Growth method for light-emitting diode epitaxial wafer

A technology of light-emitting diodes and growth methods, which is applied in the field of growth of light-emitting diode epitaxial wafers, can solve the problems of low LED luminous efficiency, and achieve the effects of improving luminous efficiency, crystal quality, and crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

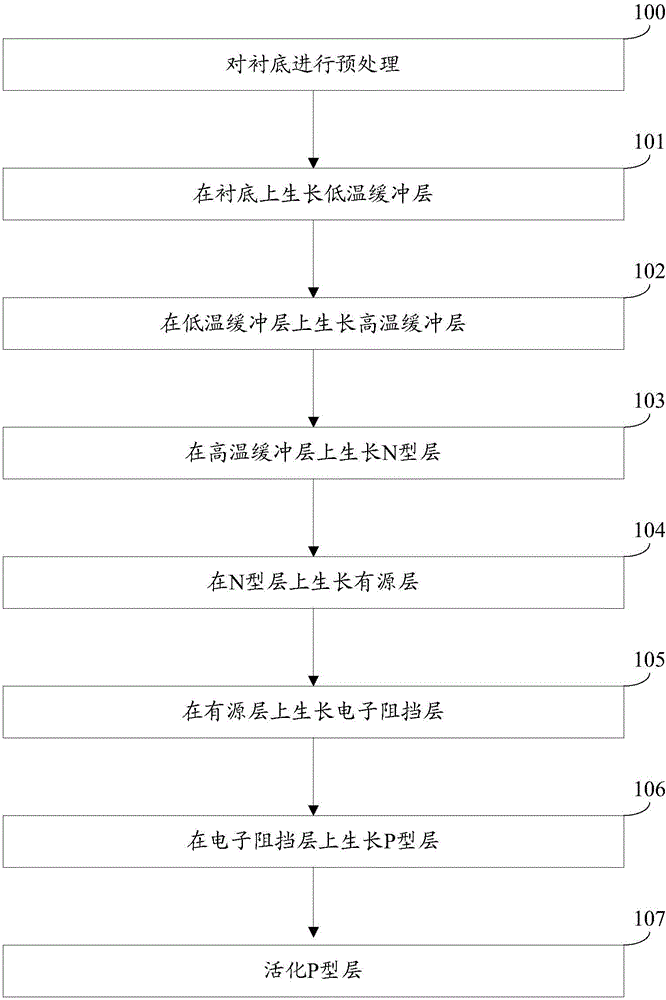

[0025] An embodiment of the present invention provides a method for growing a light-emitting diode epitaxial wafer, see figure 1 , the growth method includes:

[0026] Step 100: Perform pretreatment on the substrate.

[0027] In this embodiment, the substrate is a sapphire substrate.

[0028] Specifically, this step 100 may include:

[0029] Under a hydrogen atmosphere, treat the substrate at a high temperature for 5 min to 6 min. Wherein, the temperature of the reaction chamber is 1000° C. to 1100° C., and the pressure of the reaction chamber is controlled at 200 torr to 500 torr.

[0030] In this embodiment, a Veeco K465i or C4 metal organic chemical vapor deposition (Metal Organic Chemical Vapor Deposition, MOCVD) equipment is used to realize the LED growth method. Using high-purity hydrogen (H 2 ), high-purity nitrogen (N 2 ) or high purity H 2 and high purity N 2 The mixed gas as the carrier gas, high-purity NH 3 As the N source, trimethylgallium (TMGa) and triet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com