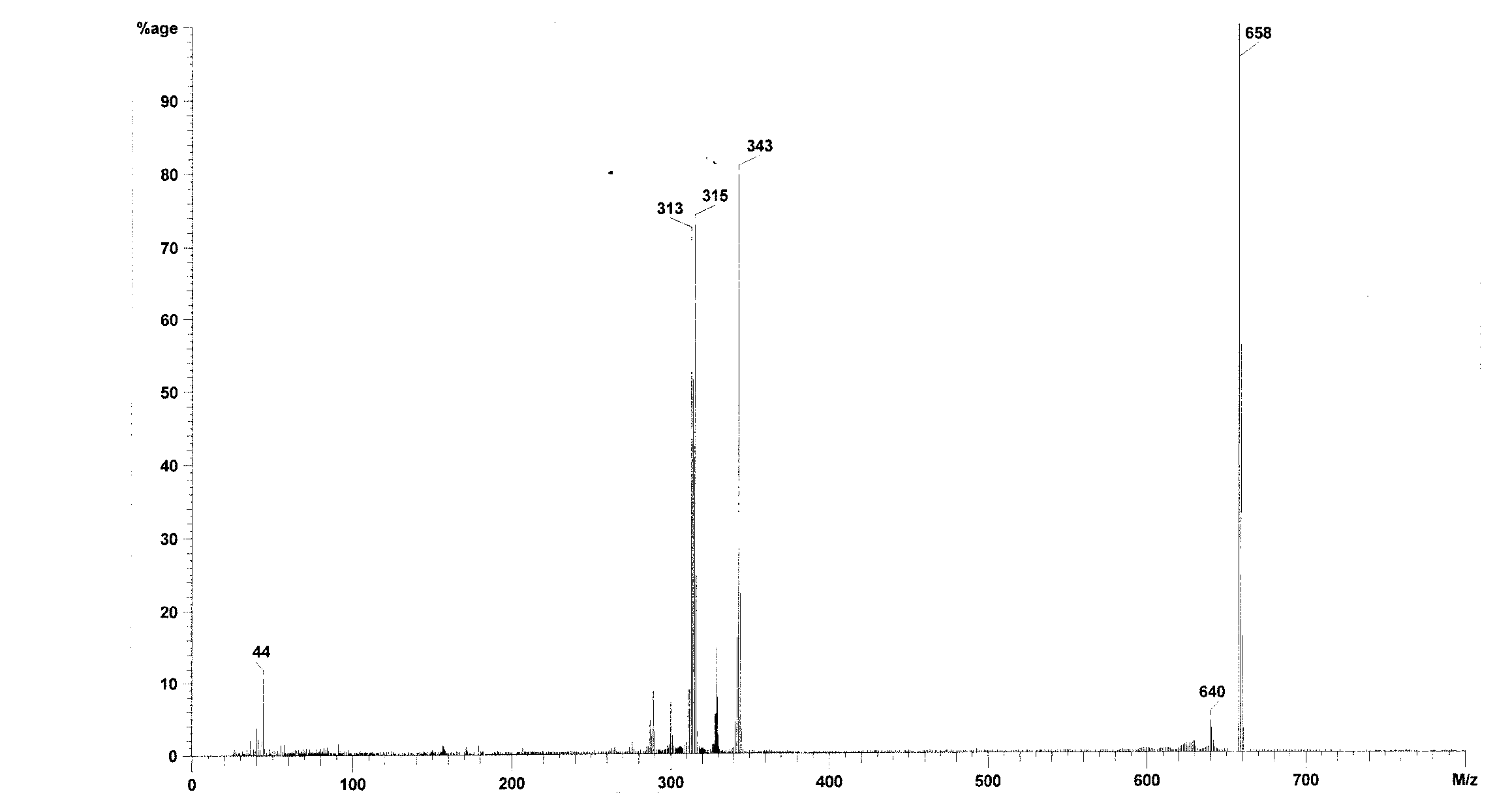

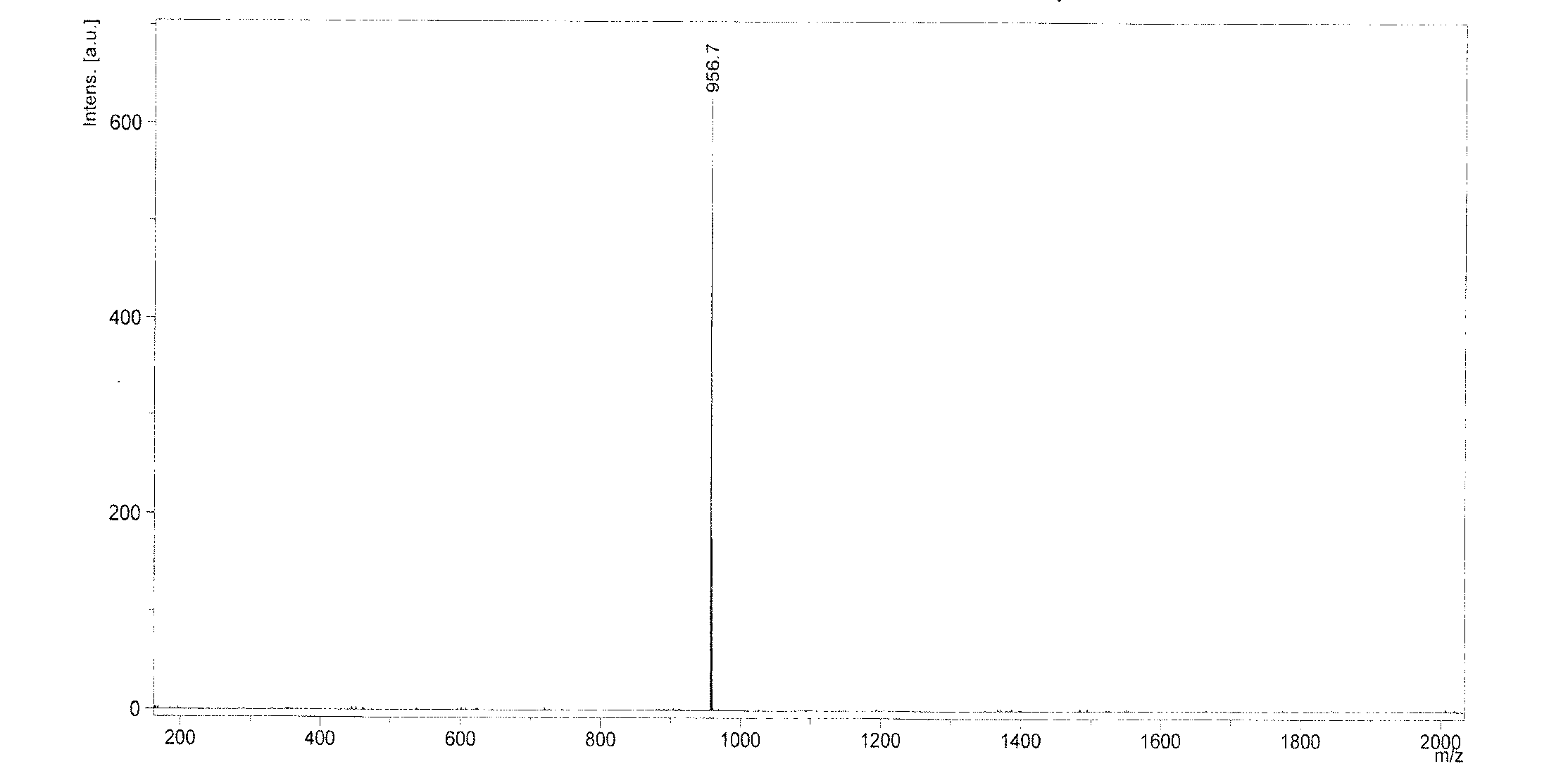

ActiveCN103187537AFlexible control of luminous intensityGuaranteed luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerHole transport layer

The invention relates to a high-efficient white-light organic electroluminescence device which comprises a substrate, an anode layer, a luminous unit layer and a cathode layer; the luminous unit layer comprises a hole injection layer which is formed on the anode layer, a hole transport layer is formed on the hole injection layer, the cathode layer is formed on an electron transport layer, a plurality of luminous layers are arranged between the hole transport layer and the electron transport layer, each luminous layer comprises a fluorescence luminous layer and a phosphorescence luminous layer, and a barrier layer consisting of an electron transport material and a hole transport material of the same parent nucleus is arranged between the fluorescence luminous layer and the phosphorescence luminous layer; and a main body material of the phosphorescence luminous layer which is adjacent to the barrier layer comprises an electron transport material and a hoe transport material of the same parent nucleus. The luminous device can effectively allocate the electron transport efficiency and the hole transport efficiency and has the advantage of high luminous efficiency.

Owner:GUAN YEOLIGHT TECH CO LTD +1

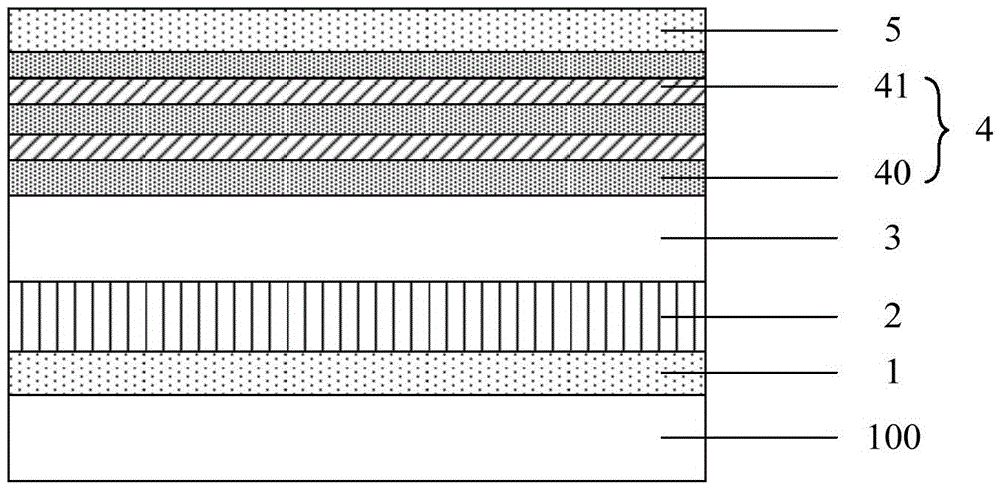

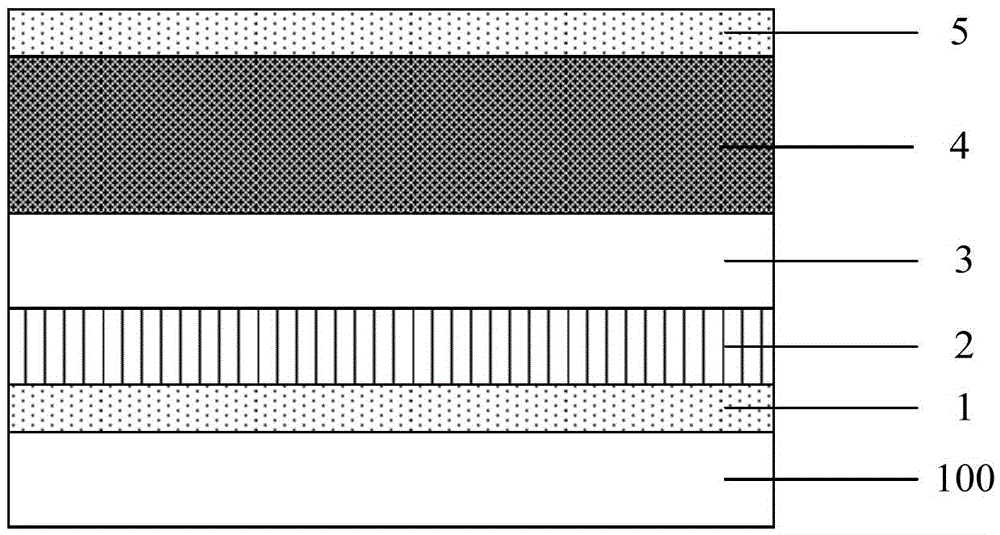

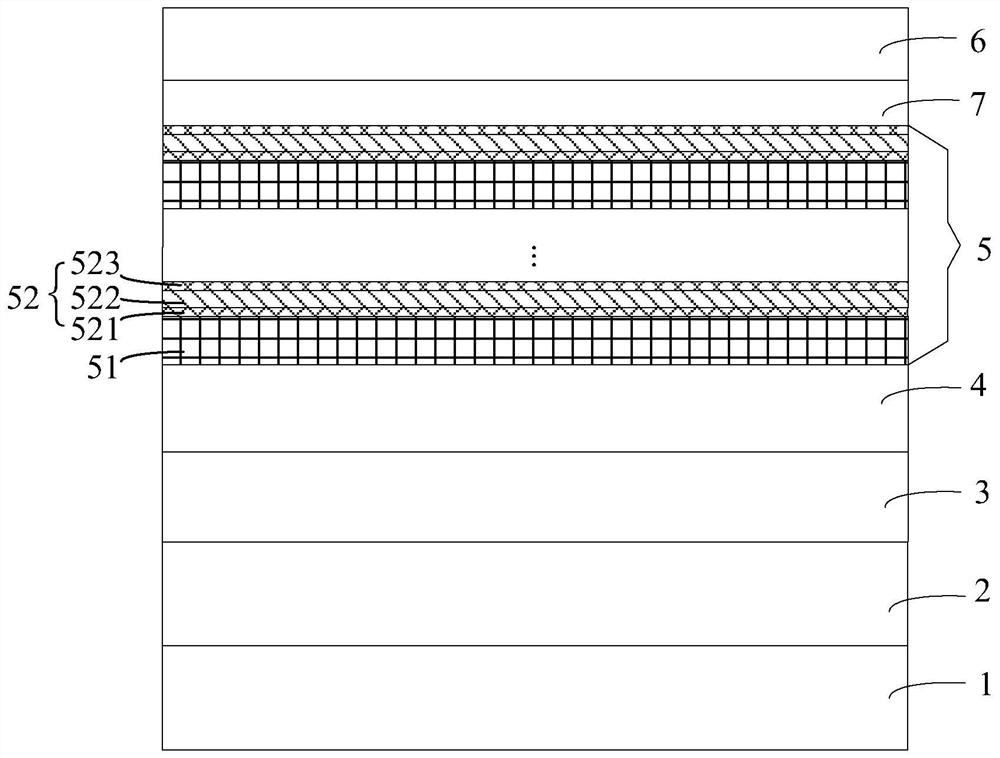

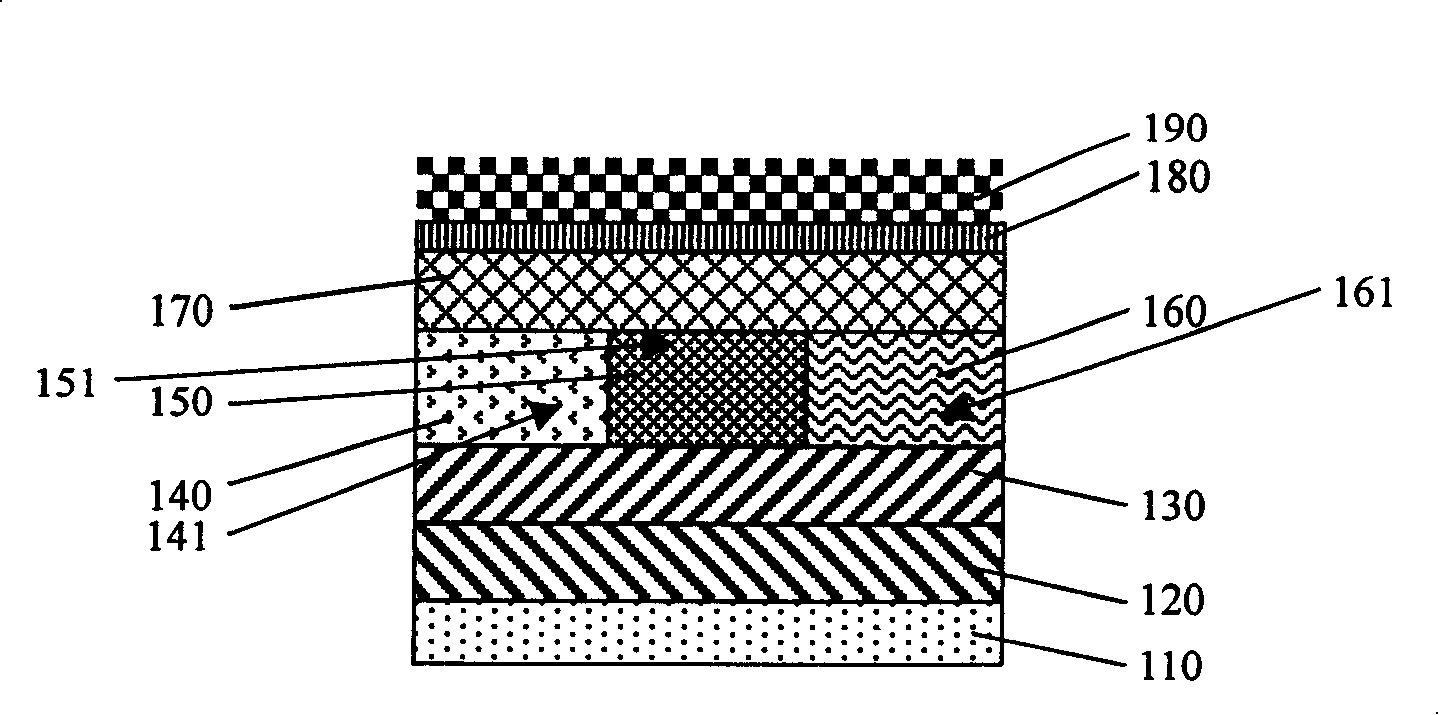

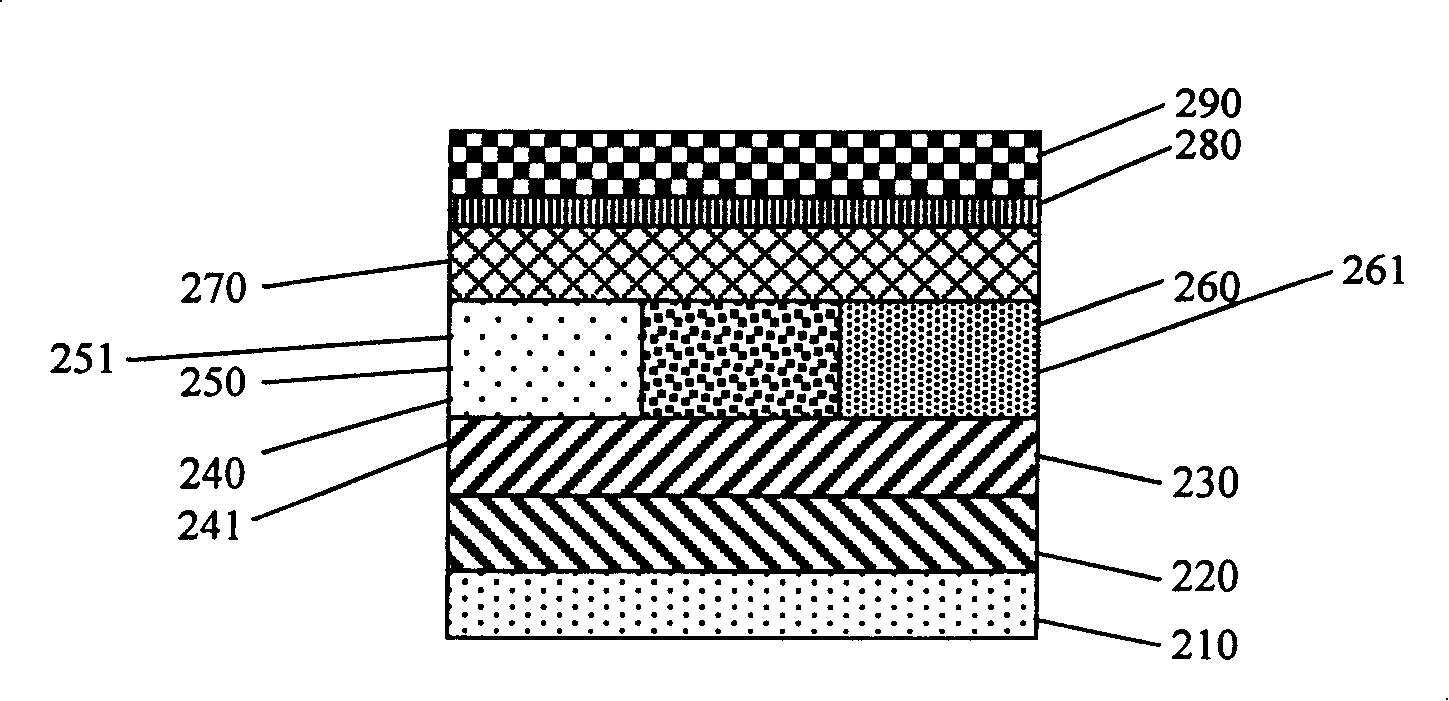

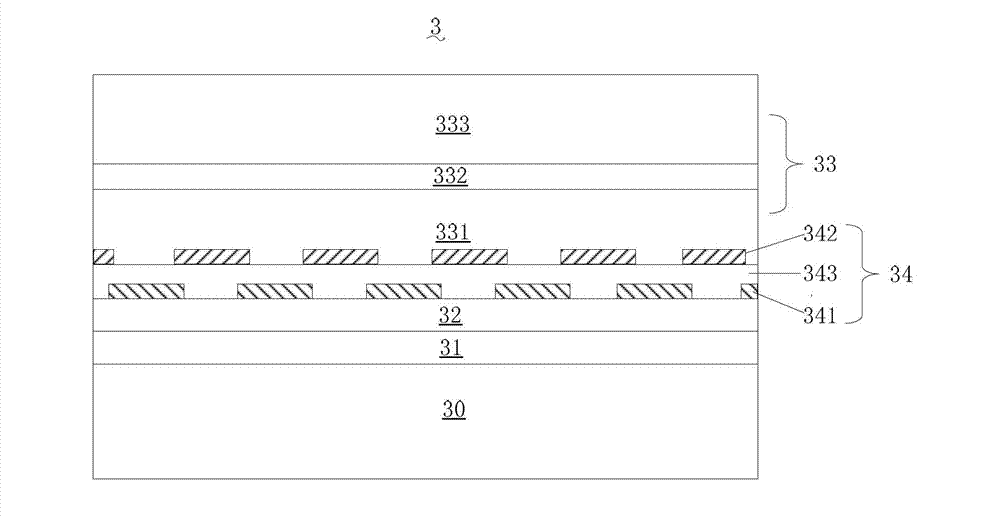

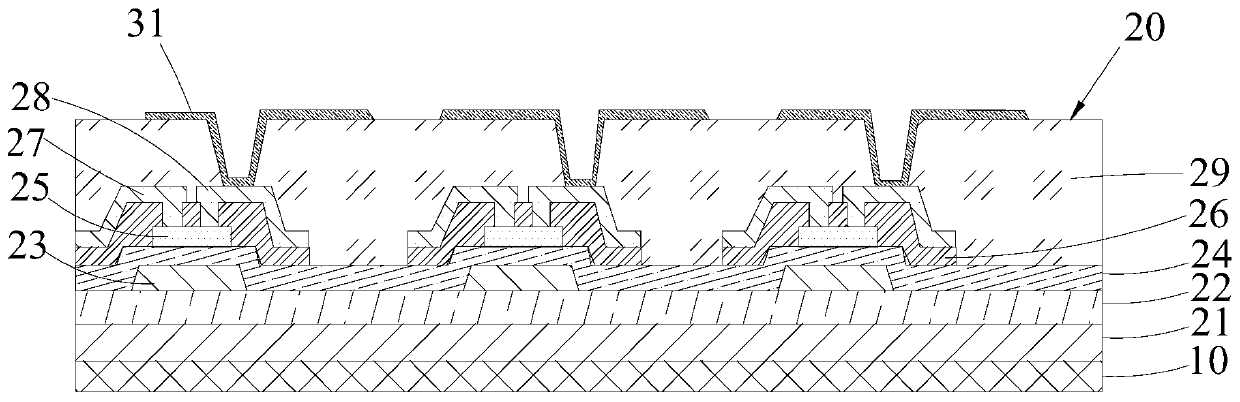

Electroluminescent device, manufacturing method thereof and display device

ActiveCN105679958AGuaranteed luminous efficiencyElectron Mobility AdjustableSolid-state devicesSemiconductor/solid-state device manufacturingElectricityDisplay device

The invention relates to the technical field of display and discloses an electroluminescent device, a manufacturing method thereof and a display device. An electron transmission layer of the electroluminescent device comprises a first film layer used for transmitting electrons and an adjusting structure in contact with the first film layer. The adjusting structure is used for adjusting the electron mobility of the electron transmission layer so as to realize matching of the electron mobility with the cavity mobility of a cavity transmission layer, so that the selection of the material of the cavity transmission layer is not limited, the production cost is lowered, and the luminescence efficiency of the device is ensured.

