Light-emitting diode chip and preparation method thereof

A technology of light-emitting diodes and chips, which is applied in the manufacturing of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of non-separation of thermoelectricity, unfavorable chip heat dissipation, etc., to reduce light loss, improve heat dissipation effect, reduce absorption or reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

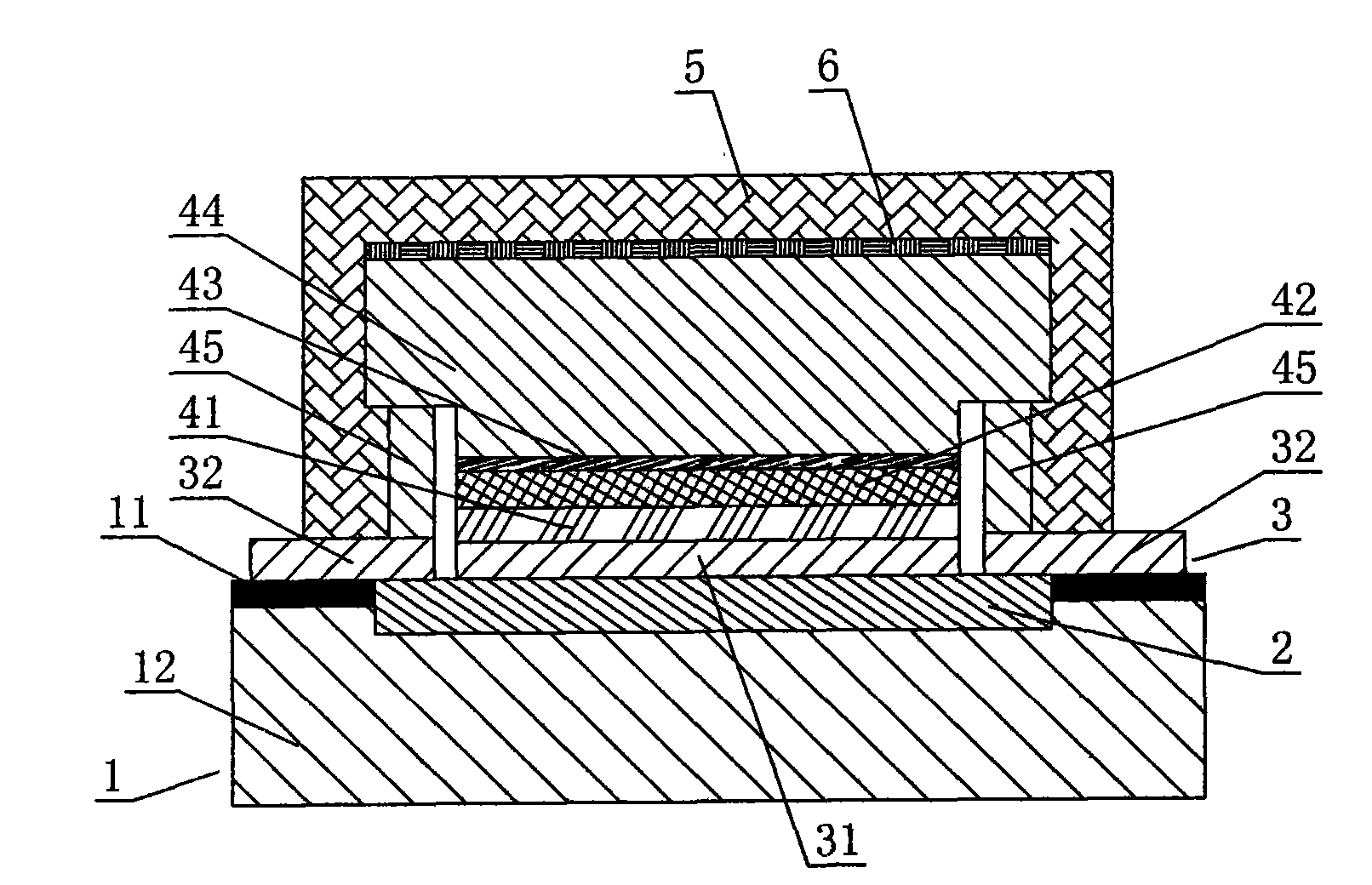

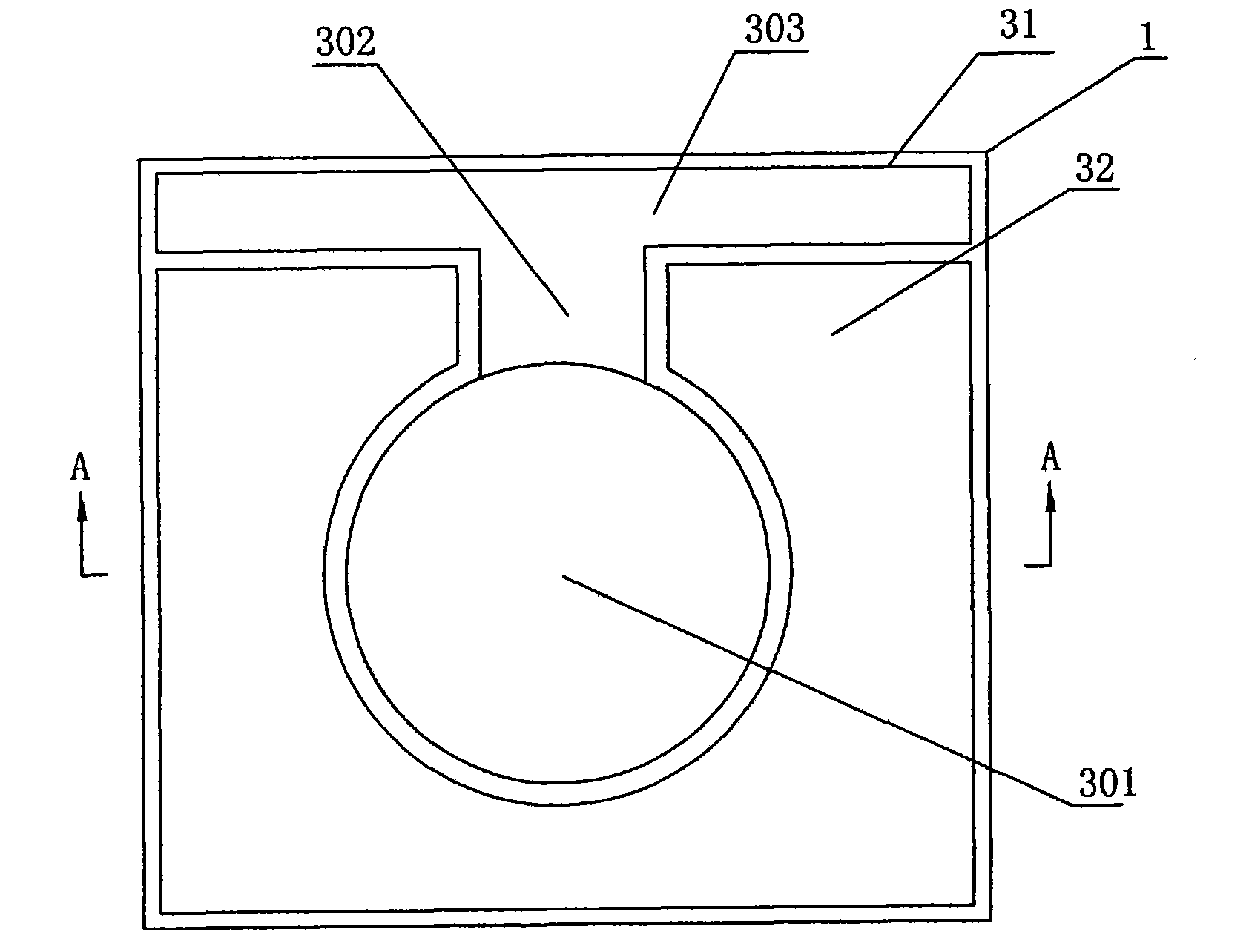

[0061] Embodiment I: first refer to figure 1 and Figure 1A-Figure 1G A method of manufacturing a light emitting diode chip according to an embodiment of the present invention is described. Such as Figure 1A , Figure 1B As shown, a heat sink substrate 1 with an insulating layer on the upper surface is first prepared, and then a metal bonding layer 3 is formed on the upper surface of the heat sink substrate 1 by methods such as sputtering and electroplating, and the metal bonding layer 3 is patterned as A first bonding layer 31 and a second bonding layer 32 isolated from each other are formed, wherein the first bonding layer 31 includes a circular central portion 301 and a ring extending outward from one side of the circular central portion 301 for connecting with a circumscribed The lead-out part 302 and the welding wire part 303 connected by the power line, the second bonding layer 32 surrounds the surrounding position of the first bonding layer 31 in an incomplete manne...