Owner:BOE TECH GRP CO LTD

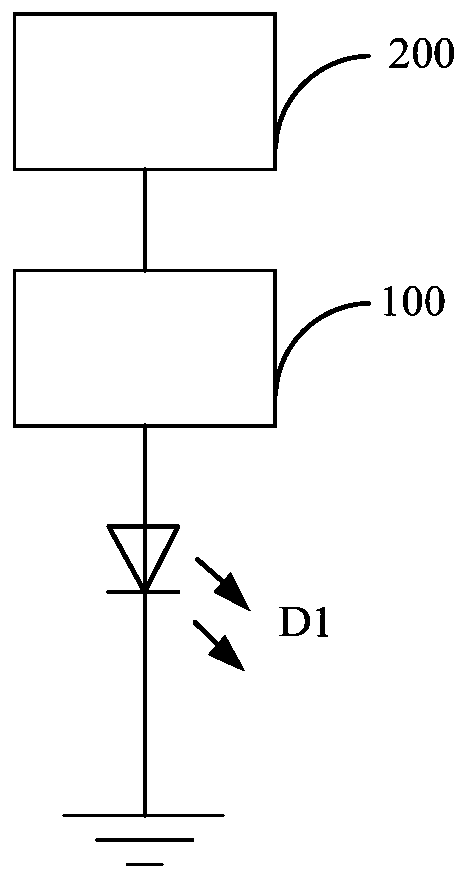

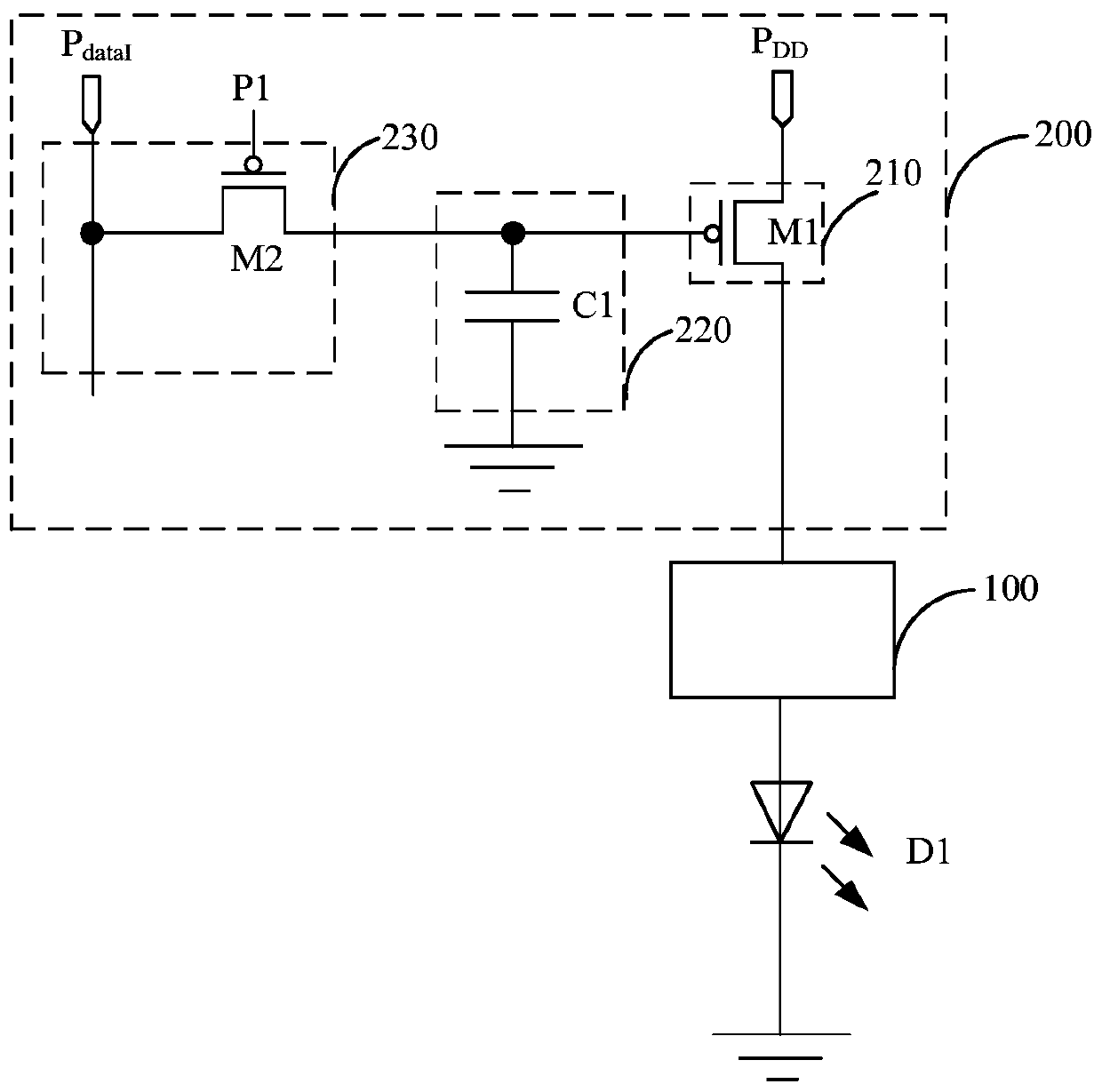

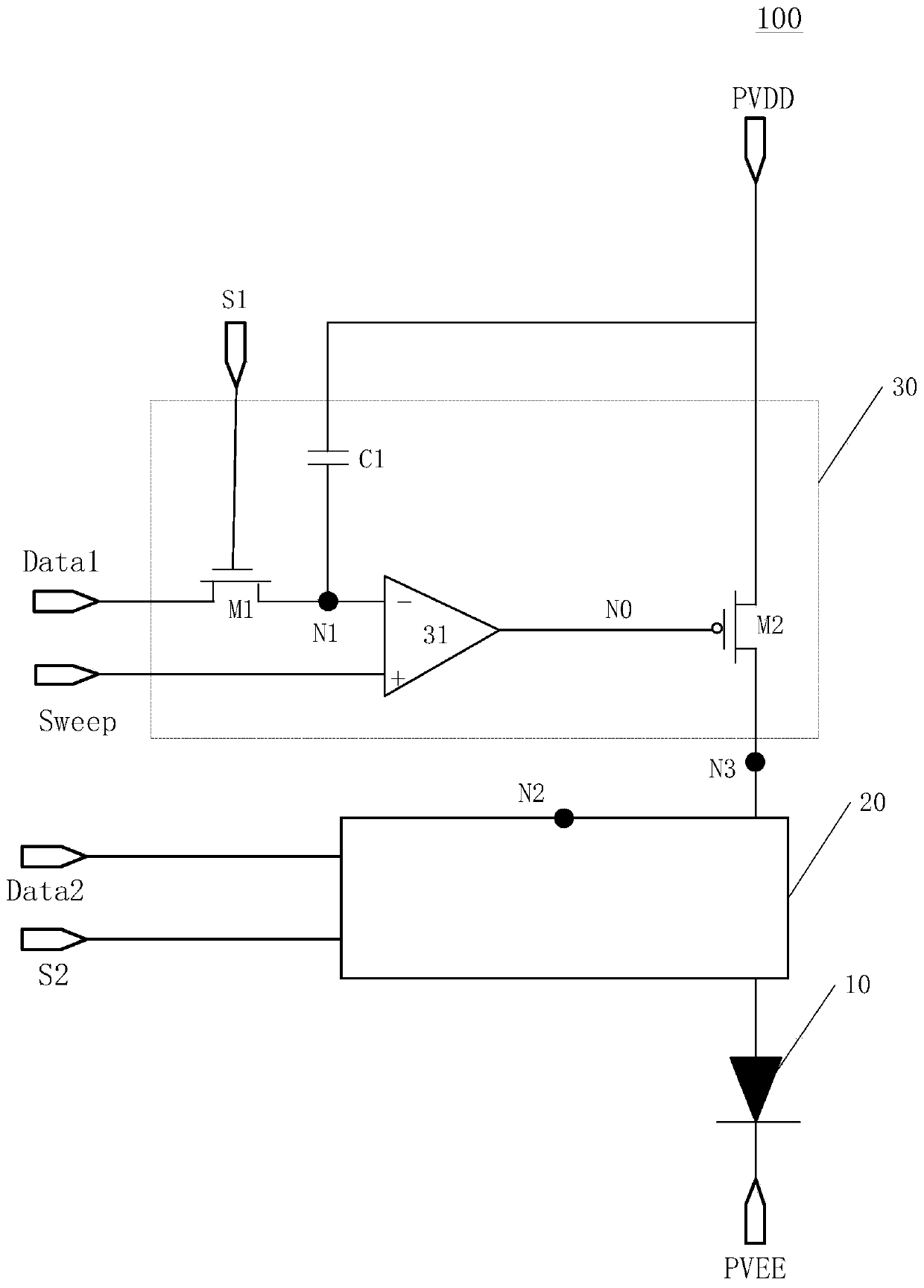

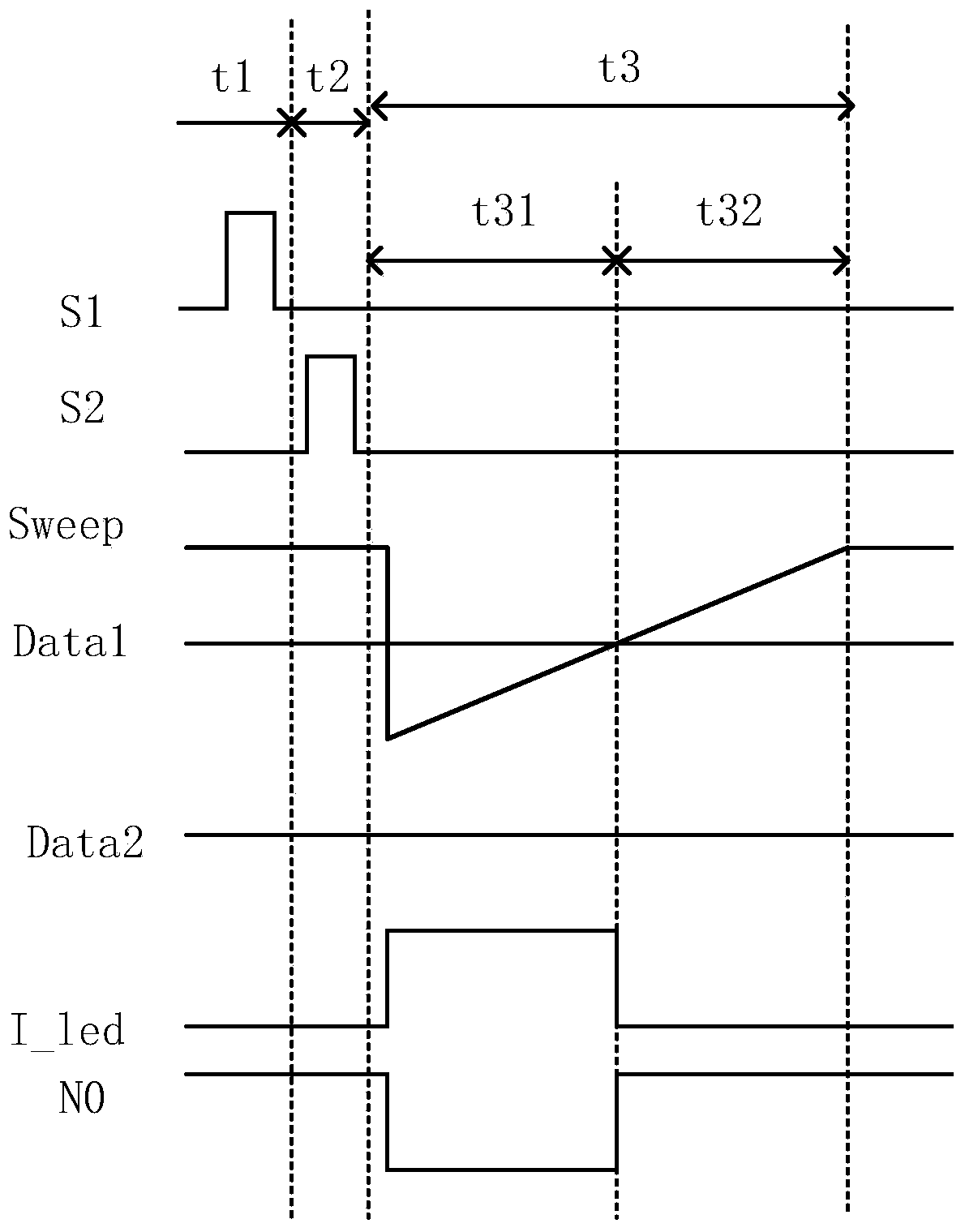

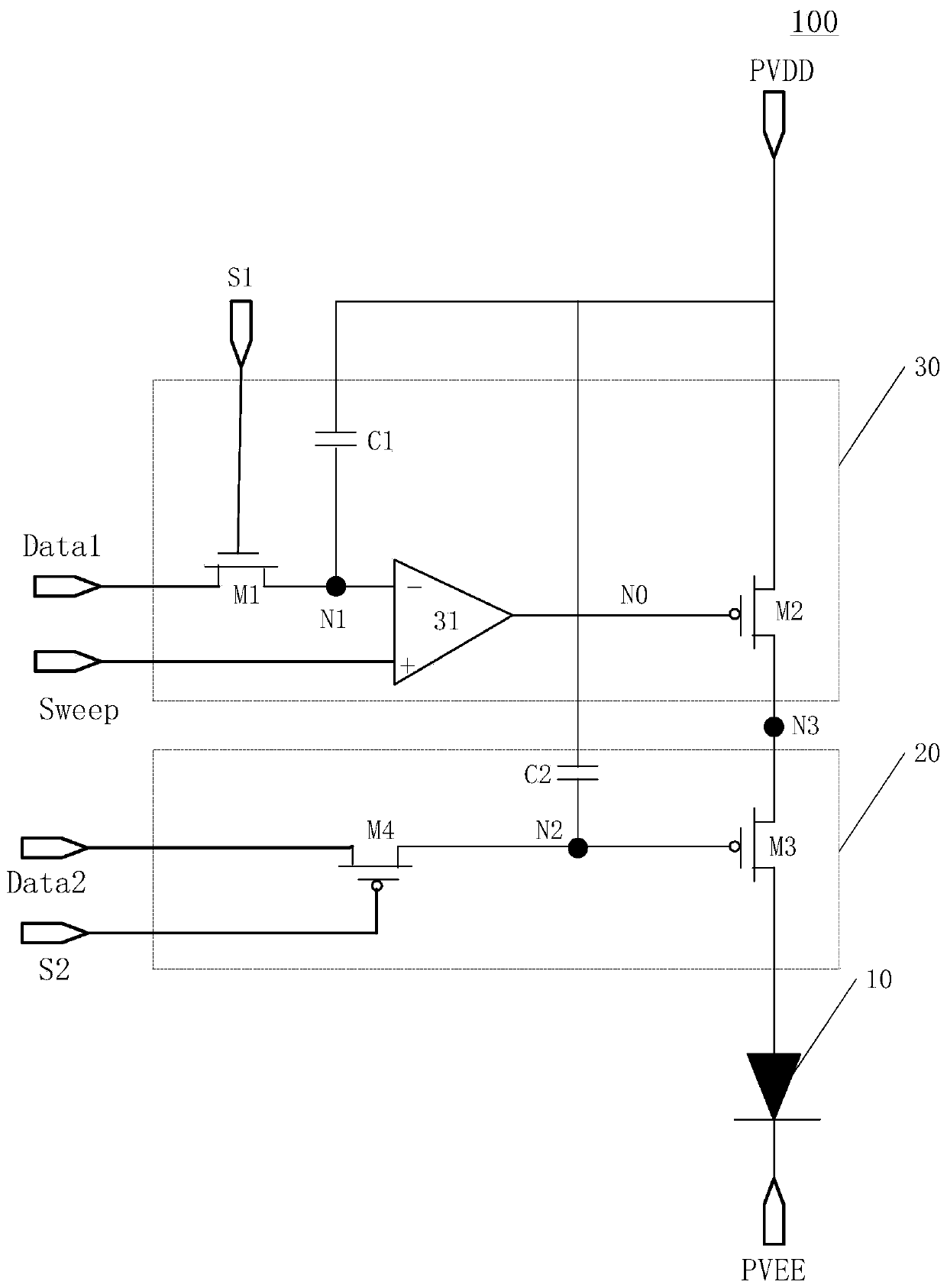

Pixel driving circuit and display panel

ActiveCN109979378AGuaranteed luminous efficiencyImprove stabilityStatic indicating devicesEngineeringPower flow

Owner:BOE TECH GRP CO LTD

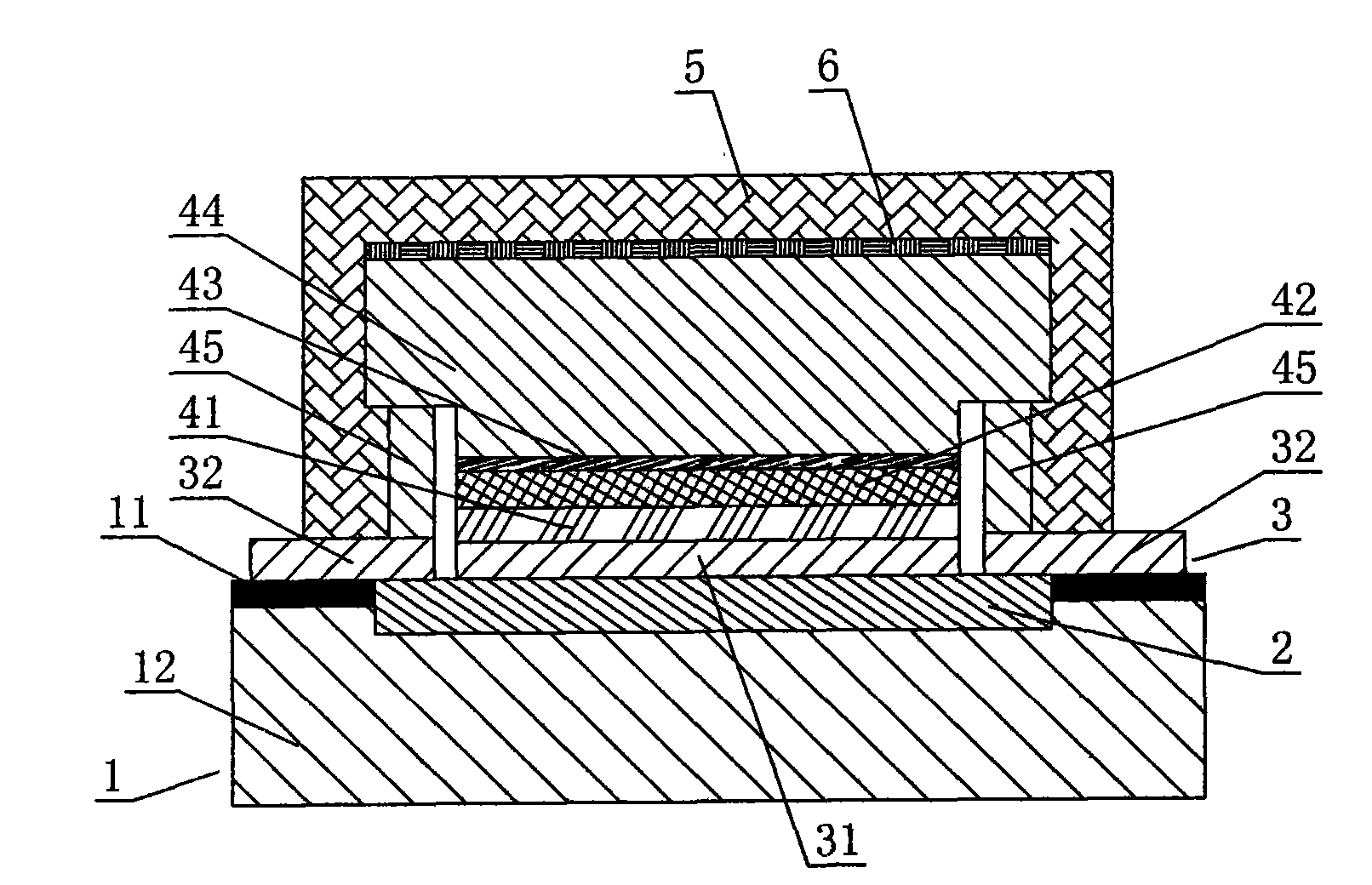

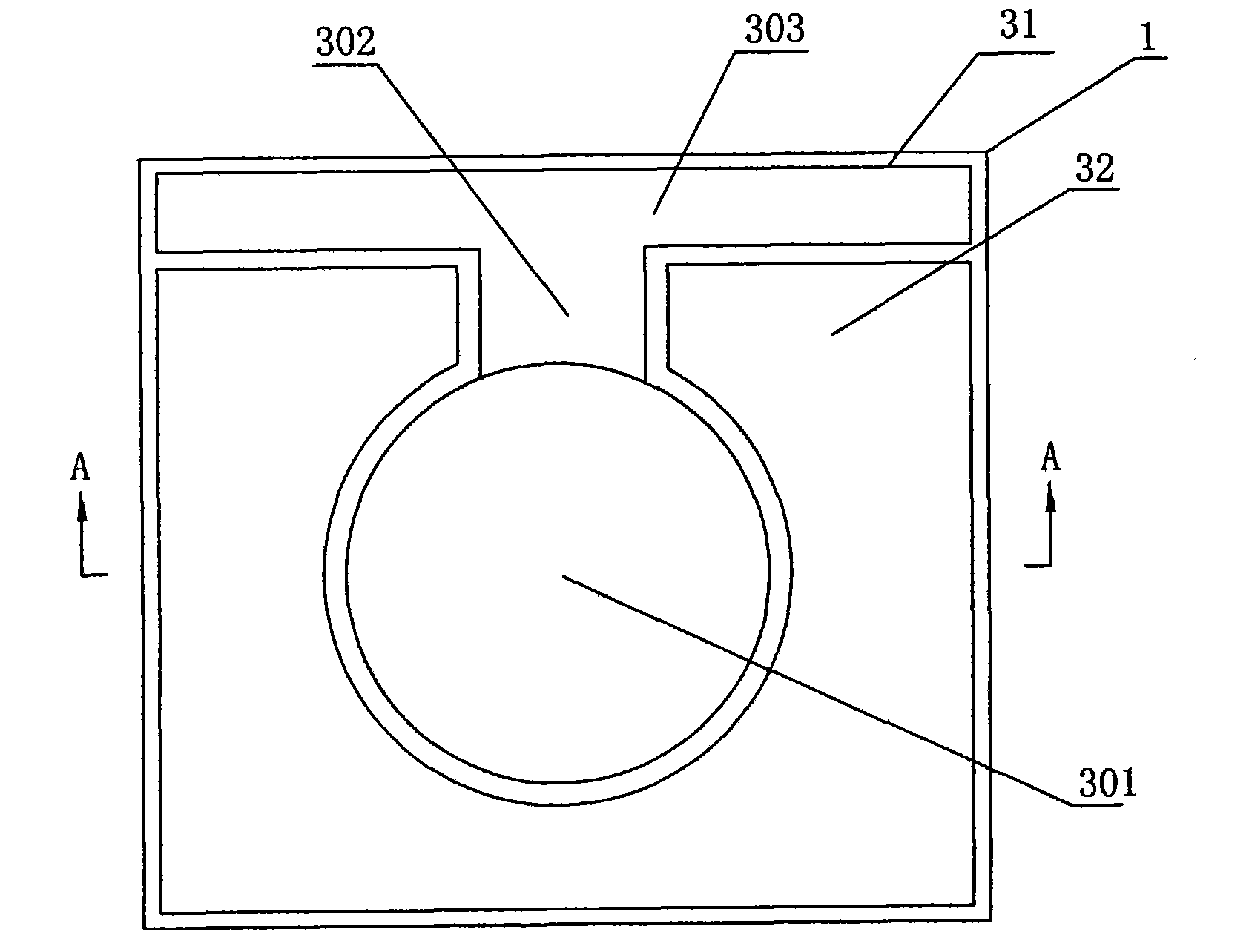

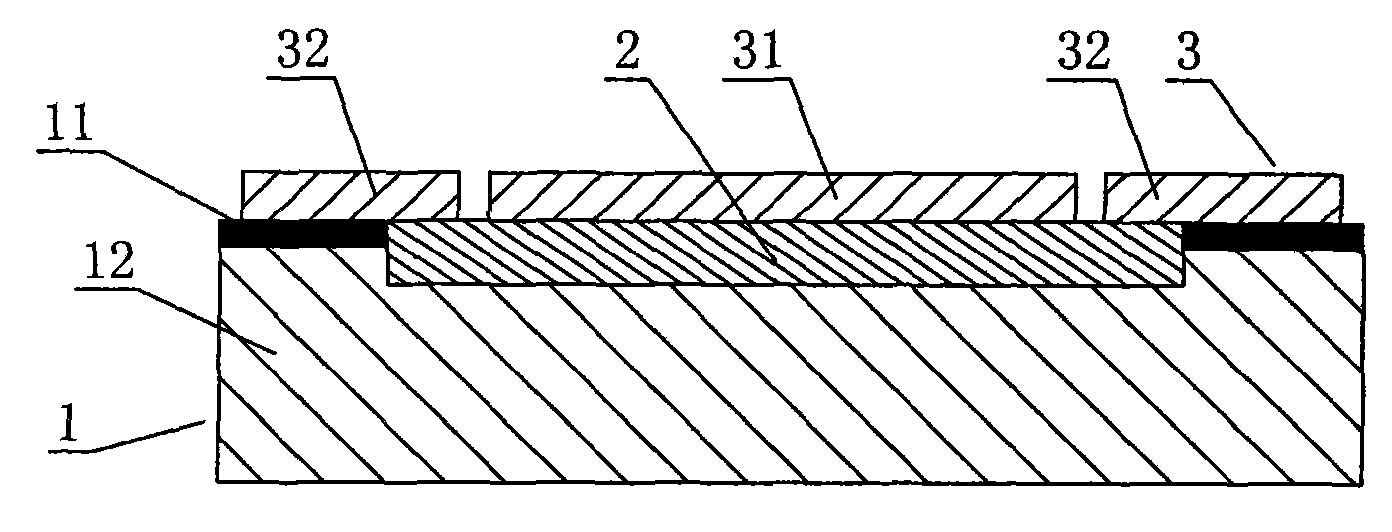

Light-emitting diode chip and preparation method thereof

InactiveCN101615611AImprove luminous efficiencyGuaranteed luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingHeat sinkLight-emitting diode

The invention relates to a light-emitting diode chip, which comprises a heat sink substrate, a metal joint layer and a bare core, wherein the bare core comprises an n-type semiconductor layer, a luminous layer, a p-type semiconductor layer, a reflecting layer and an electrode layer; and the light-emitting diode chip is characterized in that: the metal joint layer comprises a first joint layer and a second joint layer which are mutually separated and can be connected with an external power line; the first joint layer is jointed with the reflecting layer; the second joint layer is jointed with the electrode layer; at least the contact part of the upper surface of the heat sink substrate and the metal joint layer is set as an insulation part; and the bare core is connected with the external power line through the first joint layer and the second joint layer to form a current passage with thermal-electric separation. The light-emitting diode chip adopts a thermal-electric separating structure, so that the heat sink substrate is specially used for radiating, and a conduction part is completed by a metal joint layer composition, so the radiating effect is obviously improved, and simultaneously the luminous efficiency is correspondingly improved. The invention also relates to a preparation method for the light-emitting diode chip.

Owner:HE SHAN LIDE ELECTRONICS ENTERPRISE CO LTD

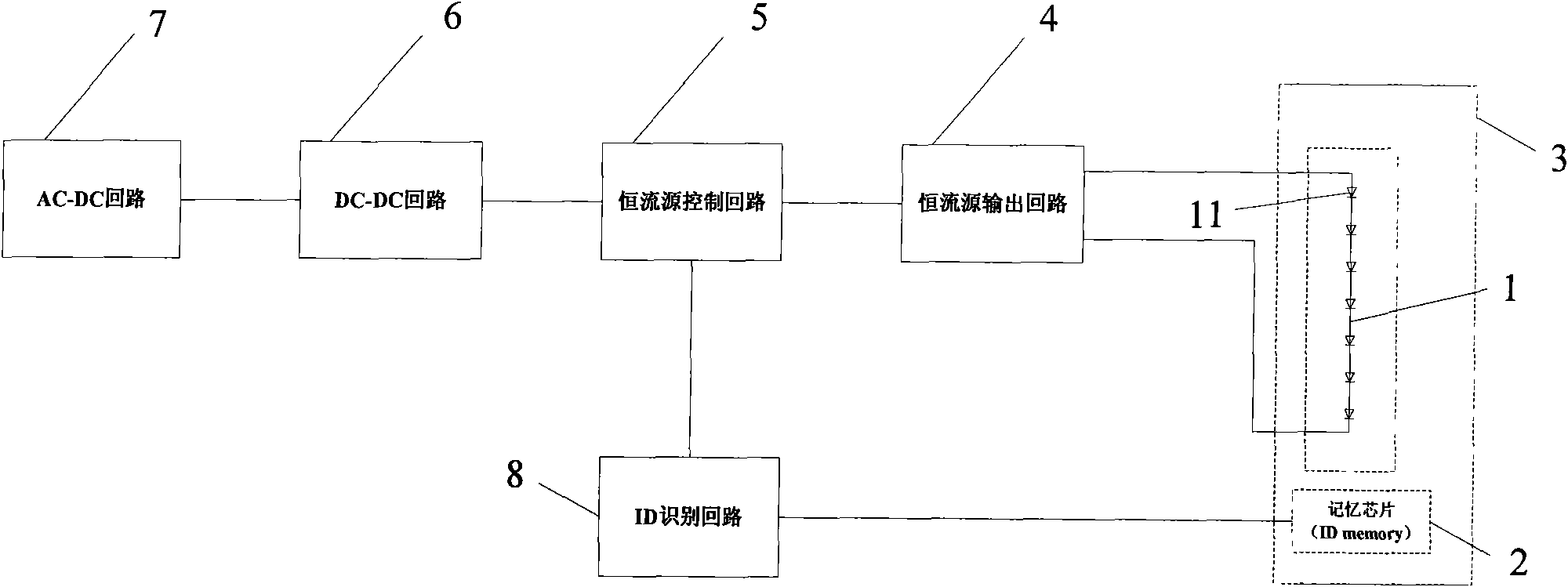

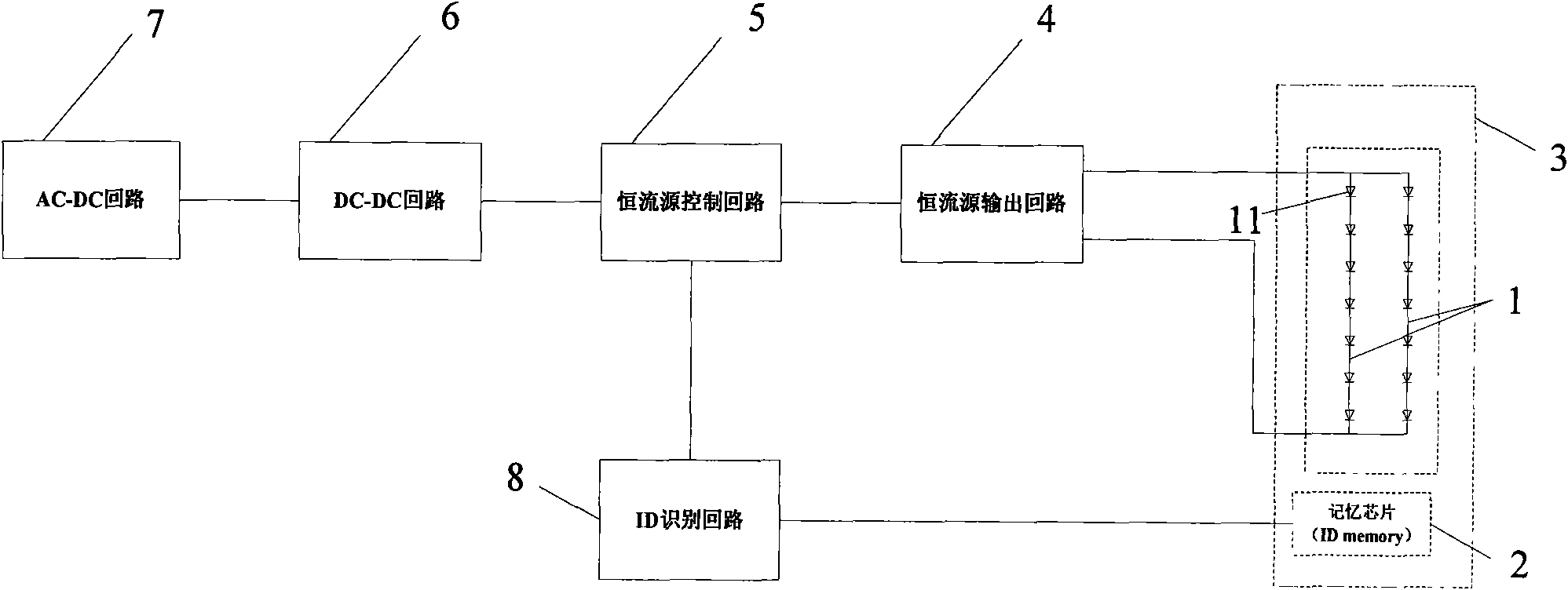

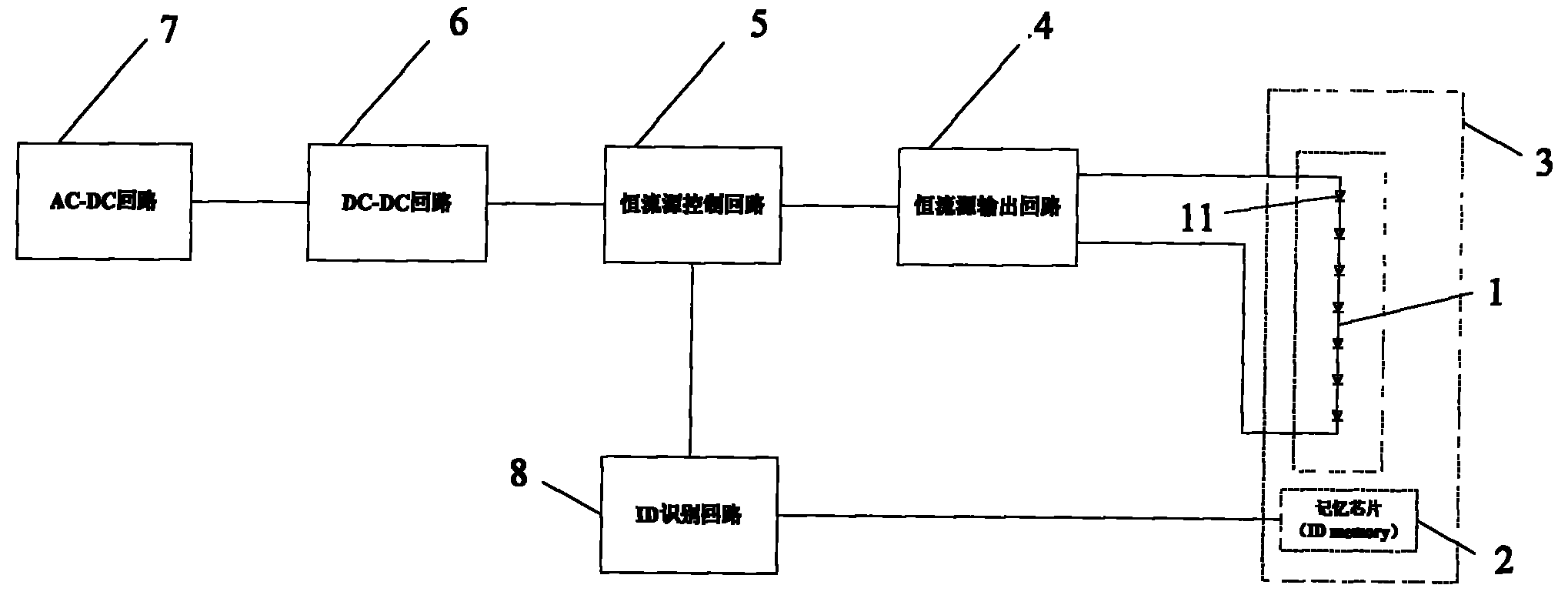

Method for automatically identifying LED load light source by using memory chip and implementation device

InactiveCN101835301ALow costImprove luminous efficiencyPoint-like light sourceElectric circuit arrangementsConstant current sourceCurrent limiting

The invention discloses a method for automatically identifying an LED load light source by using a memory chip and an implementation device thereof. The device comprises a power supply and an LED load light source, wherein the power supply mainly comprises an AC-DC loop, a DC-DC loop, a constant current source control loop, a constant current source output loop, an ID identification loop, and the like; and the LED load light source mainly comprises an LED branch, an ID memory, and the like. A general constant current control power device which is not limited by LED light source specifications and an LED light source device which is provided with characteristic identification codes have simple manufacture and can greatly reduce product types and lower manufacture and management costs. The LED load light source needs no current-limiting resistor, reduces heat energy generated by the current-limiting resistor, prolongs the service life of products, and maintains the characteristic of good generality. Compared with the common constant current source, the power supply is not only suitable for constant current output to ensure LED luminous efficiency, but also can be suitable for LED load light sources of different specifications, thereby having wider applicability.

Owner:WAVE CREST SHANGHAI

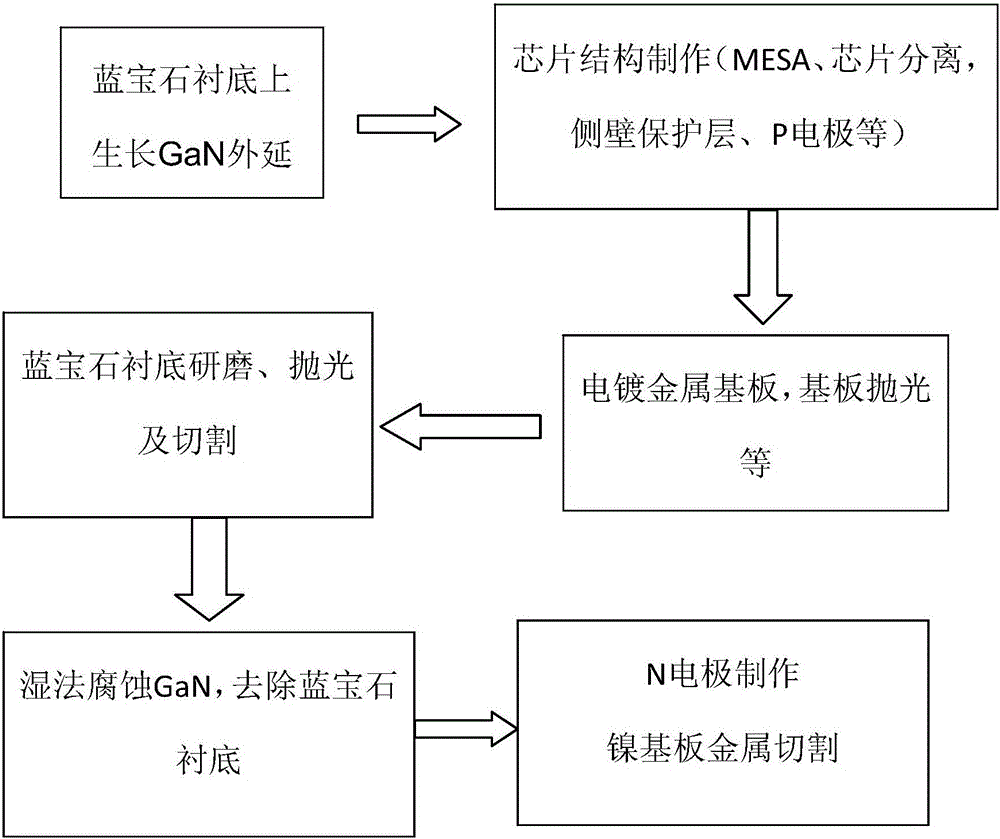

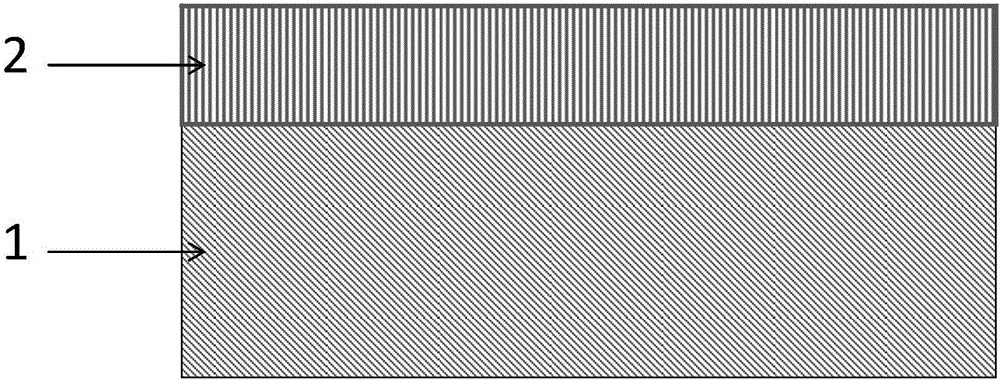

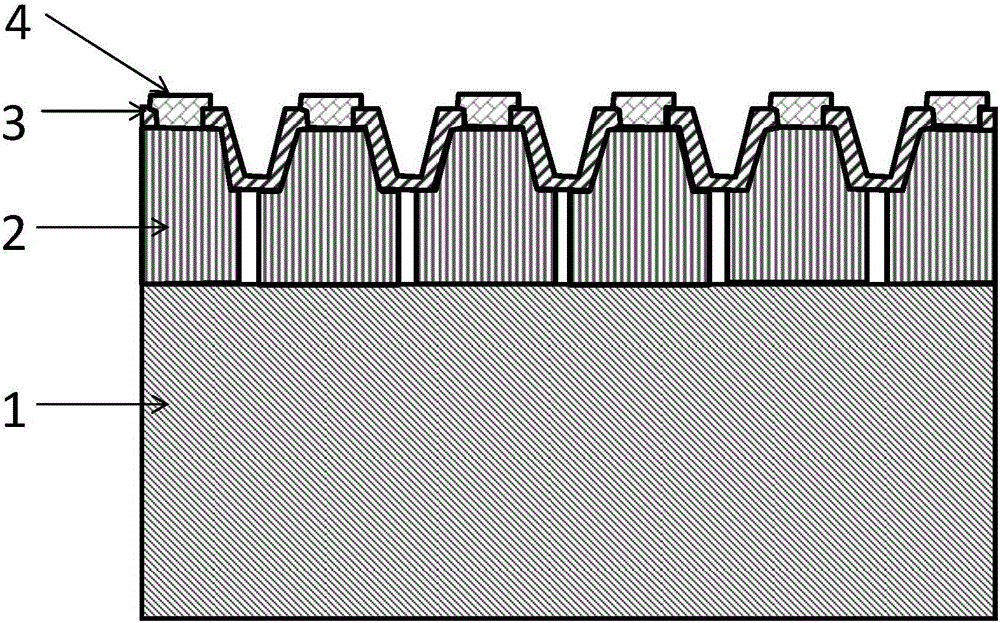

Nitride light emitting diode (LED) based on stress controlled electroplating and substrate transferring and fabrication method thereof

InactiveCN105161589AGuaranteed confidentialityIntegrity guaranteedSemiconductor devicesEtchingGallium nitride

The invention provides a nitride light emitting diode (LED) based on stress controlled electroplating and substrate transferring and a fabrication method thereof. A method for stripping a sapphire substrate through wet etching can be used for fabricating a vertical structure LED. The separation of the sapphire substrate and a gallium nitride epitaxial layer can be achieved by key steps of cutting the gallium nitride epitaxial layer, cleaning the gallium nitride epitaxial by using a hot acid, releasing gallium nitride stress, electroplating a stress-free nickel substrate, polishing a metal substrate, fabricating an inclined gallium nitride side wall, a metal sacrificial layer and a side wall protection layer, polishing the sapphire substrate, cutting in one time, corroding an N-polarity surface of the gallium nitride and the like. By the method, the crystal quality of a GaN active layer cannot be affected, and thus, the luminous efficiency of the vertical structure LED can be guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

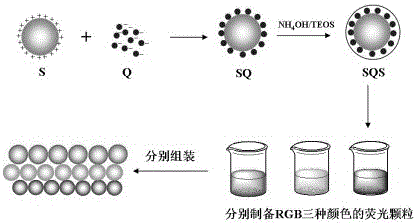

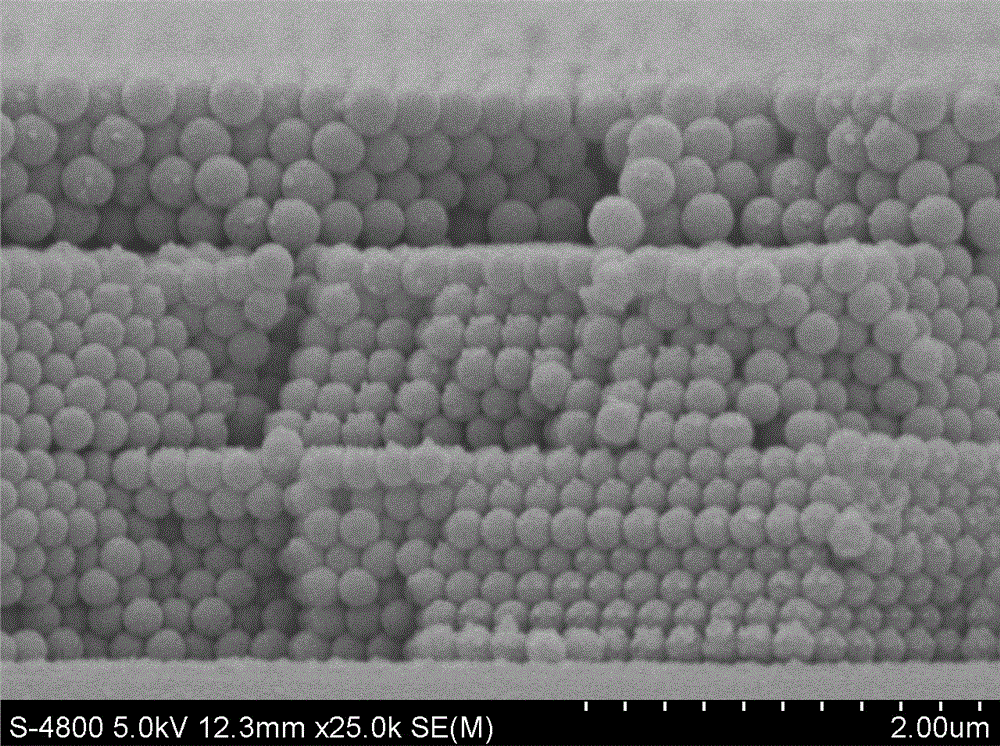

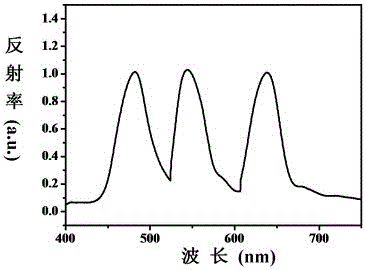

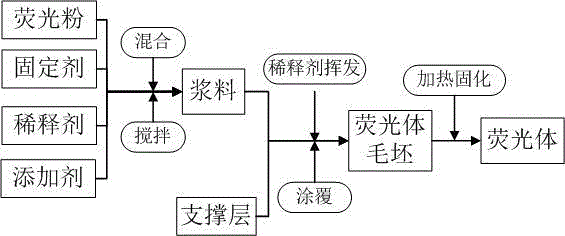

White light source containing three-band-gap photonic crystals and preparation method for white light source

ActiveCN105957944AProtection from disclosureImprove stabilitySemiconductor devicesLuminous intensityPhotonic bandgap

The invention discloses a white light source containing three-band-gap photonic crystals and a preparation method for the white light source, belongs to the technical fields of light emission and illumination, relates to the application technology of photonic crystals, and particularly relates to a preparation method for improving the luminous intensity and stability of the white light source based on the three-photonic-band-gap characteristics of the three-band-gap photonic crystals and a coating technology. According to the preparation method, mono-dispersion red, green and blue three-fundamental-color fluorescent granules are prepared separately through the coating technology; then the solid-state luminous thin films of the three-band-gap photonic crystals are established by an automatic-assembling method in a layer-by-layer assembling manner; and next, the thin films are combined with an ultraviolet LED to prepare the white light source with the excellent luminescence property.

Owner:JIANGMEN POLYTECHNIC

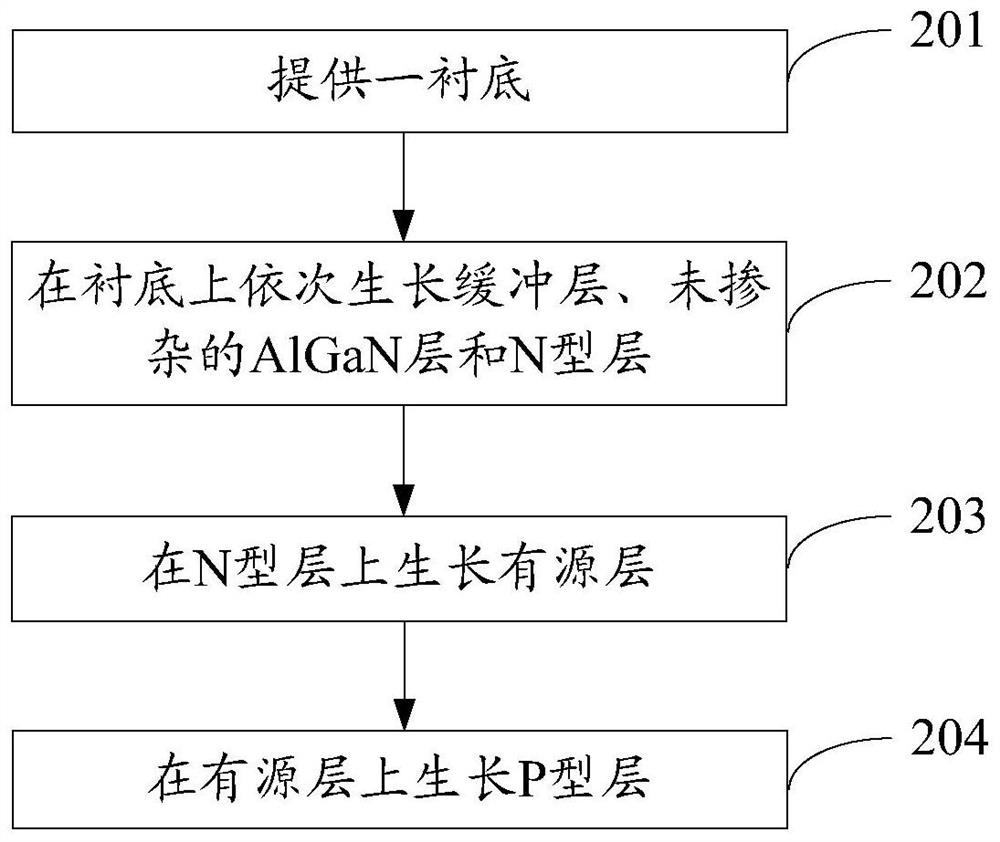

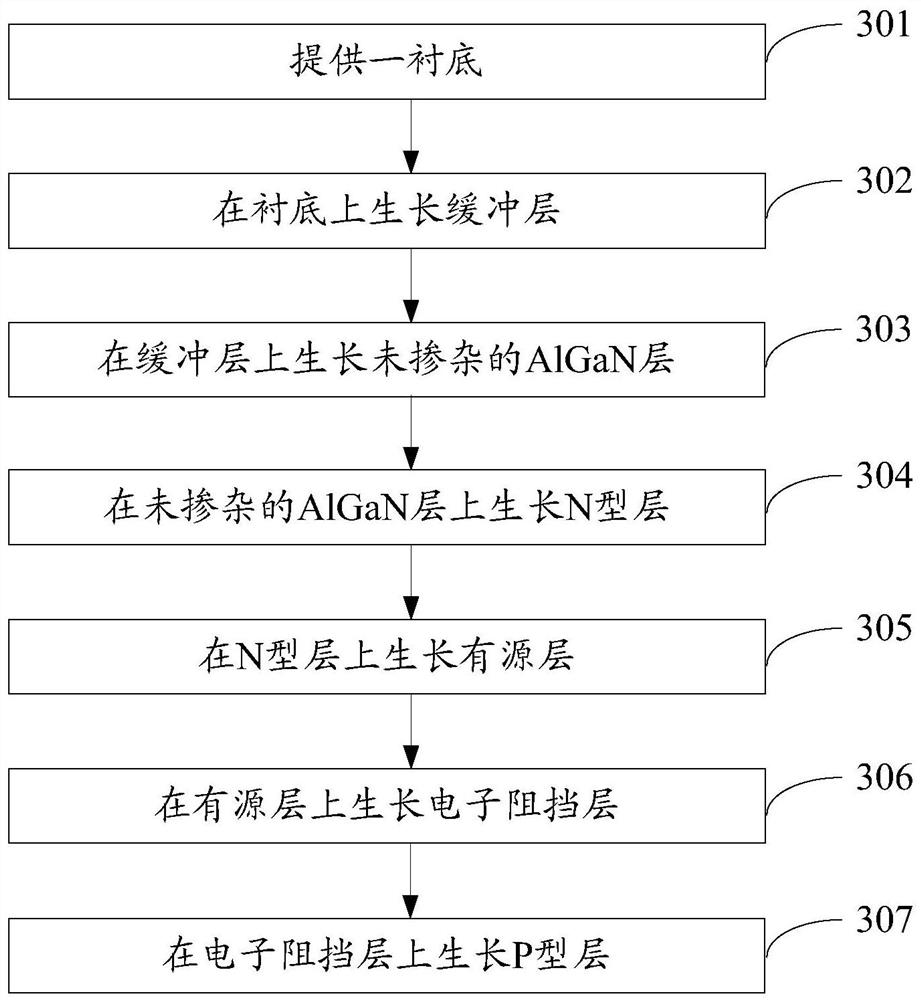

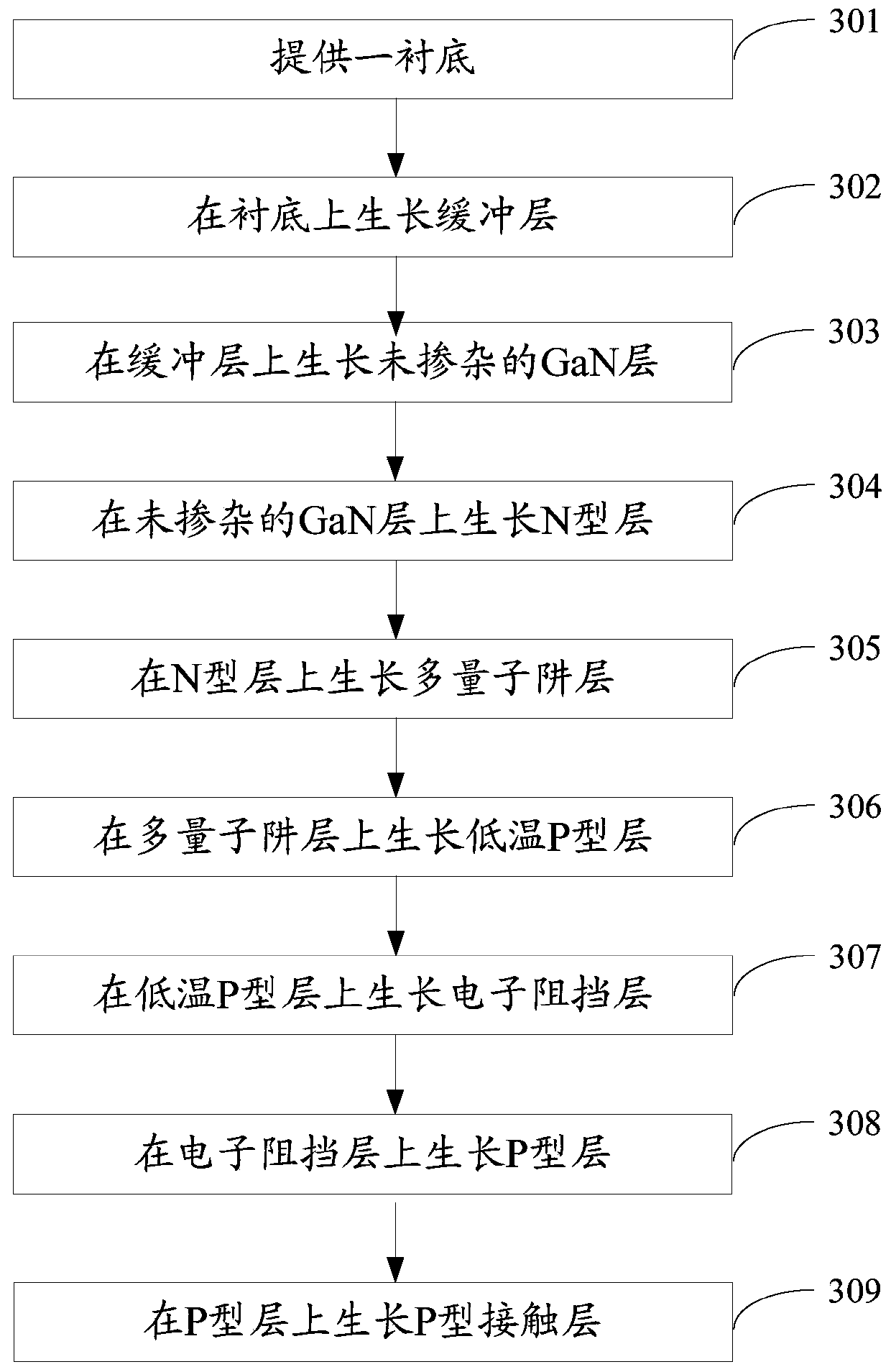

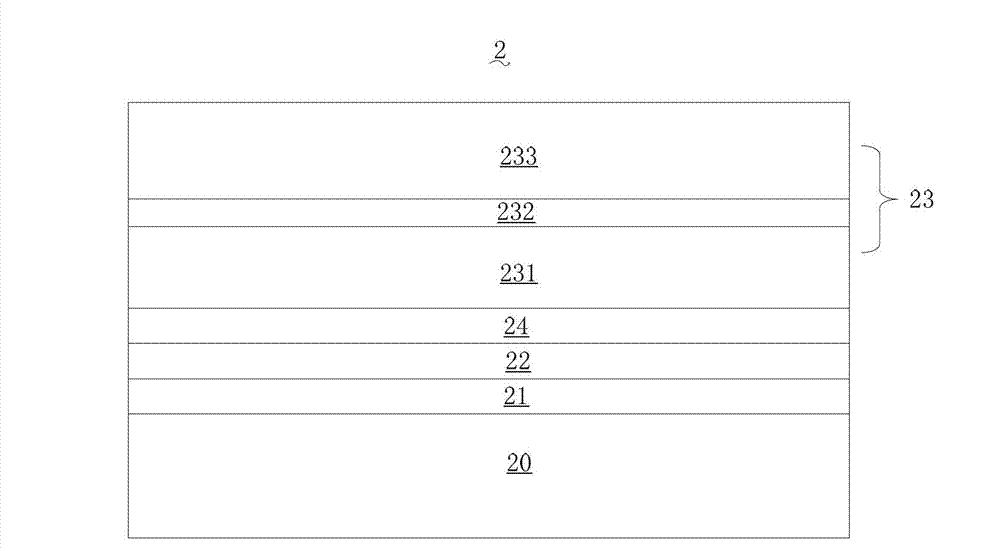

Ultraviolet light emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN112366258AImprove energy band tilt phenomenonProne to overflowSemiconductor devicesUltraviolet lightsMaterials science