Embodiment II

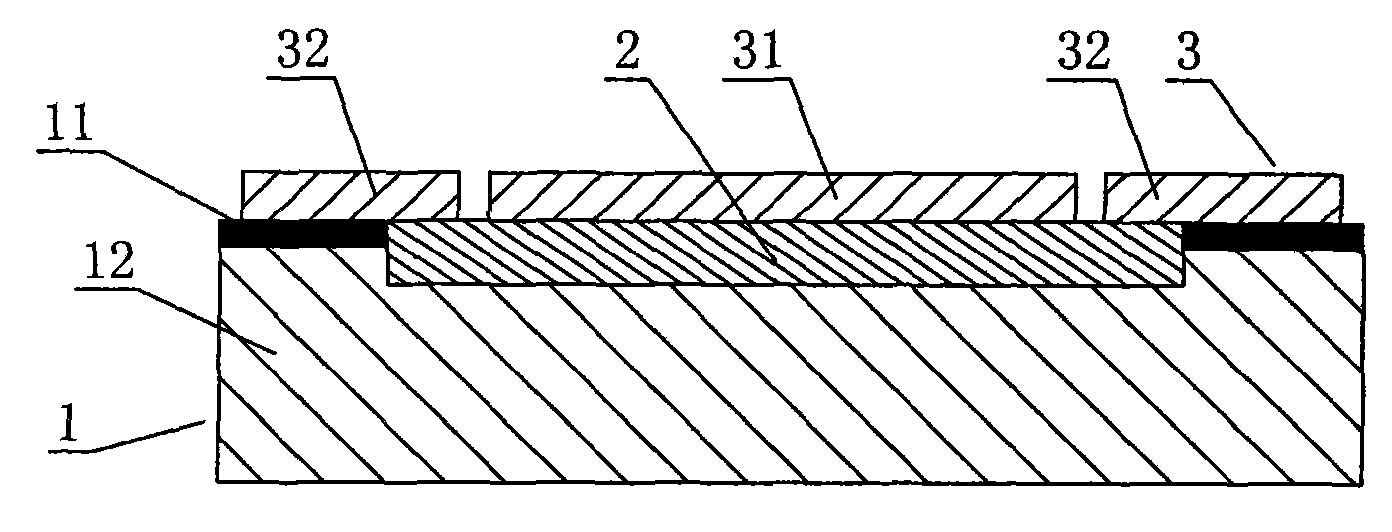

[0066] Embodiment II: as figure 2 and 2A - Figure 2F shown, refer to Figure 2A , Figure 2B , first prepare the heat sink substrate 1 with the insulating layer 11 on the upper surface. A metal bonding layer is formed on the upper surface of the heat sink substrate 1 by methods such as sputtering and electroplating, and the metal bonding layer is patterned into a first bonding layer 31 formed on the left part and a second bonding layer on the right part. 32, the first bonding layer 31 and the second bonding layer 32 are isolated from each other. The material of the metal bonding layer 3 is selected from Al, Ag, Pt, Cr, Mo, W, Au, Cu, Ni, BeAu or combinations thereof. Optionally, an electrostatic discharge ESD layer 2 of double Zener diodes can also be formed on the upper surface of the heat sink substrate 1, such as Figure 1B shown. The preferred manufacturing method of the above-mentioned heat sink substrate 1 is: first make the bottom plate 12 of the heat sink subs...

Embodiment III

[0072] Embodiment III: as image 3 and Figure 3A-3D As shown, the present invention also provides a method for manufacturing a high-power light-emitting diode chip. refer to Figure 3A Firstly, a heat sink substrate 1 with an insulating layer on the upper surface is prepared. Then, on the upper surface of the heat sink substrate 1, a metal bonding layer 3 is formed by methods such as sputtering and electroplating, and the metal bonding layer 3 is patterned into a first bonding layer 31 and a second bonding layer 31 that are separated from each other and interspersed with each other. The bonding layer 32, wherein the first bonding region 31 includes a plurality of small bonding regions 311 and a lead-out portion 314 that connects the ends of each small bonding layer 311 and extends to the side of the bare core 4 for connecting to an external power supply line and The welding wire part 313, and a plurality of circular metal contact bosses 312 distributed in a matrix are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com