The invention provides an ultraviolet light emitting diode epitaxial wafer and a manufacturing method thereof, which belong to the technical field of semiconductors. The ultraviolet light emitting diode epitaxial wafer comprises a substrate, a buffer layer, an undoped AlGaN layer, an N-type layer, an active layer and a P-type layer, the buffer layer, the undoped AlGaN layer, the N-type layer, theactive layer and the P-type layer are sequentially stacked on the substrate, the active layer comprises a plurality of quantum well layers and quantum barrier layers which alternately grow periodically, the quantum well layers are Si-doped AlxGa1-xN layers, x is greater than 0 but smaller than 0.4, thequantum barrier layer is Mg-dopedAlyGa1-yN layer, and y is greater than 0.5 but smaller than 0.7.The ultraviolet light emitting diode epitaxial wafer can effectively shield a built-in electric field generated by a polarization effect in the quantum well layer, so that the wave function overlapping rate of electrons and holes can be improved, the radiation recombination efficiency of the electrons and the holes can be improved, and finally the internal quantum efficiency of the ultraviolet light-emitting diode is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

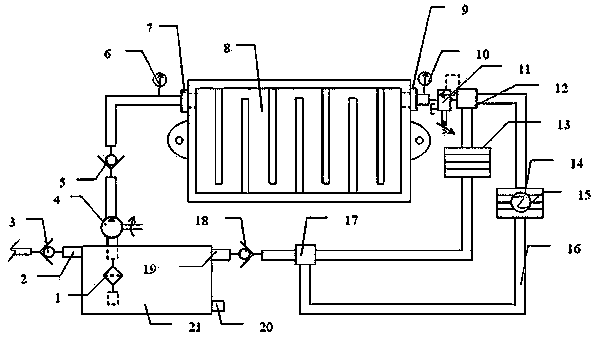

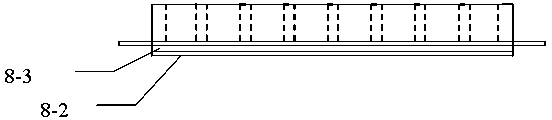

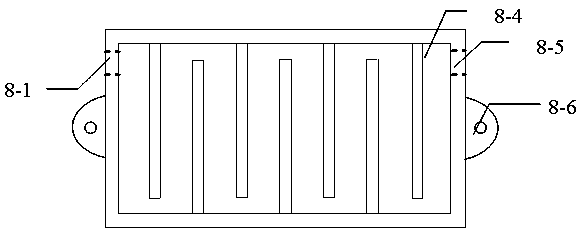

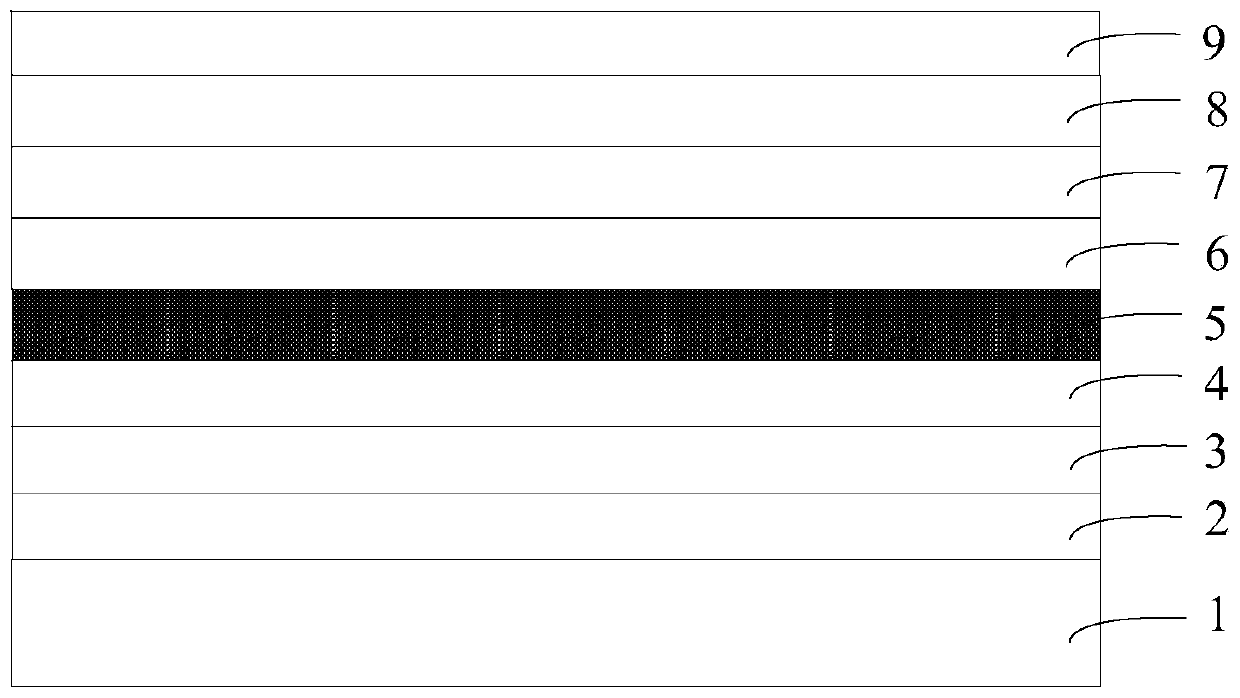

Circulating water-cooled plant factory LED (light-emitting diode) surface light source heat dissipation management system and method

InactiveCN103471061AGuaranteed luminous efficiencyReduce light decay ratePoint-like light sourceElongate light sourcesThermal energyMeasuring instrument

A circulating water-cooled plant factory LED (light-emitting diode) surface light source heat dissipation management system and method. The system comprises an LED panel heat dissipation device, a controller, a temperature measuring instrument, a heat energy replacement system and a water channel circulating system, the LED panel heat dissipation device is mounted at the back of a lamp panel, the temperature measuring instrument is mounted on a pipeline of the water channel circulating system entering and exiting the heat dissipation device, the water channel circulating system penetrates the heat dissipation device, the temperature measuring instrument acquires the temperature of inlet and outlet water passing the heat dissipation device, and the controller calculates heat in a replacement water channel of the heat energy replacement system according to the temperature of the inlet and outlet water and controls the rotating speed of a radiator fan to perform heat dissipation. Heat energy generated by LEDs can be timely dissipated, the light-emitting efficiency of the LEDs is ensured, and light attenuation rate is reduced. Besides, the heat energy dissipated from the LEDs can be used for heating the indoor environment of a plant factory in heating seasons, the heat energy is timely discharged from the indoor environment in non-heating seasons, and energy consumption for cooling in the non-heating seasons is reduced.

Owner:NANJING AGRICULTURAL UNIVERSITY

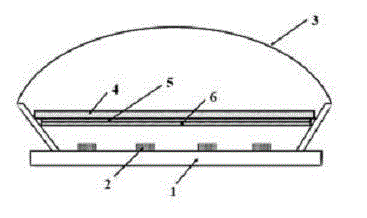

Remote phosphor structure applicable to LED lighting and production method thereof

InactiveCN102721007AGuaranteed luminous efficiencyAchieve exitPoint-like light sourceSpectral modifiersFluorescencePhosphor

The invention provides a remote phosphor structure applicable to LED lighting and a production method thereof. The remote phosphor structure applicable to LED lighting comprises a light-permeable support part and a phosphor layer arranged on the same. The phosphor layer at least comprises first-wavelength phosphor and second-wavelength phosphor. The first-wavelength phosphor forms a first phosphor layer. The second-wavelength phosphor forms a second phosphor layer. The first phosphor layer and the second phosphor layer are stacked on the light-permeable support part layer by layer. The production method includes producing at least two layers of phosphor different in wavelength on the light-permeable support part. By the design of the phosphor layers, multi-wavelength layering-stacked structure or multi-wavelength array structure, multispectral emergence is achieved, color rendering is improved, color temperature is lowered, and luminous efficiency of the phosphor is guaranteed.

Owner:NANJING HANDSON SCI & TECH CORP

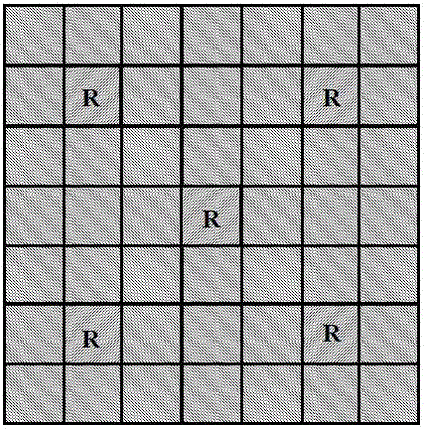

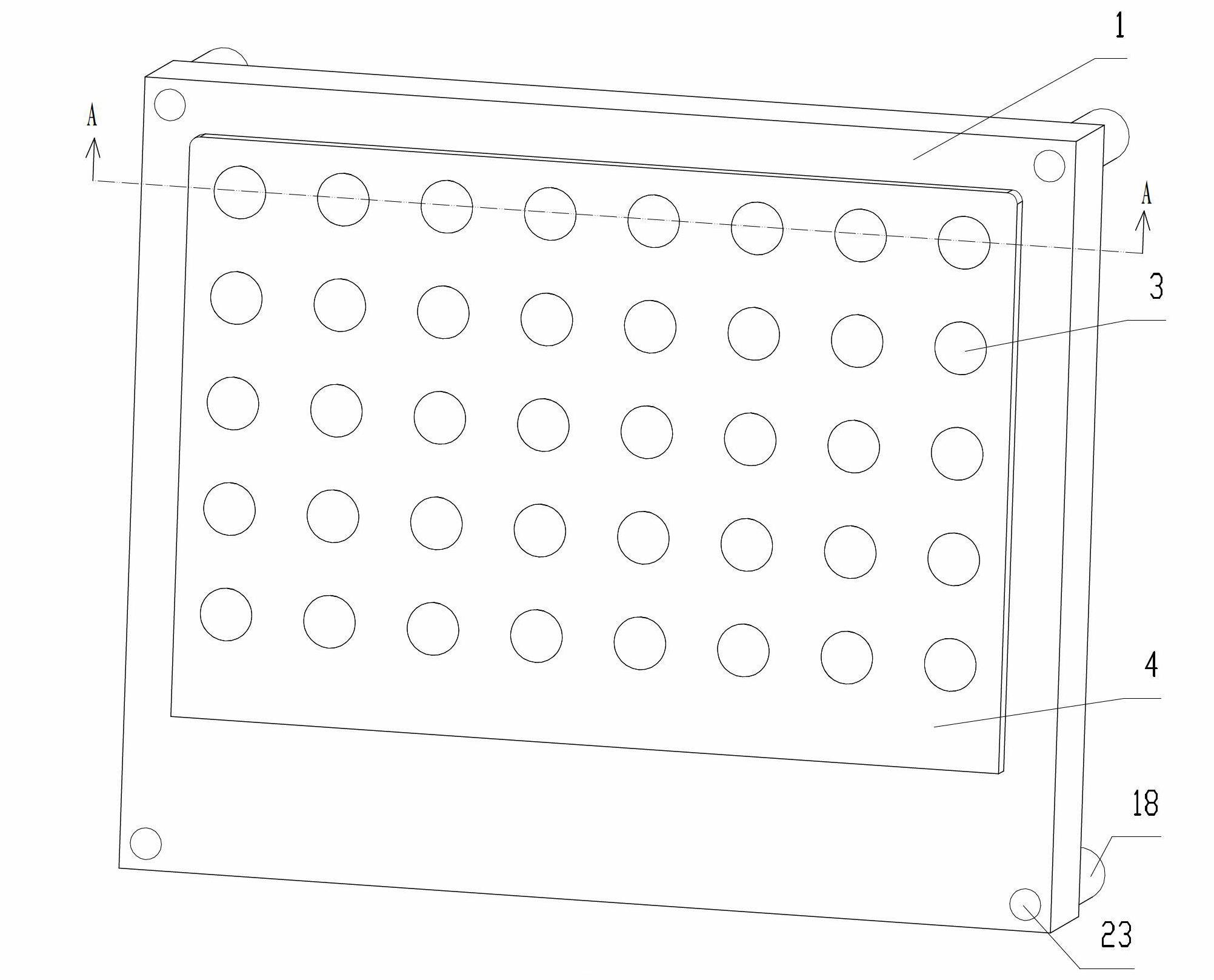

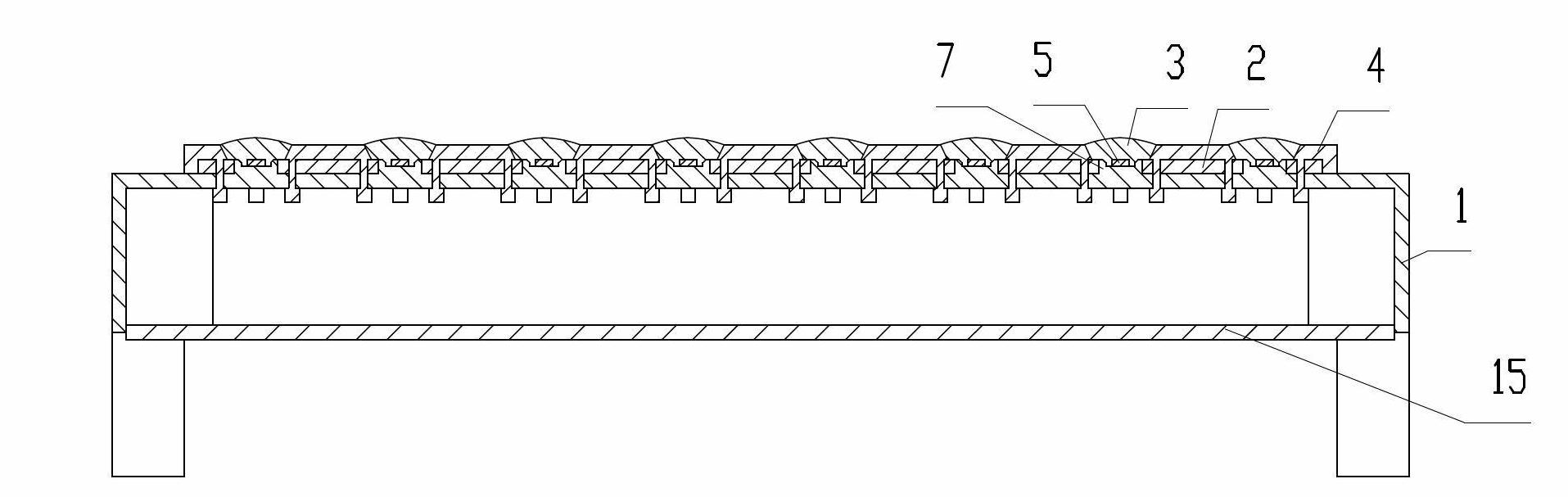

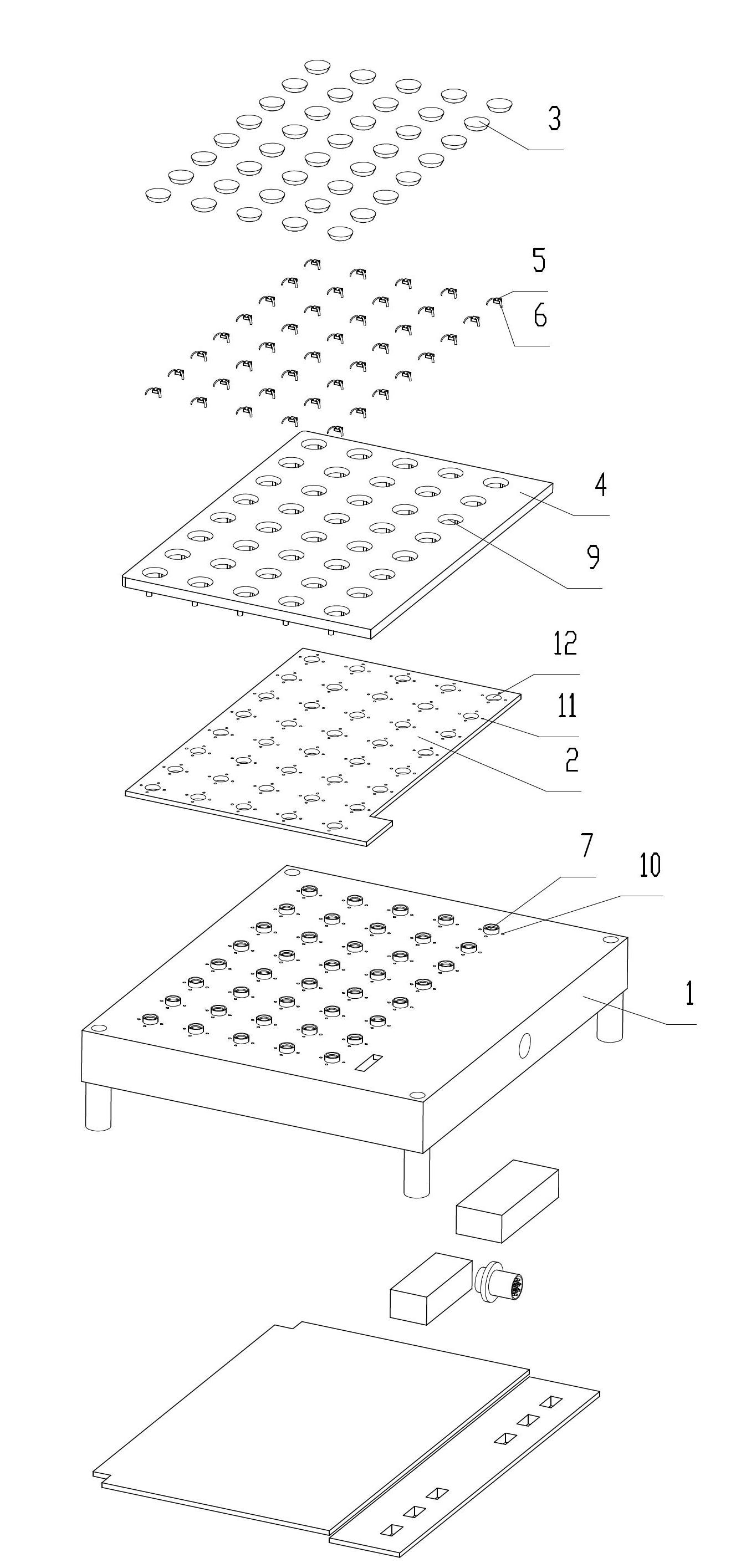

LED (light-emitting diode) dot matrix display screen and combined dot matrix display screen

InactiveCN102682671ACause material deteriorationExtend your lifeCooling/ventilation/heating modificationsIdentification meansDot-matrix displayColloid

The invention discloses an LED (light-emitting diode) dot matrix display screen and a combined dot matrix display screen. The dot matrix display screen comprises a heat-dissipating substrate, a PCB (printed circuit board), an uniformly-arrayed LED light-emitting unit, an imaging controller, a layout circuit conducting layer, a pervious-to-light packaging colloid for packaging LED chips, and a plastic plate forming the pervious-to-light packaging colloid for packaging the LED chips, wherein the LED light-emitting unit comprises more than one LED chips, guide lines and the pervious-to-light packaging colloid; the guide lines electrically connect the LED chips with the layout circuit conducting layer, and the pervious-to-light packaging colloid is used for packaging the LED chips; a hermetically-sealed outer cavity side wall which is hermetically connected with the plastic plate and the heat-dissipating substrate is arranged between the plastic plate and the heat-dissipating substrate; the heat-dissipating substrate, the hermetically sealed outer cavity side wall and the plastic plate defines a hermetically-sealed cavity, and the PCB is accommodated in the hermetically-sealed cavity; and the heat-dissipating substrate, the plastic plate and the pervious-to-light packaging colloid are directly contacted with the outside air. The dot matrix display screen disclosed by the invention has the advantages that of being simple in structure and low in cost and having good waterproof and heat-dissipating effects since the PCB is accommodated in the hermetically-sealed cavity formed by the heat-dissipating substrate, the hermetically sealed outer cavity side wall and the plastic plate.

Owner:东莞市万兴智能科技有限公司

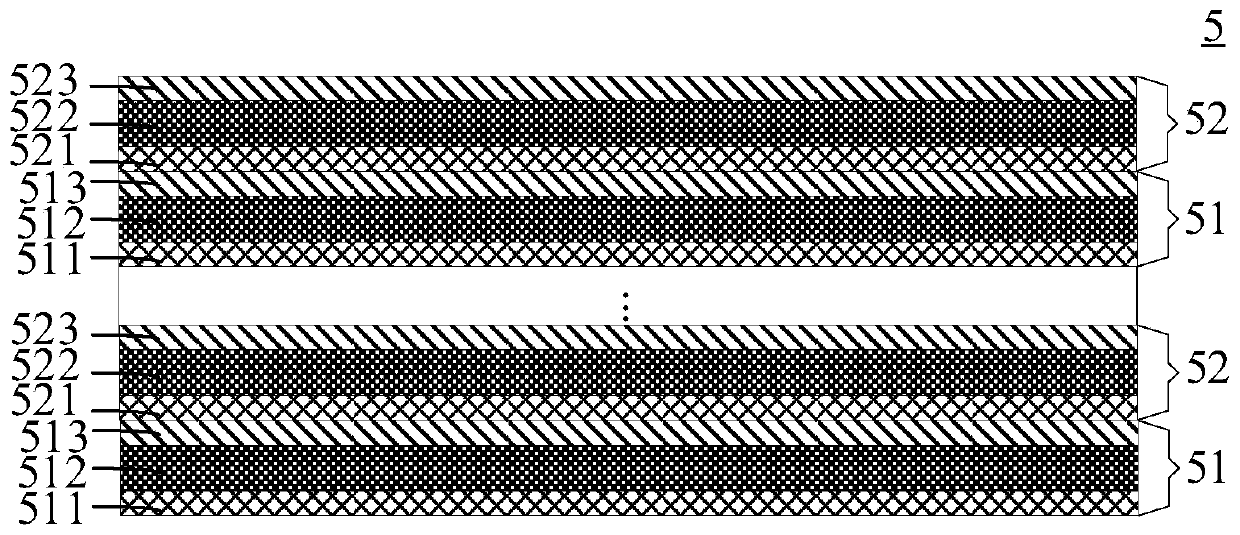

Light emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN110718612AGuaranteed luminous efficiencyReduce mismatchSemiconductor devicesQuantum efficiencyElectron hole

The invention discloses a light emitting diode epitaxial wafer and a manufacturing method thereof, and belongs to the semiconductor technology field. Each quantum well layer of a multi-quantum well layer of the light-emitting diode epitaxial wafer comprises a first quantum well sub-layer, a second quantum well sub-layer and a third quantum well sub-layer which are stacked in sequence. In / Ga ratioof the second quantum well sub-layer is greater than or equal to the In / Ga ratios of the first quantum well sub-layer and the third quantum well sub-layer. Si is doped in the first quantum well sub-layer. Each quantum barrier layer comprises a first quantum barrier sub-layer, a second quantum barrier sub-layer and a third quantum barrier sub-layer which are stacked in sequence. The Si / Ga ratio ofthe second quantum barrier sub-layer is greater than or equal to the Si / Ga ratios of the first quantum barrier sub-layer and the third quantum barrier sub-layer. The light emitting diode epitaxial wafer can improve an energy band inclination phenomenon in the multi-quantum well layer, an overlapping degree of wave functions of electrons and holes in space distribution is increased and internal quantum efficiency of an LED is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

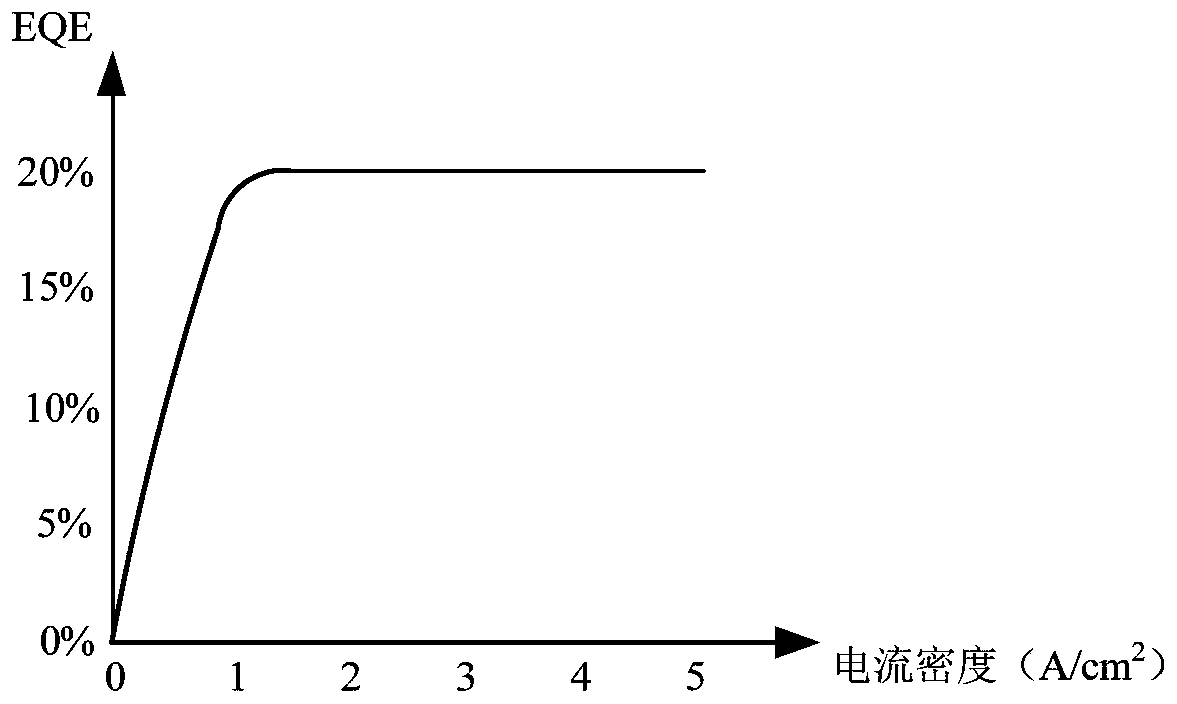

Pixel driving circuit, driving method and display panel

ActiveCN111243521AImprove job stabilityControl the glow timeStatic indicating devicesDriver circuitOxide thin-film transistor

The invention discloses a pixel driving circuit, a driving method and a display panel, and relates to the technical field of display. The pixel driving circuit comprises an inorganic light emitting diode which is electrically connected to a first power supply signal end, a first control unit which is electrically connected to a second data signal end, a second scanning signal end and a third nodeand is used for controlling the inorganic light emitting diode to work under set current density, and a second control unit which is electrically connected to a first data signal end, a first scanningsignal end, a slope voltage signal end, a third node and a second power supply signal end and is used for controlling the light emitting duration of the inorganic light emitting diode. The second control unit comprises a first transistor, and the first transistor is an oxide thin film transistor. The driving method is used for driving the pixel driving circuit to work. According to the invention,the leakage current of the inorganic light-emitting diode within the light-emitting duration can be reduced, so that the circuit is more stable.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

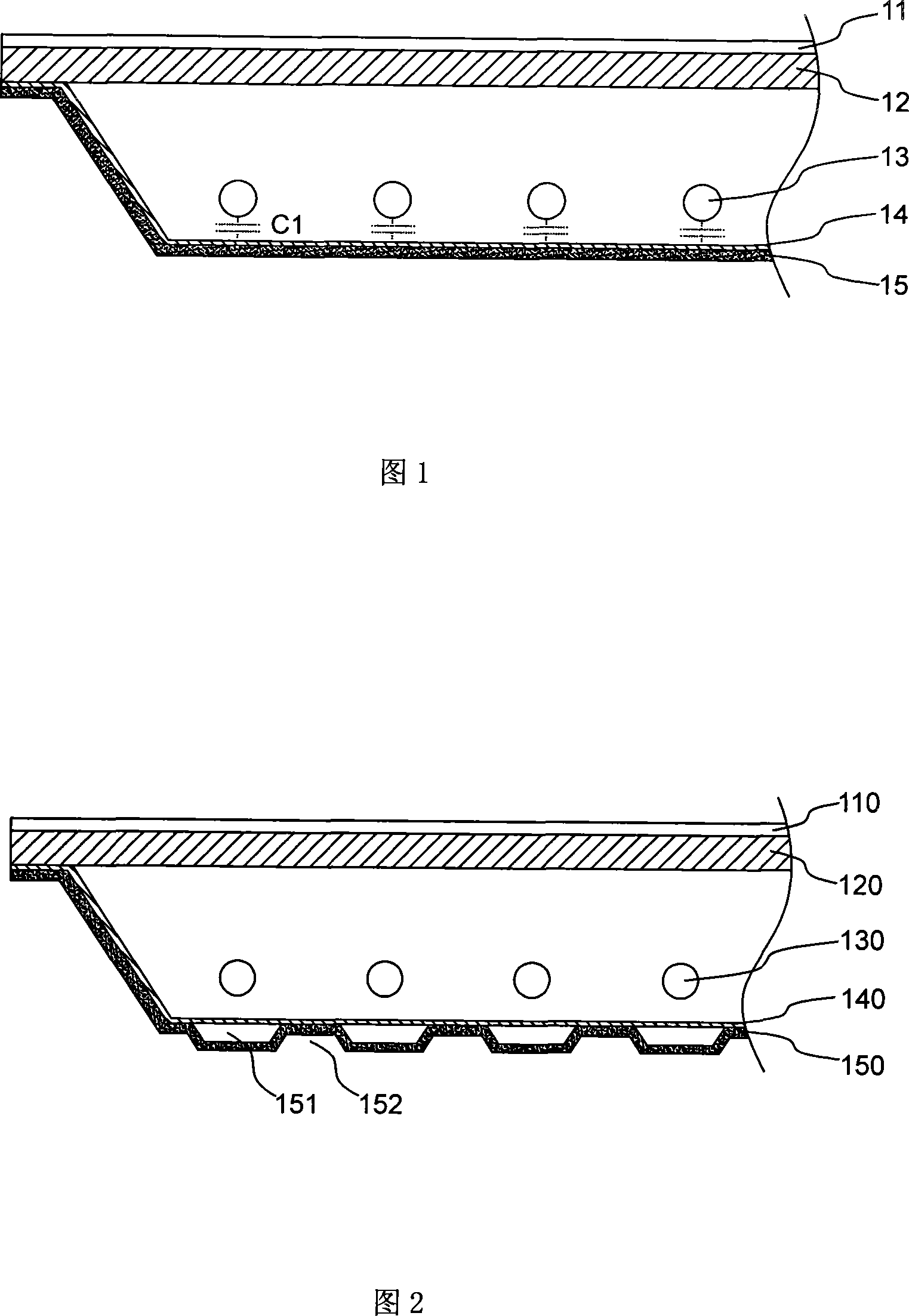

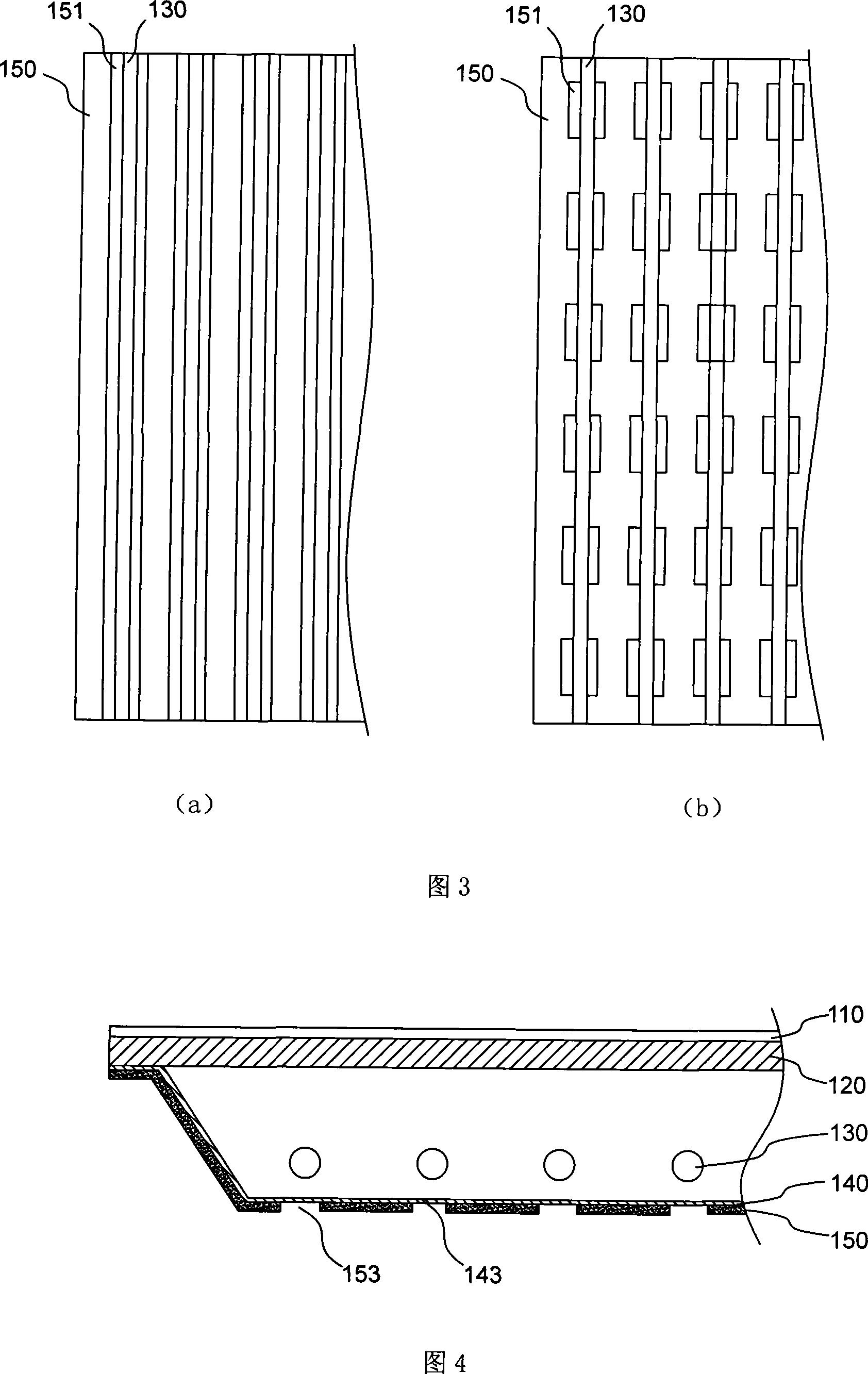

Directly-down back light module unit

InactiveCN101162325AReduce the induction currentGuaranteed luminous efficiencyNon-linear opticsLiquid-crystal displayBackplane

The invention discloses a straight down type backlight module for a liquid crystal display. The straight down type backlight module comprises an optical film, a diffuser plate arranged below the optical film, a plurality of paralleled lamp tubes arranged below the diffuser plate, a reflection piece arranged below the lamp tubes, a back plate arranged below the reflection piece, a plurality of back plate grooves which are formed by the back plate bent downward and are arranged on the back plate below the lamp tubes, or a plurality of back plate openings arranged below the lamp tubes. The straight down type backlight module of the invention can effectively reduce induced current caused by parasitic capacitance between the back plate and the lamp tubes, ensure the luminous efficiency of the lamp tubes and the luminous uniformity on both ends of the lamp tubes, and also reduce the thickness of the whole backlight module.

Owner:上海广电光电子有限公司

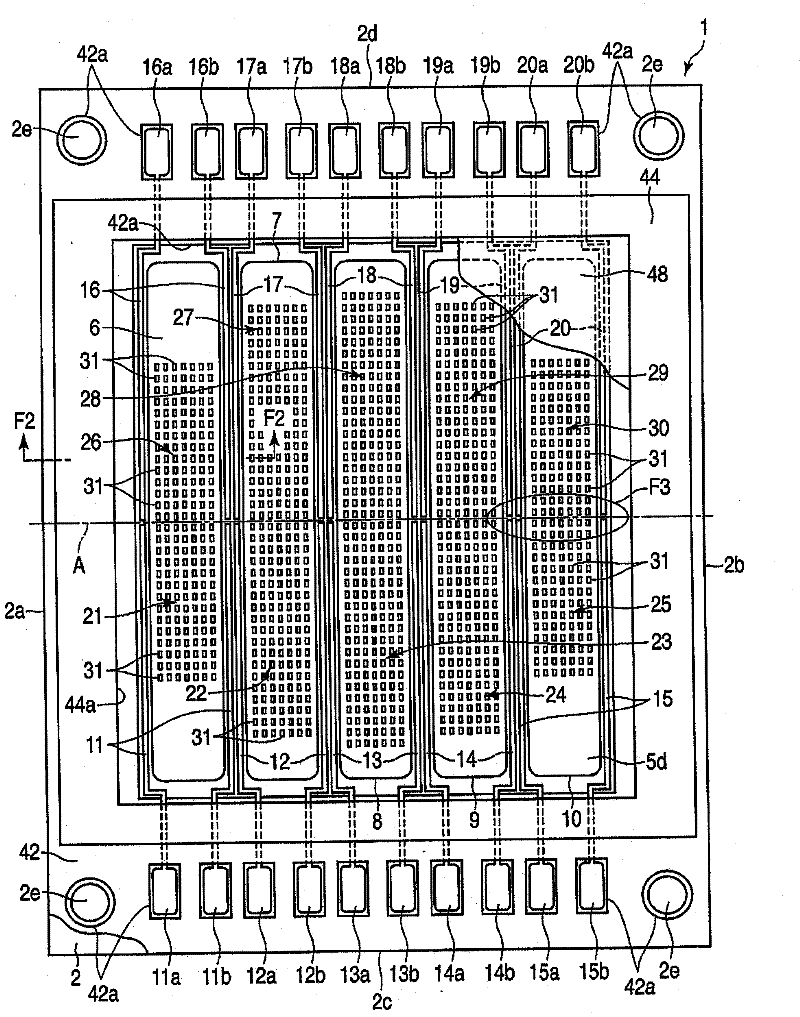

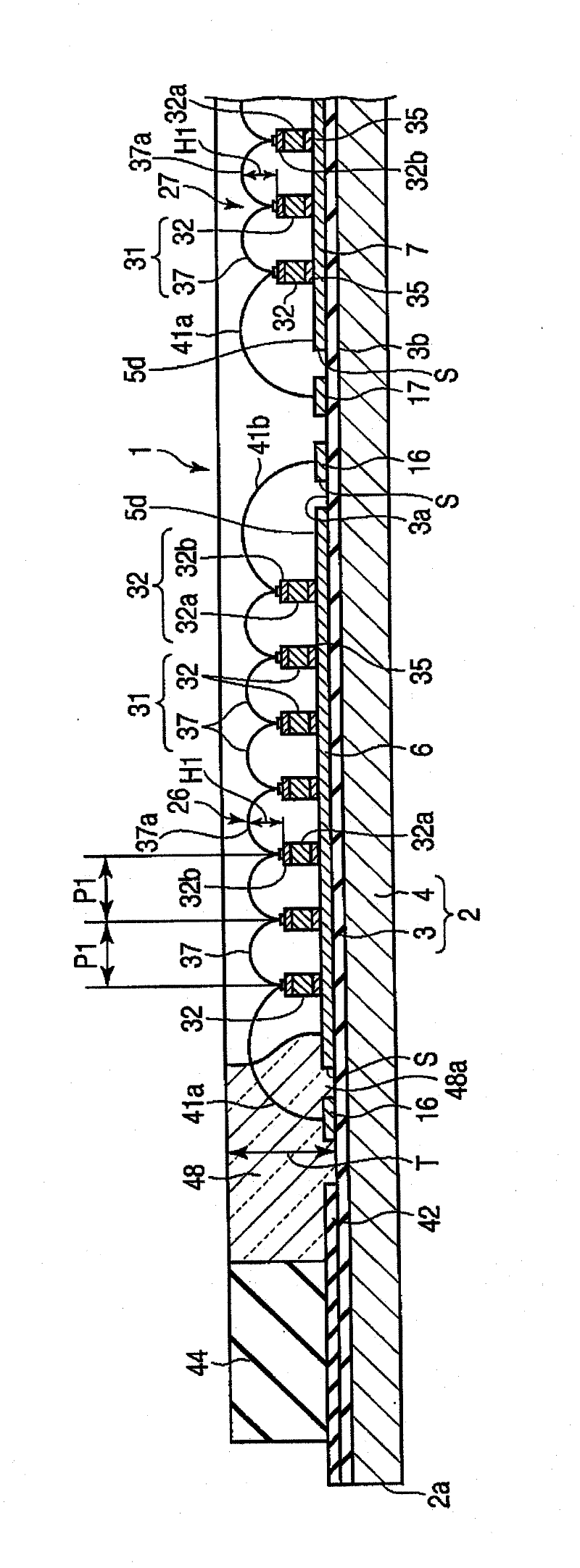

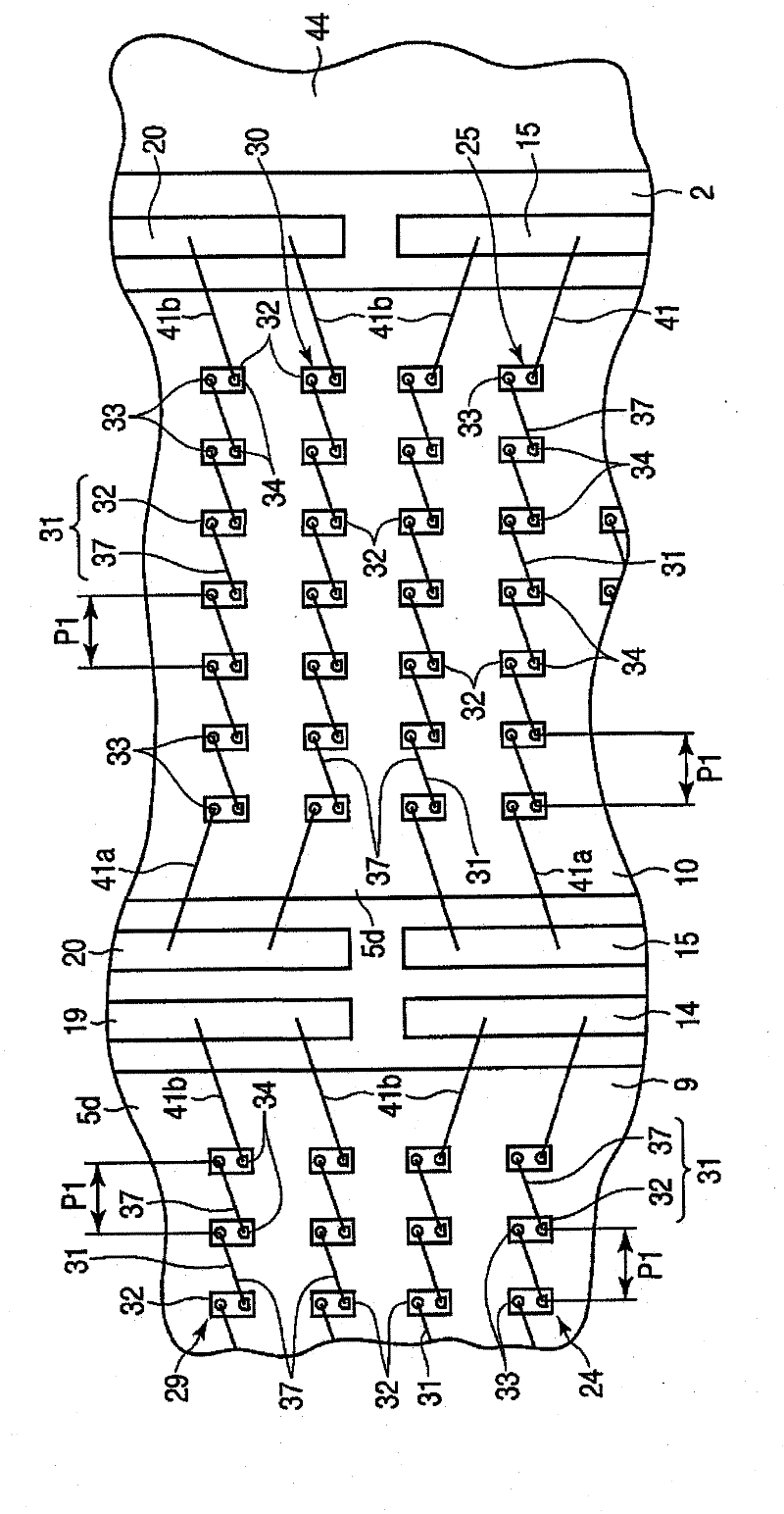

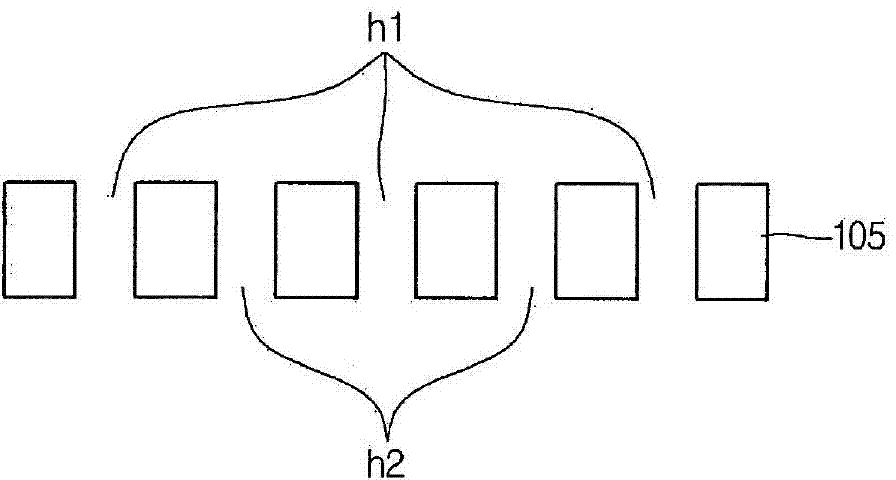

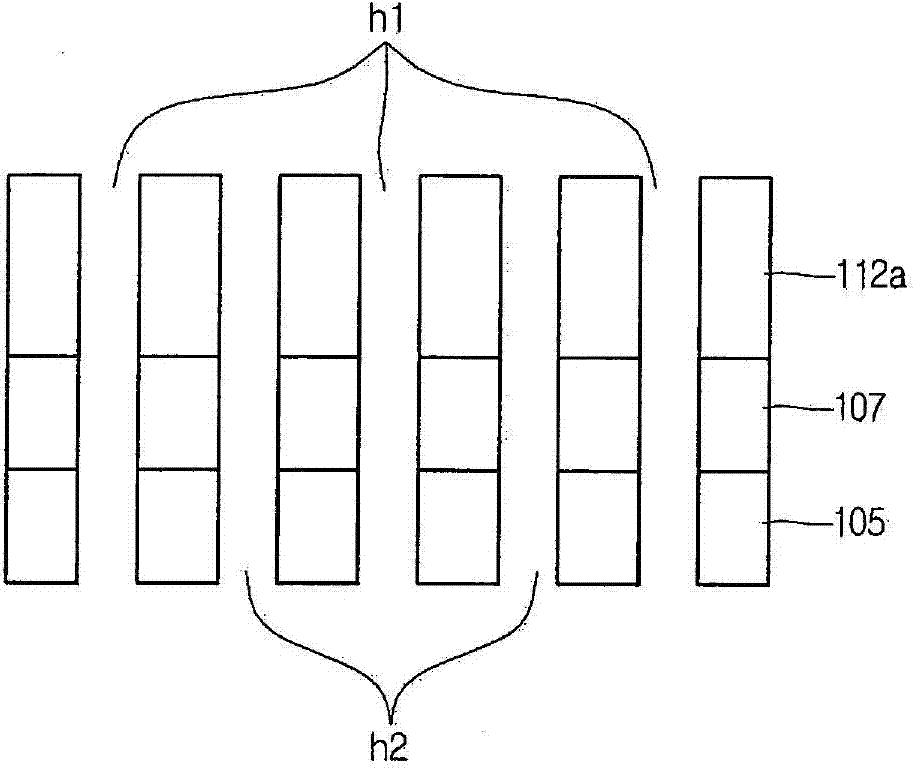

Light-emitting module and illumination apparatus

InactiveCN102334202APrevent discolorationHigh light reflectivityPlanar light sourcesPoint-like light sourceEngineeringLight-emitting diode

A light-emitting module (1) provided with a module board (2), light-emitting diode lines (31), and a sealing member (48). Each light-emitting diode line (31) includes a plurality of light-emitting diodes (32) and a plurality of bonding wires (37) connected between the light-emitting diodes (32). Each light-emitting diode (32) has a pair of electrodes (33, 34) and has a rectangular shape that extends to the direction that the electrodes (33, 34) are lined up in. The sealing member (48) is deposited on the module board (2) so as to seal the light-emitting diode lines (31). The light-emitting diodes (32) are arranged with clearance to each other in directions that intersect the direction in which the electrodes (33, 34) are lined up in, and are arranged so that the electrodes (33, 34) of the same polarity between adjacent light-emitting diodes (32) are adjacent in the arrangement direction of the light-emitting diodes (32). The bonding wires (37) are laid in a manner diagonal to the arrangement direction of the light-emitting diodes (32) so as to connect electrodes (33, 34) of different polarities of the adjacent light-emitting diodes (32).

Owner:TOSHIBA LIGHTING & TECH CORP

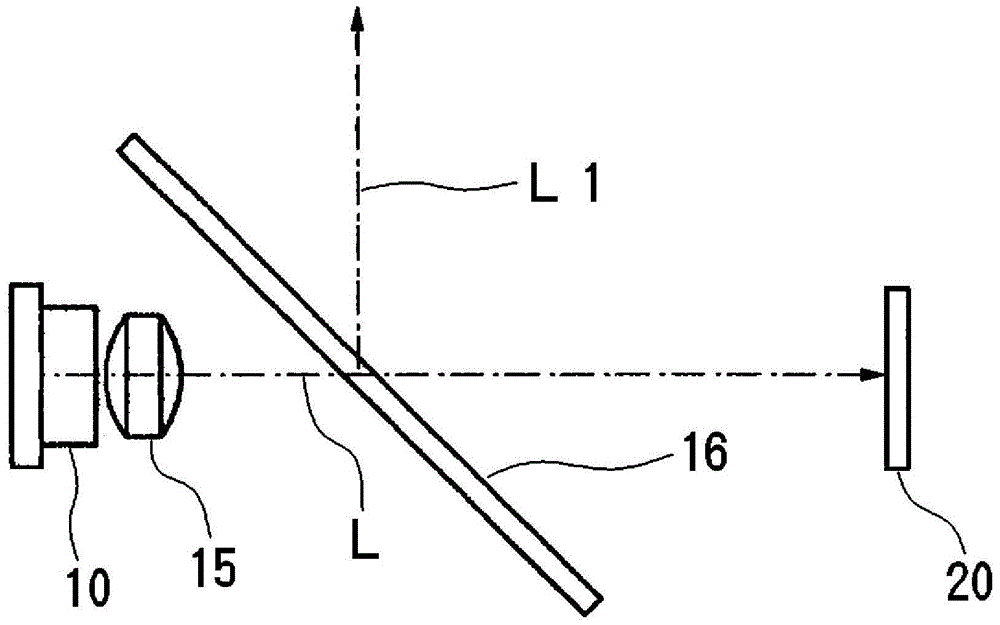

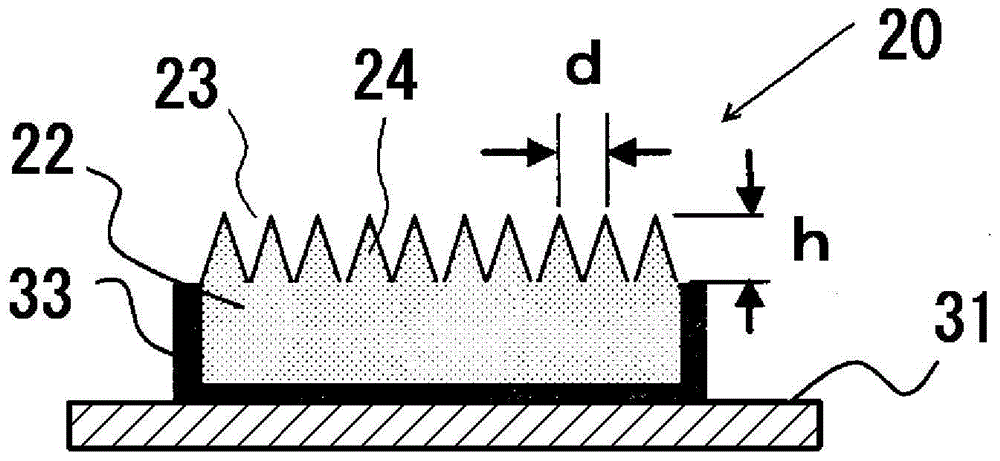

Fluorescent-light-source device

InactiveCN104969370ASuppress backscatterFull accessLaser detailsPoint-like light sourceFluorescenceWavelength conversion

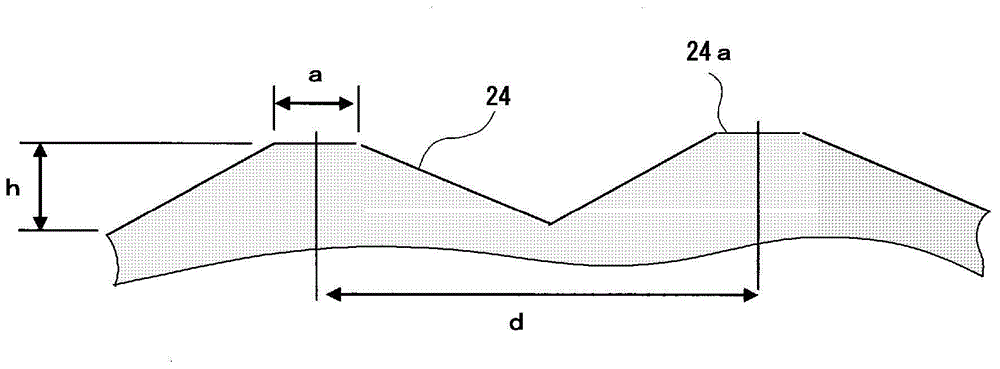

The purpose of the present invention is to provide a fluorescent-light-source device in which, when a wavelength conversion member is exposed to excitation light, backscattering of said excitation light is minimized and fluorescent light generated inside the wavelength conversion member is utilized effectively and emitted to the outside with high efficiency, yielding a high light-emission efficiency. This fluorescent-light-source device is characterized by the provision of a wavelength conversion member in the form of a florescent material that is excited by excitation light. This fluorescent-light-source device is further characterized in that: a periodic structure comprising substantially cone-shaped protrusions arrayed in a periodic fashion is formed on an excitation-light-receiving surface on the wavelength conversion member; the aspect ratio of said periodic structure, namely the quotient of the heights of the protrusions and the period of the periodic structure, is at least 0.2; and said period falls within a range within which fluorescent light emitted by the florescent material is diffracted.

Owner:USHIO DENKI KK

Organic light emitting display panel and organic light emitting display device

ActiveCN106653803APrevent leakageGuaranteed luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceHole transport layer

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +2

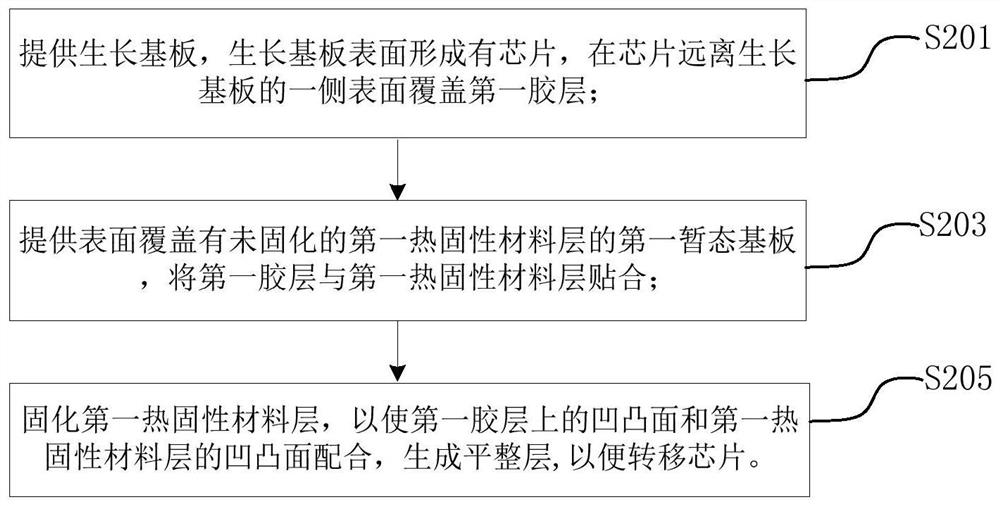

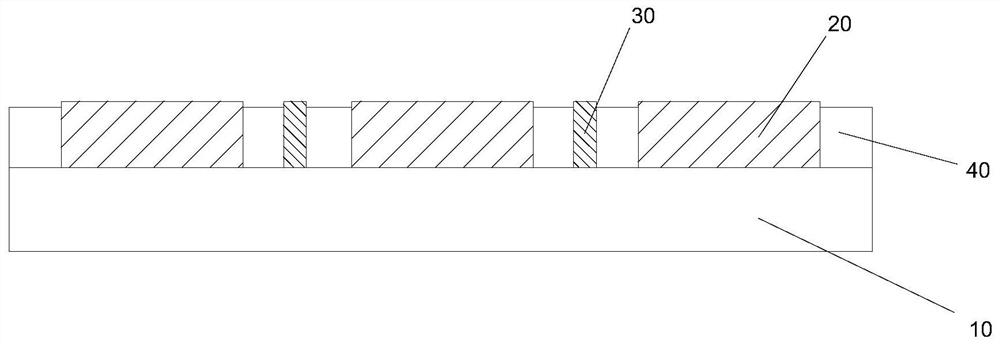

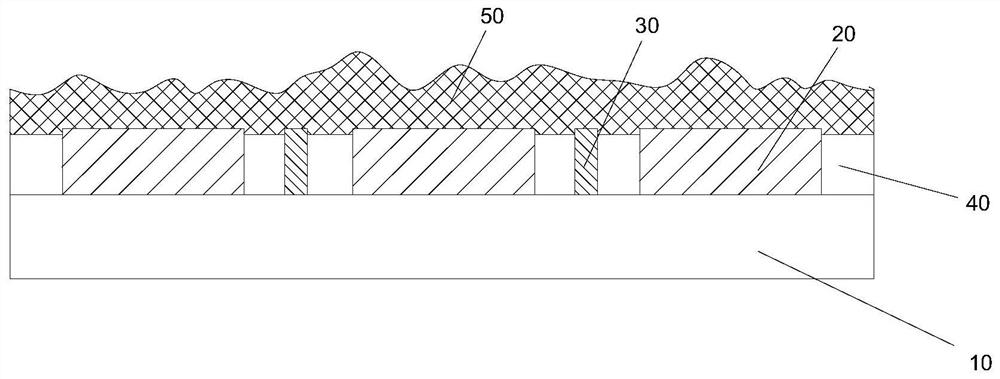

Chip transfer method and display device

ActiveCN112968106AGuaranteed transfer successEffective fit and adhesionSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsComposite material

The invention relates to a chip transfer method and a display device. The chip transfer method comprises the following steps that: a growth substrate is provided, a chip is formed on the surface of the growth substrate, and the surface of the side, away from the growth substrate, of the chip is covered with a first adhesive layer; a first transient substrate of which the surface is covered with an uncured first thermosetting material layer is provided, and the first adhesive layer is attached to the first thermosetting material layer; and the first thermosetting material layer is cured, so that a concave-convex surface on the first adhesive layer can be matched with a concave-convex surface of the first thermosetting material layer to generate a flat layer, so that the chip can be transferred. According to the chip transfer method, the situation that some chips are not completely attached or sink into a glue material on the surface of another temporary substrate due to insufficient height in the pressure attachment transfer process of the chips and the other substrate is avoided, and successful transfer of the chips is guaranteed.

Owner:CHONGQING KONKA PHOTOELECTRIC TECH RES INST CO LTD

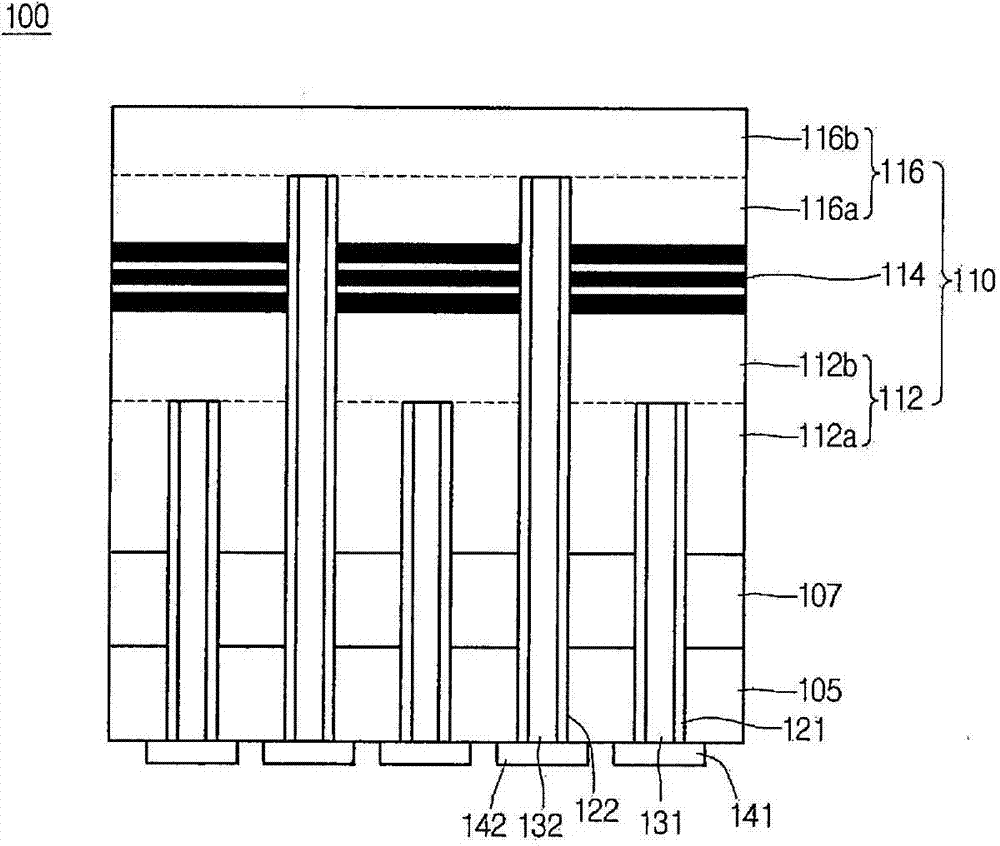

Organic light emitting device with barrier layer

ActiveCN103904225AFlexible control of luminous intensityGuaranteed luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerOrganic light emitting device

The invention relates to a barrier layer and an organic light emitting device with a barrier layer. The organic light emitting device comprises a substrate, and an anode layer, a light emitting unit layer and a cathode layer which are sequentially formed on the substrate. The light emitting unit layer includes a hole injection layer, a hole transport layer, light emitting layers and an electron transport layer, wherein the hole injection layer is formed on the anode layer, the hole transport layer is formed on the hole injection layer, the cathode layer is formed on the electron transport layer, the plurality of light emitting layers are arranged between the hole transport layer and the electron transport layer, the light emitting layers include a fluorescent light emitting layer and phosphorescent light emitting layers, and a barrier layer is arranged between the fluorescent light emitting layer and the phosphorescent light emitting layers. The main materials of the barrier layer include an electron transport material and a hole transport material which have the same mother nucleus. The electron transport efficiency and the hole transport efficiency of the organic light emitting device of the invention can be effectively adjusted, and the organic light emitting device has the advantage of high light emitting efficiency.

Owner:GUAN YEOLIGHT TECH CO LTD +1

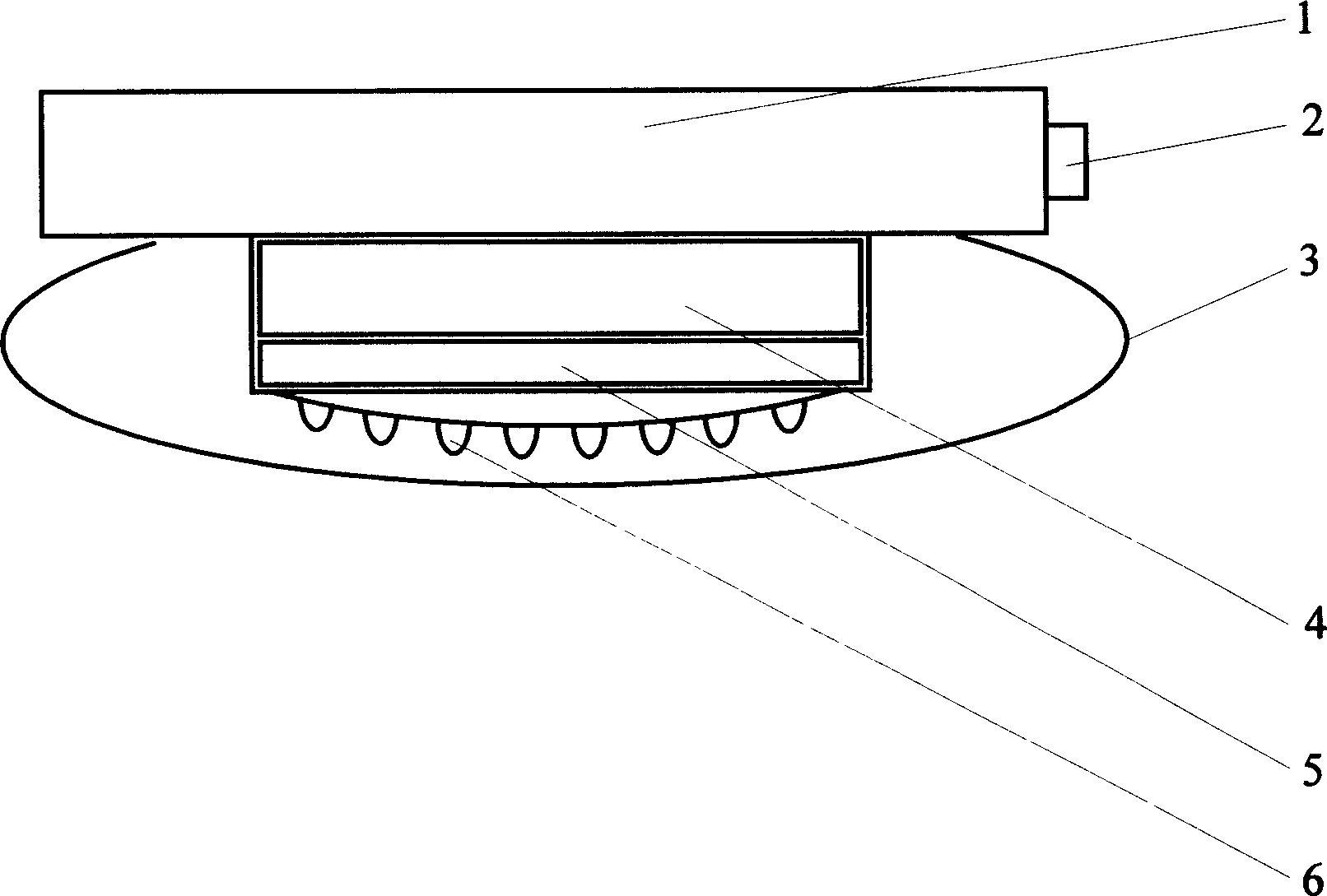

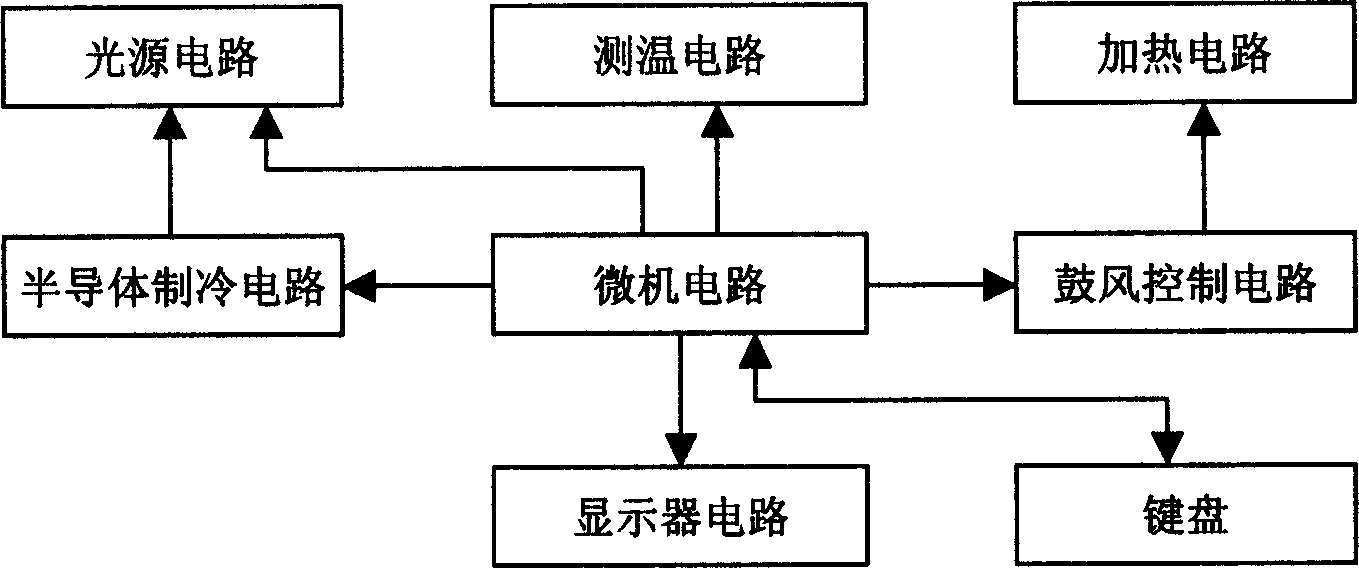

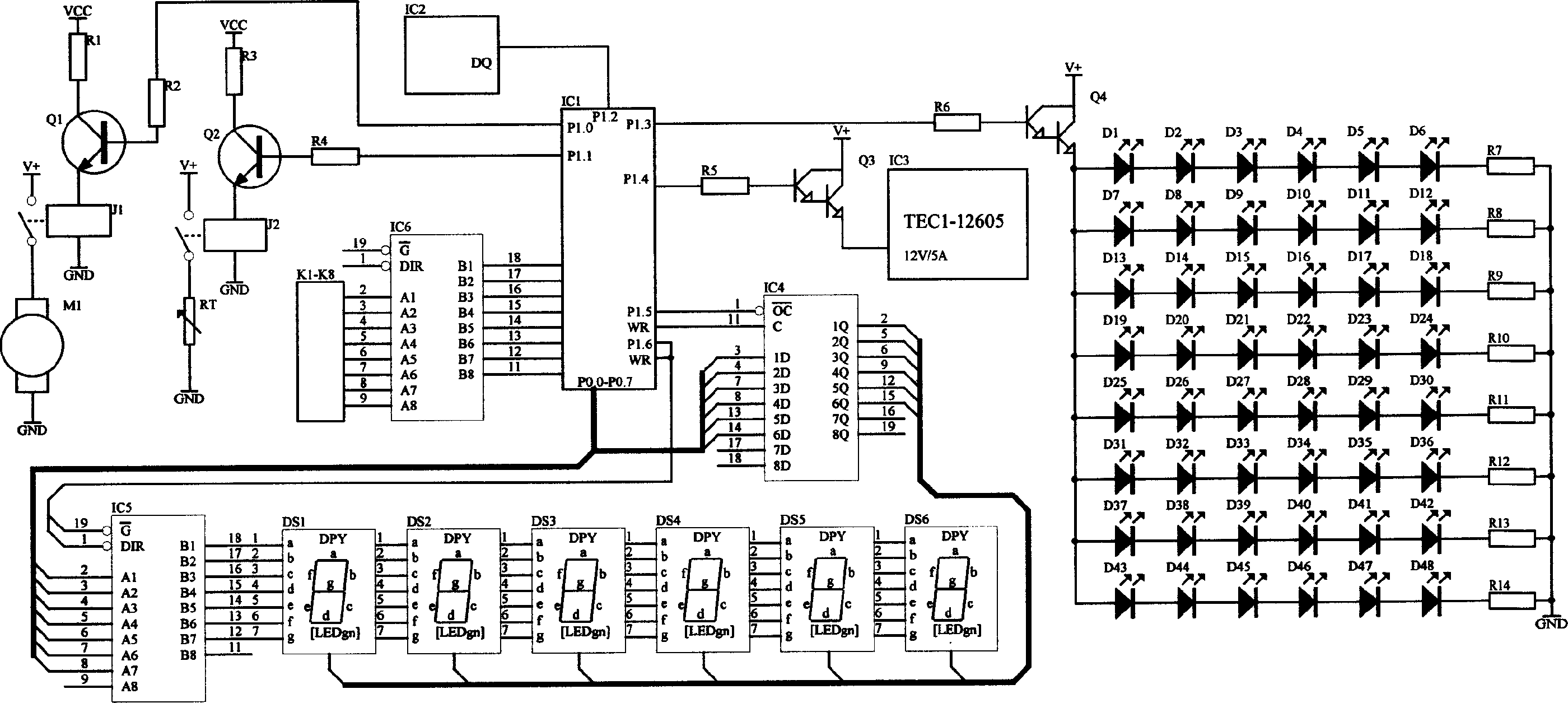

Plant growing controller with high power luminous diode light source

InactiveCN1586126AIt has the function of heating and controlling the ambient temperatureAmbient temperature measurement and displaySaving energy measuresGreenhouse cultivationMicrocomputerGrowth plant

The plant growth controller with great power LED light source has light source in the wavelength suitable for plant to grow, and can measure and control temperature and show temperature. It consists of lamp socket, power source socket, lamp shade, semiconductor refrigerating element, circuit board and LEDs. The circuit board has light source circuit, semiconductor refrigerator circuit, microcomputer circuit, temperature measuring circuit, heating circuit, blowing control circuit, display circuit and keyboard circuit. The present invention has the function of heating and controlling environment temperature, can measure and show temperature, and has LED light source with great power and selectable wavelength, semiconductor refrigerating function and high LED light emitting efficiency.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Light emitting device

ActiveCN103779471AIncrease luminous fluxImprove reliabilityPoint-like light sourceSolid-state devicesLighting systemLight emitting device

Disclosed are a light emitting device, a method of manufacturing the same, a light emitting device package, and a lighting system. The light emitting device includes a substrate, a first conductive semiconductor layer on the substrate, an active layer on the first conductive semiconductor layer, a second conductive semiconductor layer on the active layer, a first via electrode to make contact with the first conductive semiconductor layer through a via hole formed through the substrate, and a second via electrode to make contact with the second conductive semiconductor layer through a second via hole formed through the substrate, the first conductive semiconductor layer, and the active layer.

Owner:SUZHOU LEKIN SEMICON CO LTD

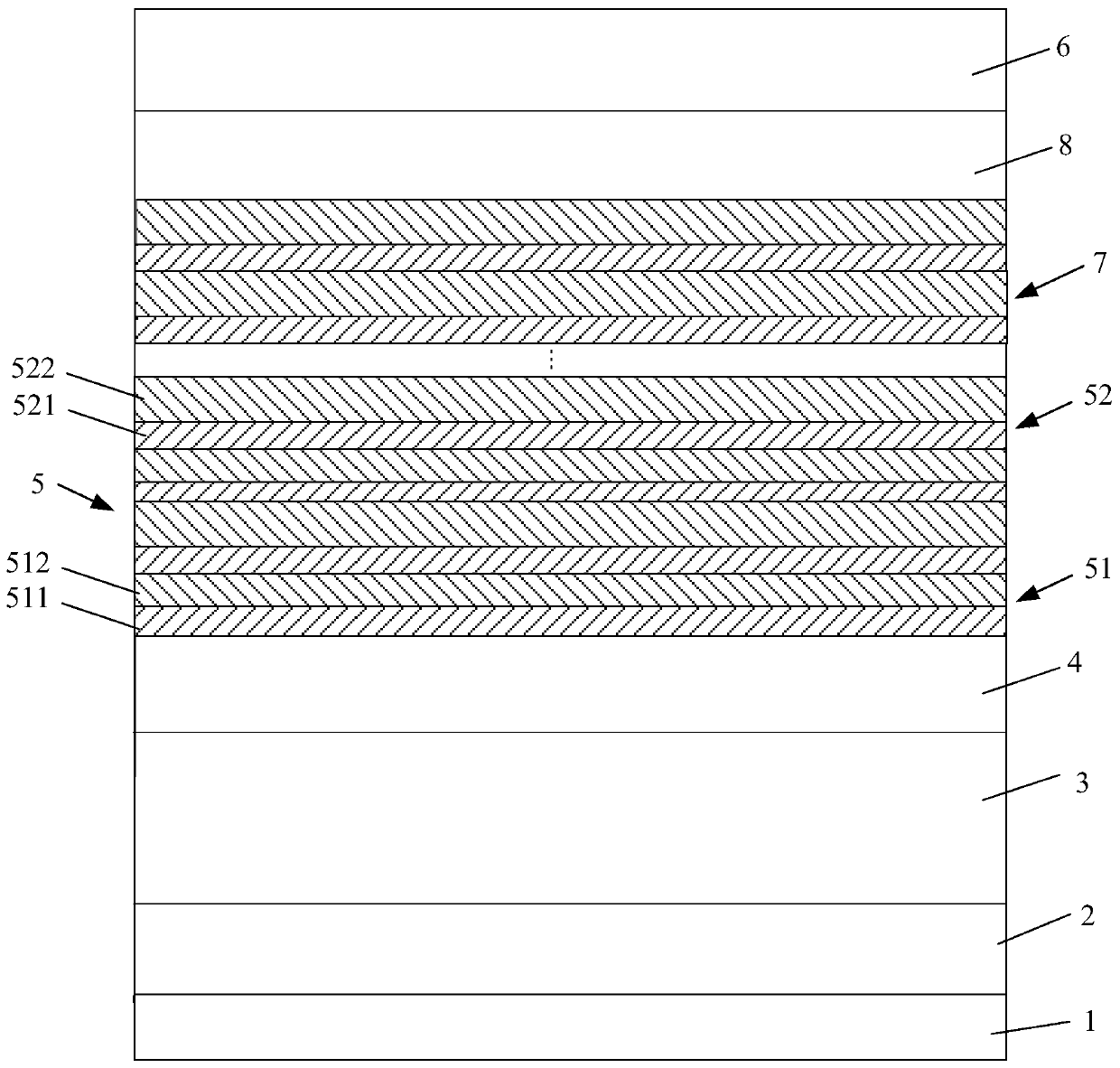

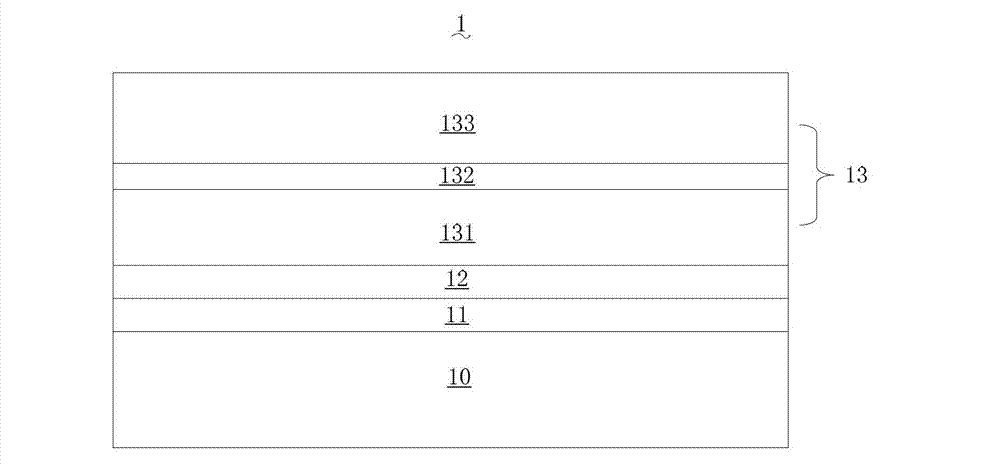

Light-emitting diode epitaxial wafer and preparation method thereof

ActiveCN111048631AGuaranteed luminous efficiencyShorten the timeSemiconductor devicesElectron holeLight-emitting diode

The invention discloses a light-emitting diode epitaxial wafer and a preparation method thereof, and belongs to the technical field of light-emitting diodes. An InGaN / GaN multi-quantum well layer in the light-emitting diode epitaxial wafer is arranged to comprise a plurality of first composite units and a plurality of second composite units which are alternately stacked, wherein the first composite unit comprises a first InGaN well layer and a first GaN barrier layer which are stacked; the second composite unit comprises a second InGaN well layer and a second GaN barrier layer which are stacked; the thickness of the first InGaN well layer is less than that of the second InGaN well layer; the second InGaN well layer ensures the luminous efficiency of the InGaN / GaN multi-quantum well layer;and the first InGaN well layer with the thickness being less than that of the second InGaN well layer can reduce the In content in the second InGaN well layer while the luminous efficiency is ensured,and the polarization effect caused by the first InGaN well layer is reduced. The second GaN barrier layer with the thickness being greater than that of the first GaN barrier layer is arranged to playa role in blocking electrons, the number of electrons and holes compounded in the InGaN / GaN multi-quantum well layer is ensured, and the light-emitting effect of the InGaN / GaN multi-quantum well layer is integrally improved.

Owner:HC SEMITEK SUZHOU

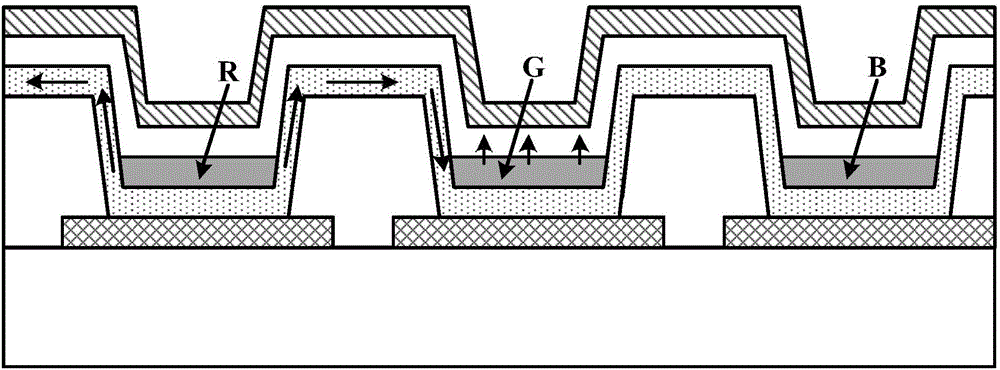

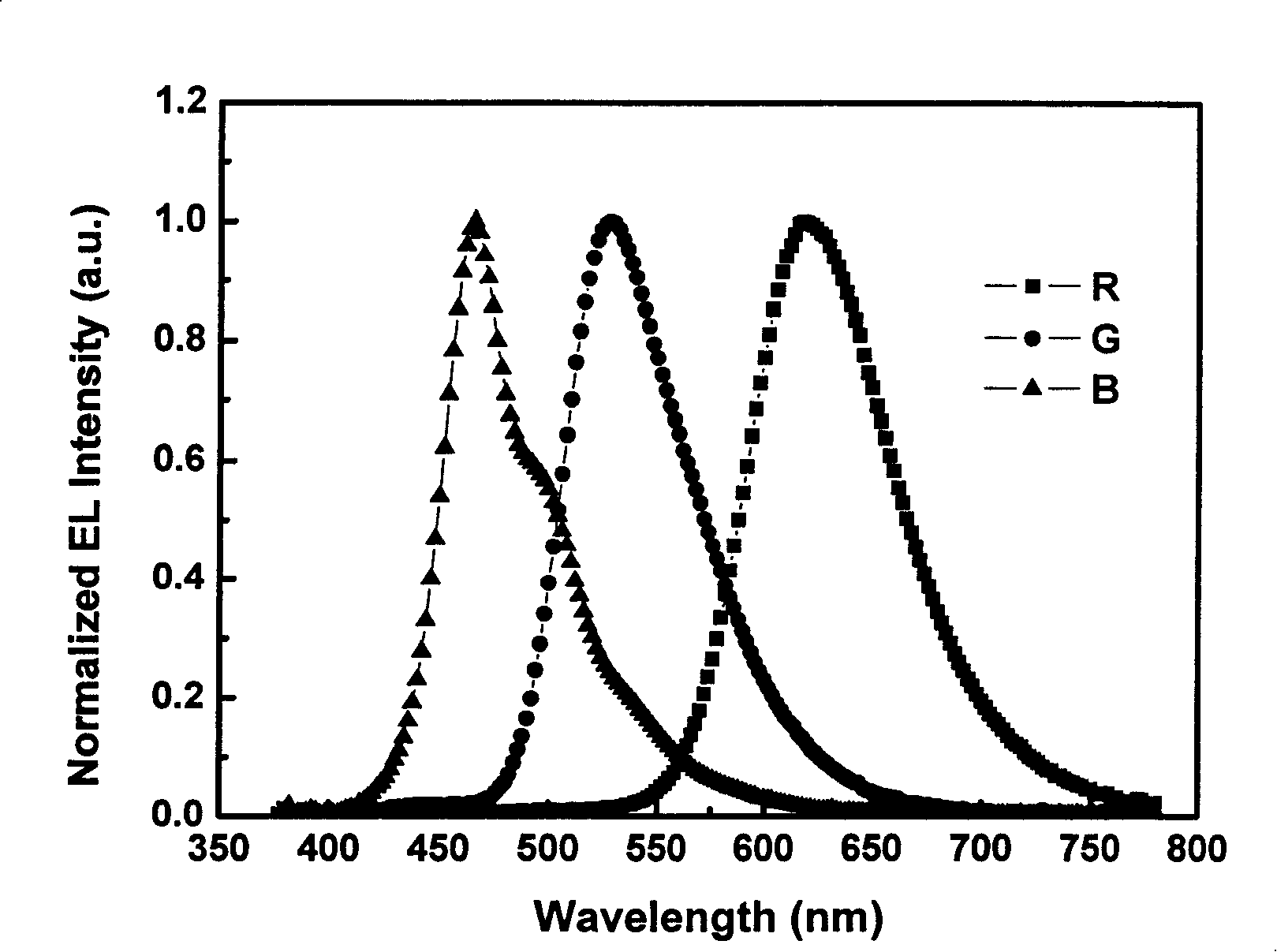

Organic electroluminescent display device and method of manufacture

InactiveCN101211960ASimple processLow investment costSolid-state devicesSemiconductor/solid-state device manufacturingState of artHole injection layer

The invention discloses an organically electroluminescent display device and a manufacture method thereof, which relates to a technical field of an electron display device. The technical issues to be solved are accelerating luminescent efficiency of the device and improving stability of the device. The luminescent device comprises a cathode layer, an electron organic-function layer including an electron injection layer and an electron transport layer, a luminescent layer with three colors of the red, green and blue (RGB), a hole organic-function layer including a hole transport layer and a hole injection layer and an anode layer from the upper part to the lower part. The invention is characterized in that in the luminescent layer, luminescent main material with same wide energy level is adopted by at least two primary colors; at the same time, luminescent guest material with different primary colors are respectively and correspondingly doped to realize the organically electroluminescent display with different colors. The invention solves the energy level matching problems caused by adopting different material in the three primary colors RGB in the prior art, accelerates the luminescent efficiency, and improves the stability of the device; the invention has the advantages of simple process, low cost and high yield.

Owner:INESA ELECTRON

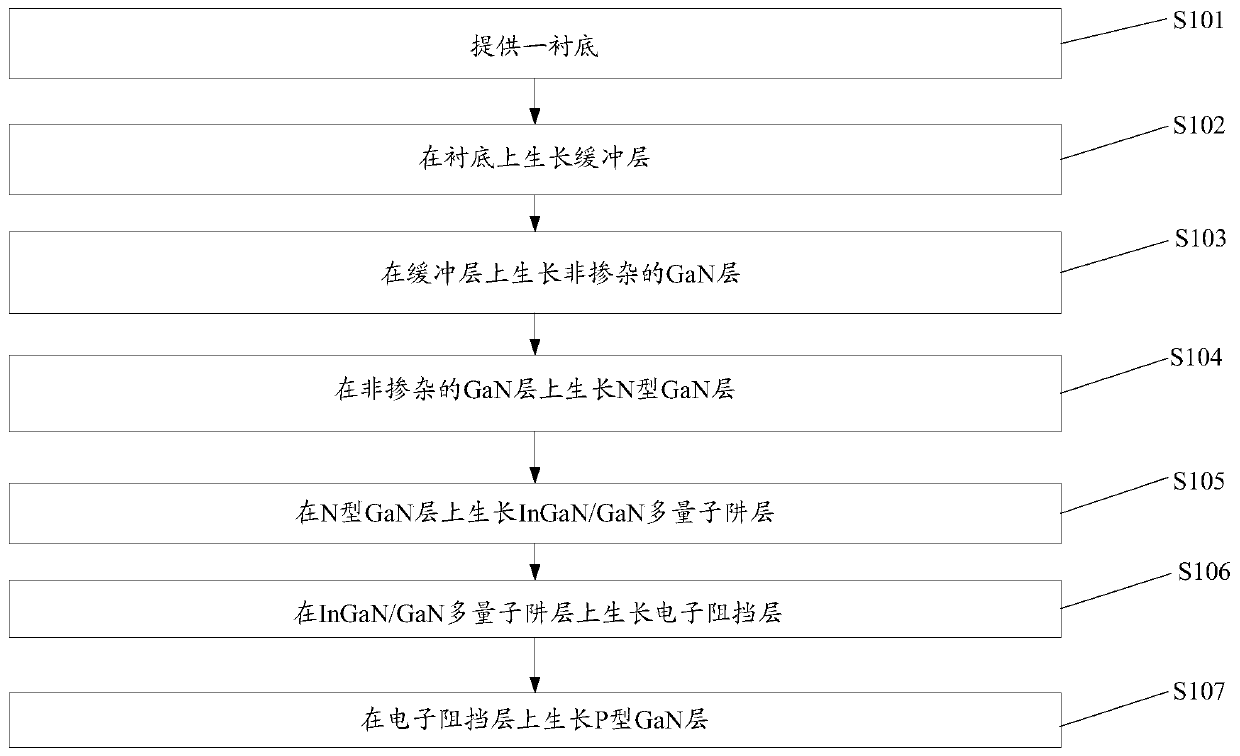

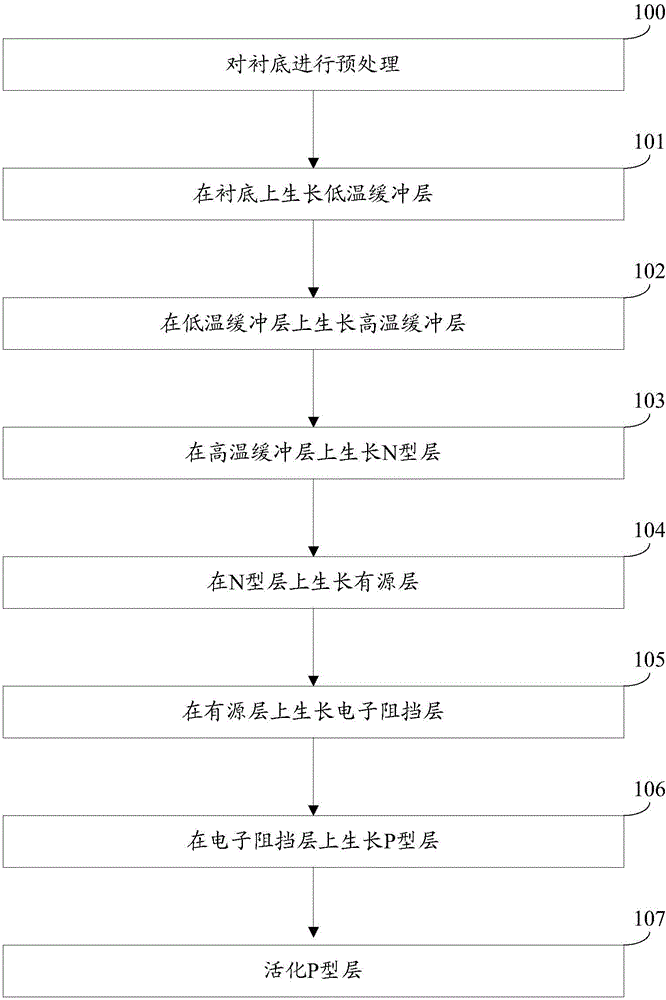

Growth method for light-emitting diode epitaxial wafer

ActiveCN105957927AReduced activityIncorporating efficiency benefitsSemiconductor devicesQuantum wellHigh pressure

The invention discloses a growth method for a light-emitting diode epitaxial wafer, and belongs to the technical field of semiconductors. The method comprises the step: sequentially growing a low-temperature buffering layer, a high-temperature buffering layer, an N-type layer, an active layer, an electronic blocking layer and a P-type layer on a substrate. The active layer comprises a first sub-layer and a second sub-layer, and the growth atmospheres of a quantum well layer in the first sub-layer, a quantum barrier layer in the first sub-layer, a quantum well layer in the second sub-layer and a quantum barrier layer in the second sub-layer are sequentially N2 and H2 mixed gas, pure H2, pure N2, and N2 and H2 mixed gas. The quantum well layer in the first sub-layer employs a variable pressure and variable temperature growth mode, and the quantum barrier layer in the first sub-layer employs a high-pressure and high-temperature growth mode. The quantum well layer in the second sub-layer employs a low-pressure and low-temperature growth mode, and the quantum barrier layer in the second sub-layer employs a variable pressure growth mode. The quantum barrier layer in the first sub-layer employs trimethyl gallium as a gallium source. The method improves the light-emitting efficiency.

Owner:HC SEMITEK SUZHOU

LED (Light-Emitting Diode) epitaxial structure and preparation method thereof

InactiveCN103078017AGood shielding effectGuaranteed luminous efficiencySemiconductor devicesGallium nitrideQuantum well

The invention relates to an LED (Light-Emitting Diode) epitaxial structure, which comprises a substrate, a buffer layer, a sacrificial layer, an N type gallium nitride layer, a quantum well layer and a P type gallium nitride layer which are sequentially arranged from bottom to top, wherein a light shielding layer is also arranged between the sacrificial layer and the quantum well layer, and the light shielding layer is one layer or multiple layers of graph-free membranes, or the light shielding layer comprises a plurality of graphical sub light shielding layers and connecting layers; and the graphs of the sub light shielding layers are mutually matched, so that laser incident from the substrate direction can be blocked by the sub light shielding layers when the substrate is subjected to laser lift-off. Meanwhile, the invention provides a preparation method of the LED epitaxial structure. When the substrate of the LED epitaxial structure is subjected to laser lift-off, the light shielding layer reduces or blocks the laser to penetrate through the light shielding layer to reach the quantum well layer.

Owner:BRILLIANT LIGHT TECH

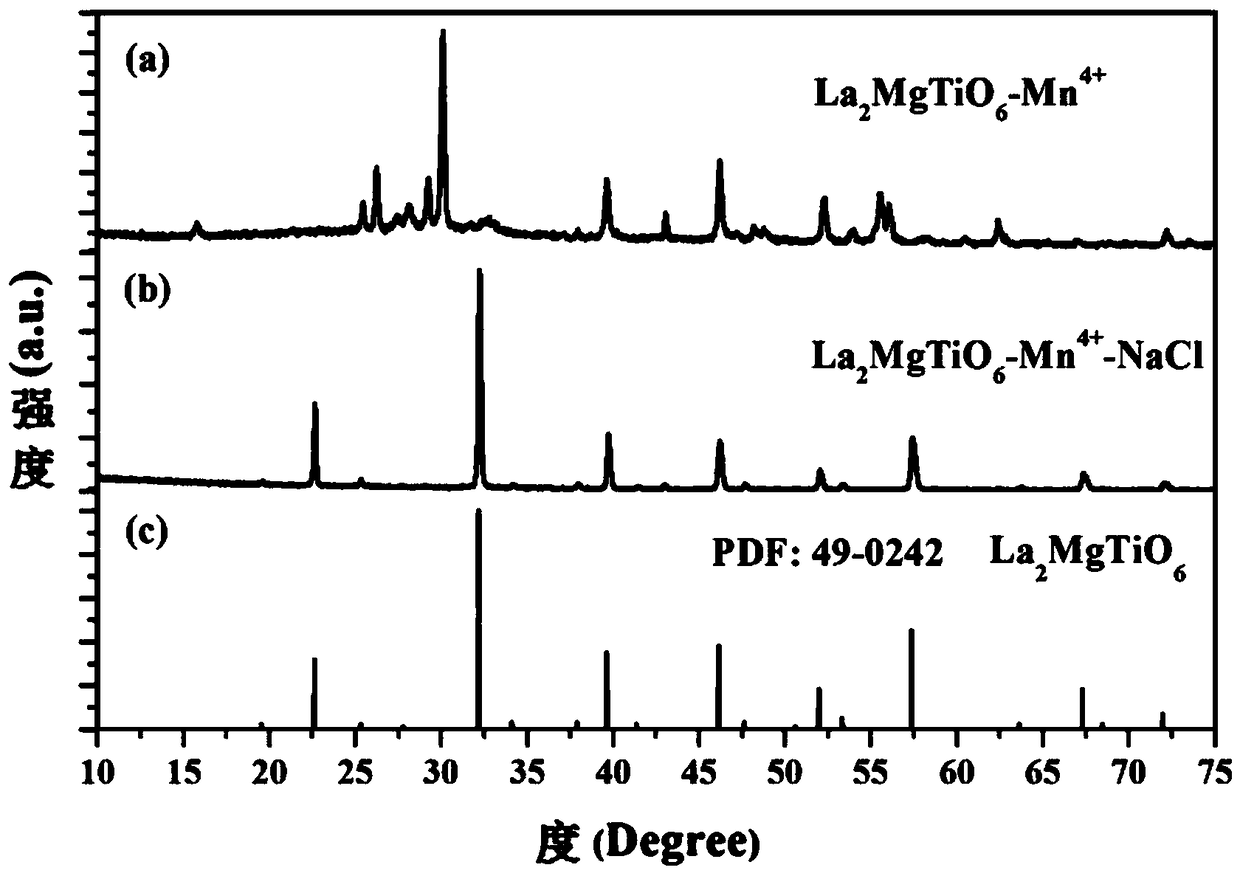

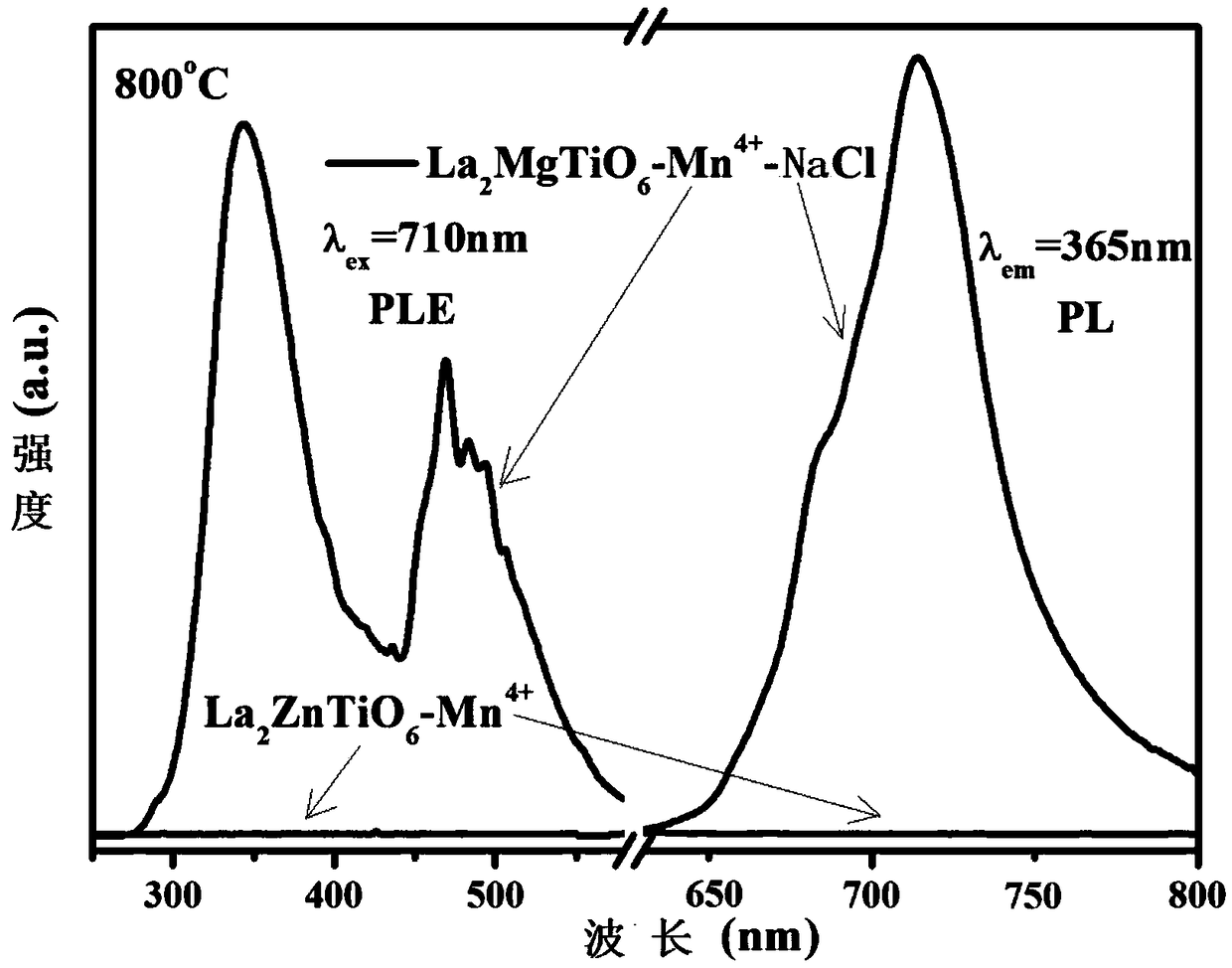

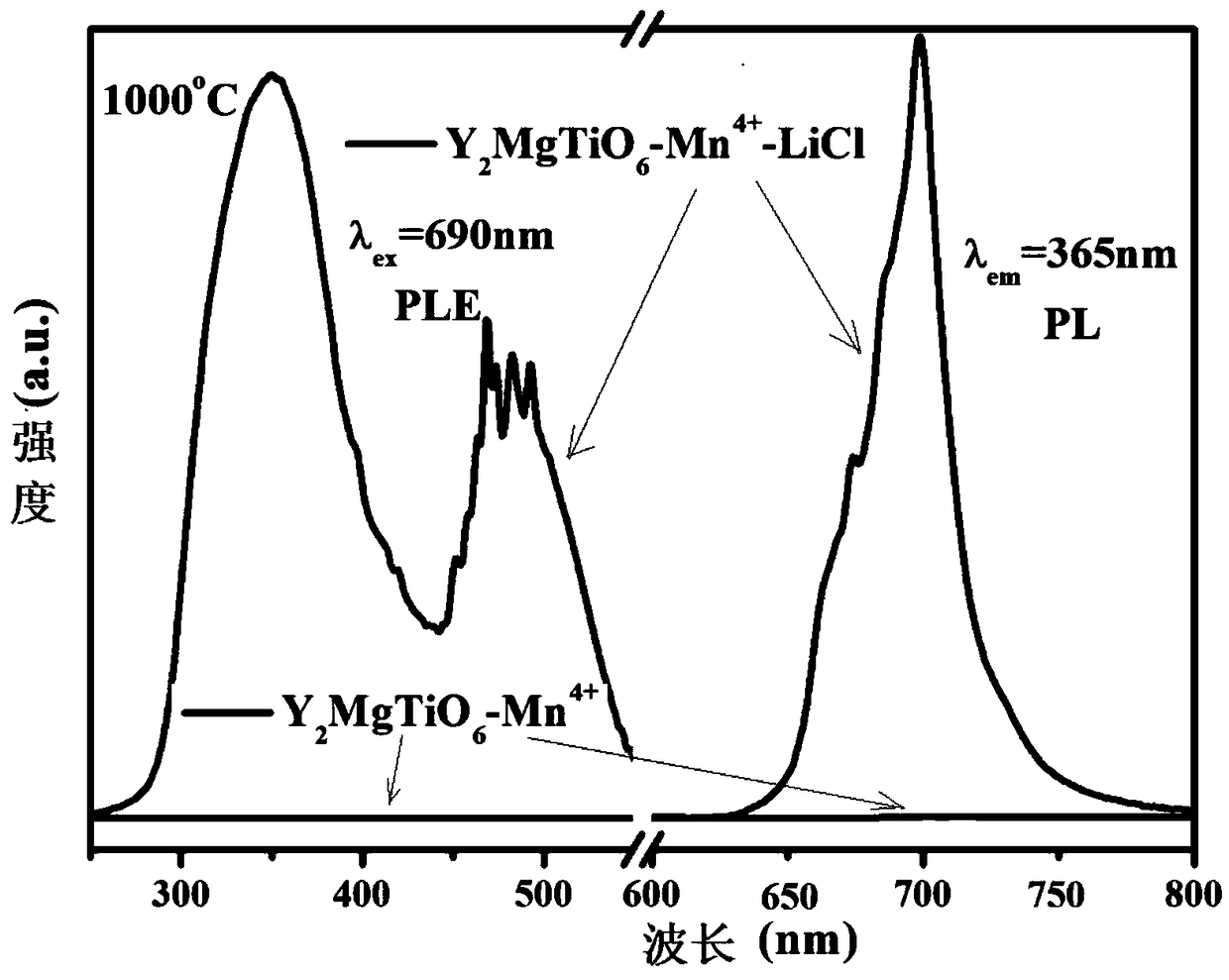

Method for preparing manganese-doped double-perovskite red fluorescent powder

ActiveCN108753294ACalcination temperature is lowReduce manufacturing costLuminescent compositionsEmission efficiencyPlant growth

The invention relates to the technical field of fluorescent powder preparation and in particular relates to a method for preparing manganese-doped double-perovskite red fluorescent powder. According to the method, chlorides (LiCl, NaCl and KCl) are creatively adopted as cosolvents, and the manganese-doped double-perovskite red fluorescent powder is synthesized under the action of the cosolvents. Compared with a calcination temperature of 1400 DEG C in the prior art, a temperature of only 800-1000 DEG C is need in the method, so that the production cost can be greatly reduced; on the other hand, compared with the prior art that the red light emission efficiency is seriously affected as the calcination temperature is reduced, the red light emission efficiency of the method is not reduced while the calcination temperature is reduced, the calcination temperature can be reduced while the red light emission efficiency is ensured, the characteristic is very unique, and as lamp fluorescent powder, the fluorescent powder can be applied to the field of LED (Light Emitting Diode) lighting and plant growth assistance artificial light sources.

Owner:JIANGXI UNIV OF SCI & TECH

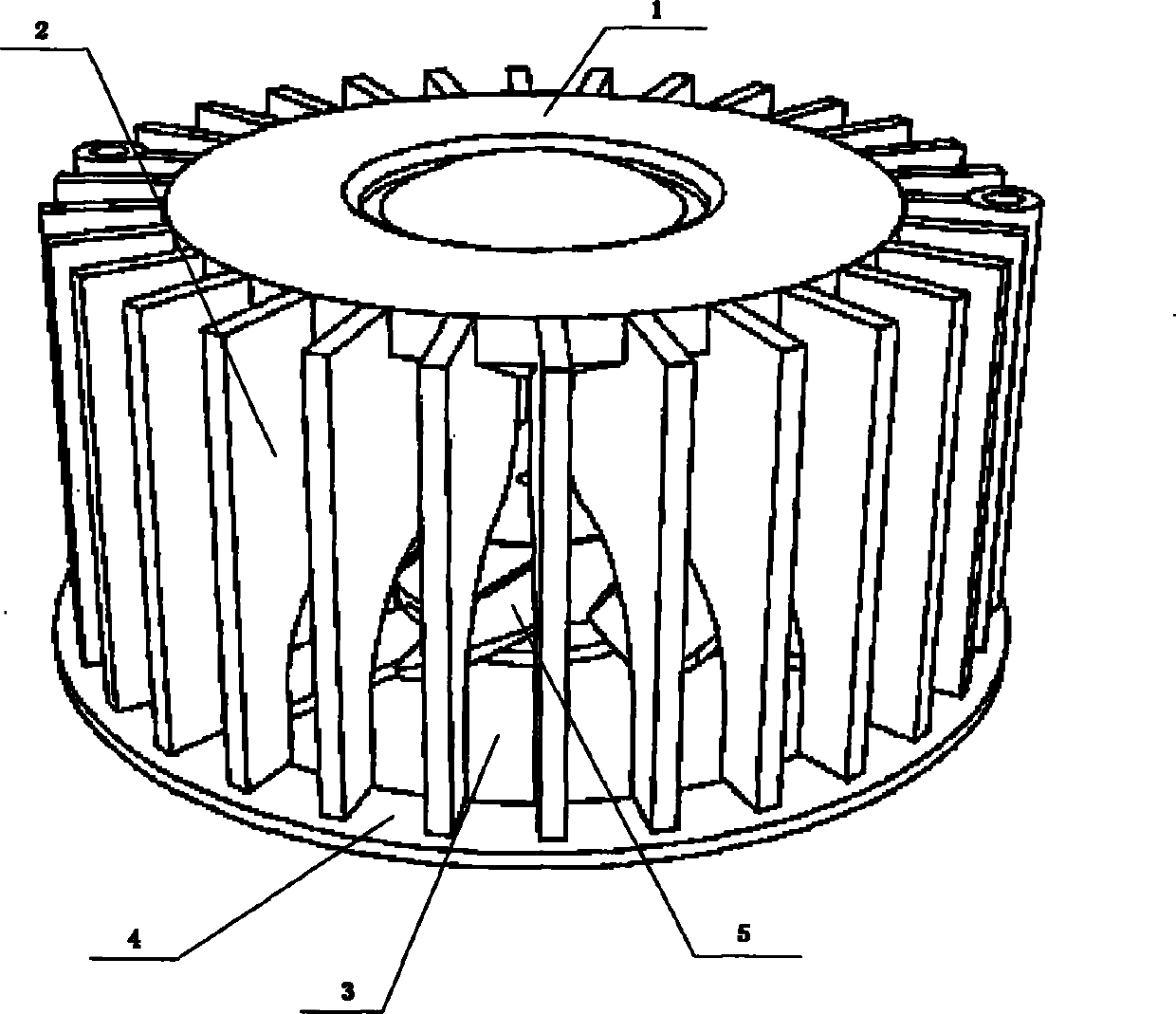

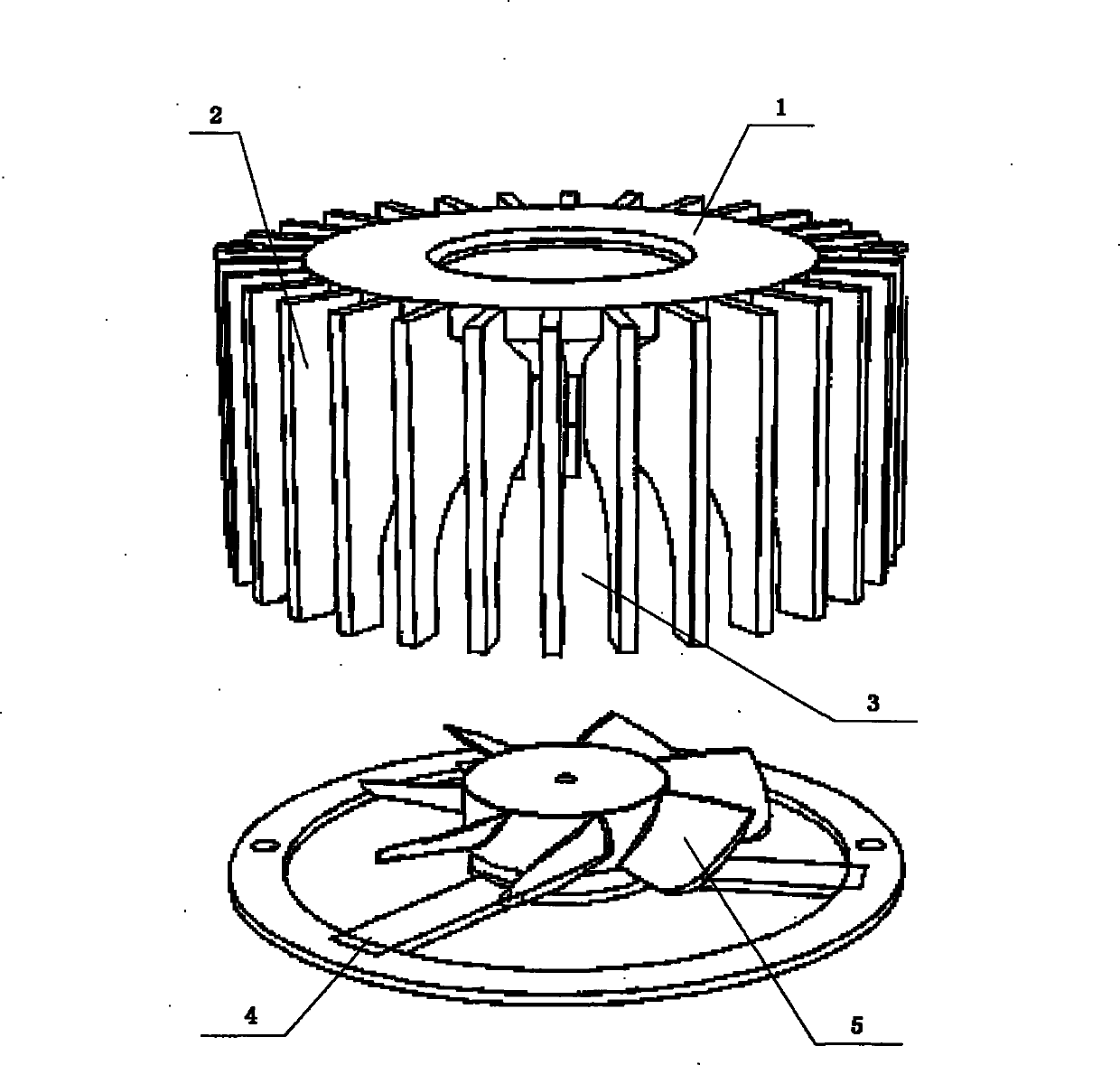

Radiator of LED (light emitting diode)

InactiveCN102200265ANot easy to accumulateGuaranteed luminous efficiencyPoint-like light sourceLighting heating/cooling arrangementsEngineeringHeat sink

The invention discloses a radiator of an LED (light emitting diode). The radiator comprises a heat sink and a rib, wherein the heat sink is of a hollow cylindrical structure; the rib is arranged on the outer side wall of the heat sink; the heat sink and the rib are integrated structurally; the rib is arranged longitudinally along a sink cylinder; the length of the rib is greater than the height of the heat sink cylinder; and the end surface of the rib exposed to the heat sink is also provided with a radiating fan. The back part of the heat sink of the radiator for the LED is difficult to collect dust, and the radiation efficiency is improved effectively.

Owner:泰州赛龙电子有限公司

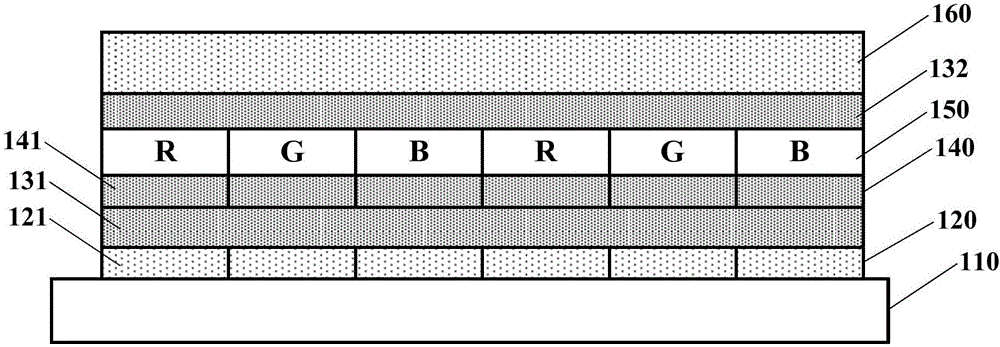

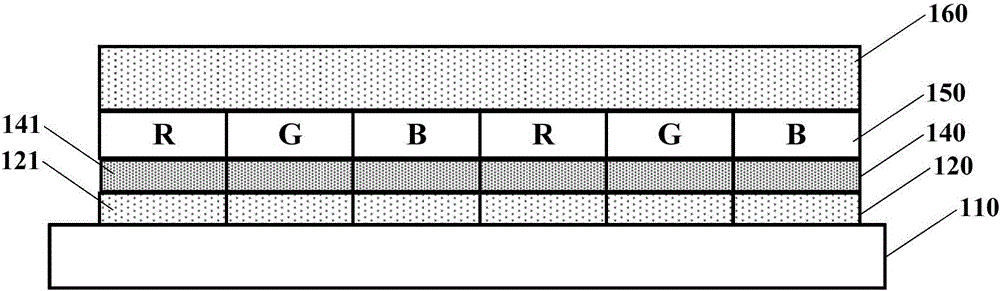

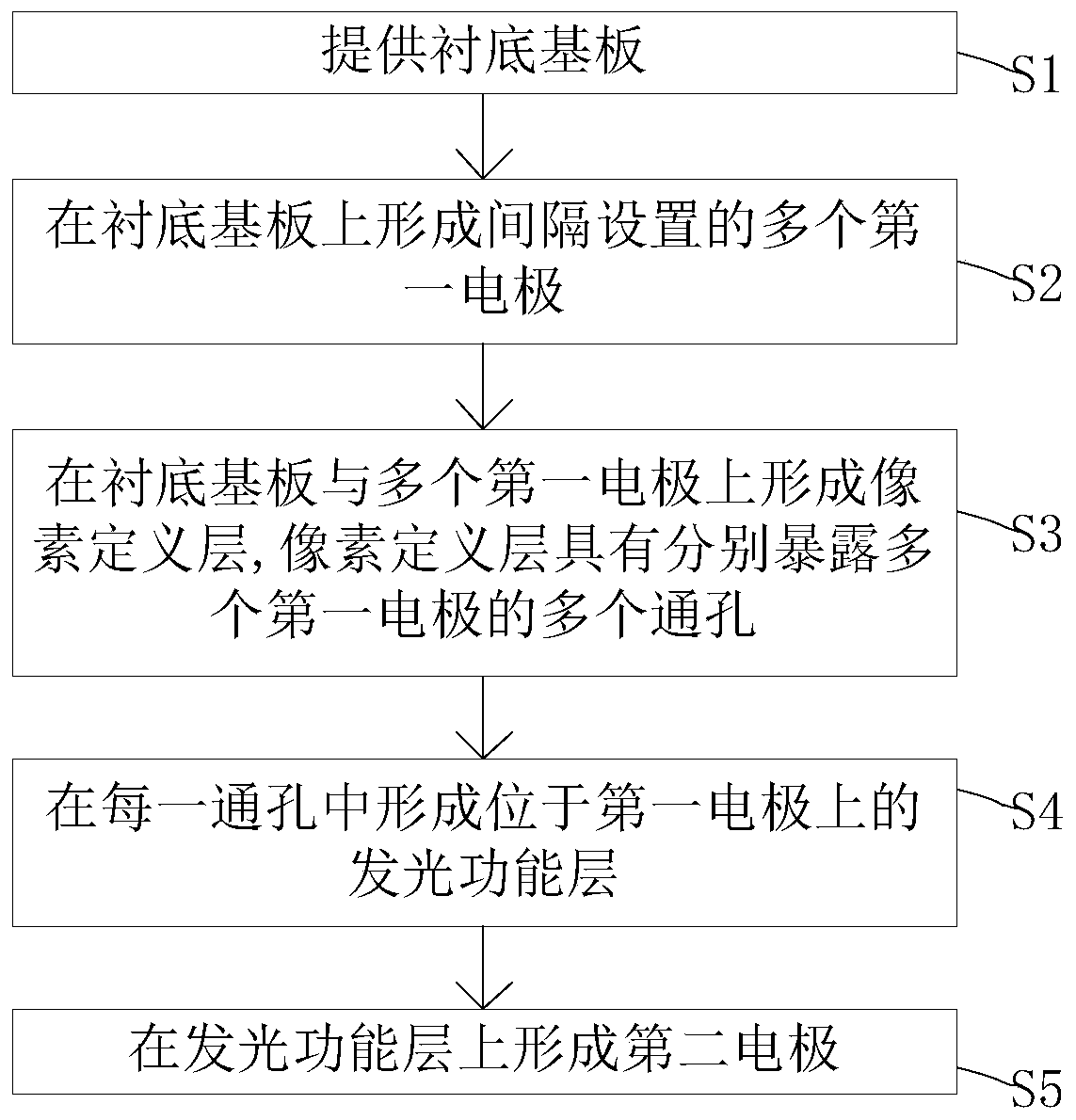

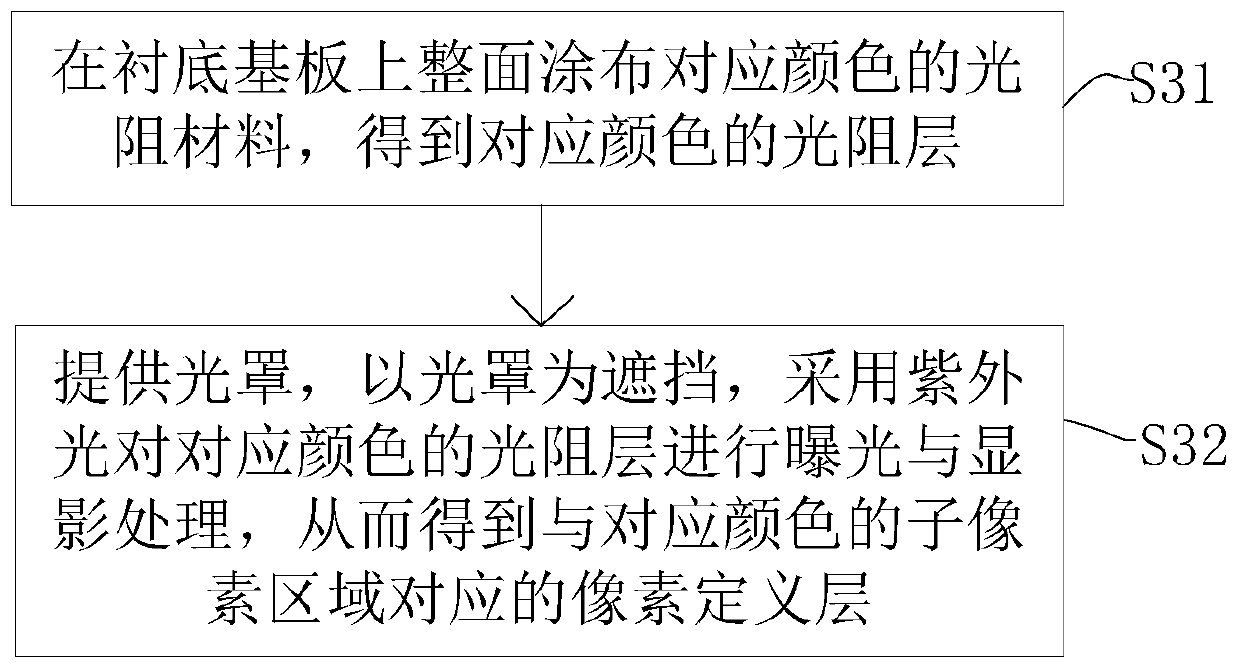

OLED substrate, production method of OLED substrate and flexible display device

InactiveCN109768180AGuaranteed luminous efficiencySolve the problem of color castSolid-state devicesSemiconductor/solid-state device manufacturingFilter materialFlexible display

The invention is applicable to the field of display technology and provides an OLED substrate, a production method of the OLED substrate and a flexible display device. The OLED substrate comprises a substrate body, multiple first electrodes and a pixel definition layer, wherein the pixel definition layer is provided with multiple through holes which respectively and correspondingly expose part ofthe multiple first electrodes; the substrate body comprises multiple pixel regions, wherein each pixel region comprises a first sub-pixel region, a second sub-pixel region and a third sub-pixel region, and the multiple through holes are located in the multiple sub-pixel regions respectively; and the pixel definition layer comprises first color-filtering layers, second color-filtering layers and third color-filtering layers corresponding to the first sub-pixel regions, the second sub-pixel regions and the third sub-pixel regions respectively, and the first color-filtering layers, the second color-filtering layers and the third color-filtering layers are made of a color-filtering material in a first color, a color-filtering material in a second color and a color-filtering material in a thirdcolor respectively. Through the OLED substrate, the technical problems of color cast, low light-emitting efficiency and high production cost of an existing OLED device can be solved.

Owner:CPT TECH GRP

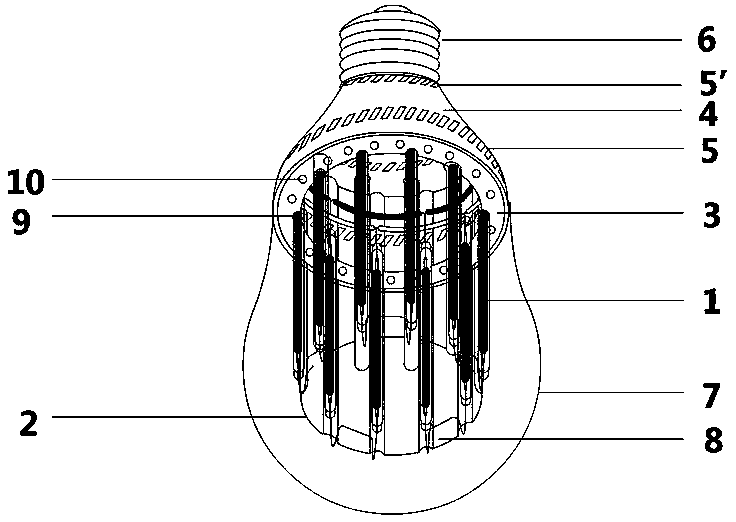

LED filament bulb

ActiveCN104033774ASolve the cooling problemGuaranteed luminous efficiencyPoint-like light sourceElectric circuit arrangementsEngineeringHeat sink

The invention relates to an LED filament bulb comprising an inner heat sink made of a transparent tube. LED light-emitting elements are arranged on the outer surface or inner surface of the transparent tube. The transparent tube serves as the inner heat sink; the LED light-emitting elements are disposed on the transparent tube; heat produced by the LED light-emitting elements is dissipated in manners, such as heat conduction, heat radiation and heat convection, and cooling is achieved. The problem that the traditional heat sink is poor in radiating performance is solved, and photoelectric indexes, such as luminous efficiency, light maintenance rate and service life, of the LED filament bulb assembled in a transparent manner are guaranteed effectively.

Owner:连云港晶德照明电器有限公司

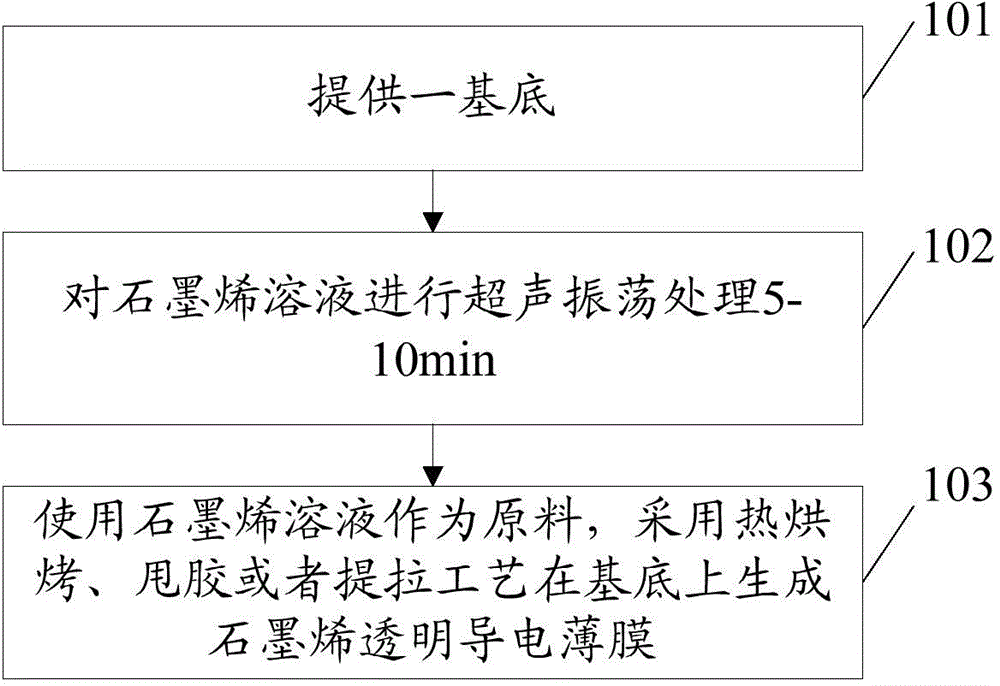

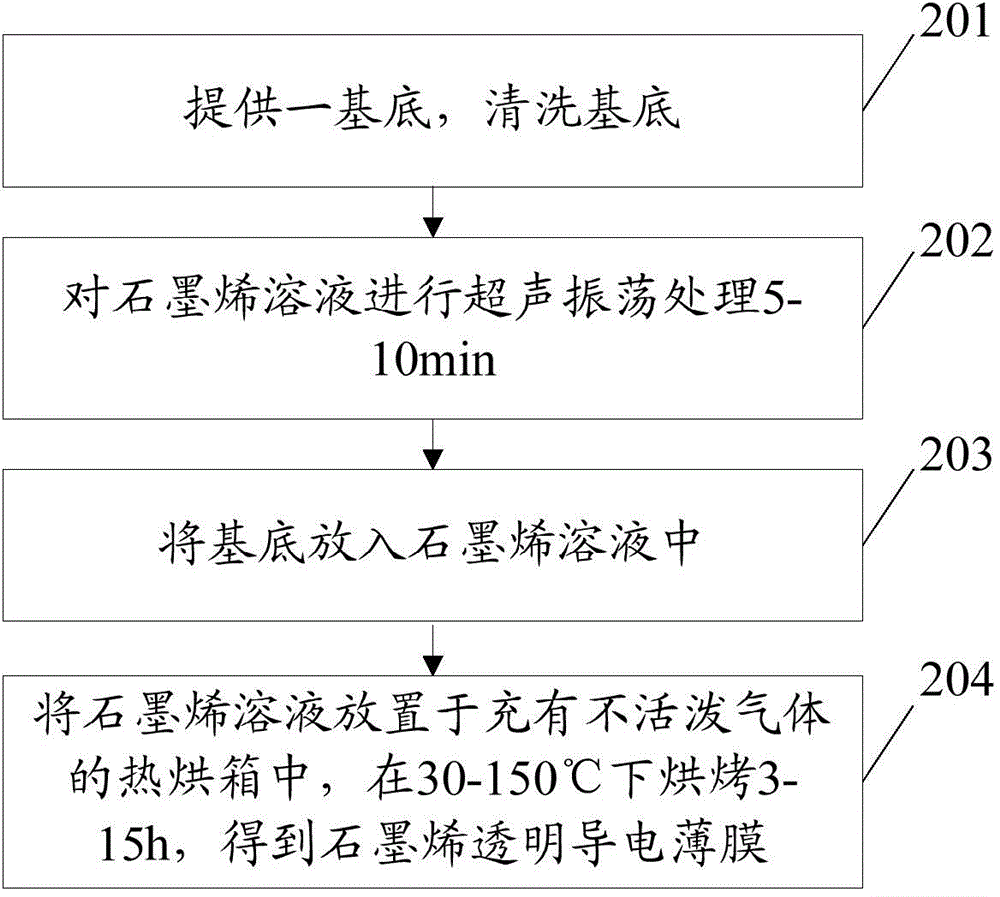

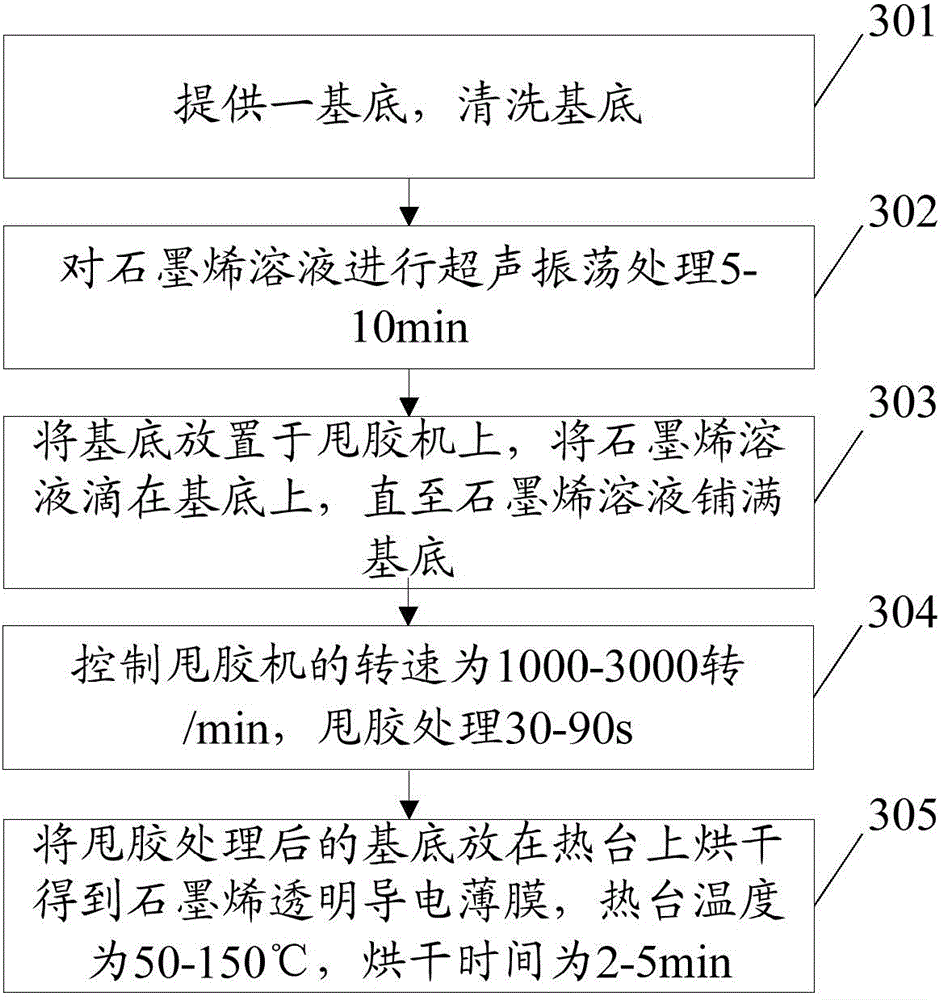

Transparent electroconductive film preparation method

InactiveCN104953001AGuaranteed luminous efficiencyLow costSemiconductor devicesCooking & bakingDip-coating

The invention discloses a transparent electroconductive film preparation method and belongs to the field of light-emitting diodes. The method includes: providing a substrate; subjecting a graphene solution to ultrasonic oscillation treatment for 5-10 minutes, wherein the concentration of the graphene solution is 1-10mg / L; using the graphene solution as a raw material, and generating the transparent graphene electroconductive film on the substrate by a heat baking technology, a whirl coating technology or a dip coating technology. The transparent electroconductive film preparation method has the advantages that the graphene solution is used as the raw material during preparation, thereby being lower than ITO (indium tin oxide) in cost; the transparent graphene electroconductive film is prepared by the heat baking technology, whirl coating technology or dip coating technology, and accordingly, the method is simple in used equipment, low in requirement on environments such as temperature and pressure and low in processing cost; the transparent graphene electroconductive film cannot absorb photons released by an active region, so that light-emitting efficiency of an LED chip is guaranteed.

Owner:HC SEMITEK SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com